Multiattribute acceptance sampling plans - Library(ISI Kolkata ...

Multiattribute acceptance sampling plans - Library(ISI Kolkata ...

Multiattribute acceptance sampling plans - Library(ISI Kolkata ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

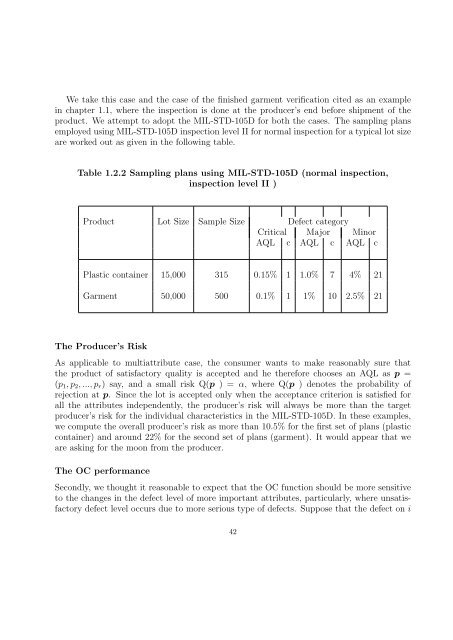

We take this case and the case of the finished garment verification cited as an example<br />

in chapter 1.1, where the inspection is done at the producer’s end before shipment of the<br />

product. We attempt to adopt the MIL-STD-105D for both the cases. The <strong>sampling</strong> <strong>plans</strong><br />

employed using MIL-STD-105D inspection level II for normal inspection for a typical lot size<br />

are worked out as given in the following table.<br />

Table 1.2.2 Sampling <strong>plans</strong> using MIL-STD-105D (normal inspection,<br />

inspection level II )<br />

Product Lot Size Sample Size Defect category<br />

Critical Major Minor<br />

AQL c AQL c AQL c<br />

Plastic container 15,000 315 0.15% 1 1.0% 7 4% 21<br />

Garment 50,000 500 0.1% 1 1% 10 2.5% 21<br />

The Producer’s Risk<br />

As applicable to multiattribute case, the consumer wants to make reasonably sure that<br />

the product of satisfactory quality is accepted and he therefore chooses an AQL as p =<br />

(p 1 , p 2 , ..., p r ) say, and a small risk Q(p ) = α, where Q(p ) denotes the probability of<br />

rejection at p. Since the lot is accepted only when the <strong>acceptance</strong> criterion is satisfied for<br />

all the attributes independently, the producer’s risk will always be more than the target<br />

producer’s risk for the individual characteristics in the MIL-STD-105D. In these examples,<br />

we compute the overall producer’s risk as more than 10.5% for the first set of <strong>plans</strong> (plastic<br />

container) and around 22% for the second set of <strong>plans</strong> (garment). It would appear that we<br />

are asking for the moon from the producer.<br />

The OC performance<br />

Secondly, we thought it reasonable to expect that the OC function should be more sensitive<br />

to the changes in the defect level of more important attributes, particularly, where unsatisfactory<br />

defect level occurs due to more serious type of defects. Suppose that the defect on i<br />

42