Multiscale Modeling of Theta ' Precipitation in Al-Cu Binary Alloys

Multiscale Modeling of Theta ' Precipitation in Al-Cu Binary Alloys

Multiscale Modeling of Theta ' Precipitation in Al-Cu Binary Alloys

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2982 V. Vaithyanathan et al. / Acta Materialia 52 (2004) 2973–2987<br />

the semi-coherent and coherent <strong>in</strong>terfaces for the two<br />

precipitate variants<br />

<br />

0 ij ð1Þ ¼ <br />

11ð1Þ 0<br />

¼ d <br />

sc 0<br />

;<br />

0 22 ð1Þ 0 d c<br />

<br />

0 ij ð2Þ ¼ <br />

11ð2Þ 0<br />

¼ d <br />

ð27Þ<br />

c 0<br />

;<br />

0 22 ð2Þ 0 d sc<br />

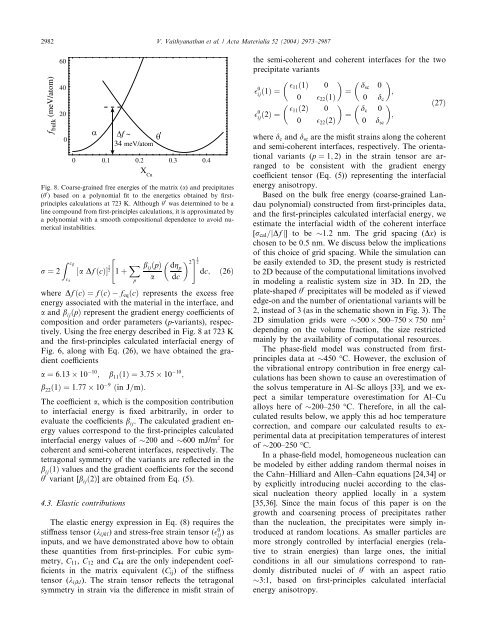

Fig. 8. Coarse-gra<strong>in</strong>ed free energies <strong>of</strong> the matrix (a) and precipitates<br />

(h 0 ) based on a polynomial fit to the energetics obta<strong>in</strong>ed by firstpr<strong>in</strong>ciples<br />

calculations at 723 K. <strong>Al</strong>though h 0 was determ<strong>in</strong>ed to be a<br />

l<strong>in</strong>e compound from first-pr<strong>in</strong>ciples calculations, it is approximated by<br />

a polynomial with a smooth compositional dependence to avoid numerical<br />

<strong>in</strong>stabilities.<br />

Z "<br />

cb<br />

r ¼ 2 ½a Df ðcÞŠ 1 2<br />

1 þ X #1<br />

<br />

b ij ðpÞ dg 2 2<br />

p<br />

dc; ð26Þ<br />

c a<br />

a dc<br />

p<br />

where Df ðcÞ ¼f ðcÞ f eq ðcÞ represents the excess free<br />

energy associated with the material <strong>in</strong> the <strong>in</strong>terface, and<br />

a and b ij ðpÞ represent the gradient energy coefficients <strong>of</strong><br />

composition and order parameters (p-variants), respectively.<br />

Us<strong>in</strong>g the free energy described <strong>in</strong> Fig. 8 at 723 K<br />

and the first-pr<strong>in</strong>ciples calculated <strong>in</strong>terfacial energy <strong>of</strong><br />

Fig. 6, along with Eq. (26), we have obta<strong>in</strong>ed the gradient<br />

coefficients<br />

a ¼ 6:13 10 10 ; b 11 ð1Þ ¼3:75 10 10 ;<br />

b 22 ð1Þ ¼1:77 10 9 ð<strong>in</strong> J=mÞ:<br />

The coefficient a, which is the composition contribution<br />

to <strong>in</strong>terfacial energy is fixed arbitrarily, <strong>in</strong> order to<br />

evaluate the coefficients b ij . The calculated gradient energy<br />

values correspond to the first-pr<strong>in</strong>ciples calculated<br />

<strong>in</strong>terfacial energy values <strong>of</strong> 200 and 600 mJ/m 2 for<br />

coherent and semi-coherent <strong>in</strong>terfaces, respectively. The<br />

tetragonal symmetry <strong>of</strong> the variants are reflected <strong>in</strong> the<br />

b ij ð1Þ values and the gradient coefficients for the second<br />

h 0 variant [b ij ð2Þ] are obta<strong>in</strong>ed from Eq. (5).<br />

4.3. Elastic contributions<br />

The elastic energy expression <strong>in</strong> Eq. (8) requires the<br />

stiffness tensor (k ijkl ) and stress-free stra<strong>in</strong> tensor ( 0 ij )as<br />

<strong>in</strong>puts, and we have demonstrated above how to obta<strong>in</strong><br />

these quantities from first-pr<strong>in</strong>ciples. For cubic symmetry,<br />

C 11 , C 12 and C 44 are the only <strong>in</strong>dependent coefficients<br />

<strong>in</strong> the matrix equivalent (C ij ) <strong>of</strong> the stiffness<br />

tensor (k ijkl ). The stra<strong>in</strong> tensor reflects the tetragonal<br />

symmetry <strong>in</strong> stra<strong>in</strong> via the difference <strong>in</strong> misfit stra<strong>in</strong> <strong>of</strong><br />

where d c and d sc are the misfit stra<strong>in</strong>s along the coherent<br />

and semi-coherent <strong>in</strong>terfaces, respectively. The orientational<br />

variants (p ¼ 1; 2) <strong>in</strong> the stra<strong>in</strong> tensor are arranged<br />

to be consistent with the gradient energy<br />

coefficient tensor (Eq. (5)) represent<strong>in</strong>g the <strong>in</strong>terfacial<br />

energy anisotropy.<br />

Based on the bulk free energy (coarse-gra<strong>in</strong>ed Landau<br />

polynomial) constructed from first-pr<strong>in</strong>ciples data,<br />

and the first-pr<strong>in</strong>ciples calculated <strong>in</strong>terfacial energy, we<br />

estimate the <strong>in</strong>terfacial width <strong>of</strong> the coherent <strong>in</strong>terface<br />

[r cal =jDf j] to be 1.2 nm. The grid spac<strong>in</strong>g (Dx) is<br />

chosen to be 0.5 nm. We discuss below the implications<br />

<strong>of</strong> this choice <strong>of</strong> grid spac<strong>in</strong>g. While the simulation can<br />

be easily extended to 3D, the present study is restricted<br />

to 2D because <strong>of</strong> the computational limitations <strong>in</strong>volved<br />

<strong>in</strong> model<strong>in</strong>g a realistic system size <strong>in</strong> 3D. In 2D, the<br />

plate-shaped h 0 precipitates will be modeled as if viewed<br />

edge-on and the number <strong>of</strong> orientational variants will be<br />

2, <strong>in</strong>stead <strong>of</strong> 3 (as <strong>in</strong> the schematic shown <strong>in</strong> Fig. 3). The<br />

2D simulation grids were 500 500–750 750 nm 2<br />

depend<strong>in</strong>g on the volume fraction, the size restricted<br />

ma<strong>in</strong>ly by the availability <strong>of</strong> computational resources.<br />

The phase-field model was constructed from firstpr<strong>in</strong>ciples<br />

data at 450 °C. However, the exclusion <strong>of</strong><br />

the vibrational entropy contribution <strong>in</strong> free energy calculations<br />

has been shown to cause an overestimation <strong>of</strong><br />

the solvus temperature <strong>in</strong> <strong>Al</strong>–Sc alloys [33], and we expect<br />

a similar temperature overestimation for <strong>Al</strong>–<strong>Cu</strong><br />

alloys here <strong>of</strong> 200–250 °C. Therefore, <strong>in</strong> all the calculated<br />

results below, we apply this ad hoc temperature<br />

correction, and compare our calculated results to experimental<br />

data at precipitation temperatures <strong>of</strong> <strong>in</strong>terest<br />

<strong>of</strong> 200–250 °C.<br />

In a phase-field model, homogeneous nucleation can<br />

be modeled by either add<strong>in</strong>g random thermal noises <strong>in</strong><br />

the Cahn–Hilliard and <strong>Al</strong>len–Cahn equations [24,34] or<br />

by explicitly <strong>in</strong>troduc<strong>in</strong>g nuclei accord<strong>in</strong>g to the classical<br />

nucleation theory applied locally <strong>in</strong> a system<br />

[35,36]. S<strong>in</strong>ce the ma<strong>in</strong> focus <strong>of</strong> this paper is on the<br />

growth and coarsen<strong>in</strong>g process <strong>of</strong> precipitates rather<br />

than the nucleation, the precipitates were simply <strong>in</strong>troduced<br />

at random locations. As smaller particles are<br />

more strongly controlled by <strong>in</strong>terfacial energies (relative<br />

to stra<strong>in</strong> energies) than large ones, the <strong>in</strong>itial<br />

conditions <strong>in</strong> all our simulations correspond to randomly<br />

distributed nuclei <strong>of</strong> h 0 with an aspect ratio<br />

3:1, based on first-pr<strong>in</strong>ciples calculated <strong>in</strong>terfacial<br />

energy anisotropy.