Innovation in Global Power - Parsons Brinckerhoff

Innovation in Global Power - Parsons Brinckerhoff

Innovation in Global Power - Parsons Brinckerhoff

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Thermal – Achiev<strong>in</strong>g New Efficiencies, Reduc<strong>in</strong>g Carbon Emissions<br />

http://www.pbworld.com/news_events/publications/network/<br />

The ma<strong>in</strong> uses of type i are for <strong>in</strong>strumentation, telecommunication<br />

devices, and similar equipment. It is well<br />

known, <strong>in</strong>expensive and readily available, but special design<br />

and <strong>in</strong>stallation rules need to be followed. Two categories<br />

of <strong>in</strong>tr<strong>in</strong>sic safety are available. Category ia, which provides<br />

the highest degree of explosion protection available,<br />

ensures safety under two faults. Category ib ensures safety<br />

under a s<strong>in</strong>gle fault.<br />

Design and Assembly Stage Inspections<br />

Inspections of the <strong>in</strong>stallation need to be conducted throughout<br />

the stages of its life cycle <strong>in</strong> accordance with IEC 60079.<br />

Design Stage. Inspections should start at the design stage<br />

by means of design review because mistakes identified at this<br />

stage are almost always easier and less costly to rectify.<br />

Factory Assembly Stage. When factory assembly of skid<br />

mounted equipment is completed and after the factory has<br />

conducted its own <strong>in</strong>spection, an <strong>in</strong>spection done by our<br />

team is advantageous. Whilst this does not present a<br />

comprehensive picture of the f<strong>in</strong>al <strong>in</strong>stallation, it can often<br />

show mistakes, and corrective measures can be planned<br />

dur<strong>in</strong>g shipp<strong>in</strong>g to the construction site.<br />

F<strong>in</strong>al Construction Inspection<br />

A f<strong>in</strong>al construction <strong>in</strong>spection, along with possible rectification<br />

of any mistake, is mandatory before explosive fluid can<br />

be <strong>in</strong>troduced to the plant. The objective of the <strong>in</strong>spections<br />

is to verify the <strong>in</strong>stallation complies with the applicable code<br />

of practice. In the case of IEC 60079, this requires ensur<strong>in</strong>g<br />

that the appropriate components were selected and that<br />

they were <strong>in</strong>stalled correctly. Discovery of an <strong>in</strong>stallation<br />

mistake at this stage may lead to project time delay.<br />

Verification of Explosion Protection. The first part of<br />

any <strong>in</strong>spection work is to make sure that the equipment is<br />

explosion protected <strong>in</strong> conformance with IEC 60079. Whilst<br />

it may be labelled with compliance <strong>in</strong>formation, a visual check<br />

of labell<strong>in</strong>g is not enough. It is necessary to obta<strong>in</strong> a copy<br />

of the orig<strong>in</strong>al certificate of conformance and use this as<br />

the <strong>in</strong>spection start-po<strong>in</strong>t. The <strong>in</strong>spector should check<br />

the certificate validity, cross check the certificate aga<strong>in</strong>st<br />

equipment labels and verify the <strong>in</strong>stallation method complies<br />

with the requirements as stated <strong>in</strong> the certificate.<br />

Use of Check Sheets. It is good practice to record the<br />

outcome of the <strong>in</strong>spection us<strong>in</strong>g check-sheets. The m<strong>in</strong>imum<br />

po<strong>in</strong>ts to be considered are peculiar to each type of protection,<br />

as summarised <strong>in</strong> the box below. In addition, the check-sheets<br />

should conta<strong>in</strong> a record of each item’s certificate number.<br />

The methods used are straightforward; however, each item of<br />

plant has its own peculiarities and some of these are often<br />

overlooked. The importance of this matter dictates that an<br />

expert lead the <strong>in</strong>spection at this stage.<br />

<br />

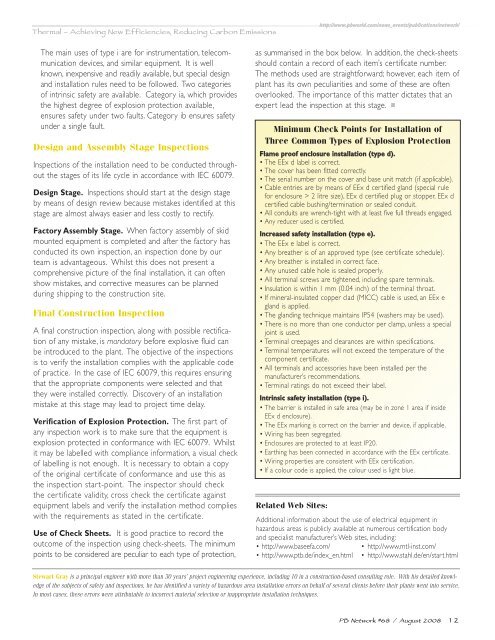

M<strong>in</strong>imum Check Po<strong>in</strong>ts for Installation of<br />

Three Common Types of Explosion Protection<br />

Flame proof enclosure <strong>in</strong>stallation (type d).<br />

• The EEx d label is correct.<br />

• The cover has been fitted correctly.<br />

• The serial number on the cover and base unit match (if applicable).<br />

• Cable entries are by means of EEx d certified gland (special rule<br />

for enclosure > 2 litre size), EEx d certified plug or stopper, EEx d<br />

certified cable bush<strong>in</strong>g/term<strong>in</strong>ation or sealed conduit.<br />

• All conduits are wrench-tight with at least five full threads engaged.<br />

• Any reducer used is certified.<br />

Increased safety <strong>in</strong>stallation (type e).<br />

• The EEx e label is correct.<br />

• Any breather is of an approved type (see certificate schedule).<br />

• Any breather is <strong>in</strong>stalled <strong>in</strong> correct face.<br />

• Any unused cable hole is sealed properly.<br />

• All term<strong>in</strong>al screws are tightened, <strong>in</strong>clud<strong>in</strong>g spare term<strong>in</strong>als.<br />

• Insulation is with<strong>in</strong> 1 mm (0.04 <strong>in</strong>ch) of the term<strong>in</strong>al throat.<br />

• If m<strong>in</strong>eral-<strong>in</strong>sulated copper clad (MICC) cable is used, an EEx e<br />

gland is applied.<br />

• The gland<strong>in</strong>g technique ma<strong>in</strong>ta<strong>in</strong>s IP54 (washers may be used).<br />

• There is no more than one conductor per clamp, unless a special<br />

jo<strong>in</strong>t is used.<br />

• Term<strong>in</strong>al creepages and clearances are with<strong>in</strong> specifications.<br />

• Term<strong>in</strong>al temperatures will not exceed the temperature of the<br />

component certificate.<br />

• All term<strong>in</strong>als and accessories have been <strong>in</strong>stalled per the<br />

manufacturer’s recommendations.<br />

• Term<strong>in</strong>al rat<strong>in</strong>gs do not exceed their label.<br />

Intr<strong>in</strong>sic safety <strong>in</strong>stallation (type i).<br />

• The barrier is <strong>in</strong>stalled <strong>in</strong> safe area (may be <strong>in</strong> zone 1 area if <strong>in</strong>side<br />

EEx d enclosure).<br />

• The EEx mark<strong>in</strong>g is correct on the barrier and device, if applicable.<br />

• Wir<strong>in</strong>g has been segregated.<br />

• Enclosures are protected to at least IP20.<br />

• Earth<strong>in</strong>g has been connected <strong>in</strong> accordance with the EEx certificate.<br />

• Wir<strong>in</strong>g properties are consistent with EEx certification.<br />

• If a colour code is applied, the colour used is light blue.<br />

Related Web Sites:<br />

Additional <strong>in</strong>formation about the use of electrical equipment <strong>in</strong><br />

hazardous areas is publicly available at numerous certification body<br />

and specialist manufacturer’s Web sites, <strong>in</strong>clud<strong>in</strong>g:<br />

• http://www.baseefa.com/ • http://www.mtl-<strong>in</strong>st.com/<br />

• http://www.ptb.de/<strong>in</strong>dex_en.html • http://www.stahl.de/en/start.html<br />

Stewart Gray is a pr<strong>in</strong>cipal eng<strong>in</strong>eer with more than 30 years’ project eng<strong>in</strong>eer<strong>in</strong>g experience, <strong>in</strong>clud<strong>in</strong>g 10 <strong>in</strong> a construction-based consult<strong>in</strong>g role. With his detailed knowledge<br />

of the subjects of safety and <strong>in</strong>spections, he has identified a variety of hazardous area <strong>in</strong>stallation errors on behalf of several clients before their plants went <strong>in</strong>to service.<br />

In most cases, these errors were attributable to <strong>in</strong>correct material selection or <strong>in</strong>appropriate <strong>in</strong>stallation techniques.<br />

PB Network #68 / August 2008 12