Download - Royal Australian Navy

Download - Royal Australian Navy

Download - Royal Australian Navy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

40 NAVY ENGINEERING BULLETIN MARCH 2003<br />

• What happens when each failure<br />

occurs?<br />

• In what way does each failure<br />

matter?<br />

• What can be done to predict or<br />

prevent each failure?<br />

• What should be done if no<br />

suitable proactive task can be<br />

found?<br />

The first four questions develop a<br />

functional Failure Modes and<br />

Effects Analysis (FMEA) and the<br />

last two define the appropriate<br />

failure management policy. The<br />

vitally important fifth question<br />

determines how we should react<br />

to the failure in relation to<br />

whether the failure is ‘Hidden’ or<br />

‘Evident’ and whether Safety, the<br />

Environment or Operations<br />

(Mission in the naval sense) are<br />

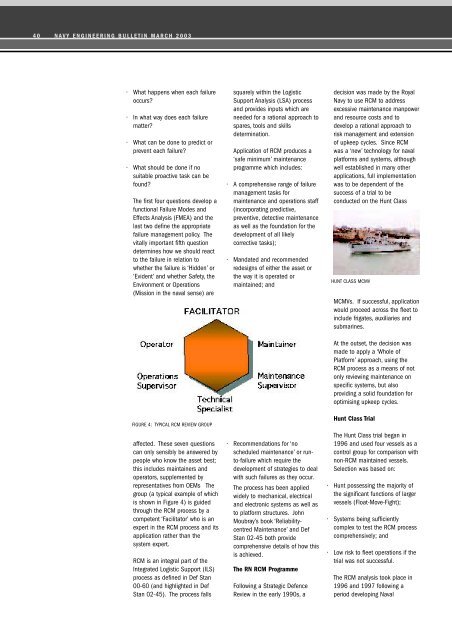

FIGURE 4: TYPICAL RCM REVIEW GROUP<br />

affected. These seven questions<br />

can only sensibly be answered by<br />

people who know the asset best;<br />

this includes maintainers and<br />

operators, supplemented by<br />

representatives from OEMs The<br />

group (a typical example of which<br />

is shown in Figure 4) is guided<br />

through the RCM process by a<br />

competent ‘Facilitator’ who is an<br />

expert in the RCM process and its<br />

application rather than the<br />

system expert.<br />

RCM is an integral part of the<br />

Integrated Logistic Support (ILS)<br />

process as defined in Def Stan<br />

00-60 (and highlighted in Def<br />

Stan 02-45). The process falls<br />

squarely within the Logistic<br />

Support Analysis (LSA) process<br />

and provides inputs which are<br />

needed for a rational approach to<br />

spares, tools and skills<br />

determination.<br />

Application of RCM produces a<br />

‘safe minimum’ maintenance<br />

programme which includes:<br />

• A comprehensive range of failure<br />

management tasks for<br />

maintenance and operations staff<br />

(incorporating predictive,<br />

preventive, detective maintenance<br />

as well as the foundation for the<br />

development of all likely<br />

corrective tasks);<br />

• Mandated and recommended<br />

redesigns of either the asset or<br />

the way it is operated or<br />

maintained; and<br />

• Recommendations for ‘no<br />

scheduled maintenance’ or runto-failure<br />

which require the<br />

development of strategies to deal<br />

with such failures as they occur.<br />

The process has been applied<br />

widely to mechanical, electrical<br />

and electronic systems as well as<br />

to platform structures. John<br />

Moubray’s book ‘Reliabilitycentred<br />

Maintenance’ and Def<br />

Stan 02-45 both provide<br />

comprehensive details of how this<br />

is achieved.<br />

The RN RCM Programme<br />

Following a Strategic Defence<br />

Review in the early 1990s, a<br />

decision was made by the <strong>Royal</strong><br />

<strong>Navy</strong> to use RCM to address<br />

excessive maintenance manpower<br />

and resource costs and to<br />

develop a rational approach to<br />

risk management and extension<br />

of upkeep cycles. Since RCM<br />

was a ‘new’ technology for naval<br />

platforms and systems, although<br />

well established in many other<br />

applications, full implementation<br />

was to be dependent of the<br />

success of a trial to be<br />

conducted on the Hunt Class<br />

HUNT CLASS MCMV<br />

MCMVs. If successful, application<br />

would proceed across the fleet to<br />

include frigates, auxiliaries and<br />

submarines.<br />

At the outset, the decision was<br />

made to apply a ‘Whole of<br />

Platform’ approach, using the<br />

RCM process as a means of not<br />

only reviewing maintenance on<br />

specific systems, but also<br />

providing a solid foundation for<br />

optimising upkeep cycles.<br />

Hunt Class Trial<br />

The Hunt Class trial began in<br />

1996 and used four vessels as a<br />

control group for comparison with<br />

non-RCM maintained vessels.<br />

Selection was based on:<br />

• Hunt possessing the majority of<br />

the significant functions of larger<br />

vessels (Float-Move-Fight);<br />

• Systems being sufficiently<br />

complex to test the RCM process<br />

comprehensively; and<br />

• Low risk to fleet operations if the<br />

trial was not successful.<br />

The RCM analysis took place in<br />

1996 and 1997 following a<br />

period developing Naval