Download - Royal Australian Navy

Download - Royal Australian Navy

Download - Royal Australian Navy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

58 NAVY ENGINEERING BULLETIN MARCH 2003<br />

organisation put together by the<br />

Defence Safety Management<br />

Agency (DSMA). The LSC<br />

promulgate defence laser safety<br />

procedures in Ref A in order to<br />

minimise the likelihood of<br />

Defence personnel being injured<br />

by laser radiation. Subject matter<br />

experts from ADFA and DSTO<br />

ensure that the LSC keep abreast<br />

of developments in laser<br />

technology, laser safety and laser<br />

incidents.<br />

<strong>Navy</strong>, Army and Air Force all have<br />

their own Service Laser Authority<br />

(SLA) each of whom is a member<br />

of the LSC. The RAN SLA is<br />

located in the Naval Acoustic and<br />

Optronic Systems (NAOS) section<br />

headed by DDNAOS and is part<br />

of the <strong>Navy</strong> ISREW Systems<br />

Group in the <strong>Navy</strong> C4ISREW<br />

Directorate of the <strong>Navy</strong> Systems<br />

Branch. DDNAOS sponsors a<br />

DI(N) (Ref B) which is a tailored,<br />

<strong>Navy</strong>-specific version of Ref A.<br />

This DI(N) details the<br />

responsibilities of laser safety in<br />

the RAN and the process by<br />

which laser safety measures are<br />

put in place.<br />

The basic elements of the laser<br />

safety process are:<br />

i. Laser Safety Paper (LSP);<br />

ii. Range Safety Paper (RSP);<br />

iii. Laser Safe To Fire Zones<br />

(LSTFZ); and<br />

iv. equipment specific Standard<br />

Operating Procedures (SOP).<br />

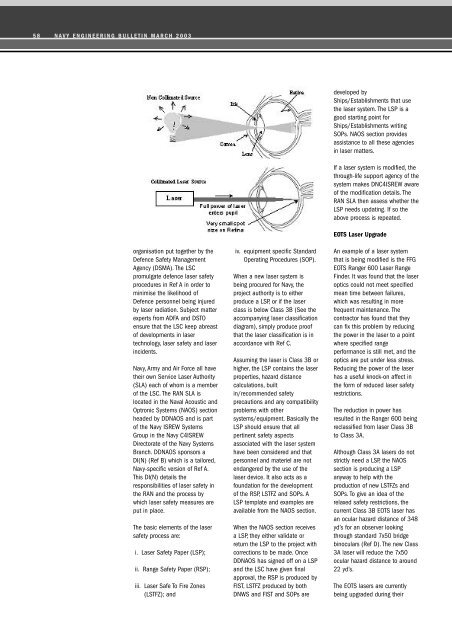

When a new laser system is<br />

being procured for <strong>Navy</strong>, the<br />

project authority is to either<br />

produce a LSP, or if the laser<br />

class is below Class 3B (See the<br />

accompanying laser classification<br />

diagram), simply produce proof<br />

that the laser classification is in<br />

accordance with Ref C.<br />

Assuming the laser is Class 3B or<br />

higher, the LSP contains the laser<br />

properties, hazard distance<br />

calculations, built<br />

in/recommended safety<br />

precautions and any compatibility<br />

problems with other<br />

systems/equipment. Basically the<br />

LSP should ensure that all<br />

pertinent safety aspects<br />

associated with the laser system<br />

have been considered and that<br />

personnel and materiel are not<br />

endangered by the use of the<br />

laser device. It also acts as a<br />

foundation for the development<br />

of the RSP, LSTFZ and SOPs. A<br />

LSP template and examples are<br />

available from the NAOS section.<br />

When the NAOS section receives<br />

a LSP, they either validate or<br />

return the LSP to the project with<br />

corrections to be made. Once<br />

DDNAOS has signed off on a LSP<br />

and the LSC have given final<br />

approval, the RSP is produced by<br />

FIST, LSTFZ produced by both<br />

DNWS and FIST and SOPs are<br />

developed by<br />

Ships/Establishments that use<br />

the laser system. The LSP is a<br />

good starting point for<br />

Ships/Establishments writing<br />

SOPs. NAOS section provides<br />

assistance to all these agencies<br />

in laser matters.<br />

If a laser system is modified, the<br />

through-life support agency of the<br />

system makes DNC4ISREW aware<br />

of the modification details. The<br />

RAN SLA then assess whether the<br />

LSP needs updating. If so the<br />

above process is repeated.<br />

EOTS Laser Upgrade<br />

An example of a laser system<br />

that is being modified is the FFG<br />

EOTS Ranger 600 Laser Range<br />

Finder. It was found that the laser<br />

optics could not meet specified<br />

mean time between failures,<br />

which was resulting in more<br />

frequent maintenance. The<br />

contractor has found that they<br />

can fix this problem by reducing<br />

the power in the laser to a point<br />

where specified range<br />

performance is still met, and the<br />

optics are put under less stress.<br />

Reducing the power of the laser<br />

has a useful knock-on affect in<br />

the form of reduced laser safety<br />

restrictions.<br />

The reduction in power has<br />

resulted in the Ranger 600 being<br />

reclassified from laser Class 3B<br />

to Class 3A.<br />

Although Class 3A lasers do not<br />

strictly need a LSP, the NAOS<br />

section is producing a LSP<br />

anyway to help with the<br />

production of new LSTFZs and<br />

SOPs. To give an idea of the<br />

relaxed safety restrictions, the<br />

current Class 3B EOTS laser has<br />

an ocular hazard distance of 348<br />

yd’s for an observer looking<br />

through standard 7x50 bridge<br />

binoculars (Ref D). The new Class<br />

3A laser will reduce the 7x50<br />

ocular hazard distance to around<br />

22 yd’s.<br />

The EOTS lasers are currently<br />

being upgraded during their