Turbovac and mag - Ideal Vacuum Products

Turbovac and mag - Ideal Vacuum Products

Turbovac and mag - Ideal Vacuum Products

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Mechanical Rotor Suspension<br />

without Compound-Stufe<br />

TURBOVAC 361, 361 C<br />

ClassicLine<br />

Turbomolecular pumps without a<br />

purge gas facility are only suited for<br />

pumping of air or inert gases.<br />

They are not suited for pumping of<br />

aggressive or reactive gases.<br />

TURBOVAC pumps with a “C” in the<br />

type designation are equipped with a<br />

purge gas facility.<br />

The purge gas protects only the<br />

bearing area <strong>and</strong> the motor of the<br />

TURBOVAC.<br />

a a<br />

60°<br />

C<br />

C<br />

ød<br />

h<br />

30°<br />

D<br />

E<br />

h 3 B<br />

B<br />

h 4<br />

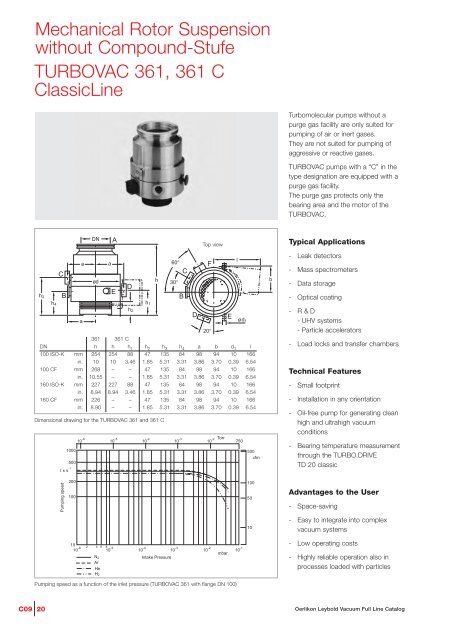

Dimensional drawing for the TURBOVAC 361 <strong>and</strong> 361 C<br />

Top view<br />

20°<br />

361 361 C<br />

DN h h h 1 h 2 h 3 h 4 a b d 1 l<br />

100 ISO-K mm 254 254 88 47 135 84 98 94 10 166<br />

in. 10 10 3.46 1.85 5.31 3.31 3.86 3.70 0.39 6.54<br />

100 CF mm 268 – – 47 135 84 98 94 10 166<br />

in. 10.55 – – 1.85 5.31 3.31 3.86 3.70 0.39 6.54<br />

160 ISO-K mm 227 227 88 47 135 84 98 94 10 166<br />

in. 8.94 8.94 3.46 1.85 5.31 3.31 3.86 3.70 0.39 6.54<br />

160 CF mm 226 – – 47 135 84 98 94 10 166<br />

in. 8.90 – – 1.85 5.31 3.31 3.86 3.70 0.39 6.54<br />

1000<br />

500<br />

a<br />

DN<br />

A<br />

h 2<br />

h 1<br />

10 -6 10 -5 10 -4 10 -3 10 -2 Torr<br />

D<br />

F<br />

E<br />

l<br />

ød 1<br />

750<br />

500<br />

cfm<br />

b<br />

Typical Applications<br />

- Leak detectors<br />

- Mass spectrometers<br />

- Data storage<br />

- Optical coating<br />

- R & D<br />

- UHV systems<br />

- Particle accelerators<br />

- Load locks <strong>and</strong> transfer chambers<br />

Technical Features<br />

- Small footprint<br />

- Installation in any orientation<br />

- Oil-free pump for generating clean<br />

high <strong>and</strong> ultrahigh vacuum<br />

conditions<br />

- Bearing temperature measurement<br />

through the TURBO.DRIVE<br />

TD 20 classic<br />

Pumping speed<br />

200<br />

100<br />

100<br />

50<br />

Advantages to the User<br />

- Space-saving<br />

10<br />

- Easy to integrate into complex<br />

vacuum systems<br />

I x s -1 10 -5 10 -4 10 -3 10 -2 10 -1<br />

10<br />

10 -6 2 4 6 8<br />

N2<br />

Ar<br />

He<br />

Intake Pressure<br />

mbar<br />

- Low operating costs<br />

- Highly reliable operation also in<br />

processes loaded with particles<br />

H2<br />

Pumping speed as a function of the inlet pressure (TURBOVAC 361 with flange DN 100)<br />

C09 20<br />

Oerlikon Leybold <strong>Vacuum</strong> Full Line Catalog