SIMATIC PCS 7 process control system

SIMATIC PCS 7 process control system

SIMATIC PCS 7 process control system

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>SIMATIC</strong> <strong>PCS</strong> 7 – the <strong>process</strong> <strong>control</strong><br />

<strong>system</strong> in Totally Integrated Automation<br />

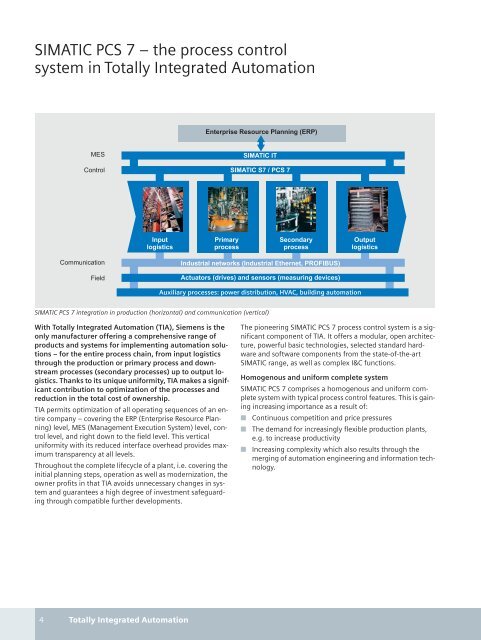

Enterprise Resource Planning (ERP)<br />

MES<br />

Control<br />

<strong>SIMATIC</strong> IT<br />

<strong>SIMATIC</strong> S7 / <strong>PCS</strong> 7<br />

Input<br />

logistics<br />

Primary<br />

<strong>process</strong><br />

Secondary<br />

<strong>process</strong><br />

Output<br />

logistics<br />

Communication<br />

Field<br />

Industrial networks (Industrial Ethernet, PROFIBUS)<br />

Actuators (drives) and sensors (measuring devices)<br />

Auxiliary <strong>process</strong>es: power distribution, HVAC, building automation<br />

<strong>SIMATIC</strong> <strong>PCS</strong> 7 integration in production (horizontal) and communication (vertical)<br />

With Totally Integrated Automation (TIA), Siemens is the<br />

only manufacturer offering a comprehensive range of<br />

products and <strong>system</strong>s for implementing automation solutions<br />

– for the entire <strong>process</strong> chain, from input logistics<br />

through the production or primary <strong>process</strong> and downstream<br />

<strong>process</strong>es (secondary <strong>process</strong>es) up to output logistics.<br />

Thanks to its unique uniformity, TIA makes a significant<br />

contribution to optimization of the <strong>process</strong>es and<br />

reduction in the total cost of ownership.<br />

TIA permits optimization of all operating sequences of an entire<br />

company – covering the ERP (Enterprise Resource Planning)<br />

level, MES (Management Execution System) level, <strong>control</strong><br />

level, and right down to the field level. This vertical<br />

uniformity with its reduced interface overhead provides maximum<br />

transparency at all levels.<br />

Throughout the complete lifecycle of a plant, i.e. covering the<br />

initial planning steps, operation as well as modernization, the<br />

owner profits in that TIA avoids unnecessary changes in <strong>system</strong><br />

and guarantees a high degree of investment safeguarding<br />

through compatible further developments.<br />

The pioneering <strong>SIMATIC</strong> <strong>PCS</strong> 7 <strong>process</strong> <strong>control</strong> <strong>system</strong> is a significant<br />

component of TIA. It offers a modular, open architecture,<br />

powerful basic technologies, selected standard hardware<br />

and software components from the state-of-the-art<br />

<strong>SIMATIC</strong> range, as well as complex I&C functions.<br />

Homogenous and uniform complete <strong>system</strong><br />

<strong>SIMATIC</strong> <strong>PCS</strong> 7 comprises a homogenous and uniform complete<br />

<strong>system</strong> with typical <strong>process</strong> <strong>control</strong> features. This is gaining<br />

increasing importance as a result of:<br />

■ Continuous competition and price pressures<br />

■ The demand for increasingly flexible production plants,<br />

e.g. to increase productivity<br />

■ Increasing complexity which also results through the<br />

merging of automation engineering and information technology.<br />

4 Totally Integrated Automation