Manual Handling Manual Handling Operations Regulations 1992 ...

Manual Handling Manual Handling Operations Regulations 1992 ...

Manual Handling Manual Handling Operations Regulations 1992 ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Health and Safety<br />

Executive<br />

Guidance<br />

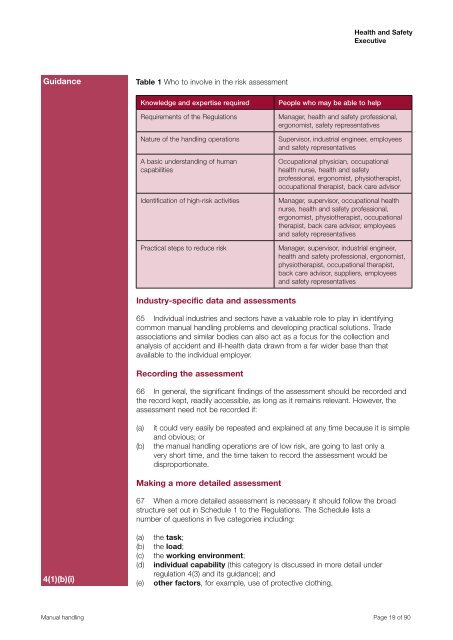

Table 1 Who to involve in the risk assessment<br />

Knowledge and expertise required<br />

Requirements of the <strong>Regulations</strong><br />

Nature of the handling operations<br />

A basic understanding of human<br />

capabilities<br />

Identification of high-risk activities<br />

Practical steps to reduce risk<br />

People who may be able to help<br />

Manager, health and safety professional,<br />

ergonomist, safety representatives<br />

Supervisor, industrial engineer, employees<br />

and safety representatives<br />

Occupational physician, occupational<br />

health nurse, health and safety<br />

professional, ergonomist, physiotherapist,<br />

occupational therapist, back care advisor<br />

Manager, supervisor, occupational health<br />

nurse, health and safety professional,<br />

ergonomist, physiotherapist, occupational<br />

therapist, back care advisor, employees<br />

and safety representatives<br />

Manager, supervisor, industrial engineer,<br />

health and safety professional, ergonomist,<br />

physiotherapist, occupational therapist,<br />

back care advisor, suppliers, employees<br />

and safety representatives<br />

Industry-specific data and assessments<br />

65 Individual industries and sectors have a valuable role to play in identifying<br />

common manual handling problems and developing practical solutions. Trade<br />

associations and similar bodies can also act as a focus for the collection and<br />

analysis of accident and ill-health data drawn from a far wider base than that<br />

available to the individual employer.<br />

Recording the assessment<br />

66 In general, the significant findings of the assessment should be recorded and<br />

the record kept, readily accessible, as long as it remains relevant. However, the<br />

assessment need not be recorded if:<br />

(a)<br />

(b)<br />

it could very easily be repeated and explained at any time because it is simple<br />

and obvious; or<br />

the manual handling operations are of low risk, are going to last only a<br />

very short time, and the time taken to record the assessment would be<br />

disproportionate.<br />

Making a more detailed assessment<br />

67 When a more detailed assessment is necessary it should follow the broad<br />

structure set out in Schedule 1 to the <strong>Regulations</strong>. The Schedule lists a<br />

number of questions in five categories including:<br />

4(1)(b)(i)<br />

(a)<br />

(b)<br />

(c)<br />

(d)<br />

(e)<br />

the task;<br />

the load;<br />

the working environment;<br />

individual capability (this category is discussed in more detail under<br />

regulation 4(3) and its guidance); and<br />

other factors, for example, use of protective clothing.<br />

<strong>Manual</strong> handling Page 19 of 90