SIMATIC PCS 7 process control system

SIMATIC PCS 7 process control system

SIMATIC PCS 7 process control system

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Automation of batch <strong>process</strong>es<br />

with <strong>SIMATIC</strong> BATCH<br />

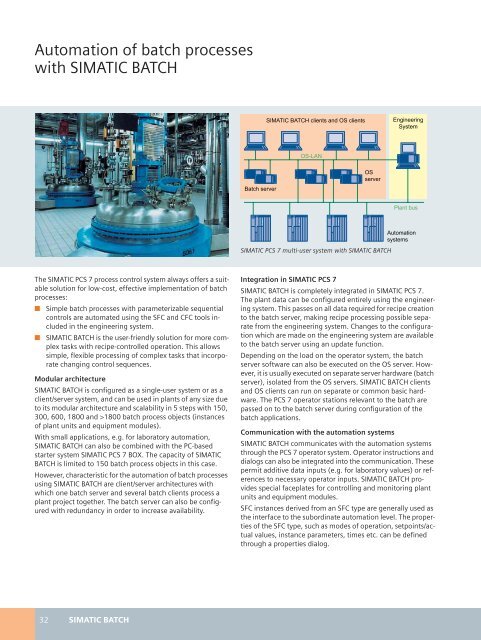

<strong>SIMATIC</strong> BATCH clients and OS clients<br />

Engineering<br />

System<br />

OS-LAN<br />

Batch server<br />

OS<br />

server<br />

Plant bus<br />

<strong>SIMATIC</strong> <strong>PCS</strong> 7 multi-user <strong>system</strong> with <strong>SIMATIC</strong> BATCH<br />

Automation<br />

<strong>system</strong>s<br />

The <strong>SIMATIC</strong> <strong>PCS</strong> 7 <strong>process</strong> <strong>control</strong> <strong>system</strong> always offers a suitable<br />

solution for low-cost, effective implementation of batch<br />

<strong>process</strong>es:<br />

■ Simple batch <strong>process</strong>es with parameterizable sequential<br />

<strong>control</strong>s are automated using the SFC and CFC tools included<br />

in the engineering <strong>system</strong>.<br />

■ <strong>SIMATIC</strong> BATCH is the user-friendly solution for more complex<br />

tasks with recipe-<strong>control</strong>led operation. This allows<br />

simple, flexible <strong>process</strong>ing of complex tasks that incorporate<br />

changing <strong>control</strong> sequences.<br />

Modular architecture<br />

<strong>SIMATIC</strong> BATCH is configured as a single-user <strong>system</strong> or as a<br />

client/server <strong>system</strong>, and can be used in plants of any size due<br />

to its modular architecture and scalability in 5 steps with 150,<br />

300, 600, 1800 and >1800 batch <strong>process</strong> objects (instances<br />

of plant units and equipment modules).<br />

With small applications, e.g. for laboratory automation,<br />

<strong>SIMATIC</strong> BATCH can also be combined with the PC-based<br />

starter <strong>system</strong> <strong>SIMATIC</strong> <strong>PCS</strong> 7 BOX. The capacity of <strong>SIMATIC</strong><br />

BATCH is limited to 150 batch <strong>process</strong> objects in this case.<br />

However, characteristic for the automation of batch <strong>process</strong>es<br />

using <strong>SIMATIC</strong> BATCH are client/server architectures with<br />

which one batch server and several batch clients <strong>process</strong> a<br />

plant project together. The batch server can also be configured<br />

with redundancy in order to increase availability.<br />

Integration in <strong>SIMATIC</strong> <strong>PCS</strong> 7<br />

<strong>SIMATIC</strong> BATCH is completely integrated in <strong>SIMATIC</strong> <strong>PCS</strong> 7.<br />

The plant data can be configured entirely using the engineering<br />

<strong>system</strong>. This passes on all data required for recipe creation<br />

to the batch server, making recipe <strong>process</strong>ing possible separate<br />

from the engineering <strong>system</strong>. Changes to the configuration<br />

which are made on the engineering <strong>system</strong> are available<br />

to the batch server using an update function.<br />

Depending on the load on the operator <strong>system</strong>, the batch<br />

server software can also be executed on the OS server. However,<br />

it is usually executed on separate server hardware (batch<br />

server), isolated from the OS servers. <strong>SIMATIC</strong> BATCH clients<br />

and OS clients can run on separate or common basic hardware.<br />

The <strong>PCS</strong> 7 operator stations relevant to the batch are<br />

passed on to the batch server during configuration of the<br />

batch applications.<br />

Communication with the automation <strong>system</strong>s<br />

<strong>SIMATIC</strong> BATCH communicates with the automation <strong>system</strong>s<br />

through the <strong>PCS</strong> 7 operator <strong>system</strong>. Operator instructions and<br />

dialogs can also be integrated into the communication. These<br />

permit additive data inputs (e.g. for laboratory values) or references<br />

to necessary operator inputs. <strong>SIMATIC</strong> BATCH provides<br />

special faceplates for <strong>control</strong>ling and monitoring plant<br />

units and equipment modules.<br />

SFC instances derived from an SFC type are generally used as<br />

the interface to the subordinate automation level. The properties<br />

of the SFC type, such as modes of operation, setpoints/actual<br />

values, instance parameters, times etc. can be defined<br />

through a properties dialog.<br />

32 <strong>SIMATIC</strong> BATCH