August 2006 Vol. 23, No. 8 – R/C - RCSoaring.com

August 2006 Vol. 23, No. 8 – R/C - RCSoaring.com

August 2006 Vol. 23, No. 8 – R/C - RCSoaring.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Lest you think the milling<br />

machine assembly, and<br />

production of the first usable<br />

parts, occurred in a matter of<br />

minutes. let me say that I<br />

invested about 800 very<br />

intense hours initially before<br />

the first rudimentary usable<br />

parts were produced! Many<br />

problems were yet to manifest<br />

themselves, and in fact the<br />

whole exercise has been one of<br />

problem solving.<br />

At first I thought prototyping<br />

in foam would be a good idea,<br />

and then milling the vacuum<br />

beds out of hard material<br />

would follow. As it worked<br />

out, Foamular 400 insulation<br />

foam has enough <strong>com</strong>pressive<br />

strength and is stable enough<br />

to be used many times over for<br />

vacuum beds. If a bed is<br />

destroyed it is a simple and<br />

inexpensive matter to retool a<br />

replacement.<br />

Aligning the cores in the soft<br />

foam vacuum beds was a<br />

problem solved by simply<br />

gluing a hard spot such as<br />

1/64" plywood with a<br />

reference hole that mated with<br />

brass tubes set in the vacuum<br />

table.<br />

Vacuum is supplied by a Fein<br />

shop-vac with bypass cooling<br />

allowing continuous<br />

operation.<br />

Soon after the first tail-surface<br />

parts were produced I was<br />

successfully milling wing<br />

cores.<br />

All flight surfaces for the<br />

Encore are now CNC milled,<br />

and then vacuum bagged.<br />

This method has allowed a<br />

variety of airfoils and plan<br />

forms to be prototyped. The<br />

resulting wing has a consistent<br />

airfoil and the robustness of a<br />

solid foam core wing.<br />

The CNC process is perfect for<br />

modular design, allowing most<br />

of the parts of the Encore to be<br />

interchangeable with earlier<br />

versions.<br />

Next month, CNC milling and<br />

vacuum bagging of Encore<br />

wings will be featured.<br />

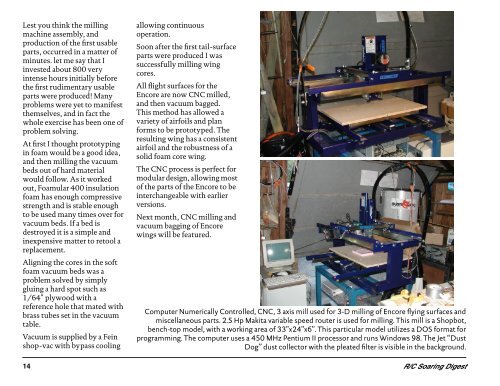

Computer Numerically Controlled, CNC, 3 axis mill used for 3-D milling of Encore flying surfaces and<br />

miscellaneous parts. 2.5 Hp Makita variable speed router is used for milling. This mill is a Shopbot,<br />

bench-top model, with a working area of 33"x24"x6". This particular model utilizes a DOS format for<br />

programming. The <strong>com</strong>puter uses a 450 MHz Pentium II processor and runs Windows 98. The Jet “Dust<br />

Dog” dust collector with the pleated filter is visible in the background.<br />

14 R/C Soaring Digest