Requirements for Unity of Application - Japan Patent Office

Requirements for Unity of Application - Japan Patent Office

Requirements for Unity of Application - Japan Patent Office

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

[Example 64]<br />

[Title <strong>of</strong> the Invention]<br />

A process <strong>of</strong> electroslag welding and the flux to be used<br />

[Claims]<br />

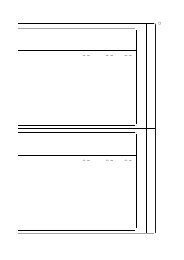

1. Light metal electroslag welding process, wherein after arranging the parts (1) to be welded<br />

together with specified gaps, inserting an electrode (3) from below the pieces into a gap<br />

together with flux fill (4) the makeup <strong>of</strong> which is 65-75% barium fluoride, 15-25% cryolite<br />

and 5-10% (by weight) sodium bromide and placing the vessels (13, 14) above and below<br />

the pieces, applying current to melt the electrode and the flux <strong>for</strong> floating up the molten<br />

metal from a slag bath (5), <strong>for</strong>ming the molten metal bath in the upper vessel (7), and<br />

opening the lower vessel by the melted electrode, and allowing the slag (5) into the said<br />

vessel, which introduces molten metal into the gap between the pieces to be welded.<br />

2. Flux <strong>for</strong> the electroslag welding comprising the following matter (weight %):<br />

65-75% barium fluoride, 15-25% cryolite and 5-10% sodium bromide<br />

[Excerpt from Detail Description <strong>of</strong> the Invention and Drawings]<br />

This invention concerns a process <strong>of</strong> electroslag welding <strong>for</strong> aluminum and other light<br />

metals using consumable electrodes and flux used in welding by this process.<br />

In welding aluminum and other light metals, the mechanical strength <strong>of</strong> the welded portion<br />

could be weakened by oxidation or penetration <strong>of</strong> gases. In this invention, by using the slag<br />

bath (5) which is heavier than the metals being welded (1), using a new flux (4) having a higher<br />

melting point and inserting the electrode (3) from below, as well as placing the molten metal<br />

bath (7) above the slag bath (5) prevents oxidation <strong>of</strong> the welding part by the slag bath (5) and<br />

maintains the molten state <strong>of</strong> the metal by the heat <strong>of</strong> the slag bath and degas the metal.<br />

Upper vessel<br />

Molten metal<br />

Flux<br />

Slag bath<br />

Piece to be welded<br />

Lower vessel<br />

During welding<br />

Completion stage<br />

[Explanation]<br />

The related invention (Claim 2), the flux does not correspond to “equipment” directly used<br />

in working the invented process, but it falls under the category <strong>of</strong> “other things.”<br />

[Concerned Section]<br />

<strong>Patent</strong> Law Section 37(iv)<br />

110