You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

WATER SUPPLY NETWORK FOR FIRE-FIGHTING SYSTEMS<br />

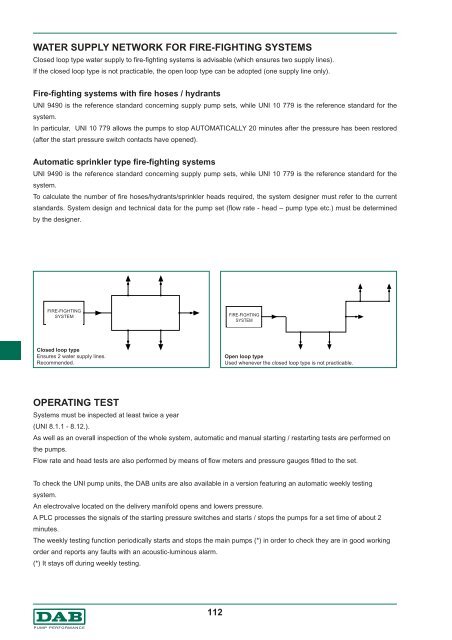

Closed loop type water supply to fire-fighting systems is advisable (which ensures two supply lines).<br />

If the closed loop type is not practicable, the open loop type can be adopted (one supply line only).<br />

Fire-fighting systems with fire hoses / hydrants<br />

UNI 9490 is the reference standard concerning supply pump sets, while UNI 10 779 is the reference standard for the<br />

system.<br />

In particular, UNI 10 779 allows the pumps to stop AUTOMATICALLY 20 minutes after the pressure has been restored<br />

(after the start pressure switch contacts have opened).<br />

Automatic sprinkler type fire-fighting systems<br />

UNI 9490 is the reference standard concerning supply pump sets, while UNI 10 779 is the reference standard for the<br />

system.<br />

To calculate the number of fire hoses/hydrants/sprinkler heads required, the system designer must refer to the current<br />

standards. System design and technical data for the pump set (flow rate - head – pump type etc.) must be determined<br />

by the designer.<br />

FIRE-FIGHTING<br />

GRUPPO<br />

ANTINCENDIO<br />

SYSTEM<br />

FIRE-FIGHTING<br />

GRUPPO<br />

ANTINCENDIO<br />

SYSTEM<br />

Closed loop type<br />

Ensures 2 water supply lines.<br />

Recommended.<br />

Open loop type<br />

Used whenever the closed loop type is not practicable.<br />

OPERATING TEST<br />

Systems must be inspected at least twice a year<br />

(UNI 8.1.1 - 8.12.).<br />

As well as an overall inspection of the whole system, automatic and manual starting / restarting tests are performed on<br />

the pumps.<br />

Flow rate and head tests are also performed by means of flow meters and pressure gauges fitted to the set.<br />

To check the UNI pump units, the DAB units are also available in a version featuring an automatic weekly testing<br />

system.<br />

An electrovalve located on the delivery manifold opens and lowers pressure.<br />

A PLC processes the signals of the starting pressure switches and starts / stops the pumps for a set time of about 2<br />

minutes.<br />

The weekly testing function periodically starts and stops the main pumps (*) in order to check they are in good working<br />

order and reports any faults with an acoustic-luminous alarm.<br />

(*) It stays off during weekly testing.<br />

112<br />

®