FIELD MANUAL For HOT MIX ASPHALT (HMA) - Mississippi ...

FIELD MANUAL For HOT MIX ASPHALT (HMA) - Mississippi ...

FIELD MANUAL For HOT MIX ASPHALT (HMA) - Mississippi ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

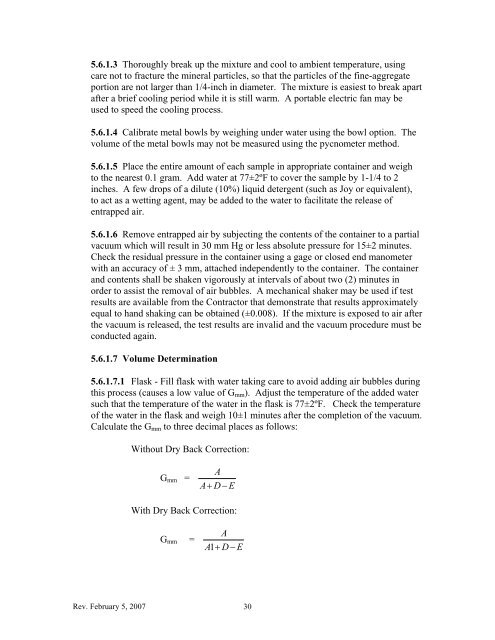

5.6.1.3 Thoroughly break up the mixture and cool to ambient temperature, using<br />

care not to fracture the mineral particles, so that the particles of the fine-aggregate<br />

portion are not larger than 1/4-inch in diameter. The mixture is easiest to break apart<br />

after a brief cooling period while it is still warm. A portable electric fan may be<br />

used to speed the cooling process.<br />

5.6.1.4 Calibrate metal bowls by weighing under water using the bowl option. The<br />

volume of the metal bowls may not be measured using the pycnometer method.<br />

5.6.1.5 Place the entire amount of each sample in appropriate container and weigh<br />

to the nearest 0.1 gram. Add water at 77±2ºF to cover the sample by 1-1/4 to 2<br />

inches. A few drops of a dilute (10%) liquid detergent (such as Joy or equivalent),<br />

to act as a wetting agent, may be added to the water to facilitate the release of<br />

entrapped air.<br />

5.6.1.6 Remove entrapped air by subjecting the contents of the container to a partial<br />

vacuum which will result in 30 mm Hg or less absolute pressure for 15±2 minutes.<br />

Check the residual pressure in the container using a gage or closed end manometer<br />

with an accuracy of ± 3 mm, attached independently to the container. The container<br />

and contents shall be shaken vigorously at intervals of about two (2) minutes in<br />

order to assist the removal of air bubbles. A mechanical shaker may be used if test<br />

results are available from the Contractor that demonstrate that results approximately<br />

equal to hand shaking can be obtained (±0.008). If the mixture is exposed to air after<br />

the vacuum is released, the test results are invalid and the vacuum procedure must be<br />

conducted again.<br />

5.6.1.7 Volume Determination<br />

5.6.1.7.1 Flask - Fill flask with water taking care to avoid adding air bubbles during<br />

this process (causes a low value of G mm ). Adjust the temperature of the added water<br />

such that the temperature of the water in the flask is 77±2ºF. Check the temperature<br />

of the water in the flask and weigh 10±1 minutes after the completion of the vacuum.<br />

Calculate the G mm to three decimal places as follows:<br />

Without Dry Back Correction:<br />

G mm =<br />

A<br />

A+<br />

D − E<br />

With Dry Back Correction:<br />

G mm =<br />

A<br />

A1+<br />

D − E<br />

Rev. February 5, 2007 30