Ways to Conserve Energy on Board - DNV

Ways to Conserve Energy on Board - DNV

Ways to Conserve Energy on Board - DNV

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

lng infrastructure<br />

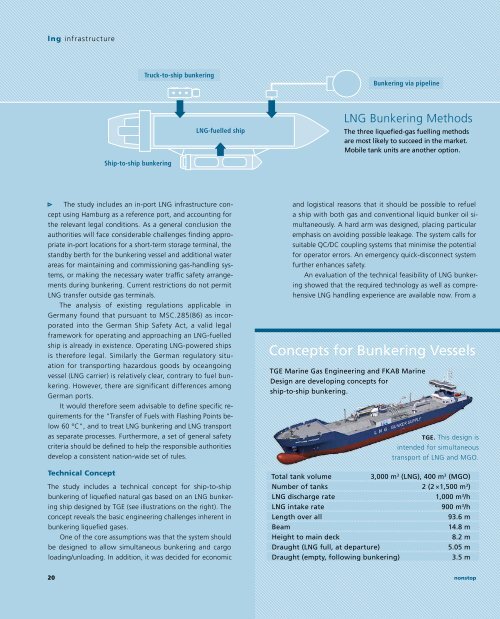

Truck-<str<strong>on</strong>g>to</str<strong>on</strong>g>-ship bunkering<br />

Bunkering via pipeline<br />

LNG-fuelled ship<br />

LNG Bunkering Methods<br />

The three liquefied-gas fuelling methods<br />

are most likely <str<strong>on</strong>g>to</str<strong>on</strong>g> succeed in the market.<br />

Mobile tank units are another opti<strong>on</strong>.<br />

Ship-<str<strong>on</strong>g>to</str<strong>on</strong>g>-ship bunkering<br />

The study includes an in-port LNG infrastructure c<strong>on</strong>cept<br />

using Hamburg as a reference port, and accounting for<br />

the relevant legal c<strong>on</strong>diti<strong>on</strong>s. As a general c<strong>on</strong>clusi<strong>on</strong> the<br />

authorities will face c<strong>on</strong>siderable challenges finding appropriate<br />

in-port locati<strong>on</strong>s for a short-term s<str<strong>on</strong>g>to</str<strong>on</strong>g>rage terminal, the<br />

standby berth for the bunkering vessel and additi<strong>on</strong>al water<br />

areas for maintaining and commissi<strong>on</strong>ing gas-handling systems,<br />

or making the necessary water traffic safety arrangements<br />

during bunkering. Current restricti<strong>on</strong>s do not permit<br />

LNG transfer outside gas terminals.<br />

The analysis of existing regulati<strong>on</strong>s applicable in<br />

Germany found that pursuant <str<strong>on</strong>g>to</str<strong>on</strong>g> MSC.285(86) as incorporated<br />

in<str<strong>on</strong>g>to</str<strong>on</strong>g> the German Ship Safety Act, a valid legal<br />

framework for operating and approaching an LNG-fuelled<br />

ship is already in existence. Operating LNG-powered ships<br />

is therefore legal. Similarly the German regula<str<strong>on</strong>g>to</str<strong>on</strong>g>ry situati<strong>on</strong><br />

for transporting hazardous goods by oceangoing<br />

vessel (LNG carrier) is relatively clear, c<strong>on</strong>trary <str<strong>on</strong>g>to</str<strong>on</strong>g> fuel bunkering.<br />

However, there are significant differences am<strong>on</strong>g<br />

German ports.<br />

It would therefore seem advisable <str<strong>on</strong>g>to</str<strong>on</strong>g> define specific requirements<br />

for the “Transfer of Fuels with Flashing Points below<br />

60 °C”, and <str<strong>on</strong>g>to</str<strong>on</strong>g> treat LNG bunkering and LNG transport<br />

as separate processes. Furthermore, a set of general safety<br />

criteria should be defined <str<strong>on</strong>g>to</str<strong>on</strong>g> help the resp<strong>on</strong>sible authorities<br />

develop a c<strong>on</strong>sistent nati<strong>on</strong>-wide set of rules.<br />

Technical C<strong>on</strong>cept<br />

The study includes a technical c<strong>on</strong>cept for ship-<str<strong>on</strong>g>to</str<strong>on</strong>g>-ship<br />

bunker ing of liquefied natural gas based <strong>on</strong> an LNG bunkering<br />

ship designed by TGE (see illustrati<strong>on</strong>s <strong>on</strong> the right). The<br />

c<strong>on</strong>cept reveals the basic engineering challenges inherent in<br />

bunkering liquefied gases.<br />

One of the core assumpti<strong>on</strong>s was that the system should<br />

be designed <str<strong>on</strong>g>to</str<strong>on</strong>g> allow simultaneous bunkering and cargo<br />

loading/unloading. In additi<strong>on</strong>, it was decided for ec<strong>on</strong>omic<br />

and logistical reas<strong>on</strong>s that it should be possible <str<strong>on</strong>g>to</str<strong>on</strong>g> refuel<br />

a ship with both gas and c<strong>on</strong>venti<strong>on</strong>al liquid bunker oil simultaneously.<br />

A hard arm was designed, placing particular<br />

emphasis <strong>on</strong> avoiding possible leakage. The system calls for<br />

suitable QC/DC coupling systems that minimise the potential<br />

for opera<str<strong>on</strong>g>to</str<strong>on</strong>g>r errors. An emergency quick-disc<strong>on</strong>nect system<br />

further enhances safety.<br />

An evaluati<strong>on</strong> of the technical feasibility of LNG bunkering<br />

showed that the required technology as well as comprehensive<br />

LNG handling experience are available now. From a<br />

C<strong>on</strong>cepts for Bunkering Vessels<br />

TGE Marine Gas Engineering and FKAB Marine<br />

Design are developing c<strong>on</strong>cepts for<br />

ship-<str<strong>on</strong>g>to</str<strong>on</strong>g>-ship bunkering.<br />

TGE. This design is<br />

intended for simultaneous<br />

transport of LNG and MGO.<br />

Total tank volume<br />

3,000 m 3 (LNG), 400 m 3 (MGO)<br />

Number of tanks 2 (2 ×1,500 m 3 )<br />

LNG discharge rate 1,000 m 3 /h<br />

LNG intake rate 900 m 3 /h<br />

Length over all<br />

93.6 m<br />

Beam<br />

14.8 m<br />

Height <str<strong>on</strong>g>to</str<strong>on</strong>g> main deck<br />

8.2 m<br />

Draught (LNG full, at departure)<br />

5.05 m<br />

Draught (empty, following bunkering)<br />

3.5 m<br />

20 n<strong>on</strong>s<str<strong>on</strong>g>to</str<strong>on</strong>g>p