Innovation in Global Power - Parsons Brinckerhoff

Innovation in Global Power - Parsons Brinckerhoff

Innovation in Global Power - Parsons Brinckerhoff

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Thermal – Achiev<strong>in</strong>g New Efficiencies, Reduc<strong>in</strong>g Carbon Emissions<br />

http://www.pbworld.com/news_events/publications/network/<br />

and sulphur dioxide, and to reduce nitrogen oxides before<br />

enter<strong>in</strong>g the carbon capture process. The carbon dioxide is<br />

absorbed <strong>in</strong>to a chemical solution 1 to remove it from the flue<br />

gas, which is then emitted to atmosphere. The carbon dioxide<br />

gas is removed from the absorbent, compressed and transported<br />

for long-term sequestration. The challenge with this<br />

technology is the need to scale up to utility-size capture.<br />

Oxyfuel. An oxyfuel plant is one <strong>in</strong> which the fuel is<br />

combusted <strong>in</strong> oxygen supplied by an air separation plant<br />

rather than air. The result<strong>in</strong>g flue gases are purified to remove<br />

particulate matter and sulphur dioxide, and to reduce nitrogen<br />

oxides. Some of the captured carbon dioxide is recycled and<br />

mixed with the oxygen feed to the boiler plant to control<br />

combustion temperature. The rema<strong>in</strong><strong>in</strong>g carbon dioxide is<br />

then purified, compressed and transported to long-term storage.<br />

The aim of oxyfuel development is to use as much of the<br />

exist<strong>in</strong>g and proven equipment as possible; although some<br />

issues rema<strong>in</strong> relat<strong>in</strong>g to the control of combustion temperatures<br />

with<strong>in</strong> the boiler and the scal<strong>in</strong>g up of air separation<br />

plant to the size necessary for use <strong>in</strong> power plant applications.<br />

Carbon Dioxide Transport and Storage<br />

Transport. Captured carbon dioxide is transported to a longterm<br />

storage location by either pipel<strong>in</strong>e, truck, tra<strong>in</strong>, or boat,<br />

although only pipel<strong>in</strong>e would be feasible for the quantities<br />

result<strong>in</strong>g from large-scale power generation—millions of tonnes<br />

per year. The pipel<strong>in</strong>e could transport carbon dioxide <strong>in</strong> the<br />

gaseous phase, at pressures below 71 bar, or at higher pressures<br />

where the carbon dioxide is present as a supercritical<br />

fluid giv<strong>in</strong>g benefits from lower frictional losses. The scale is<br />

such that a new pipel<strong>in</strong>e <strong>in</strong>frastructure would be needed.<br />

Storage. Storage of carbon dioxide is assumed to be <strong>in</strong><br />

geological formations, such as depleted oil and gas reservoirs,<br />

deep sal<strong>in</strong>e aquifers and unm<strong>in</strong>eable coal seams. These<br />

formations need to provide storage with negligible leakage<br />

to ensure that the carbon is sequestered over geological<br />

timescales—thousands, if not tens of thousands of years.<br />

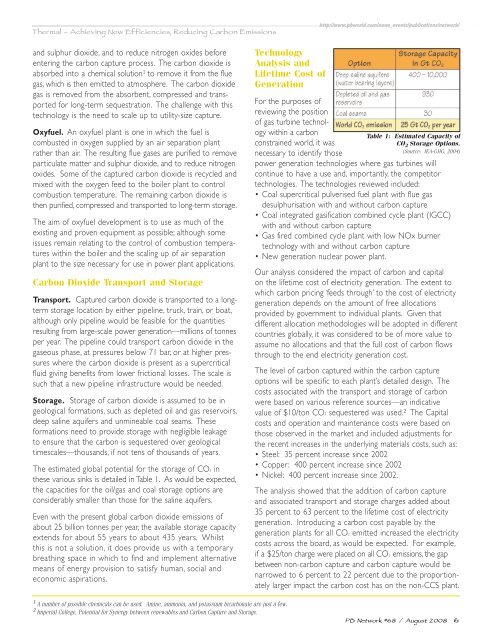

The estimated global potential for the storage of CO2 <strong>in</strong><br />

these various s<strong>in</strong>ks is detailed <strong>in</strong> Table 1. As would be expected,<br />

the capacities for the oil/gas and coal storage options are<br />

considerably smaller than those for the sal<strong>in</strong>e aquifers.<br />

Even with the present global carbon dioxide emissions of<br />

about 25 billion tonnes per year, the available storage capacity<br />

extends for about 55 years to about 435 years. Whilst<br />

this is not a solution, it does provide us with a temporary<br />

breath<strong>in</strong>g space <strong>in</strong> which to f<strong>in</strong>d and implement alternative<br />

means of energy provision to satisfy human, social and<br />

economic aspirations.<br />

Technology<br />

Analysis and<br />

Lifetime Cost of<br />

Generation<br />

For the purposes of<br />

review<strong>in</strong>g the position<br />

of gas turb<strong>in</strong>e technology<br />

with<strong>in</strong> a carbon<br />

constra<strong>in</strong>ed world, it was<br />

necessary to identify those<br />

power generation technologies where gas turb<strong>in</strong>es will<br />

cont<strong>in</strong>ue to have a use and, importantly, the competitor<br />

technologies. The technologies reviewed <strong>in</strong>cluded:<br />

• Coal supercritical pulverised fuel plant with flue gas<br />

desulphurisation with and without carbon capture<br />

• Coal <strong>in</strong>tegrated gasification comb<strong>in</strong>ed cycle plant (IGCC)<br />

with and without carbon capture<br />

• Gas fired comb<strong>in</strong>ed cycle plant with low NOx burner<br />

technology with and without carbon capture<br />

• New generation nuclear power plant.<br />

Table 1: Estimated Capacity of<br />

CO 2 Storage Options.<br />

(Source: IEA-GHG, 2004)<br />

Our analysis considered the impact of carbon and capital<br />

on the lifetime cost of electricity generation. The extent to<br />

which carbon pric<strong>in</strong>g ‘feeds through’ to the cost of electricity<br />

generation depends on the amount of free allocations<br />

provided by government to <strong>in</strong>dividual plants. Given that<br />

different allocation methodologies will be adopted <strong>in</strong> different<br />

countries globally, it was considered to be of more value to<br />

assume no allocations and that the full cost of carbon flows<br />

through to the end electricity generation cost.<br />

The level of carbon captured with<strong>in</strong> the carbon capture<br />

options will be specific to each plant’s detailed design. The<br />

costs associated with the transport and storage of carbon<br />

were based on various reference sources—an <strong>in</strong>dicative<br />

value of $10/ton CO2 sequestered was used. 2 The Capital<br />

costs and operation and ma<strong>in</strong>tenance costs were based on<br />

those observed <strong>in</strong> the market and <strong>in</strong>cluded adjustments for<br />

the recent <strong>in</strong>creases <strong>in</strong> the underly<strong>in</strong>g materials costs, such as:<br />

• Steel: 35 percent <strong>in</strong>crease s<strong>in</strong>ce 2002<br />

• Copper: 400 percent <strong>in</strong>crease s<strong>in</strong>ce 2002<br />

• Nickel: 400 percent <strong>in</strong>crease s<strong>in</strong>ce 2002.<br />

The analysis showed that the addition of carbon capture<br />

and associated transport and storage charges added about<br />

35 percent to 63 percent to the lifetime cost of electricity<br />

generation. Introduc<strong>in</strong>g a carbon cost payable by the<br />

generation plants for all CO2 emitted <strong>in</strong>creased the electricity<br />

costs across the board, as would be expected. For example,<br />

if a $25/ton charge were placed on all CO2 emissions, the gap<br />

between non-carbon capture and carbon capture would be<br />

narrowed to 6 percent to 22 percent due to the proportionately<br />

larger impact the carbon cost has on the non-CCS plant.<br />

1 A number of possible chemicals can be used. Am<strong>in</strong>e, ammonia, and potassium bicarbonate are just a few.<br />

2 Imperial College, Potential for Synergy between renewables and Carbon Capture and Storage.<br />

PB Network #68 / August 2008 6