You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

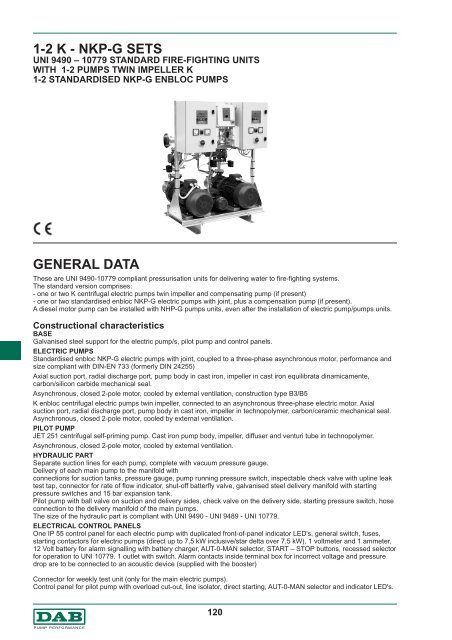

1-2 K - NKP-G <strong>SETS</strong><br />

UNI 9490 – 10779 STANDARD FIRE-FIGHTING UNITS<br />

WITH 1-2 PUMPS TWIN IMPELLER K<br />

1-2 STANDARDISED NKP-G ENBLOC PUMPS<br />

GENERAL DATA<br />

These are UNI 9490-10779 compliant pressurisation units for delivering water to fire-fighting systems.<br />

The standard version comprises:<br />

- one or two K centrifugal electric pumps twin impeller and compensating pump (if present)<br />

- one or two standardised enbloc NKP-G electric pumps with joint, <strong>plus</strong> a compensation pump (if present).<br />

A diesel motor pump can be installed with NHP-G pumps units, even after the installation of electric pump/pumps units.<br />

Constructional characteristics<br />

BASE<br />

Galvanised steel support for the electric pump/s, pilot pump and control panels.<br />

ELECTRIC PUMPS<br />

Standardised enbloc NKP-G electric pumps with joint, coupled to a three-phase asynchronous motor, performance and<br />

size compliant with DIN-EN 733 (formerly DIN 24255)<br />

Axial suction port, radial discharge port, pump body in cast iron, impeller in cast iron equilibrata dinamicamente,<br />

carbon/silicon carbide mechanical seal.<br />

Asynchronous, closed 2-pole motor, cooled by external ventilation, construction type B3/B5<br />

K enbloc centrifugal electric pumps twin impeller, connected to an asynchronous three-phase electric motor. Axial<br />

suction port, radial discharge port, pump body in cast iron, impeller in technopolymer, carbon/ceramic mechanical seal.<br />

Asynchronous, closed 2-pole motor, cooled by external ventilation.<br />

PILOT PUMP<br />

JET 251 centrifugal self-priming pump. Cast iron pump body, impeller, diffuser and venturi tube in technopolymer.<br />

Asynchronous, closed 2-pole motor, cooled by external ventilation.<br />

HYDRAULIC PART<br />

Separate suction lines for each pump, complete with vacuum pressure gauge.<br />

Delivery of each main pump to the manifold with<br />

connections for suction tanks, pressure gauge, pump running pressure switch, inspectable check valve with upline leak<br />

test tap, connector for rate of flow indicator, shut-off batterfly valve, galvanised steel delivery manifold with starting<br />

pressure switches and 15 bar expansion tank.<br />

Pilot pump with ball valve on suction and delivery sides, check valve on the delivery side, starting pressure switch, hose<br />

connection to the delivery manifold of the main pumps.<br />

The size of the hydraulic part is compliant with UNI 9490 - UNI 9489 - UNI 10779.<br />

ELECTRICAL CONTROL PANELS<br />

One IP 55 control panel for each electric pump with duplicated front-of-panel indicator LED's, general switch, fuses,<br />

starting contactors for electric pumps (direct up to 7,5 kW inclusive/star delta over 7,5 kW), 1 voltmeter and 1 ammeter,<br />

12 Volt battery for alarm signalling with battery charger, AUT-0-MAN selector, START – STOP buttons, recessed selector<br />

for operation to UNI 10779. 1 outlet with switch. Alarm contacts inside terminal box for incorrect voltage and pressure<br />

drop are to be connected to an acoustic device (supplied with the booster)<br />

Connector for weekly test unit (only for the main electric pumps).<br />

Control panel for pilot pump with overload cut-out, line isolator, direct starting, AUT-0-MAN selector and indicator LED's.<br />

120<br />

®