INAUGURAL–DISSERTATION zur Erlangung der Doktorwürde der ...

INAUGURAL–DISSERTATION zur Erlangung der Doktorwürde der ...

INAUGURAL–DISSERTATION zur Erlangung der Doktorwürde der ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

4.3. Single Bi-component Droplet Evaporation and Solid Layer Formation 85<br />

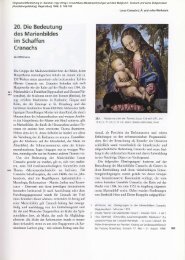

Fig. 4.34: SEM images of mannitol samples spray dried at 70 ◦ C (a), 100 ◦ C (b) and<br />

90 ◦ C (c). Zoomed images of the surface structures of these particles at<br />

70 ◦ C (d), 100 ◦ C (e) and 90 ◦ C (f) [225].<br />

This shell formation is in good accordance with the simulations performed so far.<br />

The particle surface consists of small, needle shaped structures in case of low drying<br />

temperatures as shown in Fig. 4.34(d), and smaller, non-needle shaped structures for<br />

higher drying temperatures, cf. Fig. 4.34(e), and the shift from needle shape to nonneedle<br />

structures is seen in Fig. 4.34(f). The increased gas temperature not only effects<br />

the final particle shape but also internal structure [225]. In computations, the change<br />

in particle shape is not accounted for, and it is assumed to be spherical throughout the<br />

evaporation and drying period, therefore, the present numerical results show increase<br />

in porosity with temperature as anticipated, see Fig. 4.33. This behavior will change<br />

when the final drying step is added to the present model, and if non-spherical particle<br />

formation will be consi<strong>der</strong>ed.<br />

Figure 4.35 shows the effect of gas temperatures of 60 ◦ C and 95 ◦ C and relative<br />

humidity of 1% R.H. (left) and 30% R.H. (right), respectively, on the droplet surface<br />

area and comparison with experimental data. The experiments are carried out by<br />

Sedelmayer et al. [224] at the University of Hamburg in an acoustic levitator. The<br />

simulation results show excellent agreement with the experiment. The droplet surface<br />

area continuously decreases due to water evaporation until a critical value where the<br />

solid layer formation starts, which is quite nicely predicted by the simulation. Increased<br />

temperature increases the evaporation rate and thereby quicker solid layer formation<br />

as seen in left part of Fig. 4.35, whereas increased humidity increases the solid layer<br />

formation time, i.e., at 60 ◦ C at 1% R.H. the solid layer forms in about 65 s and with