Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

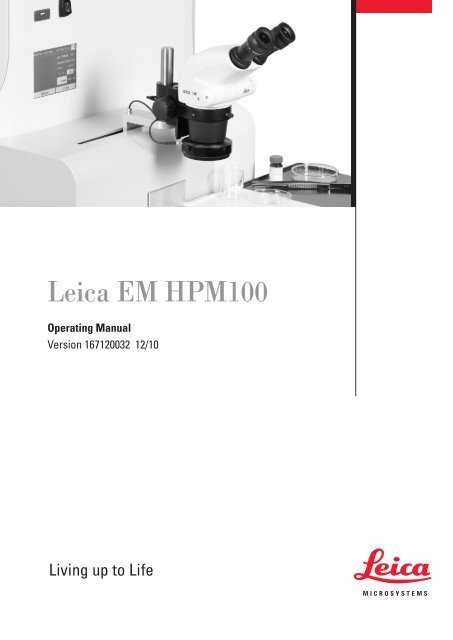

<strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong><br />

Operating Manual<br />

Version 167120032 12/10

Important Note<br />

<strong>Leica</strong> reserves the right to change technical specifications as well as manufacturing<br />

processes without prior notice. Only in this way is it possible to continuously improve<br />

the technology and manufacturing techniques used to provide our customers with<br />

excellent products.<br />

Any copyrights of this document are retained by <strong>Leica</strong> Mikrosysteme GmbH, Vienna.<br />

Any reproduction of text and illustrations (or any parts thereof) by printing, photocopying,<br />

or other methods (including electronic systems and media) requires express prior<br />

permission in writing.<br />

Issued by:<br />

<strong>Leica</strong> Mikrosysteme GmbH<br />

Hernalser Hauptstrasse 219<br />

A-1170 Vienna

<strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong><br />

Operating Manual<br />

<strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Serial Number:<br />

Date of purchase:<br />

For the instrument serial number, please refer to the name type label on the<br />

back of the instrument!<br />

Please read this instruction manual carefully<br />

before operating the instrument.

Foreword<br />

This technical documentation is intended to provide essential information about the<br />

proper operation and servicing of the <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong>. The system is used for<br />

cryo-immobilization of the ultrastructure of biological material to enable examination<br />

of the specimens under an electron microscope (<strong>EM</strong>) or a light microscope (LM).<br />

This user manual describes commissioning of the <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> High Pressure<br />

Freezer, phased testing and adjustment of all components and movement<br />

sequences, and restoring the basic functionality.<br />

Service and operating staff must familiarize themselves with all components of the<br />

system before commissioning. Particular attention must be paid to the aspect of<br />

safety.<br />

This user manual must be retained for future reference.<br />

Texts, schedules and tables may not be copied or reproduced without our express<br />

consent.<br />

It should be noted that this Technical Documentation does not constitute a part of any<br />

existing, prior agreement or covenant or legal relationship. All obligations arise from<br />

the purchase contract, which also is the sole regulator of the warranty conditions.<br />

Contractual regulations are not affected by this technical documentation.<br />

In addition, all generally applicable legal and otherwise binding regulations for<br />

preventing accidents and protecting the environment must be observed and<br />

communicated.<br />

Page 1 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

Tabel of contents<br />

1. Introduction ............................................................................................................................. 4<br />

2. Identification............................................................................................................................ 5<br />

2.1 Product mark and type designation..................................................................................... 5<br />

2.2 Name and address of the manufacturer.............................................................................. 5<br />

3. Product description ................................................................................................................ 6<br />

3.1 Field of application and proper use..................................................................................... 6<br />

3.2 Dimensions and weight (for transport) ................................................................................ 6<br />

3.3 Consumption and emissions............................................................................................... 6<br />

3.4 Environmental conditions for operation and storage........................................................... 7<br />

3.5 Safety information ............................................................................................................... 7<br />

3.5.1 General instructions..................................................................................................... 7<br />

3.5.2 Design safety measures .............................................................................................. 7<br />

3.5.3 Safety measures at the installation site ....................................................................... 7<br />

3.5.4 Safety measures when working with nitrogen ............................................................. 8<br />

3.5.4.1 Physical and chemical properties of nitrogen........................................................ 8<br />

3.5.4.2 Dangers of nitrogen............................................................................................... 8<br />

3.5.4.3 Safety precautions and rules for use..................................................................... 9<br />

3.5.5 Residual hazards ....................................................................................................... 10<br />

3.5.6 Qualification of operating personnel .......................................................................... 10<br />

3.5.7 Emergency procedure ............................................................................................... 11<br />

4. Preparing the system for use............................................................................................... 12<br />

4.1 Transportation and storage conditions.............................................................................. 12<br />

4.2 Installation conditions........................................................................................................ 12<br />

4.2.1 Work area conditions ................................................................................................. 12<br />

4.2.2 Connection conditions ............................................................................................... 12<br />

4.3 Installing, assembling and commissioning........................................................................ 13<br />

4.3.1 Unpacking and assembling the parts......................................................................... 13<br />

4.3.2 Setup ......................................................................................................................... 25<br />

4.3.3 Safe storage of the packing material ......................................................................... 25<br />

4.3.4 Electrical connections ................................................................................................ 25<br />

4.3.5 Commissioning .......................................................................................................... 25<br />

4.3.6 Repacking to prevent damage during transportation................................................. 25<br />

5. Operating instructions.......................................................................................................... 26<br />

5.1 Introduction ....................................................................................................................... 26<br />

5.2 Operating the <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> ..................................................................................... 26<br />

5.2.1 Switching on the system ............................................................................................ 26<br />

5.2.2 Cooling the system .................................................................................................... 33<br />

5.2.3 Inserting the specimen holder in the loading station.................................................. 35<br />

5.2.4 Inserting specimen and carriers into the specimen cartridge .................................... 37<br />

5.2.5 Starting the automatic freezing process .................................................................... 38<br />

Page 2 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

5.3 Actions following the freezing process.............................................................................. 40<br />

5.3.1 Checking the processing quality based on process data........................................... 40<br />

5.3.2 Documentation of freezing processes ....................................................................... 41<br />

5.3.3 Separating and sorting specimen carriers ................................................................. 42<br />

5.3.4 Transferring the frozen specimens ............................................................................ 42<br />

5.3.5 Switching off the system ............................................................................................ 44<br />

5.3.5.1 Draining the LN 2 Dewars..................................................................................... 45<br />

5.3.5.2 Bake out of the system........................................................................................ 46<br />

5.4 Changing settings on the main screen.............................................................................. 48<br />

5.4.1 Change directory for saving settings ......................................................................... 48<br />

5.4.2 Reset cycle counter ................................................................................................... 49<br />

5.4.3 Changing the temperature of the process chamber .................................................. 50<br />

5.4.4 Turning off the alcohol ............................................................................................... 51<br />

6. Servicing and cleaning ......................................................................................................... 53<br />

6.1 Draining fluids ................................................................................................................... 53<br />

6.2 Cleaning the <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong>....................................................................................... 53<br />

7. Messages during operation.................................................................................................. 54<br />

7.1 Standard messages during operation ............................................................................... 54<br />

7.2 Error messages during operation...................................................................................... 54<br />

8. Appendix I.............................................................................................................................. 55<br />

Page 3 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

1. Introduction<br />

In order to ensure the safety of service technicians and operators, and to prevent any<br />

damage to the <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> High Pressure Freezer, it is essential to read this<br />

manual carefully before beginning any work with the system.<br />

This user manual is intended to help the user to understand the system more<br />

completely, to use it within the specified limits of its working capabilities, and to<br />

maintain and service it in accordance with its physical parameters.<br />

This user manual includes important information regarding proper commissioning,<br />

operation, servicing, troubleshooting and repair. Observing these instructions will<br />

help to prevent hazards, reduce repair and downtime costs, and prolong the system's<br />

service life.<br />

Symbols used in this manual:<br />

Paragraphs with this symbol contain instructions regarding possible hazards.<br />

Failure to observe these alerts may result in serious injury! These instructions<br />

must be complied with in all cases.<br />

Paragraphs with this symbol contain important information which may<br />

endanger staff or result in damage to the system if it is ignored.<br />

Paragraphs with this symbol contain further information relating to a previous<br />

explanation, which does not have a safety-critical function. However, it is<br />

important to observe this information to ensure that the system functions<br />

optimally.<br />

Page 4 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

2. Identification<br />

2.1 Product mark and type designation<br />

<strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> UVN High Pressure Freezer: 100-130V / 50-60Hz<br />

<strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> EVN High Pressure Freezer: 200-240V / 50-60Hz<br />

2.2 Name and address of the manufacturer<br />

<strong>Leica</strong> Mikrosysteme GmbH<br />

Hernalser Hauptstrasse 219<br />

A-1170 Wien<br />

Tel.: +43 1 48899-0<br />

Fax: +43 1 48899-350<br />

Web: www.leica-microsystems.com<br />

Page 5 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

3. Product description<br />

3.1 Field of application and proper use<br />

The <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> High Pressure Freezer is used for freezing aqueous<br />

specimens for examination of the specimens with an electron microscope, a light<br />

microscope or other surface-analysis methods, such as atomic force microscopy,<br />

secondary ion mass spectrometry or photoelectron spectroscopy. Additional<br />

preparation stages may occur between freezing and examination.<br />

Specimens are frozen with liquid nitrogen at a temperature of –197 °C under a<br />

pressure of 210 kPa. Only liquefied nitrogen can be used as the cryogen.<br />

Various specimens such as tissue, cell cultures, cosmetic products, food,<br />

suspensions etc. can be processed.<br />

The high pressure greatly reduces the volume of gaseous substances in the<br />

specimen, so specimens should not contain any gas bubbles, which could reduce<br />

pressure transmission and reduce the freezing quality.<br />

When hazardous substances (e.g., radioactive, explosive, toxic or human pathogenic<br />

substances) are processed the substance-specific safety precautions must be<br />

implemented.<br />

The <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> must not be used beyond the limits specified in Technical<br />

Data.<br />

3.2 Dimensions and weight (for transport)<br />

Dimensions of the shipping container:<br />

Depth:<br />

149cm<br />

Width:<br />

81cm<br />

Height:<br />

146cm<br />

Weight of transport system: approx. 510kg<br />

For detailed information on the <strong>HPM100</strong> dimensions see Appendix I.<br />

3.3 Consumption and emissions<br />

Voltage:<br />

Current:<br />

Power consumption:<br />

LN 2 consumption during cool down:<br />

LN 2 consumption in operation:<br />

LN 2 consumption per freezing process:<br />

Ethanol consumption per freezing process:<br />

Volumetric capacity of the LN 2 Dewar:<br />

Volumetric capacity of the ethanol tank:<br />

Nitrogen gas emission:<br />

Noise level during pressure build-up:<br />

Maximum noise level during the freezing process:<br />

100-130V / 50-60Hz<br />

200-240V / 50-60Hz<br />

max. 7A for 230V<br />

max. 14A for 115V<br />

max. 1200W<br />

approx. 20 liters<br />

approx. 5 liters per hour<br />

50 ml<br />

2 ml<br />

20 liters<br />

0.5 liters<br />

approx. 50m 3 per day<br />

approx. 60dB(A)<br />

approx. 75dB(A)<br />

Page 6 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

3.4 Environmental conditions for operation and storage<br />

Operating temperature:<br />

Storage temperature:<br />

Relative humidity:<br />

+15°C to +35°C<br />

+05°C to +40°C<br />

max. 85% non-condensing for operation and storage<br />

Use and store the instrument in an environment free of dust and other destructive<br />

particles.<br />

3.5 Safety information<br />

3.5.1 General instructions<br />

The <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> High pressure Freezer can be handled safely and easily<br />

provided it is operated in accordance with the instructions in this manual.<br />

Failure to follow these safety instructions may endanger people and the<br />

system.<br />

3.5.2 Design safety measures<br />

All mechanical components are protected by enclosures (doors, panels, etc.). These<br />

enclosures must not be opened except for servicing<br />

The <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> High Pressure Freezer must not be operated unless all<br />

enclosures are properly in place.<br />

3.5.3 Safety measures at the installation site<br />

The following measures must be implemented to prevent incorrect use at the<br />

installation site:<br />

• The media connections for the system must be connected at the installation<br />

location by qualified technicians.<br />

• Media must not be added or topped up except by authorized and trained<br />

personnel.<br />

• The system must not be operated except by trained and authorized technicians.<br />

• Repairs may only be made to the system by staff of the manufacturer's technical<br />

department.<br />

If the <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> High Pressure Freezer is installed incorrectly, the<br />

system may be damaged.<br />

Page 7 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

3.5.4 Safety measures when working with nitrogen<br />

3.5.4.1 Physical and chemical properties of nitrogen<br />

Nitrogen gas (N 2 ) is a colorless, odorless and tasteless inert gas and is not<br />

combustible. Nitrogen has no physiological effect, therefore it is not poisonous to<br />

humans and other living things. The nitrogen content of atmospheric air is approx.<br />

78%, along with approx. 21% oxygen (O 2 ). The danger of nitrogen is in the<br />

displacement of atmospheric oxygen as a result of the release of nitrogen. At less<br />

than 17% O 2 depending on the duration of inhalation and the value of the actual<br />

oxygen concentration, symptoms of drowsiness, uneasiness, nausea, high blood<br />

pressure and breathing difficulties culminating in unconsciousness will occur. If an<br />

unconscious person remains in a low-oxygen environment, death will result. In a<br />

virtually pure nitrogen atmosphere unconsciousness is immediate (with no warning<br />

by odor), followed shortly after by death.<br />

Cold liquid nitrogen (LN 2 ) is a very cold liquid (boils at –196°C), it is colorless,<br />

odorless, non-reactive and non-combustible. Escaping cold (~ –190°C) nitrogen gas<br />

(GN 2 ) is initially heavier than air and may accumulate near the floor and in lower<br />

areas. When the gas is released a cold fog is formed by condensation and freezing of<br />

moisture in the air, which can spread out over a wide area. If the gas warms up to<br />

room temperature, it is somewhat lighter than air. If the ventilation is inadequate the<br />

oxygen will be replaced.<br />

Evaporation of one liter of liquid nitrogen generates about 0.75m 3 of nitrogen gas.<br />

3.5.4.2 Dangers of nitrogen<br />

• Cold damage: freezing, frost blisters and serious eye damage on direct contact:<br />

o with liquid nitrogen<br />

o with the escaping cold gas or the resulting fog<br />

o with objects or surfaces that have come into contact with liquid nitrogen or<br />

escaping gas (e.g. pipe joints, tubes, valves, tanks, metallic surfaces etc.).<br />

• Freezing to cold surfaces (e.g. metal) on direct contact.<br />

• Headache, nausea, sleepiness, breathing difficulties<br />

• Unconsciousness with no irritation or warning effect, as a result of oxygen<br />

depletion (i.e., less than 17% O2).<br />

• Ice formation on frozen plugs or other gas-tight Dewar flasks can prevent the<br />

evaporation of nitrogen. If this container is shaken or moved, explosive release of<br />

nitrogen gas (delayed boiling) may rupture the container.<br />

• Uncontrolled boiling and increased vaporization of liquid nitrogen may occur if<br />

damaged or poorly insulated Dewar flasks are used.<br />

• When warm objects are cooled in LN 2 , an insulating gas layer will first form around<br />

the object, and slow the heat transfer (minimal boiling of nitrogen). However, when<br />

the object is cooled beyond a certain point, strong boiling often occurs<br />

unexpectedly and liquid nitrogen may be sprayed out.<br />

Page 8 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

• Accidental release of liquid nitrogen resulting from material damage caused by<br />

some steels and organic materials (plastic, rubber etc.) becoming brittle by<br />

exposure to cold<br />

• Glass Dewar flasks are very sensitive to impact and may burst even if lightly<br />

touched by metal instruments. (Temperature tension because of the high<br />

conductivity of metal)<br />

• O 2 enrichment may occur at the exterior walls of non-insulated tanks and<br />

pipes.<br />

o Creates a fire and explosion hazard if a container is open and during use<br />

where organic substances are present. The vaporizing, very fire-promoting<br />

liquid oxygen may cause spontaneous combustion. Oxygen enrichment can<br />

be recognized by a slight bluish coloring of the liquid nitrogen.<br />

3.5.4.3 Safety precautions and rules for use<br />

• Ensure good ventilation at all times.<br />

• Do not actuate isolation valves on Dewar tanks suddenly, check regularly for<br />

leaks.<br />

• Fill liquid nitrogen only into clean, completely dry containers and apparatus.<br />

• Use only intact Dewar flasks: check the insulation of the flasks regularly by the<br />

vaporization rate. Light boiling at the container walls is an indication of poor<br />

insulation.<br />

• Never seal Dewar flasks with gas-tight covers without a safety valve. Use only<br />

easily operated covers designed for Dewar flasks. Never use closures with a<br />

gasket.<br />

• Thaw ice on apparatus and containers with warm air or hot water only, never use a<br />

flame or red-hot objects.<br />

• If possible, do not use glass Dewar flasks, and particularly do not use glass Dewar<br />

flasks with a capacity greater than 2L. Dewar flasks of metal are preferred.<br />

• Use lightly covered Dewar flasks with a sheet metal mantle for small volumes.<br />

• Large storage containers of stainless steel (over 10L capacity) must be fitted with<br />

a tilt mechanism or a lever system.<br />

• Store containers in a cool, well-ventilated place.<br />

• Provide a fresh-air feed in case of possible enrichment of N2 gas. If applicable,<br />

provide an exhaust system.<br />

• Use only freshly prepared colorless liquid nitrogen.<br />

• Do not spill it when filling and transferring.<br />

• Do not fill container past the fill level with liquid nitrogen. Fill Dewar flasks with a<br />

bottleneck only to clearly below the neck (please note that the length of the Dewar<br />

neck may be different from the length of the lagging).<br />

• Allow overfull flasks to empty partially by leaving them open.<br />

• Do not immerse objects at room temperature in liquid nitrogen.<br />

• Cover small barrels and specimen chambers immediately after use with light<br />

covers that are not gas tight to prevent condensation of oxygen (fire hazard). Move<br />

closed unpressurized containers slowly to prevent spray or overflow.<br />

• Transport only in high-quality insulated containers for very cold gases (cryoflasks).<br />

• Secure containers to prevent falling.<br />

• Avoid any damage and unnecessary agitation.<br />

• Only sealed, unpressurized metal Dewar flasks are permitted in elevators.<br />

Page 9 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

• Wear a face shield or safety glasses (open above and below, not enclosed<br />

glasses).<br />

• Wear cryo gloves or leather work gloves with a very long sleeve.<br />

• Always wear a floor-length PE apron when pouring from Dewar flasks.<br />

Do not allow liquid nitrogen to penetrate into or under protective clothing.<br />

Penetrating N 2 will vaporize immediately and cause serious freezing injuries<br />

before the protective clothing can be removed. If possible, keep the sleeve over<br />

the top of the safety gloves and do not use protective clothing that could be<br />

penetrated by liquid nitrogen.<br />

3.5.5 Residual hazards<br />

The <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> High Pressure Freezer represents the latest technology and<br />

conforms to recognized safety regulations: even so, hazards still exist.<br />

All modifications and conversions to the system are prohibited!<br />

Objects may fall into the system in spite of all possible precautions. In this<br />

case stop the system and switch off the main switch. If the search for the<br />

object that has fallen in is not successful, inform the service department before<br />

continuing to work with the system. Continuing operation may cause damage<br />

to the system.<br />

Install or update software only with data media supplied by <strong>Leica</strong><br />

Microsystems.<br />

When handling toxic or human pathogenic substances observe the biohazard<br />

regulations.<br />

3.5.6 Qualification of operating personnel<br />

The operating personnel must be familiar with and follow the recognized rules for<br />

safety at work.<br />

The operating personnel tasked with operating and maintaining the <strong>Leica</strong> <strong>EM</strong><br />

<strong>HPM100</strong> High Pressure Freezer must satisfy the specific professional requirements<br />

for their respective duties.<br />

The operating personnel must have received training and must be familiar with the<br />

duties that have been assigned to them and for which they are responsible.<br />

The professional profiles for operating personnel responsible for the system are<br />

outlined in the following.<br />

Operator (user class 2)<br />

Personnel with technical training, able to perform simple tasks, i.e., operate the <strong>Leica</strong><br />

<strong>EM</strong> <strong>HPM100</strong> High Pressure Freezer and load and unload samples.<br />

Administrator (user class 1)<br />

Page 10 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

Staff with technical training, able to perform the tasks of qualification 2, and also<br />

typical simple maintenance, adjustment and startup activities with protective devices<br />

switched off as well as restarting the system.<br />

Manufacturer's technician (<strong>Leica</strong> Microsystems – user class 0)<br />

Trained technician provided by the manufacturer, who is able to carry out more<br />

complex work in exceptional situations or in cases where such has been agreed with<br />

the user.<br />

3.5.7 Emergency procedure<br />

In case of faults, the display shows an error message that describes the<br />

recommended procedure for correcting the fault.<br />

If unusual operating conditions or unaccustomed noises occur, the system may be<br />

switched off using the main system switch.<br />

If firefighting measures are called for, a CO 2 fire extinguisher must be used.<br />

The Technical Service must be consulted before resuming work with the system.<br />

Page 11 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

4. Preparing the system for use<br />

4.1 Transportation and storage conditions<br />

The <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> High Pressure Freezer is delivered properly packed and in<br />

the semi-assembled state. The customer must check the condition of the system<br />

upon delivery and file a damage report with the shipping company if the equipment is<br />

damaged. The customer must immediately inform the manufacturer of any possible<br />

damage in transit.<br />

The system must be positioned upright for transporting.<br />

The overall weight including packaging is approx. 510 kg.<br />

The packed equipment must be stored in clean, dry areas at temperatures between<br />

5° and 40°C and must not be exposed to aggressive substance that could cause<br />

corrosion.<br />

4.2 Installation conditions<br />

4.2.1 Work area conditions<br />

The system must be installed on a level horizontal base. There must be a specific<br />

clearance around it.<br />

The minimum working distances are 20 cm at the back and to the right and 60<br />

cm at the front and left.<br />

4.2.2 Connection conditions<br />

The following connections must be assured:<br />

• power supply 100-130V / 50-60Hz for <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> UVN<br />

• power supply 200-240V / 50-60Hz for <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> EVN<br />

Page 12 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

4.3 Installing, assembling and commissioning<br />

The packaged <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> High Pressure Freezer must be transported with a<br />

forklift truck or a pallet hoist.<br />

4.3.1 Unpacking and assembling the parts<br />

After selecting the installation location, remove the top cover and all side panels of<br />

the wooden crate.<br />

Remove the packaging material in the crate. Do not remove plastic packaging from<br />

around the machine. Place all included boxes in a secure place to the side.<br />

Page 13 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

Remove the screws and remove the wooden brace at the front of the machine.<br />

Remove the screws from the sides of the top wood wedges and remove the wedges<br />

from under the system.<br />

Page 14 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

Use the two wedges as a ramp to roll the <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> to the floor from the<br />

pallet.<br />

Release the roller brakes and carefully move the system down the ramps to the floor.<br />

Never do this alone. The heavy weight of the <strong>Leica</strong> <strong>EM</strong> HPM 100 High Pressure<br />

Freezer may be hazardous to persons if it tilts or when moving it on slopes.<br />

Carefully unpack the boxes with the disassembled parts of the system. Check with<br />

the packing slip that all parts are included and check for damage.<br />

Page 15 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

Remove the plastic packaging from the <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong>.<br />

Loosely fasten the metal support to the loading station with 2 bolts and washers<br />

(6mm hex).<br />

Page 16 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

Fasten the worktop to the loading station of the <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> with the supplied<br />

bolts.<br />

The long bolt attaches through the metal support. Tighten all 7 bolts.<br />

Page 17 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

Undo the loading mechanism from the lever axis by removing the two (2mm hex)<br />

bolts.<br />

Loading<br />

mechanism<br />

Lever axis<br />

Place the loading mechanism into the loading station.<br />

Page 18 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

Insert the lever axis through the worktop and the loading mechanism.<br />

Fix the lever axis to the loading mechanism of the loading station with the two hex<br />

bolts.<br />

Page 19 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

Unpack the box containing the stereomicroscope, two eye pieces, support ring and<br />

ring-light.<br />

Place the stereomicroscope support ring onto the microscope column.<br />

Page 20 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

Place the stereomicroscope into the support ring.<br />

Fasten the stereomicroscope to the support ring.<br />

Page 21 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

Remove the eye piece caps.<br />

Attach the eye piece to the stereomicroscope.<br />

Page 22 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

Attach the ring-light to the outside of the objective lens.<br />

Connect the cable from the microscope column to the ring-light.<br />

Page 23 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

Unscrew the back panel of the <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> leaving the bottom screws in<br />

place.<br />

Leave the bottom<br />

screws in place<br />

Fasten the handle to the back panel from the inside of the <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> with<br />

the supplied bolts.<br />

Page 24 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

4.3.2 Setup<br />

The <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> is moved to the installation location on the integrated rollers.<br />

Release the roller brakes and set them again once the final position has been<br />

reached.<br />

The back rollers have a fixed direction. The front rollers can swivel for steering<br />

the <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> when it is being moved.<br />

Avoid moving the <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> over slopes and uneven ground. The<br />

system must never be tilted more than 3°.<br />

The system must be installed on a hard floor or on a floor plate that is at least 100 cm<br />

deep and 70 cm wide.<br />

Sufficient space is required to allow comfortable operation of the <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong><br />

and also for maintenance and service. Reserve a minimum working distance of 20<br />

cm at the back and right and 60 cm at the front and left.<br />

4.3.3 Safe storage of the packing material<br />

The packing material for the <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> must be kept safely for use if the<br />

system is shipped again, since the system may be damaged if it is not transported in<br />

the original packing. Store the packaging for the parts and the floor of the crate with<br />

the side panels of the lagging.<br />

4.3.4 Electrical connections<br />

The electrical terminal is on the back of the <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong>. Power is supplied via<br />

a connector for non-heating appliances. Install a country-specific electrical plug to<br />

connect the power supply at the installation location.<br />

4.3.5 Commissioning<br />

The <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> is commissioned by employees of <strong>Leica</strong> Microsystems<br />

and specially trained and authorized technicians.<br />

Before commissioning the system, carry out the following steps:<br />

• unpack the <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong><br />

• install the high pressure freezer<br />

• connect the power<br />

Once the above steps have been completed, commissioning involves following the<br />

operator actions to ensure the machine is functioning properly.<br />

4.3.6 Repacking to prevent damage during transportation<br />

To disassemble and pack the system, carry out the steps for assembly and<br />

unpacking in reverse order.<br />

Page 25 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

5. Operating instructions<br />

5.1 Introduction<br />

The formation of ice crystals can be greatly reduced if the specimen is subjected to a<br />

pressure of 2100 bar before the freezing process has started. Aqueous specimens<br />

can be frozen without ice crystals up to a thickness of 200 µm. Pressure may cause<br />

changes in the physical and chemical equilibrium, such as dissociation or the<br />

reactivity of enzymes. This must be prevented to immobilize the specimen in as close<br />

to a natural state as possible. The pressure should be applied as quickly as possible<br />

and once the specimen is under 2100 bar it should be cooled to at least –140 °C as<br />

quickly as possible. Below this temperature amorphous (vitrified) ice remains stable.<br />

The diagram (Kanno et al. 1975) shows the stable states of water depending on<br />

pressure and temperature. The melting temperature and the temperature for<br />

homogenous nucleation reach a minimum at 2100 bar. At this pressure water can be<br />

supercooled to -90 °C and changes to a very viscous liquid. I, II and III show ranges<br />

in which H 2 O is present as hexagonally oriented ice.<br />

5.2 Operating the <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong><br />

The next section explains the complete freezing process in detail.<br />

5.2.1 Switching on the system<br />

Close all valves at the back of the machine. Switch on the system at the main switch<br />

on the front panel. The compressor starts to build up the operating pressure. This can<br />

take up to 15 minutes if there is no residual air pressure in the machine.<br />

Page 26 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

Close valves at the back of the machine.<br />

Position of main switch<br />

Main switch<br />

Page 27 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

If a USB stick is connected to the port on the front panel, the process parameters for<br />

every freezing cycle will be saved in the selected directory.<br />

If the USB stick is not connected the process parameters will be displayed following<br />

each freezing cycle, but will not be saved.<br />

Connection for<br />

the USB stick<br />

If you use a directory name that has already been used with the USB stick the<br />

older process parameter will be overwritten!<br />

Create a directory name using the touch screen. Press Enter to confirm the name. Up<br />

to 8 characters can be used.<br />

Page 28 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

After pressing “ENTER” on the “directory screen” the following display will appear.<br />

Add isopropanol or absolute ethanol to the <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong>.<br />

The tank must be filled with 100% isopropanol or absolute ethanol only!<br />

To add isopropanol or absolute ethanol slide the microscope to the right until it<br />

comes to a stop.<br />

Page 29 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

Open the front safety cover and prop it using the cover support lock.<br />

Cover support lock<br />

Alcohol tank<br />

Unscrew the alcohol tank cap and fill the tank with 40ml isopropanol or absolute<br />

ethanol.<br />

After filling, screw the tank lid closed (hand tight only). Close the safety cover by<br />

pushing the cover support back to release the lock.<br />

Page 30 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

The touch screen shows a “wait for air pressure” message until the compressor has<br />

built up the operating pressure.<br />

Page 31 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

Once the operating pressure has been reached the main touch screen will appear.<br />

Settings can be made with the main touch screen. See Section 5.4.7.<br />

Buttons always have a light background and open a new window when pressed.<br />

2<br />

3<br />

1<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

1 status display(During the cooling process the main screen shows "wait for cool<br />

down“)<br />

2 alcohol On/Off display<br />

3 cycle counter<br />

4 storage Dewar fill level display<br />

5 actual temperature in process chamber<br />

6 button for setpoint temperature in process chamber<br />

7 directory selection button<br />

8 file name display for saving the process data<br />

9 service button (access for service technicians only)<br />

10 system button (includes draining and bake-out)<br />

Page 32 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

5.2.2 Cooling the system<br />

The <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> is cooled with LN 2 while the system is reaching operating<br />

pressure.<br />

Add liquid nitrogen to the storage Dewar. Use caution as rapid LN 2 evaporation<br />

during the first cooling stages can cause splashing of the LN 2 .<br />

A small pop-up rod in the top cover rises when the Dewar is completely full of LN 2 .<br />

Page 33 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

The display on the main screen shows the “LN 2 Storage” level as a percentage.<br />

The internal LN 2 pump will start when the storage Dewar registers at least 30% full.<br />

The current status is displayed in the top left corner of the main screen.<br />

Fill the specimen Dewar with liquid nitrogen before freezing.<br />

After cryofixation, the frozen sample is automatically released into the specimen<br />

Dewar.<br />

Drawer for removable<br />

specimen Dewar<br />

Note: Freezing can not take place if the specimen Dewar is not filled with LN 2 .<br />

Page 34 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

Fill the specimen Dewar with liquid nitrogen before freezing.<br />

Open the specimen Dewar drawer by pulling the drawer away from the machine.<br />

Position the LN 2 filled specimen Dewar firmly against the metal holder and then close<br />

the drawer.<br />

Specimen LN Dewar<br />

Metal holder<br />

When the system is fully cooled (approximately 30 minutes after the internal LN 2<br />

pump starts) and the small LN 2 Dewar is filled, the main screen shows “ready for<br />

freezing” in the top left corner. The freezing process can begin.<br />

5.2.3 Inserting the specimen holder in the loading station<br />

The loading mechanism must be open to insert the three-piece cartridge consisting of<br />

an upper cylinder, carrier plate and lower cylinder.<br />

Open the loading mechanism by rotating it towards you into the front locking position<br />

with the loading lever.<br />

Hold the bottom half of the closure with the right forefinger and turn the top half to a<br />

vertical position with the loading lever.<br />

Front locking<br />

position of the<br />

loading<br />

mechanism<br />

Loading lever<br />

Page 35 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

Insert the upper and lower cylinder into the loading mechanism. The upper cylinder is<br />

placed in the top closure and the lower cylinder is placed in the bottom closure. A pin<br />

in the bottom closure ensures it is placed correctly.<br />

Place the carrier plate onto the lower cylinder. Note that the side openings of the<br />

carrier plate match with the side openings of the lower cylinder.<br />

Upper<br />

cylinder<br />

Side openings<br />

Lower cylinder<br />

Carrier plate<br />

If the carrier plate is incorrectly oriented it will be damaged when the specimen<br />

is ejected.<br />

Page 36 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

5.2.4 Inserting specimen and carriers into the specimen cartridge<br />

The <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> requires two specimen carriers for standard freezing. The<br />

following section explains the insertion of the standard 3 mm specimen carriers (Type<br />

A and B). For more detail and insertion of different specimen carriers, e.g. Type C or<br />

others please see the relevant data sheet.<br />

Specimen<br />

carrier and<br />

specimen<br />

Place a type A specimen carrier into the round hole of the carrier plate with the<br />

hollow section of the specimen carrier facing upwards.<br />

Place the specimen into the Type A specimen carrier. Make sure that the specimen<br />

does not extend above the well in the carrier and that the space inside the carrier is<br />

completely filled and there are no air bubbles.<br />

Place a type B specimen carrier with the smooth side down onto the Type A carrier<br />

containing the specimen. Make sure that the carriers are even with the plane of the<br />

carrier plate.<br />

The carrier must be completely filled with liquid (eg Hexadecen, culture media,<br />

cryoprotectant, etc) before freezing<br />

When the carriers are in place, rotate the loading lever so that the top closure locks<br />

(clicks) into the bottom.<br />

Page 37 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

The loading mechanism is now closed and the sample is ready for freezing.<br />

5.2.5 Starting the automatic freezing process<br />

Rotate the loading lever 180°C until the process button is in position.<br />

Process<br />

button<br />

Page 38 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

Push the process button to start the freezing process.<br />

The microscope must not be used during the freezing process. The motion of<br />

the device may cause injury to the eyes.<br />

After cryo-fixation the three-piece cartridge and specimen carriers are automatically<br />

ejected into the specimen Dewar and are ready for transfer (see Section 5.3.4). The<br />

freezing process is now complete.<br />

Page 39 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

5.3 Actions following the freezing process<br />

5.3.1 Checking the processing quality based on process data<br />

After the freezing process has finished, the following measurement parameters can<br />

be read on the main screen:<br />

Rise Time - The time [ms] it took for the pressure to rise to 2100 bar<br />

Shift p/T - The time [ms] between when pressure rose above 2100 bar and when<br />

the temperature dropped below -100 °C<br />

HP Dwell - The time [ms] from when the pressure rose past 2100 bar until it<br />

dropped back down below 2100 bar<br />

Cooling - The cooling speed [°C/s]<br />

Display of measurement parameters:<br />

The measurement values for temperature and pressure can also be viewed as a<br />

graph. To display the graph press the GRAPH button at the bottom left.<br />

Display of measurement as curves:<br />

Page 40 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

The first 500 ms are shown. At the left is the axis for the temperature and on the right<br />

the axis for the pressure. The top curve shows the pressure trend, the bottom the<br />

temperature trend. To display the first 20 ms press the DETAILS button.<br />

Display of measurement curves in detail:<br />

Press VALUES button to return to the main screen.<br />

5.3.2 Documentation of freezing processes<br />

If a USB stick was connected before starting the freezing process, all processing data<br />

are saved to the selected directory under the displayed name (e.g. 002.xls). These<br />

files can be opened with Microsoft Excel and other programs. The following picture<br />

shows an extract from such a file. The header contains general information such as<br />

date and time. Pressure and temperature data are shown below. A value is saved<br />

every 50 µs for the first 50 ms, then every 2.5 ms.<br />

Overview of saved data:<br />

<strong>Leica</strong><br />

Microsystems 17/10/2010 08:21<br />

<strong>HPM100</strong> Version V4.06<br />

Directory name hpm100<br />

Filename<br />

001.xls<br />

Rise time 4.0 ms<br />

Shift p/T 1.1 ms<br />

hp Dwell 310.4 ms<br />

Cooling rate 13986 °C/s<br />

============ ============ ============<br />

time [µs] pressure [bar] temperature[°C]<br />

0 60 18<br />

50 65 18<br />

100 72 20<br />

150 77 20<br />

Page 41 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

5.3.3 Separating and sorting specimen carriers<br />

At the end of the freezing process the upper and lower cylinder can be removed from<br />

the specimen Dewar and heated. Clean the cylinders with a lint-free paper towel.<br />

Handling the carrier plate with the frozen sample in it is explained in the following<br />

section.<br />

5.3.4 Transferring the frozen specimens<br />

Place the inset for sample carrier release (3 mm, 4.5 mm or 6 mm respectively) and<br />

the specimen container in the metal bath. Connect the lever by screwing it to the<br />

punching device.<br />

Fill the bath with LN 2 and allow all parts to cool before transferring the specimens.<br />

The container has six numbered storage positions.<br />

Page 42 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

Position the carrier plate (arresting the frozen specimen) in the slot of the inset using<br />

cold forceps. Push the carrier plate into the guide until it stops.<br />

Punching<br />

tool<br />

Carrier plate slot<br />

Page 43 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

Push the lever forward.<br />

The specimen carrier is ejected from the carrier plate into a small specimen container<br />

within the insert where they can be retrieved from.<br />

Transfer the released specimen in specimen container under the desired<br />

number.<br />

5.3.5 Switching off the system<br />

Once all freezing is complete, the <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> can be shut down. If the<br />

machine will not be used for several days it is safe to simply turn off the power and let<br />

the LN 2 evaporate and the machine gradually warm to room temperature. If the <strong>Leica</strong><br />

<strong>EM</strong> <strong>HPM100</strong> is to be used within the next 24 hours, the following drain and bake-out<br />

protocol should be followed.<br />

Page 44 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

5.3.5.1 Draining the LN 2 Dewars<br />

The <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> operates with two LN 2 Dewars, one storage Dewar (20 ltr)<br />

and a process Dewar (10 ltr).<br />

Two valves at the back panel of the instrument allow draining of both Dewars.<br />

Storage Dewar<br />

drain valve<br />

Process Dewar<br />

drain valve<br />

Place a small Dewar or LN 2 bucket under the hose and open the storage and/or<br />

process Dewar valves to drain the LN 2 . The LN 2 can be used for other purposes or<br />

disposed of.<br />

Before commissioning the instrument again, close both the storage and process<br />

Dewar valves.<br />

Page 45 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

5.3.5.2 Bake out of the system<br />

Once the storage Dewar has reached a level of below 20%, select SYST<strong>EM</strong> from the<br />

main screen.<br />

Select AIR HEATER ON display button to activate the heating cycle.<br />

The 80°C heating cycle will only start when the chamber temperature warms to 10°C.<br />

Page 46 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

When the heating cycle is activated the status display reads “air heater working”.<br />

The screen displays the cycle time left (starting at 8000 seconds), and the<br />

temperatures of the air inlet, draw tube, storage Dewar and the connecting pipe<br />

(in °C).<br />

The bake-out will automatically terminate after reaching the end of the cycle leaving<br />

the instrument ready for the next use. Once the cycle is complete, the machine<br />

switches back to the standard screen.<br />

Note: Leave the main power on for the heating cycle to run.<br />

The heating cycle can be terminated at any time by pressing “Air Heater Off”.<br />

During the bake-out cycle DO NOT turn the system and main power off for this<br />

will terminate the bake-out and the bake-out cycle.<br />

Page 47 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

5.4 Changing settings on the main screen<br />

Certain parameters and settings can be changed on the main screen and are<br />

explained below.<br />

5.4.1 Change directory for saving settings<br />

To change the current directory press the current directory name on the main screen.<br />

The new directory is ready for input.<br />

Confirm your input by pressing Enter.<br />

Page 48 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

5.4.2 Reset cycle counter<br />

The cycle counter starts from zero when the system is switched on. The counter can<br />

also be reset manually during operation.<br />

To reset the cycle counter press the “cycle no.” counter button in the top right corner.<br />

Confirm the reset by pressing YES.<br />

Resetting the cycle number does not influence the file name in which the process<br />

data are saved when a USB stick is connected.<br />

Page 49 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

5.4.3 Changing the temperature of the process chamber<br />

The temperature of the process chamber can be controlled. The current nominal and<br />

actual values of the cryo chamber can be read on the main screen.<br />

To change the temperature of the process chamber press the nominal temperature<br />

button.<br />

Increase or decrease the temperature using the two arrow buttons.<br />

Confirm the temperature by pressing the nominal temperature and the main screen<br />

will appear.<br />

Page 50 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

5.4.4 Turning off the alcohol<br />

A freezing process can be carried out without alcohol if needed.<br />

To turn off the alcohol select SYST<strong>EM</strong> from the main screen (see 5.3.5.2) and press<br />

ALCOHOL ON.<br />

The display button changes to ALCOHOL OFF.<br />

Page 51 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

The machine is ready to freeze without alcohol, which is indicated on the main<br />

screen.<br />

Page 52 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

6. Servicing and cleaning<br />

Servicing and cleaning<br />

• preserves the perfect condition and operating readiness of the system,<br />

• increases the system's rate of use by avoiding downtime;<br />

• enables efficient planning of maintenance work and materials.<br />

6.1 Draining fluids<br />

There are three valves on the back lower panel of the <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong><br />

The FRESH ALCOHOL OUT valve drains the pure (clean) alcohol from the alcohol<br />

tank.<br />

The WASTE ALCOHOL OUT valve drains the collected waste (used) alcohol and<br />

should be drained into a beaker and disposed of in accordance with local chemical<br />

disposal guidelines. The valve should be opened slowly and carefully.<br />

The AIR PRESSURE OUT valve releases the air pressure from the reserve tank. The<br />

power should be turned off before opening this valve. It is only necessary to release<br />

the air pressure if the instrument is going to be shipped<br />

6.2 Cleaning the <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong><br />

It is recommended to periodically wipe the machine with a mild cleaning solution and<br />

a soft cloth. Use of solvents will damage the finish.<br />

Page 53 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

7. Messages during operation<br />

7.1 Standard messages during operation<br />

Message Explanation Solution<br />

Close safety cover Safety cover is open Close safety cover<br />

Wait for air pressure<br />

Wait for storage<br />

pressure<br />

The machine has not<br />

reached operating<br />

pressure<br />

The machine has not<br />

reached storage pressure<br />

Wait for the machine<br />

to reach operating<br />

pressure<br />

Wait for the machine<br />

to reach storage<br />

pressure<br />

7.2 Error messages during operation<br />

Message Explanation Solution<br />

INIT Rotor The rotor is out of position Press the Init button<br />

Check specimen holder<br />

INIT HP Cylinder<br />

Refill Alcohol<br />

Close LN 2 storage<br />

Dewar<br />

Refill LN 2 storage Dewar<br />

Check Drawer LN 2<br />

Dewar<br />

Check Process<br />

Chamber<br />

Cartridge is not loaded or<br />

the specimen was lost<br />

before the freezing<br />

process<br />

The cylinder is out of<br />

position<br />

The alcohol level is low<br />

The LN 2 specimen Dewar<br />

drawer is open<br />

The specimen Dewar is<br />

empty or the level of LN 2<br />

is low<br />

The specimen Dewar is<br />

missing<br />

The cartridge is lost after<br />

the freezing process<br />

Open the safety cover.<br />

Remove the lost<br />

cartridge pieces from<br />

the rotor. Press exit.<br />

Press INIT<br />

Open safety cover and<br />

refill the alcohol tank<br />

Close the LN 2<br />

specimen Dewar<br />

drawer<br />

Fill the specimen<br />

Dewar with LN 2 or<br />

position the specimen<br />

Dewar firmly against<br />

the metal holder<br />

Place the specimen<br />

Dewar in the drawer<br />

and fill with LN 2<br />

Open the safety cover.<br />

Remove the lost<br />

cartridge pieces from<br />

the process chamber<br />

or the rotor.<br />

In the event other error messages appear on your <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> touch screen,<br />

please contact your local service representative.<br />

Page 54 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

8. Appendix I<br />

Numbers show dimensions in millimeters.<br />

Page 55 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

Numbers show dimensions in millimeters.<br />

Page 56 <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong> Operating Manual Version 12/10

EC Declaration<br />

EC Declaration of Conformity<br />

EG Konformitäts-Erklärung<br />

Déclaration CE de Conformité<br />

We/Wir/Nous<br />

<strong>Leica</strong> Mikrosysteme GmbH<br />

Hernalser Hauptstrasse 219<br />

A-1170 Wien, Austria<br />

declare in exclusive responsibility that the product<br />

erklären in alleiniger Verantwortung, dass das Produkt<br />

déclarons sous notre seule responsabilité que le produit<br />

Model<br />

Modell<br />

modèle<br />

<strong>EM</strong> <strong>HPM100</strong><br />

<strong>EM</strong> <strong>HPM100</strong><br />

<strong>EM</strong> <strong>HPM100</strong><br />

Type/Typenbezeichnung/type<br />

<strong>HPM100</strong><br />

to which this declaration relates is in conformity with the following standards:<br />

auf das sich diese Erklärung bezieht, mit den folgenden Normen übereinstimmt:<br />

auquel se réfère cette déclaration est conforme aux normes :<br />

EN 61010-1<br />

EN 61326-1<br />

following the provisions of directive<br />

gemäss den Bestimmungen der Richtlinie<br />

conformément aux dispositions de directive<br />

2004/108/EC<br />

2006/95/EC<br />

2006/42/EC<br />

87/404/EWG<br />

(Electromagnetic compatibility)<br />

(Elektromagnetische Verträglichkeit)<br />

(Low Voltage Equipment)<br />

(Niederspannungsrichtlinie)<br />

(Machinery)<br />

(Maschinen)<br />

(Pressure Vessel)<br />

(Druckbehälter)<br />

Wien, 15. Februar 2008<br />

Dr. Reinhard Lihl<br />

Entwicklungsleiter<br />

R & D Manager<br />

Chef du service développement<br />

<strong>Leica</strong> Microsysteme GmbH Tel. +43 1 48899<br />

Hernalser Hauptstrasse 219 Fax +43 1 48899-350<br />

A-1170 Wien www.leica-microsystems.com

Minutes<br />

LMS Holdings GmbH Tel. +49(0)6441/29-2327<br />

Ernst-Leitz-Strasse 17-37 Fax +49(0)6441/29-2211<br />

D-35578 Wetzlar www.leica-microsystems.com

www.leica-microsystems.com<br />

Copyright © <strong>Leica</strong> Mikrosysteme GmbH, Hernalser Hauptstrasse 219, 1170 Vienna, Austria · Tel. +43 1 48899, Fax +43 1 48899350 LEICA and the <strong>Leica</strong> logos are registered trademarks of Leic IR GmbH.<br />

Order nos. of the editions in: Operating Manual <strong>Leica</strong> <strong>EM</strong> <strong>HPM100</strong>, Version 167120032 12/10 Printed on chlorine-free bleached paper.