Ways to Conserve Energy on Board - DNV

Ways to Conserve Energy on Board - DNV

Ways to Conserve Energy on Board - DNV

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

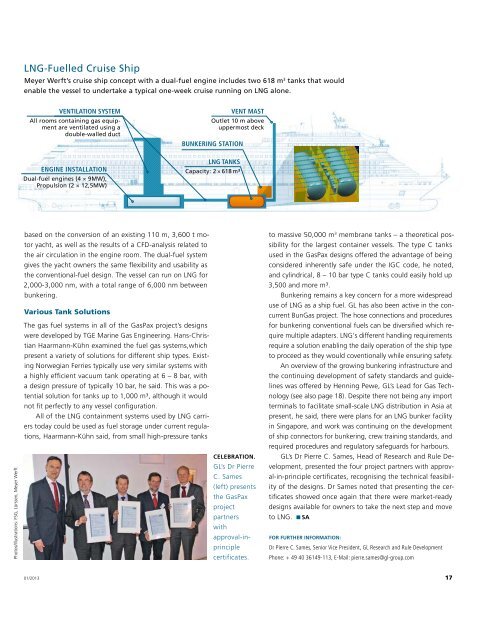

LNG-Fuelled Cruise Ship<br />

Meyer Werft’s cruise ship c<strong>on</strong>cept with a dual-fuel engine includes two 618 m 3 tanks that would<br />

enable the vessel <str<strong>on</strong>g>to</str<strong>on</strong>g> undertake a typical <strong>on</strong>e-week cruise running <strong>on</strong> LNG al<strong>on</strong>e.<br />

Ventilati<strong>on</strong> system<br />

All rooms c<strong>on</strong>taining gas equipment<br />

are ventilated using a<br />

double-walled duct<br />

Vent mast<br />

Outlet 10 m above<br />

uppermost deck<br />

Bunkering stati<strong>on</strong><br />

Engine Installati<strong>on</strong><br />

Dual-fuel engines (4 × 9MW),<br />

Propulsi<strong>on</strong> (2 × 12,5MW)<br />

LNG Tanks<br />

Capacity: 2 × 618 m³<br />

Pho<str<strong>on</strong>g>to</str<strong>on</strong>g>s/Illustrati<strong>on</strong>s: FSG, Lürssen, Meyer Werft<br />

based <strong>on</strong> the c<strong>on</strong>versi<strong>on</strong> of an existing 110 m, 3,600 t mo<str<strong>on</strong>g>to</str<strong>on</strong>g>r<br />

yacht, as well as the results of a CFD-analysis related <str<strong>on</strong>g>to</str<strong>on</strong>g><br />

the air circulati<strong>on</strong> in the engine room. The dual-fuel system<br />

gives the yacht owners the same flexibility and usability as<br />

the c<strong>on</strong>venti<strong>on</strong>al-fuel design. The vessel can run <strong>on</strong> LNG for<br />

2,000-3,000 nm, with a <str<strong>on</strong>g>to</str<strong>on</strong>g>tal range of 6,000 nm between<br />

bunkering.<br />

Various Tank Soluti<strong>on</strong>s<br />

The gas fuel systems in all of the GasPax project’s designs<br />

were developed by TGE Marine Gas Engineering. Hans-Christian<br />

Haarmann-Kühn examined the fuel gas systems,which<br />

present a variety of soluti<strong>on</strong>s for different ship types. Existing<br />

Norwegian Ferries typically use very similar systems with<br />

a highly efficient vacuum tank operating at 6 – 8 bar, with<br />

a design pressure of typically 10 bar, he said. This was a potential<br />

soluti<strong>on</strong> for tanks up <str<strong>on</strong>g>to</str<strong>on</strong>g> 1,000 m³, although it would<br />

not fit perfectly <str<strong>on</strong>g>to</str<strong>on</strong>g> any vessel c<strong>on</strong>figurati<strong>on</strong>.<br />

All of the LNG c<strong>on</strong>tainment systems used by LNG carriers<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g>day could be used as fuel s<str<strong>on</strong>g>to</str<strong>on</strong>g>rage under current regulati<strong>on</strong>s,<br />

Haarmann-Kühn said, from small high-pressure tanks<br />

Celebrati<strong>on</strong>.<br />

GL’s Dr Pierre<br />

C. Sames<br />

(left) presents<br />

the GasPax<br />

project<br />

partners<br />

with<br />

approval-inprinciple<br />

certificates.<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g> massive 50,000 m 3 membrane tanks – a theoretical possibility<br />

for the largest c<strong>on</strong>tainer vessels. The type C tanks<br />

used in the GasPax designs offered the advantage of being<br />

c<strong>on</strong>sidered inherently safe under the IGC code, he noted,<br />

and cylindrical, 8 – 10 bar type C tanks could easily hold up<br />

3,500 and more m³.<br />

Bunkering remains a key c<strong>on</strong>cern for a more widespread<br />

use of LNG as a ship fuel. GL has also been active in the c<strong>on</strong>current<br />

BunGas project. The hose c<strong>on</strong>necti<strong>on</strong>s and procedures<br />

for bunkering c<strong>on</strong>venti<strong>on</strong>al fuels can be diversified which require<br />

multiple adapters. LNG's different handling requirements<br />

require a soluti<strong>on</strong> enabling the daily operati<strong>on</strong> of the ship type<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g> proceed as they would coventi<strong>on</strong>ally while ensuring safety.<br />

An overview of the growing bunkering infrastructure and<br />

the c<strong>on</strong>tinuing development of safety standards and guidelines<br />

was offered by Henning Pewe, GL’s Lead for Gas Technology<br />

(see also page 18). Despite there not being any import<br />

terminals <str<strong>on</strong>g>to</str<strong>on</strong>g> facilitate small-scale LNG distributi<strong>on</strong> in Asia at<br />

present, he said, there were plans for an LNG bunker facility<br />

in Singapore, and work was c<strong>on</strong>tinuing <strong>on</strong> the development<br />

of ship c<strong>on</strong>nec<str<strong>on</strong>g>to</str<strong>on</strong>g>rs for bunkering, crew training standards, and<br />

required procedures and regula<str<strong>on</strong>g>to</str<strong>on</strong>g>ry safeguards for harbours.<br />

GL’s Dr Pierre C. Sames, Head of Research and Rule Development,<br />

presented the four project partners with approval-in-principle<br />

certificates, recognising the technical feasibility<br />

of the designs. Dr Sames noted that presenting the certificates<br />

showed <strong>on</strong>ce again that there were market-ready<br />

designs available for owners <str<strong>on</strong>g>to</str<strong>on</strong>g> take the next step and move<br />

<str<strong>on</strong>g>to</str<strong>on</strong>g> LNG. SA<br />

For further Informati<strong>on</strong>:<br />

Dr Pierre C. Sames, Senior Vice President, GL Research and Rule Development<br />

Ph<strong>on</strong>e: + 49 40 36149-113, E-Mail: pierre.sames@gl-group.com<br />

01/2013<br />

17