Annual Report 2002 - Agfa

Annual Report 2002 - Agfa

Annual Report 2002 - Agfa

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

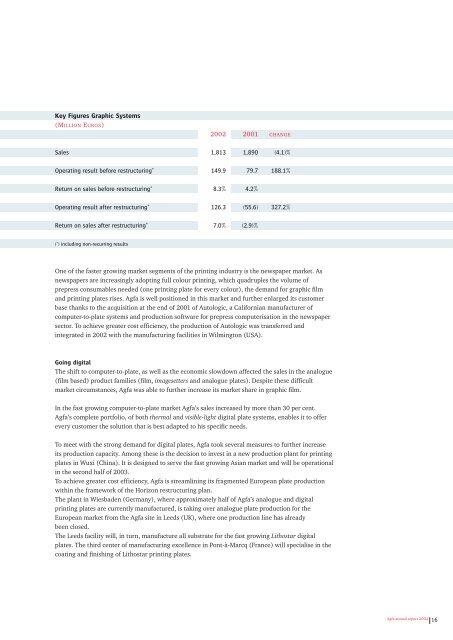

Key Figures Graphic Systems<br />

(MILLION EUROS)<br />

<strong>2002</strong> 2001 CHANGE<br />

Sales 1,813 1,890 (4.1)%<br />

Operating result before restructuring* 149.9 79.7 188.1%<br />

Return on sales before restructuring* 8.3% 4.2%<br />

Operating result after restructuring* 126.3 (55.6) 327.2%<br />

Return on sales after restructuring* 7.0% (2.9)%<br />

(*) including non-recurring results<br />

One of the faster growing market segments of the printing industry is the newspaper market. As<br />

newspapers are increasingly adopting full colour printing, which quadruples the volume of<br />

prepress consumables needed (one printing plate for every colour), the demand for graphic film<br />

and printing plates rises. <strong>Agfa</strong> is well positioned in this market and further enlarged its customer<br />

base thanks to the acquisition at the end of 2001 of Autologic, a Californian manufacturer of<br />

computer-to-plate systems and production software for prepress computerisation in the newspaper<br />

sector. To achieve greater cost efficiency, the production of Autologic was transferred and<br />

integrated in <strong>2002</strong> with the manufacturing facilities in Wilmington (USA).<br />

Going digital<br />

The shift to computer-to-plate, as well as the economic slowdown affected the sales in the analogue<br />

(film based) product families (film, imagesetters and analogue plates). Despite these difficult<br />

market circumstances, <strong>Agfa</strong> was able to further increase its market share in graphic film.<br />

In the fast growing computer-to-plate market <strong>Agfa</strong>’s sales increased by more than 30 per cent.<br />

<strong>Agfa</strong>’s complete portfolio, of both thermal and visible-light digital plate systems, enables it to offer<br />

every customer the solution that is best adapted to his specific needs.<br />

To meet with the strong demand for digital plates, <strong>Agfa</strong> took several measures to further increase<br />

its production capacity. Among these is the decision to invest in a new production plant for printing<br />

plates in Wuxi (China). It is designed to serve the fast growing Asian market and will be operational<br />

in the second half of 2003.<br />

To achieve greater cost efficiency, <strong>Agfa</strong> is streamlining its fragmented European plate production<br />

within the framework of the Horizon restructuring plan.<br />

The plant in Wiesbaden (Germany), where approximately half of <strong>Agfa</strong>’s analogue and digital<br />

printing plates are currently manufactured, is taking over analogue plate production for the<br />

European market from the <strong>Agfa</strong> site in Leeds (UK), where one production line has already<br />

been closed.<br />

The Leeds facility will, in turn, manufacture all substrate for the fast growing Lithostar digital<br />

plates. The third center of manufacturing excellence in Pont-à-Marcq (France) will specialise in the<br />

coating and finishing of Lithostar printing plates.<br />

<strong>Agfa</strong> annual report <strong>2002</strong><br />

16