Innovation in Global Power - Parsons Brinckerhoff

Innovation in Global Power - Parsons Brinckerhoff

Innovation in Global Power - Parsons Brinckerhoff

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

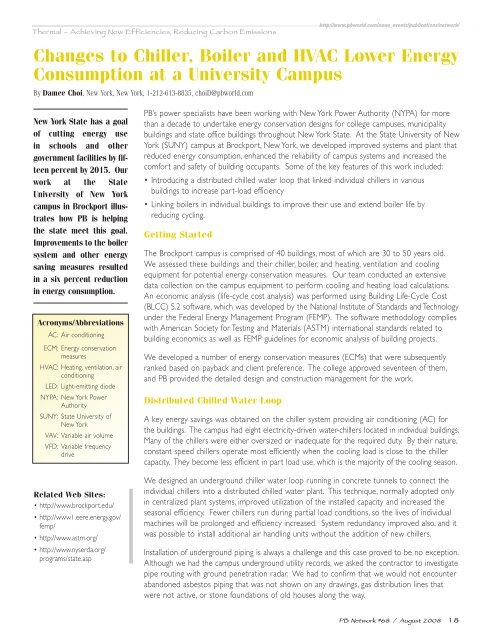

Thermal – Achiev<strong>in</strong>g New Efficiencies, Reduc<strong>in</strong>g Carbon Emissions<br />

http://www.pbworld.com/news_events/publications/network/<br />

Changes to Chiller, Boiler and HVAC Lower Energy<br />

Consumption at a University Campus<br />

By Damee Choi, New York, New York, 1-212-613-8835, choiD@pbworld.com<br />

New York State has a goal<br />

of cutt<strong>in</strong>g energy use<br />

<strong>in</strong> schools and other<br />

government facilities by fifteen<br />

percent by 2015. Our<br />

work at the State<br />

University of New York<br />

campus <strong>in</strong> Brockport illustrates<br />

how PB is help<strong>in</strong>g<br />

the state meet this goal.<br />

Improvements to the boiler<br />

system and other energy<br />

sav<strong>in</strong>g measures resulted<br />

<strong>in</strong> a six percent reduction<br />

<strong>in</strong> energy consumption.<br />

Acronyms/Abbreviations<br />

AC: Air condition<strong>in</strong>g<br />

ECM: Energy conservation<br />

measures<br />

HVAC: Heat<strong>in</strong>g, ventilation, air<br />

condition<strong>in</strong>g<br />

LED: Light-emitt<strong>in</strong>g diode<br />

NYPA: New York <strong>Power</strong><br />

Authority<br />

SUNY: State University of<br />

New York<br />

VAV: Variable air volume<br />

VFD: Variable frequency<br />

drive<br />

Related Web Sites:<br />

• http://www.brockport.edu/<br />

• http://www1.eere.energy.gov/<br />

femp/<br />

• http://www.astm.org/<br />

• http://www.nyserda.org/<br />

programs/state.asp<br />

PB’s power specialists have been work<strong>in</strong>g with New York <strong>Power</strong> Authority (NYPA) for more<br />

than a decade to undertake energy conservation designs for college campuses, municipality<br />

build<strong>in</strong>gs and state office build<strong>in</strong>gs throughout New York State. At the State University of New<br />

York (SUNY) campus at Brockport, New York, we developed improved systems and plant that<br />

reduced energy consumption, enhanced the reliability of campus systems and <strong>in</strong>creased the<br />

comfort and safety of build<strong>in</strong>g occupants. Some of the key features of this work <strong>in</strong>cluded:<br />

• Introduc<strong>in</strong>g a distributed chilled water loop that l<strong>in</strong>ked <strong>in</strong>dividual chillers <strong>in</strong> various<br />

build<strong>in</strong>gs to <strong>in</strong>crease part-load efficiency<br />

• L<strong>in</strong>k<strong>in</strong>g boilers <strong>in</strong> <strong>in</strong>dividual build<strong>in</strong>gs to improve their use and extend boiler life by<br />

reduc<strong>in</strong>g cycl<strong>in</strong>g.<br />

Gett<strong>in</strong>g Started<br />

The Brockport campus is comprised of 40 build<strong>in</strong>gs, most of which are 30 to 50 years old.<br />

We assessed these build<strong>in</strong>gs and their chiller, boiler, and heat<strong>in</strong>g, ventilation and cool<strong>in</strong>g<br />

equipment for potential energy conservation measures. Our team conducted an extensive<br />

data collection on the campus equipment to perform cool<strong>in</strong>g and heat<strong>in</strong>g load calculations.<br />

An economic analysis (life-cycle cost analysis) was performed us<strong>in</strong>g Build<strong>in</strong>g Life-Cycle Cost<br />

(BLCC) 5.2 software, which was developed by the National Institute of Standards and Technology<br />

under the Federal Energy Management Program (FEMP). The software methodology complies<br />

with American Society for Test<strong>in</strong>g and Materials (ASTM) <strong>in</strong>ternational standards related to<br />

build<strong>in</strong>g economics as well as FEMP guidel<strong>in</strong>es for economic analysis of build<strong>in</strong>g projects.<br />

We developed a number of energy conservation measures (ECMs) that were subsequently<br />

ranked based on payback and client preference. The college approved seventeen of them,<br />

and PB provided the detailed design and construction management for the work.<br />

Distributed Chilled Water Loop<br />

A key energy sav<strong>in</strong>gs was obta<strong>in</strong>ed on the chiller system provid<strong>in</strong>g air condition<strong>in</strong>g (AC) for<br />

the build<strong>in</strong>gs. The campus had eight electricity-driven water-chillers located <strong>in</strong> <strong>in</strong>dividual build<strong>in</strong>gs.<br />

Many of the chillers were either oversized or <strong>in</strong>adequate for the required duty. By their nature,<br />

constant speed chillers operate most efficiently when the cool<strong>in</strong>g load is close to the chiller<br />

capacity. They become less efficient <strong>in</strong> part load use, which is the majority of the cool<strong>in</strong>g season.<br />

We designed an underground chiller water loop runn<strong>in</strong>g <strong>in</strong> concrete tunnels to connect the<br />

<strong>in</strong>dividual chillers <strong>in</strong>to a distributed chilled water plant. This technique, normally adopted only<br />

<strong>in</strong> centralized plant systems, improved utilization of the <strong>in</strong>stalled capacity and <strong>in</strong>creased the<br />

seasonal efficiency. Fewer chillers run dur<strong>in</strong>g partial load conditions, so the lives of <strong>in</strong>dividual<br />

mach<strong>in</strong>es will be prolonged and efficiency <strong>in</strong>creased. System redundancy improved also, and it<br />

was possible to <strong>in</strong>stall additional air handl<strong>in</strong>g units without the addition of new chillers.<br />

Installation of underground pip<strong>in</strong>g is always a challenge and this case proved to be no exception.<br />

Although we had the campus underground utility records, we asked the contractor to <strong>in</strong>vestigate<br />

pipe rout<strong>in</strong>g with ground penetration radar. We had to confirm that we would not encounter<br />

abandoned asbestos pip<strong>in</strong>g that was not shown on any draw<strong>in</strong>gs, gas distribution l<strong>in</strong>es that<br />

were not active, or stone foundations of old houses along the way.<br />

PB Network #68 / August 2008 18