Innovation in Global Power - Parsons Brinckerhoff

Innovation in Global Power - Parsons Brinckerhoff

Innovation in Global Power - Parsons Brinckerhoff

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

A technical<br />

journal by<br />

<strong>Parsons</strong><br />

Br<strong>in</strong>ckerhoff<br />

employees<br />

and colleagues<br />

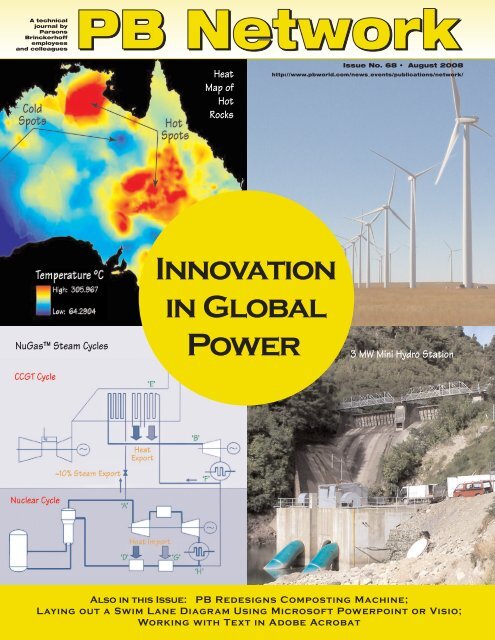

Heat<br />

Map of<br />

Hot<br />

Rocks<br />

Issue No. 68 • August 2008<br />

http://www.pbworld.com/news_events/publications/network/<br />

NuGas Steam Cycles<br />

<strong>Innovation</strong><br />

<strong>in</strong> <strong>Global</strong><br />

<strong>Power</strong><br />

3 MW M<strong>in</strong>i Hydro Station<br />

Also <strong>in</strong> this Issue: PB Redesigns Compost<strong>in</strong>g Mach<strong>in</strong>e;<br />

Lay<strong>in</strong>g out a Swim Lane Diagram Us<strong>in</strong>g Microsoft <strong>Power</strong>po<strong>in</strong>t or Visio;<br />

Work<strong>in</strong>g with Text <strong>in</strong> Adobe Acrobat

<strong>Innovation</strong> <strong>in</strong> <strong>Global</strong> <strong>Power</strong><br />

TABLE OF<br />

CONTENTS<br />

Guest Editors for this<br />

issue: Kather<strong>in</strong>e Jackson<br />

and Arthur Ekwue.<br />

Guest Technical Reviewers:<br />

John Douglas, Ferrel Ensign,<br />

Steve Loyd, Chris Meadows,<br />

Brian Van Weele, and<br />

John Wichall.<br />

Special thanks to Paul Kenyon<br />

and Matthew Chan for their<br />

assistance.<br />

Cover photo (lower right):<br />

©Tony Mulholland<br />

Note: Soon after distribution,<br />

this issue will be available<br />

on the Web at http://www.<br />

pbworld.com/news_events/<br />

publications/network/<br />

Issue_68/68_<strong>in</strong>dex.asp<br />

Introduction (Burton) ...........................................................3<br />

GENERATION<br />

THERMAL – ACHIEVING NEW EFFICIENCIES,<br />

REDUCING CARBON EMISSIONS<br />

Best Practices Across a Range of Technologies (Kenyon)..4<br />

The Effect of Carbon Capture and Storage and<br />

Carbon Pric<strong>in</strong>g on the Competitiveness of Gas<br />

Turb<strong>in</strong>e <strong>Power</strong> Plants (Cook)..................................................5<br />

The NuGas TM Concept: Comb<strong>in</strong><strong>in</strong>g a Nuclear <strong>Power</strong><br />

Plant with a Gas-fired Plant (Willson, Smith).................8<br />

PB Inspections Help To Ensure <strong>Power</strong> Plant Safety<br />

(Gray) .................................................................................................11<br />

Project Brief: Us<strong>in</strong>g Monte Carlo Techniques to<br />

Size a <strong>Power</strong> Station (Emmerton).....................................13<br />

Project Brief: Energiz<strong>in</strong>g S<strong>in</strong>gapore’s Economy (Gill)........13<br />

Comb<strong>in</strong>ed Heat and <strong>Power</strong> for USA’s Largest<br />

Residential Development (Bautista, Swensen)............14<br />

Ensur<strong>in</strong>g Cont<strong>in</strong>ual <strong>Power</strong> Supply for New York<br />

City Hospitals (Krupnik, Andrews) ....................................16<br />

Changes to Chiller, Boiler and HVAC Lower Energy<br />

Consumption at a University Campus (Choi)............18<br />

<strong>Power</strong> Term<strong>in</strong>ology: Units and Conversions<br />

(Ebau) .................................................................................................20<br />

HYDROPOWER – NEW TECHNOLOGIES, NEW<br />

CONSIDERATIONS<br />

Does Hydro have a Future? (Wichall).......................................21<br />

Pumped Storage Technology: Recent Developments,<br />

Future Applications (McClymont, Reilly)........................22<br />

Plann<strong>in</strong>g for M<strong>in</strong>i Hydro <strong>in</strong> Distributed Generation<br />

(Mulholland)....................................................................................25<br />

Develop<strong>in</strong>g, Eng<strong>in</strong>eer<strong>in</strong>g and Licens<strong>in</strong>g a New<br />

Hydropower Dam (Chan, Schad<strong>in</strong>ger)...........................27<br />

Develop<strong>in</strong>g Hydropower Resources <strong>in</strong> Greenland<br />

(Kropelnicki,Tucker, Shiers).....................................................30<br />

Successful Relicens<strong>in</strong>g of a Federally Regulated<br />

Hydropower Project (Bynoe, Shiers, Williamson,<br />

Plizga)..................................................................................................32<br />

Us<strong>in</strong>g OASIS Software to Model Water Allocation<br />

for Hydropower Generation Projects<br />

(Shiers, Williamson,Tsai)..........................................................35<br />

Dam Safety: State-of-the Art Methodology<br />

Demonstrates that Costly Dam Remediation is<br />

Not Needed (Greska, Mochrie).........................................38<br />

Deck Slot Cutt<strong>in</strong>g and Ta<strong>in</strong>ter Gate Remediation<br />

Extend Safe Operations of a Hydroelectric<br />

Dam (Buratto, Plizga, Shiers).................................................41<br />

RENEWABLES – THE RISKS, CONCERNS AND<br />

POTENTIAL<br />

The Grow<strong>in</strong>g <strong>Power</strong> of Renewables (Loyd).............44<br />

Renewable Energy—Susta<strong>in</strong>able Economy? (Cook)........45<br />

Test Bed to Turnkey: Introduc<strong>in</strong>g New Thermal<br />

Renewable Energy Technologies (Burdon) ...................48<br />

Realis<strong>in</strong>g the <strong>Power</strong> Potential from Hot Rocks<br />

(Curtis) ..............................................................................................51<br />

Project Brief: Tidal <strong>Power</strong> (Kydd) .........................................53<br />

Convert<strong>in</strong>g Landfill Gas to High Btu Fuel (Lemos)...........54<br />

Photovoltaics, With a Focus on Spa<strong>in</strong>* (Lejarza)..........56<br />

TRANSMISSION AND DISTRIBUTION<br />

TRANSPORTING POWER ACROSS THE GRID<br />

Electricity Transmission, Build<strong>in</strong>g on 120 Years of<br />

Experience (Ekwue)...................................................................58<br />

Meet<strong>in</strong>g the Need for Reliable, Cheaper and Nonpollut<strong>in</strong>g<br />

Electricity <strong>in</strong> Cambodia (Park<strong>in</strong>son, Roe).........59<br />

Rehabilitation and Reconstruction of Abu Dhabi<br />

Transmission Network (Jayasimha) ...................................62<br />

HVDC Transmission Strengthen<strong>in</strong>g <strong>in</strong> Southern<br />

Africa (Tuson)......................................................................................63<br />

Assess<strong>in</strong>g Transmission Network Condition: 3D<br />

Data Capture and Report<strong>in</strong>g (Reynolds)......................66<br />

DISTRIBUTING POWER TO USERS<br />

The Wide Range of Distribution (Douglas)....................68<br />

Research & <strong>Innovation</strong>: Us<strong>in</strong>g Dynamic Thermal<br />

Rat<strong>in</strong>gs and Active Control to Unlock Distribution<br />

Network Capacity (Neumann)...........................................69<br />

Upside Down! How <strong>Innovation</strong> <strong>in</strong> Distribution<br />

Networks is Challeng<strong>in</strong>g Tradition (Neumann) .........72<br />

A Survey of <strong>Power</strong> System Packages for Distribution<br />

Network Analysis (Ekwue, Roscoe, Lynch) ..................75<br />

Improv<strong>in</strong>g 11 kV Network Performance <strong>in</strong> Al A<strong>in</strong><br />

(Nikolic).............................................................................................77<br />

Energy Demand Management Programs <strong>in</strong><br />

Western Sydney (Duo)............................................................79<br />

PLANNING AND THE ROLE OF REGULATORS<br />

Plann<strong>in</strong>g and Regulat<strong>in</strong>g <strong>Power</strong> Infrastructure<br />

<strong>in</strong> a World of Change (Stedall) ...........................................81<br />

Asset Replacement: The Regulator’s View (Douglas)...........82<br />

New Zealand Energy Strategy–A Plan for a<br />

Susta<strong>in</strong>able Nation (Barneveld)...........................................86<br />

<strong>Power</strong> Articles <strong>in</strong> PB Network, NOTES, and<br />

<strong>Power</strong>l<strong>in</strong>es (Chow) ...................................................................89<br />

DEPARTMENTS<br />

Network<strong>in</strong>g: PB Redesigns a Compost<strong>in</strong>g Mach<strong>in</strong>e<br />

for Improved Operations (Altés)* ....................................91<br />

Water Factory Will Help to Address Water<br />

Shortage Concerns (Hodgk<strong>in</strong>son) ....................................94<br />

Swim Lanes Part 2: Lay<strong>in</strong>g Out a Swim Lane Diagram<br />

us<strong>in</strong>g Microsoft <strong>Power</strong>Po<strong>in</strong>t or Visio (Sloan)................94<br />

Computer Tutor: Work<strong>in</strong>g with Text <strong>in</strong> Adobe<br />

Acrobat Pro: Copy text to other software<br />

applications, use built-<strong>in</strong> OCR, make corrections<br />

with the TouchUp Text tool (H<strong>in</strong>shaw) ..........................99<br />

PlanetWise: Go<strong>in</strong>g Green: Walk<strong>in</strong>g the Walk!!<br />

(Sammut).......................................................................................101<br />

In Future Issues/Call for Articles................................102<br />

The Net View: Fish<strong>in</strong>g <strong>Power</strong> (Clark)....................104<br />

* La edición en lengua española del presente artículo está disponible en la dirección Web de PB Network.<br />

PB Network #68 / August 2008 2

http://www.pbworld.com/news_events/publications/network/<br />

<strong>Innovation</strong> <strong>in</strong> <strong>Global</strong> <strong>Power</strong><br />

This issue of PB Network focuses on the power expertise that PB provides to clients around the<br />

world. There cont<strong>in</strong>ues to be a rapid rate of change <strong>in</strong> the global power <strong>in</strong>dustry as it responds<br />

to a range of external drivers, <strong>in</strong>clud<strong>in</strong>g governmental and regulatory targets, fuel price changes,<br />

ris<strong>in</strong>g equipment costs and environmental pressures. These changes are happen<strong>in</strong>g at the same<br />

time that the demand for electrical power world-wide cont<strong>in</strong>ues to accelerate at unprecedented rates.<br />

PB’s ability to <strong>in</strong>novate has become <strong>in</strong>creas<strong>in</strong>gly important to power clients look<strong>in</strong>g for solutions<br />

and a competitive advantage <strong>in</strong> this rapidly chang<strong>in</strong>g environment. Reduc<strong>in</strong>g carbon emissions<br />

through us<strong>in</strong>g more efficient and lower carbon forms of generation, a greater <strong>in</strong>terest <strong>in</strong> extend<strong>in</strong>g<br />

the lifetime and capacity of exist<strong>in</strong>g power assets, and a requirement to squeeze more <strong>in</strong>to<br />

exist<strong>in</strong>g land space must all be key to help<strong>in</strong>g ensure a susta<strong>in</strong>able future<br />

One of PB’s stated values is “to work with our clients to contribute to their success,” and<br />

a number of the articles demonstrate how we are us<strong>in</strong>g <strong>in</strong>novation to do this, <strong>in</strong>clud<strong>in</strong>g:<br />

• Information about the advice we are currently provid<strong>in</strong>g to the UK government on carbon<br />

capture and storage<br />

• The creation of the NuGas concept that can improve thermal efficiencies to unprecedented<br />

levels by comb<strong>in</strong><strong>in</strong>g nuclear power generation with a small comb<strong>in</strong>ed cycle gas fired plant<br />

• The development of designs for high-temperature hot dry rock power generation <strong>in</strong> Australia<br />

• PB’s role <strong>in</strong> the research and development of a distribution network active thermal controller<br />

that uses local meteorological data to calculate real time equipment rat<strong>in</strong>gs and control network<br />

power flows.<br />

Other articles demonstrate how PB’s eng<strong>in</strong>eers have successfully applied novel th<strong>in</strong>k<strong>in</strong>g to solv<strong>in</strong>g<br />

problems on a range of projects, <strong>in</strong>clud<strong>in</strong>g:<br />

• Increas<strong>in</strong>g the lifetime of hydropower dams<br />

• Ensur<strong>in</strong>g that New York City hospitals cont<strong>in</strong>ue to operate dur<strong>in</strong>g power blackouts<br />

• Develop<strong>in</strong>g a 3D asset data capture system for transmission networks; and develop<strong>in</strong>g demand<br />

reduction strategies.<br />

Another of PB’s stated values is to “share knowledge with our colleagues to deliver professional<br />

excellence.” PB Network and the Practice Area Networks (PANs) all assist with achiev<strong>in</strong>g<br />

this goal, and I would like to thank all of the PANs, authors, reviewers and the edit<strong>in</strong>g team who<br />

have contributed to this issue. In the spirit of shar<strong>in</strong>g knowledge with our non-power colleagues,<br />

we have <strong>in</strong>cluded a list of standard power term<strong>in</strong>ology, def<strong>in</strong>itions, and conversion factors (Ebau,<br />

page 20). Colleagues have shared over 30 other power articles <strong>in</strong> recent PB Networks, NOTES,<br />

and <strong>Power</strong>l<strong>in</strong>es (see list on pp. 89-90).<br />

Kather<strong>in</strong>e Jackson and Arthur Ekwue were the guest editors who compiled all the articles and<br />

developed the framework for the publication. The guest reviewers who helped hone the technical<br />

content were John Douglas, Steve Loyd, Chris Meadows, John Wichall, Paul Kenyon, Brian Van<br />

Weele, and Ferrel Ensign. This issue was sponsored by PB’s <strong>Power</strong> bus<strong>in</strong>ess units globally and<br />

by four of PB’s power PANs (conventional thermal generation; high voltage transmission and<br />

distribution; power system plann<strong>in</strong>g, analysis, and restructur<strong>in</strong>g; and renewable energy sources).<br />

Eric Burton<br />

Manag<strong>in</strong>g Director, <strong>Power</strong> International<br />

Newcastle, UK<br />

INTRODUCTION<br />

3 PB Network #68 / August 2008

GENERATION:<br />

Thermal – Achiev<strong>in</strong>g New Efficiencies, Reduc<strong>in</strong>g Carbon Emissions<br />

Best Practices Across a Range of Technologies<br />

The public awareness of climate change and energy issues has risen dramatically <strong>in</strong> the last two to<br />

three years. There appears to be grow<strong>in</strong>g acceptance of the need to be energy smart and to<br />

reduce carbon emissions.<br />

An example is the identification of energy sav<strong>in</strong>gs by f<strong>in</strong>esse of thermal cycle. The NuGas<br />

concept and the energy efficiency projects at Co-op City and the SUNY campus <strong>in</strong> Brockport,<br />

New York comb<strong>in</strong>e an already efficient plant <strong>in</strong> a way that ga<strong>in</strong>s an extra advantage. The process<br />

for clean<strong>in</strong>g the steam and evaporator units at the Keppel Energy Plant <strong>in</strong> S<strong>in</strong>gapore reduced<br />

on-site time and improved steam and water quality dur<strong>in</strong>g commission<strong>in</strong>g. These are elegant<br />

no-cost or low-cost solutions that were developed by th<strong>in</strong>k<strong>in</strong>g that went the extra step.<br />

The demand for <strong>in</strong>creas<strong>in</strong>g thermal efficiencies <strong>in</strong> our power plants is push<strong>in</strong>g up temperatures,<br />

mak<strong>in</strong>g it even more important to ensure safe design and operation of these facilities. Stewart<br />

Gray has developed an expertise <strong>in</strong> hazardous areas eng<strong>in</strong>eer<strong>in</strong>g due, <strong>in</strong> part to hav<strong>in</strong>g witnessed<br />

many <strong>in</strong>stances of people not understand<strong>in</strong>g the rules and vocabulary <strong>in</strong>volved, and he knows of<br />

the severe consequences that can result. His article highlights some of the steps eng<strong>in</strong>eers can<br />

take a various stages to help ensure such disasters do not occur.<br />

The paper on carbon capture and storage gives <strong>in</strong>sight to a dilemma fac<strong>in</strong>g many of PB’s clients.<br />

The world-wide management of carbon dioxide emissions to the atmosphere is crucial to slow<strong>in</strong>g<br />

the rate of global warm<strong>in</strong>g. This can be achieved by comb<strong>in</strong>ations of improved efficiency <strong>in</strong><br />

combustion of fossil fuels, moves to low-carbon or carbon-free fuels, or carbon capture. At present<br />

carbon capture is not mandated but this may arise, just as happened with reduction of nitrogen<br />

oxides emissions (NO and NO2). As with Renewable Energy Certificates, a market may develop<br />

to provide <strong>in</strong>centives to “clean” operators, funded by penalties on those with less clean processes.<br />

PB is well placed to assist its clients <strong>in</strong> this topical and important area of technology.<br />

The use of Monte Carlo techniques is a novel approach to optimize generation capacity for a<br />

random load profile. The team went beyond traditional eng<strong>in</strong>eer<strong>in</strong>g analysis, reduced uncerta<strong>in</strong>ty<br />

and provided the client with <strong>in</strong>creased confidence <strong>in</strong> PB’s appraisal. Other PB teams can adopt<br />

this approach to determ<strong>in</strong>e the most economical technical solution yet m<strong>in</strong>imize the risk of a<br />

shortfall <strong>in</strong> <strong>in</strong>stalled capacity.<br />

The emergency power generation project for hospitals <strong>in</strong> New York City applied PB expertise<br />

and good practice to solve a real and serious issue with old and <strong>in</strong>adequate life-safety<br />

equipment. The projects required improvement work to progress on old, dispersed,<br />

sometimes poorly documented <strong>in</strong>frastructure without disruption to essential services.<br />

These articles illustrate projects and technologies with a range of complexity, but each team has<br />

a depth of expertise and knowledge to assist clients <strong>in</strong> its sector.<br />

Please see page 89 for a list of many additional thermal generation and carbon reduction articles<br />

from past PB publications.<br />

Paul Kenyon<br />

Eng<strong>in</strong>eer<strong>in</strong>g Manager, Newark, New Jersey<br />

PB Network #68 / August 2008 4

Thermal – Achiev<strong>in</strong>g New Efficiencies, Reduc<strong>in</strong>g Carbon Emissions<br />

http://www.pbworld.com/news_events/publications/network/<br />

The Effect of Carbon Capture and Storage and<br />

Carbon Pric<strong>in</strong>g on the Competitiveness of Gas<br />

Turb<strong>in</strong>e <strong>Power</strong> Plants By Dom<strong>in</strong>ic Cook, Newcastle-upon-Tyne, UK, 44 191 226 2203, cookDo@pbworld.com<br />

Carbon capture and storage<br />

presents an opportunity for<br />

the cont<strong>in</strong>ued use of fossil<br />

fuel <strong>in</strong> power generation<br />

whilst mitigat<strong>in</strong>g its contribution<br />

to carbon emissions.<br />

But at what cost? Will electricity<br />

still be affordable?<br />

Will the technology be<br />

attractive to <strong>in</strong>vestors?<br />

The author expla<strong>in</strong>s the<br />

capture and transport/<br />

storage processes, explores<br />

the answers to these questions,<br />

and tells about some<br />

considerations clients will<br />

face when decid<strong>in</strong>g whether<br />

or not to implement CCS.<br />

Figure 1: Effectiveness of Carbon<br />

Capture.<br />

Current th<strong>in</strong>k<strong>in</strong>g is that atmospheric CO2 concentrations must be stabilised at 450 parts per<br />

million by volume if we are to at least slow down, if not stop, global warm<strong>in</strong>g. This goal will<br />

require a reduction <strong>in</strong> greenhouse gas emissions by a factor of four to five <strong>in</strong> the <strong>in</strong>dustrialised<br />

nations. Whilst there is a cont<strong>in</strong>ued and necessary focus on the development, improvement<br />

and implementation of renewable and carbon-neutral power generation technologies and the<br />

adoption of energy efficiency measures, there is a large gap <strong>in</strong> the short and medium terms<br />

<strong>in</strong> the level of carbon reductions that can be delivered through these routes alone.<br />

The power generation <strong>in</strong>dustry produces about half the world’s CO2 emissions, so it offers<br />

considerable opportunity for <strong>in</strong>troduc<strong>in</strong>g large-scale emission reduction technologies. Current<br />

global debate is focuss<strong>in</strong>g on the development of carbon capture and storage (CCS), which<br />

can extract 85 percent to 95 percent of the CO2 produced by a fossil-fuel power generation<br />

facility. Even though carbon capture reduces a plant’s thermal efficiency, mean<strong>in</strong>g that the use<br />

of fuel per unit of electricity produced <strong>in</strong>creases, the overall carbon reduction is still high—<br />

about 80 percent to 90 percent. The effectiveness of carbon capture technology on power<br />

plant emissions is illustrated <strong>in</strong> Figure 1.<br />

CCS technologies impact the cost of electricity generation, however, so if we are to move<br />

forward with this technology, it is important that we consider the impact of carbon pric<strong>in</strong>g on<br />

lifetime costs, the attractiveness of the technology to <strong>in</strong>vestors, and how vary<strong>in</strong>g the carbon price<br />

will affect the competitiveness of gas turb<strong>in</strong>e plant with other methods of power generation.<br />

Carbon Capture Technologies<br />

The ma<strong>in</strong> carbon capture technologies under development are classed as either<br />

pre-combustion or post-combustion. The one pre-combustion and two post-combustion<br />

options available, which represent the first generation of commercial carbon capture, are<br />

shown <strong>in</strong> Figure 2 and reviewed below.<br />

Pre-combustion. The fuel is first reformed <strong>in</strong>to more basic constituents by its reaction<br />

with oxygen. The fuel can be solid, such as coal, petcoke or biomass; liquid, such as a heavy<br />

fuel oil; or gas, such as natural gas. The resultant product, known as syngas (synthetic<br />

gas), conta<strong>in</strong>s ma<strong>in</strong>ly carbon monoxide and hydrogen. Other constituents <strong>in</strong>clude some<br />

methane, some carbon dioxide, hydrogen sulphide and many other m<strong>in</strong>or compounds<br />

<strong>in</strong>clud<strong>in</strong>g ash if a solid fuel is used. Ash is usually <strong>in</strong> a fused form and easily separated<br />

from the syngas. The syngas is treated to convert the carbon monoxide to carbon dioxide<br />

that is removed <strong>in</strong> a chemical absorption process, leav<strong>in</strong>g a predom<strong>in</strong>antly a high purity<br />

hydrogen gas stream suitable for compression, transportation and long-term sequestration.<br />

The ma<strong>in</strong> plant components of the pre-combustion reformation and capture stages are considered<br />

to be proven technologies, although there will be some process eng<strong>in</strong>eer<strong>in</strong>g required to br<strong>in</strong>g<br />

these to the scale required for large scale CCS. Some further operational<br />

prov<strong>in</strong>g of the gas turb<strong>in</strong>e for use on hydrogen fuel is required before<br />

the process can be regarded as be<strong>in</strong>g a normal operational procedure.<br />

Figure 2: Carbon Capture<br />

and Storage Schematic.<br />

Post Combustion. A post combustion carbon capture plant can<br />

use the same fuels as a pre-combustion capture plant. The fuels are<br />

combusted <strong>in</strong> either conventional boiler plant or, if suitable, <strong>in</strong> gas<br />

turb<strong>in</strong>e plant. The flue gases are treated to remove particulate matter<br />

<br />

5 PB Network #68 / August 2008

Thermal – Achiev<strong>in</strong>g New Efficiencies, Reduc<strong>in</strong>g Carbon Emissions<br />

http://www.pbworld.com/news_events/publications/network/<br />

and sulphur dioxide, and to reduce nitrogen oxides before<br />

enter<strong>in</strong>g the carbon capture process. The carbon dioxide is<br />

absorbed <strong>in</strong>to a chemical solution 1 to remove it from the flue<br />

gas, which is then emitted to atmosphere. The carbon dioxide<br />

gas is removed from the absorbent, compressed and transported<br />

for long-term sequestration. The challenge with this<br />

technology is the need to scale up to utility-size capture.<br />

Oxyfuel. An oxyfuel plant is one <strong>in</strong> which the fuel is<br />

combusted <strong>in</strong> oxygen supplied by an air separation plant<br />

rather than air. The result<strong>in</strong>g flue gases are purified to remove<br />

particulate matter and sulphur dioxide, and to reduce nitrogen<br />

oxides. Some of the captured carbon dioxide is recycled and<br />

mixed with the oxygen feed to the boiler plant to control<br />

combustion temperature. The rema<strong>in</strong><strong>in</strong>g carbon dioxide is<br />

then purified, compressed and transported to long-term storage.<br />

The aim of oxyfuel development is to use as much of the<br />

exist<strong>in</strong>g and proven equipment as possible; although some<br />

issues rema<strong>in</strong> relat<strong>in</strong>g to the control of combustion temperatures<br />

with<strong>in</strong> the boiler and the scal<strong>in</strong>g up of air separation<br />

plant to the size necessary for use <strong>in</strong> power plant applications.<br />

Carbon Dioxide Transport and Storage<br />

Transport. Captured carbon dioxide is transported to a longterm<br />

storage location by either pipel<strong>in</strong>e, truck, tra<strong>in</strong>, or boat,<br />

although only pipel<strong>in</strong>e would be feasible for the quantities<br />

result<strong>in</strong>g from large-scale power generation—millions of tonnes<br />

per year. The pipel<strong>in</strong>e could transport carbon dioxide <strong>in</strong> the<br />

gaseous phase, at pressures below 71 bar, or at higher pressures<br />

where the carbon dioxide is present as a supercritical<br />

fluid giv<strong>in</strong>g benefits from lower frictional losses. The scale is<br />

such that a new pipel<strong>in</strong>e <strong>in</strong>frastructure would be needed.<br />

Storage. Storage of carbon dioxide is assumed to be <strong>in</strong><br />

geological formations, such as depleted oil and gas reservoirs,<br />

deep sal<strong>in</strong>e aquifers and unm<strong>in</strong>eable coal seams. These<br />

formations need to provide storage with negligible leakage<br />

to ensure that the carbon is sequestered over geological<br />

timescales—thousands, if not tens of thousands of years.<br />

The estimated global potential for the storage of CO2 <strong>in</strong><br />

these various s<strong>in</strong>ks is detailed <strong>in</strong> Table 1. As would be expected,<br />

the capacities for the oil/gas and coal storage options are<br />

considerably smaller than those for the sal<strong>in</strong>e aquifers.<br />

Even with the present global carbon dioxide emissions of<br />

about 25 billion tonnes per year, the available storage capacity<br />

extends for about 55 years to about 435 years. Whilst<br />

this is not a solution, it does provide us with a temporary<br />

breath<strong>in</strong>g space <strong>in</strong> which to f<strong>in</strong>d and implement alternative<br />

means of energy provision to satisfy human, social and<br />

economic aspirations.<br />

Technology<br />

Analysis and<br />

Lifetime Cost of<br />

Generation<br />

For the purposes of<br />

review<strong>in</strong>g the position<br />

of gas turb<strong>in</strong>e technology<br />

with<strong>in</strong> a carbon<br />

constra<strong>in</strong>ed world, it was<br />

necessary to identify those<br />

power generation technologies where gas turb<strong>in</strong>es will<br />

cont<strong>in</strong>ue to have a use and, importantly, the competitor<br />

technologies. The technologies reviewed <strong>in</strong>cluded:<br />

• Coal supercritical pulverised fuel plant with flue gas<br />

desulphurisation with and without carbon capture<br />

• Coal <strong>in</strong>tegrated gasification comb<strong>in</strong>ed cycle plant (IGCC)<br />

with and without carbon capture<br />

• Gas fired comb<strong>in</strong>ed cycle plant with low NOx burner<br />

technology with and without carbon capture<br />

• New generation nuclear power plant.<br />

Table 1: Estimated Capacity of<br />

CO 2 Storage Options.<br />

(Source: IEA-GHG, 2004)<br />

Our analysis considered the impact of carbon and capital<br />

on the lifetime cost of electricity generation. The extent to<br />

which carbon pric<strong>in</strong>g ‘feeds through’ to the cost of electricity<br />

generation depends on the amount of free allocations<br />

provided by government to <strong>in</strong>dividual plants. Given that<br />

different allocation methodologies will be adopted <strong>in</strong> different<br />

countries globally, it was considered to be of more value to<br />

assume no allocations and that the full cost of carbon flows<br />

through to the end electricity generation cost.<br />

The level of carbon captured with<strong>in</strong> the carbon capture<br />

options will be specific to each plant’s detailed design. The<br />

costs associated with the transport and storage of carbon<br />

were based on various reference sources—an <strong>in</strong>dicative<br />

value of $10/ton CO2 sequestered was used. 2 The Capital<br />

costs and operation and ma<strong>in</strong>tenance costs were based on<br />

those observed <strong>in</strong> the market and <strong>in</strong>cluded adjustments for<br />

the recent <strong>in</strong>creases <strong>in</strong> the underly<strong>in</strong>g materials costs, such as:<br />

• Steel: 35 percent <strong>in</strong>crease s<strong>in</strong>ce 2002<br />

• Copper: 400 percent <strong>in</strong>crease s<strong>in</strong>ce 2002<br />

• Nickel: 400 percent <strong>in</strong>crease s<strong>in</strong>ce 2002.<br />

The analysis showed that the addition of carbon capture<br />

and associated transport and storage charges added about<br />

35 percent to 63 percent to the lifetime cost of electricity<br />

generation. Introduc<strong>in</strong>g a carbon cost payable by the<br />

generation plants for all CO2 emitted <strong>in</strong>creased the electricity<br />

costs across the board, as would be expected. For example,<br />

if a $25/ton charge were placed on all CO2 emissions, the gap<br />

between non-carbon capture and carbon capture would be<br />

narrowed to 6 percent to 22 percent due to the proportionately<br />

larger impact the carbon cost has on the non-CCS plant.<br />

1 A number of possible chemicals can be used. Am<strong>in</strong>e, ammonia, and potassium bicarbonate are just a few.<br />

2 Imperial College, Potential for Synergy between renewables and Carbon Capture and Storage.<br />

PB Network #68 / August 2008 6

Thermal – Achiev<strong>in</strong>g New Efficiencies, Reduc<strong>in</strong>g Carbon Emissions<br />

http://www.pbworld.com/news_events/publications/network/<br />

across the board, as would be expected. For example, if a<br />

€25/ton charge were placed on all CO2 emissions, the gap<br />

between non-carbon capture and carbon capture would be<br />

narrowed to 6 percent to 22 percent due to the proportionately<br />

larger impact the carbon cost has on the non-CCS plant.<br />

Figure 3 shows that the carbon costs <strong>in</strong>curred by unabated<br />

generation <strong>in</strong>crease the cost of generation significantly whilst<br />

ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g the mix of generation technologies to coal, gas<br />

and nuclear. There did not appear to be a clear w<strong>in</strong>ner.<br />

Figure 3: Relative costs of plant with and without carbon capture.<br />

Where Are We Now?<br />

A number of CCS projects of vary<strong>in</strong>g sizes are underway<br />

around the world. The European Union (EU) projects are<br />

shown <strong>in</strong> Figure 4. As can be seen, only three are identified<br />

as be<strong>in</strong>g operational with the bulk be<strong>in</strong>g <strong>in</strong> the ‘planned’ stage.<br />

Figure 4: Carbon Capture projects <strong>in</strong> the European Union.<br />

These projects will be implemented at various times up to<br />

2015, with the majority scheduled for delivery around 2010.<br />

The fact that these development projects are mov<strong>in</strong>g forward<br />

is a step <strong>in</strong> right direction; however, there is a need to accelerate<br />

this if we wish to conta<strong>in</strong> the global concentrations of<br />

atmospheric CO2 below the 450 ppmv level that is presently<br />

given as our target.<br />

Other Opportunities<br />

A carbon capture plant had been considered to date as<br />

be<strong>in</strong>g <strong>in</strong>flexible <strong>in</strong> its operation and less able to respond to<br />

short-term changes <strong>in</strong> electricity demand. This view is chang<strong>in</strong>g,<br />

however, with recent studies consider<strong>in</strong>g the specific capabilities<br />

of the power generation plant and the carbon capture plant<br />

separately. With this new view comes the potential to<br />

<strong>in</strong>clude additional carbon storage on post-combustion capture<br />

plants, a change that will allow additional power to be provided<br />

from the generator <strong>in</strong> response to system events, such as<br />

transmission system faults, power station forced outages, or<br />

spikes <strong>in</strong> demand. This change could provide valuable flexibility<br />

services to the transmission system operator when rapid<br />

response to system events is required.<br />

In the case of pre-combustion plant, whether the fuel is coal<br />

or gas, the hydrogen fraction of the syngas could provide the<br />

beg<strong>in</strong>n<strong>in</strong>g for establish<strong>in</strong>g a hydrogen economy. This would<br />

be prior to the commercial realisation of nuclear fission. It<br />

would also be applicable <strong>in</strong> countries that do not have sufficient<br />

<strong>in</strong>solation (<strong>in</strong>cident solar radiation) or available land area to<br />

drive large solar plant that could be used to generate hydrogen.<br />

Summary<br />

The technology relat<strong>in</strong>g to carbon capture is progress<strong>in</strong>g<br />

and reach<strong>in</strong>g a po<strong>in</strong>t where it is at a pre-commercial stage.<br />

The mechanisms to allow the costs associated with carbon<br />

emissions to <strong>in</strong>centivise <strong>in</strong>vestment <strong>in</strong> carbon capture plant<br />

are beg<strong>in</strong>n<strong>in</strong>g to emerge, but they will need a strong political<br />

will to ensure that the costs associated with carbon emissions<br />

become sufficient to tip the balance <strong>in</strong> favour of carbon<br />

capture. This political decision will need to take <strong>in</strong>to<br />

account the extent to which the end customer <strong>in</strong>curs<br />

additional charges and the rate at which any additional costs<br />

are <strong>in</strong>troduced <strong>in</strong>to the economy. This is a balanc<strong>in</strong>g act<br />

and it will have a time constant associated with it. It must<br />

be remembered, however, that:<br />

CCS IS NOT A SOLUTION — IT’S A STOP GAP!<br />

Dom<strong>in</strong>ic Cook has 20+ years of utility and consultancy experience <strong>in</strong> the power <strong>in</strong>dustry. He has been <strong>in</strong>volved <strong>in</strong> regulatory audits and the development of power<br />

generation plant, and <strong>in</strong> provid<strong>in</strong>g advice to f<strong>in</strong>ancial <strong>in</strong>stitutions. His publications <strong>in</strong>cluded “<strong>Power</strong><strong>in</strong>g the Nation” <strong>in</strong> June 2006 and he is presently <strong>in</strong>volved with the<br />

UK government on the carbon capture competition.<br />

Note: This article was adapted from a paper presented at the annual conference of the Institute of Diesel and Gas Turb<strong>in</strong>e Eng<strong>in</strong>eers (IDGTE) <strong>in</strong> November 2007.<br />

7 PB Network #68 / August 2008

Thermal – Achiev<strong>in</strong>g New Efficiencies, Reduc<strong>in</strong>g Carbon Emissions<br />

http://www.pbworld.com/news_events/publications/network/<br />

The NuGas TM Concept: Comb<strong>in</strong><strong>in</strong>g a Nuclear <strong>Power</strong><br />

Plant with a Gas-Fired Plant<br />

By Paul Willson, Manchester, UK, 44 161 200 5210 willsonPa@pbworld.com; and Alistair Smith, 44 161 200 5114, smithAlistair@pbworld.com<br />

Nuclear power is experienc<strong>in</strong>g<br />

renewed <strong>in</strong>terest<br />

around the world because<br />

of its low carbon emissions<br />

and affordability. As with<br />

other thermal generation<br />

technologies, however, its<br />

thermal efficiency is limited.<br />

PB has developed a new<br />

concept that comb<strong>in</strong>es<br />

current nuclear technology<br />

with comb<strong>in</strong>ed cycle gas<br />

turb<strong>in</strong>e technology to<br />

achieve unprecedented<br />

levels of thermal efficiency.<br />

The authors expla<strong>in</strong> how<br />

it works and how it can be<br />

implemented <strong>in</strong> new <strong>in</strong>stallations<br />

or <strong>in</strong> retrofitt<strong>in</strong>g<br />

exist<strong>in</strong>g nuclear stations.<br />

PB’s power specialists <strong>in</strong> the UK have developed and patented a completely new concept<br />

for high-efficiency electricity generation. This ground-break<strong>in</strong>g development, called NuGas TM ,<br />

comb<strong>in</strong>es the advantages of nuclear power generation with a smaller comb<strong>in</strong>ed cycle gas turb<strong>in</strong>e<br />

(CCGT)-based power technology to create a low-cost, highly reliable hybrid system that:<br />

• Increases output and thermal efficiencies to levels that are far higher than even the most<br />

ambitious forecasts<br />

• Achieves a simple, safe and effective <strong>in</strong>terface between the cycles.<br />

Improved performance comes from better use of heat <strong>in</strong> the steam cycles of the CCGT and<br />

nuclear plant where currently unavoidable large temperature differences prevent the maximum<br />

work be<strong>in</strong>g obta<strong>in</strong>ed from the heat. By l<strong>in</strong>k<strong>in</strong>g a CCGT with the low-temperature steam cycle<br />

typical of a nuclear power plant, these temperature differences can be reduced significantly,<br />

releas<strong>in</strong>g additional power output without go<strong>in</strong>g outside conventional design conditions.<br />

Because NuGas TM enhances thermodynamic cycle design rather than chang<strong>in</strong>g operat<strong>in</strong>g conditions<br />

to improve efficiency, it <strong>in</strong>troduces no new technology risks <strong>in</strong> its implementation. This is a<br />

significant advantage over the more complex and unproven technologies be<strong>in</strong>g <strong>in</strong>troduced for<br />

new gas turb<strong>in</strong>e designs as eng<strong>in</strong>eers pursue ever higher temperature operation.<br />

NuGas TM can be used either for retrofitt<strong>in</strong>g exist<strong>in</strong>g nuclear stations or for new-build <strong>in</strong>stallations.<br />

While the new-build design allows for maximum optimization, the retrofitted option will<br />

enable rapid return on <strong>in</strong>vestment with m<strong>in</strong>imal impact on normal day-to-day operation<br />

of the exist<strong>in</strong>g nuclear plant dur<strong>in</strong>g construction of the CCGT unit.<br />

Improv<strong>in</strong>g Thermal Efficiency<br />

When analyz<strong>in</strong>g a nuclear power station design, the question often asked by non-eng<strong>in</strong>eers or<br />

scientists is ‘why can’t you convert all the heat generated <strong>in</strong> the reactor <strong>in</strong>to electricity?’ For<br />

example, the thermal efficiency of the latest pressurized water reactors (PWRs) is just 37 percent.<br />

Even if there were no losses <strong>in</strong> the system, the maximum Ideal Efficiency would still be well<br />

below 100 percent. For a PWR operat<strong>in</strong>g at an upper steam temperature of 540°F (280°C),<br />

the maximum possible efficiency would be just 45 percent. The way to push the Ideal Efficiency<br />

up is to <strong>in</strong>crease the upper temperature <strong>in</strong> the cycle, which is why gas-cooled high temperature<br />

reactors are aga<strong>in</strong> be<strong>in</strong>g considered.<br />

Temperatures have been pushed up also <strong>in</strong> fossil fuelled power plants, and the most modern<br />

coal-fired super-critical boilers can achieve a thermal efficiency of 44 percent. This level is now<br />

be<strong>in</strong>g exceeded when two cycles are comb<strong>in</strong>ed, such as the CCGT, where temperatures are<br />

around 2300°F (1200°C) and a thermal efficiency of 57 percent can now be achieved. The<br />

desire to raise system efficiencies beyond current levels has proven challeng<strong>in</strong>g, however.<br />

Despite considerable <strong>in</strong>vestment <strong>in</strong> research and development, it appears that significant<br />

<strong>in</strong>cremental improvements are becom<strong>in</strong>g more expensive and harder to achieve without<br />

sacrific<strong>in</strong>g reliability.<br />

By comb<strong>in</strong><strong>in</strong>g current nuclear and CCGT technologies. NuGas TM raises thermal efficiencies to<br />

unprecedented levels. Under this concept, the two separate power generation systems can operate<br />

<strong>in</strong> tandem as a s<strong>in</strong>gle comb<strong>in</strong>ed unit on the same site. In the case of breakdown or planned<br />

ma<strong>in</strong>tenance, either the nuclear plant or the gas turb<strong>in</strong>e-powered unit can revert to <strong>in</strong>dependent<br />

operation, thereby maximiz<strong>in</strong>g availability of power and m<strong>in</strong>imiz<strong>in</strong>g upset to the power networks.<br />

PB Network #68 / August 2008 8

Thermal – Achiev<strong>in</strong>g New Efficiencies, Reduc<strong>in</strong>g Carbon Emissions<br />

http://www.pbworld.com/news_events/publications/network/<br />

The basic concept would allow a large nuclear power plant<br />

with a typical output of 800 to 1700 MWe to be comb<strong>in</strong>ed<br />

with a 300 MW CCGT generat<strong>in</strong>g unit. L<strong>in</strong>k<strong>in</strong>g the steamcycles<br />

of the two plants enables them to operate as an<br />

<strong>in</strong>tegrated power production unit and reduces losses of<br />

potential output, <strong>in</strong>creas<strong>in</strong>g total efficiency. Cycle efficiency<br />

ga<strong>in</strong>s enable the CCGT to contribute an <strong>in</strong>creased output for<br />

no additional fuel, with the efficiency of convert<strong>in</strong>g the energy<br />

<strong>in</strong> the gas to electricity <strong>in</strong>creased to about 62 percent.<br />

How NuGas TM Works<br />

Although a CCGT system has a high thermal efficiency, it<br />

relies on us<strong>in</strong>g the heat from the exhaust gases of the gas<br />

turb<strong>in</strong>e to boil water to produce steam that drives the<br />

turb<strong>in</strong>e. As the exhaust gases cool, water is evaporated <strong>in</strong><br />

the boiler tubes but temperature differences of up to 400ºF<br />

(200ºC) arise <strong>in</strong> the boiler due to the large amount of heat<br />

needed to evaporate the water. These temperature differences<br />

limit the potential work that can be extracted from the<br />

steam, reduc<strong>in</strong>g the output of the steam cycle.<br />

The NuGas TM cycle overcomes this limitation by ‘borrow<strong>in</strong>g’ a<br />

small proportion (typically 10 percent) of the steam from the<br />

nuclear steam cycle (po<strong>in</strong>t ‘A’ on Figure 1). The dry saturated<br />

steam is superheated us<strong>in</strong>g the exhaust heat of the gas<br />

turb<strong>in</strong>e. The high temperature steam (‘B’) is then used to<br />

drive a separate conventional condens<strong>in</strong>g steam turb<strong>in</strong>e to<br />

provide additional output from the plant. Superheat<strong>in</strong>g steam<br />

rather than boil<strong>in</strong>g water enables a much lower temperature<br />

difference to be ma<strong>in</strong>ta<strong>in</strong>ed <strong>in</strong> the heat recovery system,<br />

maximiz<strong>in</strong>g the value of the energy recovered.<br />

The heat <strong>in</strong> the gas turb<strong>in</strong>e exhaust flow between about<br />

570ºF and 320ºF (300ºC and 160ºC) is recovered via a high<br />

temperature economizer (‘C’) to generate high temperature<br />

Figure 1: Schematic Comb<strong>in</strong>ation of the Steam Cycles.<br />

feedwater, which is returned to the nuclear cycle (‘D’),<br />

ensur<strong>in</strong>g that the <strong>in</strong>let temperature to the steam generator<br />

is ma<strong>in</strong>ta<strong>in</strong>ed close to the design value.<br />

The heat <strong>in</strong> the gas turb<strong>in</strong>e exhaust below about 320ºF (160ºC)<br />

(‘E’) is used to heat part of the condensate from the high<br />

temperature steam turb<strong>in</strong>e (‘F’) before it is deaerated and<br />

returned to the nuclear cycle feed pumps (‘G’). The rema<strong>in</strong><strong>in</strong>g<br />

condensate from the high temperature steam turb<strong>in</strong>e is<br />

returned to the nuclear cycle condensate system (‘H’).<br />

The flows of energy around the cycle differ somewhat to<br />

those <strong>in</strong> a conventional CCGT. Figure 2 shows a simplified<br />

Sankey diagram for the NuGas TM cycle, <strong>in</strong>clud<strong>in</strong>g the energy<br />

exchanges between the CCGT and PWR cycles shown along<br />

the lower edge of the diagram.<br />

Identify<strong>in</strong>g the separate performance of the CCGT cycle<br />

when it is l<strong>in</strong>ked to the PWR cycle requires that the design<br />

PWR energy balance be ma<strong>in</strong>ta<strong>in</strong>ed. Thus, the CCGT returns<br />

power to the PWR to compensate for the reduction <strong>in</strong><br />

output due to the ‘borrowed’ steam and returns rejected<br />

heat <strong>in</strong> the CCGT cool<strong>in</strong>g water to the PWR to account<br />

for the reduced heat rejection from the nuclear turb<strong>in</strong>e<br />

condenser. The diagram therefore shows the additional<br />

energy <strong>in</strong>put, the additional losses and the additional power<br />

generated by the cycle, demonstrat<strong>in</strong>g its high efficiency.<br />

Safety Considerations<br />

Downstream failure is limited. The extraction of steam<br />

from the ma<strong>in</strong> steam system has the potential to disturb<br />

reactor operat<strong>in</strong>g conditions. However, the PWR system is<br />

designed to allow for a 10 percent step change <strong>in</strong> flow to the<br />

ma<strong>in</strong> steam turb<strong>in</strong>e without exceed<strong>in</strong>g the appropriate limits<br />

for a frequent operat<strong>in</strong>g condition. It is likely, nevertheless,<br />

Figure 2: Simplified Sankey Diagram for NuGas Cycle.<br />

<br />

9 PB Network #68 / August 2008

Thermal – Achiev<strong>in</strong>g New Efficiencies, Reduc<strong>in</strong>g Carbon Emissions<br />

http://www.pbworld.com/news_events/publications/network/<br />

that a suitably qualified shut-off valve and additional bypass<br />

valves would be needed to limit the potential impact of any<br />

downstream failure <strong>in</strong> the NuGas TM cycle.<br />

Installation risks are m<strong>in</strong>imized. The <strong>in</strong>terconnection<br />

design m<strong>in</strong>imizes <strong>in</strong>stallation risks and ensures that the ma<strong>in</strong><br />

plant is unaffected by ma<strong>in</strong>tenance of the NuGas TM plant and<br />

that CCGT operation can cont<strong>in</strong>ue <strong>in</strong>dependently of reactor<br />

operation. This is fundamental, as significant costs would be<br />

charged by the grid operator for <strong>in</strong>creas<strong>in</strong>g the loss of generation<br />

result<strong>in</strong>g from a s<strong>in</strong>gle fault. In addition, the project<br />

economics would be adversely affected if the availability of<br />

either plant was to be degraded by the l<strong>in</strong>k<strong>in</strong>g of the cycles.<br />

Safety case is ma<strong>in</strong>ta<strong>in</strong>ed. NuGas TM raises overall efficiency<br />

by enhanc<strong>in</strong>g the thermodynamic cycle rather than chang<strong>in</strong>g<br />

operat<strong>in</strong>g conditions, so <strong>in</strong> addition to be<strong>in</strong>g <strong>in</strong>expensive, it<br />

<strong>in</strong>troduces no new technology risks <strong>in</strong> its implementation.<br />

The plant design <strong>in</strong>corporates additional systems to control<br />

high temperature steam flows l<strong>in</strong>k<strong>in</strong>g the nuclear and CCGT<br />

units, ensur<strong>in</strong>g that the <strong>in</strong>tegrity of the nuclear safety case is<br />

ma<strong>in</strong>ta<strong>in</strong>ed.<br />

To ensure that all the additional hazards associated with the<br />

<strong>in</strong>troduction of the CCGT are assessed, a full HAZOP has<br />

been carried out to ensure that risks are well with<strong>in</strong> the<br />

currently assessed fault scenarios.<br />

New Build<br />

Currently, the two lead<strong>in</strong>g candidate PWR designs for new<br />

nuclear construction are the Evolutionary Pressurized Water<br />

Reactor (EPR) from AREVA with a nom<strong>in</strong>al power rat<strong>in</strong>g of<br />

1600 MWe and the West<strong>in</strong>ghouse AP1000 reactor with an<br />

output of around 1140 MWe. Either the EPR or AP1000<br />

could be <strong>in</strong>tegrated with a NuGas TM cycle to offer extra<br />

capacity with the highest possible efficiency for fossil fuel<br />

conversion without significantly <strong>in</strong>creas<strong>in</strong>g the loss of output<br />

<strong>in</strong> the event of a reactor trip.<br />

If the NuGas TM concept was applied to an AP1000 with a<br />

nuclear plant electrical output of 1140 MW, the comb<strong>in</strong>ed<br />

plant would have an output of approximately 1470 MW for an<br />

additional capital cost of around $250 million ($800 to $1000<br />

per <strong>in</strong>cremental kW). The cost of the NuGas TM <strong>in</strong>tegration is<br />

approximately $50 million, which can be considered to offer<br />

additional capacity with no additional fuel burn. Pessimistically<br />

at a fuel price of $7/MMBTU, a cost that is conservatively<br />

below current levels and below recent longer term forecasts,<br />

the <strong>in</strong>vestment to comb<strong>in</strong>e the plants would have a typical<br />

payback time of less than three years. At higher gas prices,<br />

the benefits are <strong>in</strong>creased and the payback period<br />

correspond<strong>in</strong>gly reduced.<br />

Backfit<br />

The renaissance of <strong>in</strong>terest <strong>in</strong> new nuclear power plants will<br />

mean that by 2015 and beyond more nuclear plants will be<br />

brought on-l<strong>in</strong>e, but for the next seven years utilities wait<strong>in</strong>g<br />

for their new nuclear plants to be licensed and built may be<br />

faced with a generat<strong>in</strong>g capacity gap. Some utilities are,<br />

therefore, consider<strong>in</strong>g build<strong>in</strong>g <strong>in</strong>terim plants with a low capital<br />

cost and rapid construction times, characteristics of the<br />

CCGT. Build<strong>in</strong>g a CCGT and comb<strong>in</strong><strong>in</strong>g it with an exist<strong>in</strong>g<br />

nuclear power plant can provide a rapid method for <strong>in</strong>creas<strong>in</strong>g<br />

power generation capacity with exceptionally high thermal<br />

efficiency, mak<strong>in</strong>g it far more profitable than stand-alone<br />

CCGTs. The necessary connections to the nuclear steam<br />

cycle can be readily made dur<strong>in</strong>g the refuell<strong>in</strong>g outages on<br />

the nuclear plant, thereby m<strong>in</strong>imiz<strong>in</strong>g disruption and cost.<br />

A further key advantage for the NuGas TM concept arises<br />

where the nuclear plant has <strong>in</strong>creased operat<strong>in</strong>g marg<strong>in</strong>s<br />

such that more heat can be emitted by the reactor. In some<br />

cases this extra output cannot be converted to electricity<br />

as the exist<strong>in</strong>g steam system cannot operate at significantly<br />

higher rates. Because the NuGas TM cycle <strong>in</strong>creases steam<br />

utilization capability by at least 10 percent, it can use excess<br />

steam without expenditure or shutdowns for costly steam<br />

cycle upgrades, mak<strong>in</strong>g the NuGas TM conversion even more<br />

attractive f<strong>in</strong>ancially.<br />

Conclusion<br />

By re-exam<strong>in</strong><strong>in</strong>g power generation options and focus<strong>in</strong>g on<br />

improv<strong>in</strong>g efficiency to reduce carbon emissions, it has been<br />

possible to develop<strong>in</strong>g a novel concept that br<strong>in</strong>gs together<br />

the best aspects of nuclear and gas-fired power generat<strong>in</strong>g<br />

technologies. The concept is now be<strong>in</strong>g developed with<br />

utilities and plant vendors, with a target of go<strong>in</strong>g <strong>in</strong>to service<br />

before 2013.<br />

<br />

Paul Willson, Deputy Director of Eng<strong>in</strong>eer<strong>in</strong>g, Generation with<strong>in</strong> PB’s power and energy bus<strong>in</strong>ess <strong>in</strong> Manchester, has worked for PB and its predecessors for more than 25<br />

years. He leads the Development and Emerg<strong>in</strong>g Technology Group, which is responsible for <strong>in</strong>dependent power and water project development and for <strong>in</strong>novations. Paul<br />

is co-<strong>in</strong>ventor of the NuGas technology.<br />

Alistair Smith, Director of Nuclear Services for PB based <strong>in</strong> Manchester, has worked <strong>in</strong> the nuclear power <strong>in</strong>dustry for 27 years and has worked on all phases of the<br />

nuclear plant lifecycle cover<strong>in</strong>g design, construction, operation and decommission<strong>in</strong>g. He is the chairman of the UK Institution of Mechanical Eng<strong>in</strong>eers Nuclear <strong>Power</strong><br />

Committee, chairman of the Nuclear Industry Association’s <strong>in</strong>dustrial group, and is a spokesman for the UK nuclear <strong>in</strong>dustry.<br />

PB Network #68 / August 2008 10

http://www.pbworld.com/news_events/publications/network/<br />

Thermal – Achiev<strong>in</strong>g New Efficiencies, Reduc<strong>in</strong>g Carbon Emissions<br />

PB Inspections Help to Ensure <strong>Power</strong> Plant Safety<br />

By Stewart Gray, Bangkok, Thailand, 66 (0) 2343 8866, gray.stewart@pbworld.com<br />

The author provides some<br />

<strong>in</strong>sight <strong>in</strong>to the application<br />

of eng<strong>in</strong>eer<strong>in</strong>g to prevent<br />

explosions and fire <strong>in</strong> highly<br />

hazardous areas of power<br />

plants fuelled by oil or gas.<br />

Acronyms/Abbreviations<br />

IEC:<br />

International<br />

Electrotechnical<br />

Commission<br />

Figure 1: Schematic of the<br />

pr<strong>in</strong>ciple of a flameproof<br />

enclosure.<br />

In modern thermal power plants fuelled by either oil or gas, fuel handl<strong>in</strong>g processes give rise<br />

to situations where electrical equipment could cause an explosion due to a hot surface or a<br />

spark. Indeed, there have been several <strong>in</strong>cidents <strong>in</strong> the past where lives have been lost and<br />

plant destroyed. Places where these situations arise are termed “hazardous” or “classified areas.”<br />

Special eng<strong>in</strong>eer<strong>in</strong>g practices designed to prevent explosions <strong>in</strong> these areas are available.<br />

These practices are often misunderstood and applied <strong>in</strong>correctly, however, expert supervision<br />

should always be used at a project start-up to ensure such eng<strong>in</strong>eer<strong>in</strong>g practices are implemented<br />

properly. The follow<strong>in</strong>g <strong>in</strong>formation is based on the experiences of some of PB’s<br />

workers <strong>in</strong> this field, particularly our assessments of power plant <strong>in</strong>stallations and our ensur<strong>in</strong>g<br />

that relevant codes and practices, local statute and <strong>in</strong>surance requirements are adhered to.<br />

Applicable Codes or Practice<br />

The code or practice applicable to each <strong>in</strong>stallation is normally determ<strong>in</strong>ed by its locality,<br />

although the several different practices applied worldwide have many similarities. The most<br />

commonly applied codes are International Electrotechnical Commission (IEC) 60079 “Electrical<br />

apparatus for explosive gas atmospheres” and National Fire Protection Association (NFPA) 70<br />

“National Electrical Code.” Both def<strong>in</strong>e sets of special precautions (types of protection) required<br />

for electrical equipment <strong>in</strong> hazardous/classified areas us<strong>in</strong>g some very def<strong>in</strong>ite vocabulary.<br />

Choice of Types of Explosion Protection<br />

Figure 2: Schematic of the<br />

pr<strong>in</strong>ciple of <strong>in</strong>creased safety.<br />

Figure 3: Schematic of the<br />

pr<strong>in</strong>ciple of <strong>in</strong>tr<strong>in</strong>sic safety.<br />

It is important to establish the extent of hazardous areas that exist at an early stage of any<br />

plant’s design. These areas are customarily del<strong>in</strong>eated us<strong>in</strong>g a plan called a “hazardous areas<br />

layout draw<strong>in</strong>g.” While it is always best to <strong>in</strong>stall the electrical equipment elsewhere, do<strong>in</strong>g so<br />

is often unavoidable.<br />

All electrical equipment <strong>in</strong>stalled <strong>in</strong> a hazardous area requires explosion protection. IEC<br />

60079 def<strong>in</strong>es n<strong>in</strong>e types of such protection. Of these, the three types of protection most<br />

commonly found <strong>in</strong> modern power plant are:<br />

• Flame proof enclosure (type d). This technique limits the effect of an explosion. Parts<br />

that could cause an explosion are placed <strong>in</strong>side a special enclosure that is strong enough to<br />

conta<strong>in</strong> an <strong>in</strong>ternal explosion (Figure 1). The result<strong>in</strong>g hot gasses exit through a specially<br />

mach<strong>in</strong>ed path that is relatively long and narrow. As they exit they are cooled sufficiently<br />

to avoid spread<strong>in</strong>g the explosion outside.<br />

The ma<strong>in</strong> uses for this type of protection are electrical power equipment, switches, etc.<br />

While this is a well known technique, it is somewhat less readily available than others. It<br />

is also expensive and requires special <strong>in</strong>stallation rules.<br />

• Increased safety (type e). This technique (Figure 2) prevents explosions. Parts that could<br />

cause an explosion are made with a superior degree of safety, <strong>in</strong>clud<strong>in</strong>g long creepages and<br />

clearances, and temperature limitations. Its ma<strong>in</strong> use is for junction boxes. This technique is<br />

well known, readily available, and <strong>in</strong>expensive. Its use requires observation of special design<br />

and <strong>in</strong>stallation rules.<br />

• Intr<strong>in</strong>sic safety (type i). This technique (Figure 3) also prevents explosions. The circuit<br />

is arranged so the amount of energy that can flow <strong>in</strong>to the hazardous area is limited and<br />

<strong>in</strong>capable of caus<strong>in</strong>g an ignition. Normally, energy limit<strong>in</strong>g “barrier” devices used <strong>in</strong> the safe<br />

area conta<strong>in</strong> zenner diodes or optical isolators to achieve the energy limitation. Care needs<br />

to be taken to ensure that the hazardous area part of the circuit cannot store large amounts<br />

of energy (i.e., use of low capacitance cables).<br />

<br />

11 PB Network #68 / August 2008

Thermal – Achiev<strong>in</strong>g New Efficiencies, Reduc<strong>in</strong>g Carbon Emissions<br />

http://www.pbworld.com/news_events/publications/network/<br />

The ma<strong>in</strong> uses of type i are for <strong>in</strong>strumentation, telecommunication<br />

devices, and similar equipment. It is well<br />

known, <strong>in</strong>expensive and readily available, but special design<br />

and <strong>in</strong>stallation rules need to be followed. Two categories<br />

of <strong>in</strong>tr<strong>in</strong>sic safety are available. Category ia, which provides<br />

the highest degree of explosion protection available,<br />

ensures safety under two faults. Category ib ensures safety<br />

under a s<strong>in</strong>gle fault.<br />

Design and Assembly Stage Inspections<br />

Inspections of the <strong>in</strong>stallation need to be conducted throughout<br />

the stages of its life cycle <strong>in</strong> accordance with IEC 60079.<br />

Design Stage. Inspections should start at the design stage<br />

by means of design review because mistakes identified at this<br />

stage are almost always easier and less costly to rectify.<br />

Factory Assembly Stage. When factory assembly of skid<br />

mounted equipment is completed and after the factory has<br />

conducted its own <strong>in</strong>spection, an <strong>in</strong>spection done by our<br />

team is advantageous. Whilst this does not present a<br />

comprehensive picture of the f<strong>in</strong>al <strong>in</strong>stallation, it can often<br />

show mistakes, and corrective measures can be planned<br />

dur<strong>in</strong>g shipp<strong>in</strong>g to the construction site.<br />

F<strong>in</strong>al Construction Inspection<br />

A f<strong>in</strong>al construction <strong>in</strong>spection, along with possible rectification<br />

of any mistake, is mandatory before explosive fluid can<br />

be <strong>in</strong>troduced to the plant. The objective of the <strong>in</strong>spections<br />

is to verify the <strong>in</strong>stallation complies with the applicable code<br />

of practice. In the case of IEC 60079, this requires ensur<strong>in</strong>g<br />

that the appropriate components were selected and that<br />

they were <strong>in</strong>stalled correctly. Discovery of an <strong>in</strong>stallation<br />

mistake at this stage may lead to project time delay.<br />

Verification of Explosion Protection. The first part of<br />

any <strong>in</strong>spection work is to make sure that the equipment is<br />

explosion protected <strong>in</strong> conformance with IEC 60079. Whilst<br />

it may be labelled with compliance <strong>in</strong>formation, a visual check<br />

of labell<strong>in</strong>g is not enough. It is necessary to obta<strong>in</strong> a copy<br />

of the orig<strong>in</strong>al certificate of conformance and use this as<br />

the <strong>in</strong>spection start-po<strong>in</strong>t. The <strong>in</strong>spector should check<br />

the certificate validity, cross check the certificate aga<strong>in</strong>st<br />

equipment labels and verify the <strong>in</strong>stallation method complies<br />

with the requirements as stated <strong>in</strong> the certificate.<br />

Use of Check Sheets. It is good practice to record the<br />

outcome of the <strong>in</strong>spection us<strong>in</strong>g check-sheets. The m<strong>in</strong>imum<br />

po<strong>in</strong>ts to be considered are peculiar to each type of protection,<br />

as summarised <strong>in</strong> the box below. In addition, the check-sheets<br />

should conta<strong>in</strong> a record of each item’s certificate number.<br />

The methods used are straightforward; however, each item of<br />

plant has its own peculiarities and some of these are often<br />

overlooked. The importance of this matter dictates that an<br />

expert lead the <strong>in</strong>spection at this stage.<br />

<br />

M<strong>in</strong>imum Check Po<strong>in</strong>ts for Installation of<br />

Three Common Types of Explosion Protection<br />

Flame proof enclosure <strong>in</strong>stallation (type d).<br />

• The EEx d label is correct.<br />

• The cover has been fitted correctly.<br />

• The serial number on the cover and base unit match (if applicable).<br />

• Cable entries are by means of EEx d certified gland (special rule<br />

for enclosure > 2 litre size), EEx d certified plug or stopper, EEx d<br />

certified cable bush<strong>in</strong>g/term<strong>in</strong>ation or sealed conduit.<br />

• All conduits are wrench-tight with at least five full threads engaged.<br />

• Any reducer used is certified.<br />

Increased safety <strong>in</strong>stallation (type e).<br />

• The EEx e label is correct.<br />

• Any breather is of an approved type (see certificate schedule).<br />

• Any breather is <strong>in</strong>stalled <strong>in</strong> correct face.<br />

• Any unused cable hole is sealed properly.<br />

• All term<strong>in</strong>al screws are tightened, <strong>in</strong>clud<strong>in</strong>g spare term<strong>in</strong>als.<br />

• Insulation is with<strong>in</strong> 1 mm (0.04 <strong>in</strong>ch) of the term<strong>in</strong>al throat.<br />

• If m<strong>in</strong>eral-<strong>in</strong>sulated copper clad (MICC) cable is used, an EEx e<br />

gland is applied.<br />

• The gland<strong>in</strong>g technique ma<strong>in</strong>ta<strong>in</strong>s IP54 (washers may be used).<br />

• There is no more than one conductor per clamp, unless a special<br />

jo<strong>in</strong>t is used.<br />

• Term<strong>in</strong>al creepages and clearances are with<strong>in</strong> specifications.<br />

• Term<strong>in</strong>al temperatures will not exceed the temperature of the<br />

component certificate.<br />

• All term<strong>in</strong>als and accessories have been <strong>in</strong>stalled per the<br />

manufacturer’s recommendations.<br />

• Term<strong>in</strong>al rat<strong>in</strong>gs do not exceed their label.<br />

Intr<strong>in</strong>sic safety <strong>in</strong>stallation (type i).<br />

• The barrier is <strong>in</strong>stalled <strong>in</strong> safe area (may be <strong>in</strong> zone 1 area if <strong>in</strong>side<br />

EEx d enclosure).<br />

• The EEx mark<strong>in</strong>g is correct on the barrier and device, if applicable.<br />

• Wir<strong>in</strong>g has been segregated.<br />

• Enclosures are protected to at least IP20.<br />

• Earth<strong>in</strong>g has been connected <strong>in</strong> accordance with the EEx certificate.<br />

• Wir<strong>in</strong>g properties are consistent with EEx certification.<br />

• If a colour code is applied, the colour used is light blue.<br />

Related Web Sites:<br />

Additional <strong>in</strong>formation about the use of electrical equipment <strong>in</strong><br />

hazardous areas is publicly available at numerous certification body<br />

and specialist manufacturer’s Web sites, <strong>in</strong>clud<strong>in</strong>g:<br />

• http://www.baseefa.com/ • http://www.mtl-<strong>in</strong>st.com/<br />

• http://www.ptb.de/<strong>in</strong>dex_en.html • http://www.stahl.de/en/start.html<br />

Stewart Gray is a pr<strong>in</strong>cipal eng<strong>in</strong>eer with more than 30 years’ project eng<strong>in</strong>eer<strong>in</strong>g experience, <strong>in</strong>clud<strong>in</strong>g 10 <strong>in</strong> a construction-based consult<strong>in</strong>g role. With his detailed knowledge<br />

of the subjects of safety and <strong>in</strong>spections, he has identified a variety of hazardous area <strong>in</strong>stallation errors on behalf of several clients before their plants went <strong>in</strong>to service.<br />

In most cases, these errors were attributable to <strong>in</strong>correct material selection or <strong>in</strong>appropriate <strong>in</strong>stallation techniques.<br />

PB Network #68 / August 2008 12

Thermal – Achiev<strong>in</strong>g New Efficiencies, Reduc<strong>in</strong>g Carbon Emissions<br />

http://www.pbworld.com/news_events/publications/network/<br />

Project Brief: Us<strong>in</strong>g Monte Carlo Techniques to<br />

Size a <strong>Power</strong> Station By Mike Emmerton, Hong Kong, 65 6290 0737, emmertonM@pbworld.com<br />

1 Two earlier PB Network articles<br />

tell how Monte Carlo techniques<br />

were used <strong>in</strong> risk management.<br />

Please see:<br />

• “Project Risk Management and<br />

Madrid’s New Airport” by Paul<br />

Callender, Issue 51, January 2002,<br />

pp. 56-58 and on l<strong>in</strong>e at http://<br />

www.pbworld.com/news_events/<br />

publications/network/issue_51/<br />

51_24_callenderp_madrid<br />

airport.asp.<br />

• “A Risk Assessment and Analysis<br />

for an Exist<strong>in</strong>g Water Conveyance<br />

Tunnel” by Kyle Ott and Joe Wang,<br />

Issue 51, January 2002,<br />

pp. 38-40, 43 and on l<strong>in</strong>e at<br />

http://www.pbworld.com/news_<br />

events/publications/network/<br />

issue_51/51_17_ottk_risk<br />

assessmentanalysistunnel.asp<br />

In early 2007, PB was selected to assist one of the world’s largest port owner-operators to<br />

determ<strong>in</strong>e the least-cost approach to meet<strong>in</strong>g the power needs of a proposed conta<strong>in</strong>er port<br />

development <strong>in</strong> Pakistan. The major electrical loads of a conta<strong>in</strong>er port are the quay cranes<br />

used for load<strong>in</strong>g and unload<strong>in</strong>g conta<strong>in</strong>er ships. The client required our power specialists to<br />

determ<strong>in</strong>e whether a stand-alone power station would be more economical than us<strong>in</strong>g on-board<br />

quay crane diesel motors. The key challenge <strong>in</strong> siz<strong>in</strong>g the power station was to deal with the<br />

uncerta<strong>in</strong>ty associated with the load<strong>in</strong>g pattern of 16 quay cranes. The electrical loads of<br />

these cranes vary with their duty cycles, and the total load varies with the number of cranes<br />

<strong>in</strong> operation In turn, this, is dependent on the rate of arrival/departure and the capacity of the<br />

conta<strong>in</strong>er ships.<br />

Our team comb<strong>in</strong>ed eng<strong>in</strong>eer<strong>in</strong>g and Monte Carlo techniques to successfully deal with this<br />

problem. Monte Carlo is a method of analyz<strong>in</strong>g stochastic processes, which are those governed<br />

by laws of probability, that are so difficult that a purely mathematical treatment is not practical. 1<br />

Client feedback <strong>in</strong>dicated that this technique was the most conv<strong>in</strong>c<strong>in</strong>g method they had seen<br />

used <strong>in</strong> the <strong>in</strong>dustry, whereas solutions based on traditional eng<strong>in</strong>eer<strong>in</strong>g methods only were<br />

judged to be unreliable or conservative.<br />

<br />

Mike Emmerton is a management consultant who has been with PB s<strong>in</strong>ce 2004.<br />

Project Brief: Energiz<strong>in</strong>g S<strong>in</strong>gapore’s Economy<br />

By Kamaljit Gill, S<strong>in</strong>gapore, 65 6533 7333, gillK@pbworld.com<br />

PB acted as owner’s eng<strong>in</strong>eer to Keppel Energy for its development of the Keppel Merlimau<br />

Cogen power plant, a 500 MW comb<strong>in</strong>ed cycle facility on Jurong Island <strong>in</strong> southwest S<strong>in</strong>gapore.<br />

The plant now supplies power to the S<strong>in</strong>gapore grid, and has provision to feed process steam<br />

to chemical plants that are due to be part of the evolv<strong>in</strong>g petrochemical <strong>in</strong>dustry on the island.<br />