PHYS01200804001 Sohrab Abbas - Homi Bhabha National Institute

PHYS01200804001 Sohrab Abbas - Homi Bhabha National Institute

PHYS01200804001 Sohrab Abbas - Homi Bhabha National Institute

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

5.1.1 Achieving high precision b c through optimisation of various parameters<br />

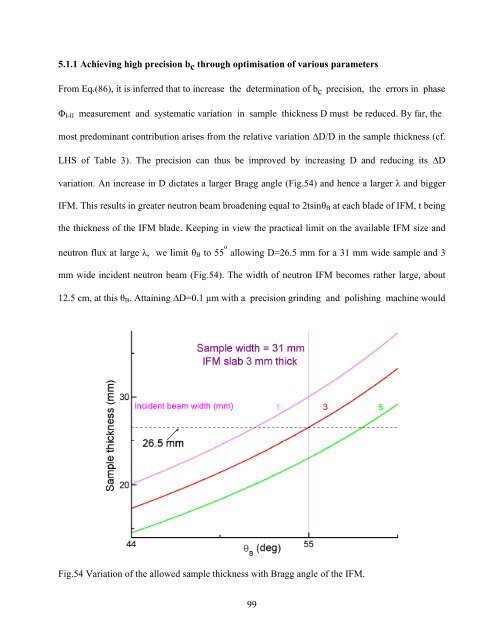

From Eq.(86), it is inferred that to increase the determination of b c precision, the errors in phase<br />

Φ I-II measurement and systematic variation in sample thickness D must be reduced. By far, the<br />

most predominant contribution arises from the relative variation D/D in the sample thickness (cf.<br />

LHS of Table 3). The precision can thus be improved by increasing D and reducing its D<br />

variation. An increase in D dictates a larger Bragg angle (Fig.54) and hence a larger λ and bigger<br />

IFM. This results in greater neutron beam broadening equal to 2tsinθ B at each blade of IFM, t being<br />

the thickness of the IFM blade. Keeping in view the practical limit on the available IFM size and<br />

neutron flux at large λ, we limit θ B to 55 o allowing D=26.5 mm for a 31 mm wide sample and 3<br />

mm wide incident neutron beam (Fig.54). The width of neutron IFM becomes rather large, about<br />

12.5 cm, at this θ B . Attaining D=0.1 μm with a precision grinding and polishing machine would<br />

Fig.54 Variation of the allowed sample thickness with Bragg angle of the IFM.<br />

99