DTC P0107, P0108 5.19 - harley-davidson-sweden.se

DTC P0107, P0108 5.19 - harley-davidson-sweden.se

DTC P0107, P0108 5.19 - harley-davidson-sweden.se

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

7<br />

HOME<br />

<strong>DTC</strong> <strong>P0107</strong>, <strong>P0108</strong> <strong>5.19</strong><br />

GENERAL<br />

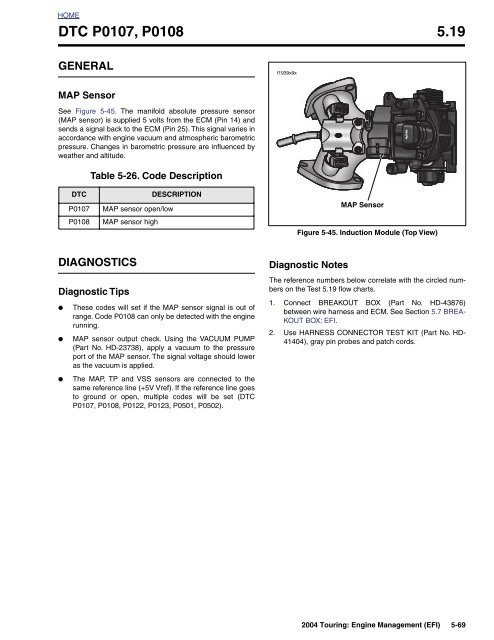

f1939x9x<br />

MAP Sensor<br />

See Figure 5-45. The manifold absolute pressure <strong>se</strong>nsor<br />

(MAP <strong>se</strong>nsor) is supplied 5 volts from the ECM (Pin 14) and<br />

<strong>se</strong>nds a signal back to the ECM (Pin 25). This signal varies in<br />

accordance with engine vacuum and atmospheric barometric<br />

pressure. Changes in barometric pressure are influenced by<br />

weather and altitude.<br />

Table 5-26. Code Description<br />

<strong>DTC</strong><br />

<strong>P0107</strong><br />

<strong>P0108</strong><br />

MAP <strong>se</strong>nsor open/low<br />

MAP <strong>se</strong>nsor high<br />

DESCRIPTION<br />

MAP Sensor<br />

Figure 5-45. Induction Module (Top View)<br />

DIAGNOSTICS<br />

Diagnostic Tips<br />

●<br />

●<br />

●<br />

The<strong>se</strong> codes will <strong>se</strong>t if the MAP <strong>se</strong>nsor signal is out of<br />

range. Code <strong>P0108</strong> can only be detected with the engine<br />

running.<br />

MAP <strong>se</strong>nsor output check. Using the VACUUM PUMP<br />

(Part No. HD-23738), apply a vacuum to the pressure<br />

port of the MAP <strong>se</strong>nsor. The signal voltage should lower<br />

as the vacuum is applied.<br />

The MAP, TP and VSS <strong>se</strong>nsors are connected to the<br />

same reference line (+5V Vref). If the reference line goes<br />

to ground or open, multiple codes will be <strong>se</strong>t (<strong>DTC</strong><br />

<strong>P0107</strong>, <strong>P0108</strong>, P0122, P0123, P0501, P0502).<br />

Diagnostic Notes<br />

The reference numbers below correlate with the circled numbers<br />

on the Test <strong>5.19</strong> flow charts.<br />

1. Connect BREAKOUT BOX (Part No. HD-43876)<br />

between wire harness and ECM. See Section 5.7 BREA-<br />

KOUT BOX: EFI.<br />

2. U<strong>se</strong> HARNESS CONNECTOR TEST KIT (Part No. HD-<br />

41404), gray pin probes and patch cords.<br />

2004 Touring: Engine Management (EFI) 5-69

HOME<br />

f1743q9s<br />

MAP<br />

Sensor<br />

[80A]<br />

A B C<br />

[80B]<br />

A<br />

B<br />

C<br />

BK/W<br />

V/W<br />

R/W<br />

To TP, ET &<br />

IAT Sensors<br />

To TP and<br />

VSS <strong>se</strong>nsors<br />

V/W<br />

R/W<br />

BK/W<br />

[78B]<br />

[78A]<br />

ECM<br />

14 25 26<br />

Figure 5-46. MAP Sensor Circuit<br />

Table 5-27. Wire Harness Connectors in Figure 5-46.<br />

NO. DESCRIPTION TYPE LOCATION<br />

[78] ECM 36-Place Packard Under Right Side Cover<br />

[80] MAP Sensor 3-Place Packard Top of Induction Module<br />

5-70 2004 Touring: Engine Management (EFI)

HOME<br />

Test <strong>5.19</strong> (Part 1 of 2)<br />

MAP SENSOR: <strong>DTC</strong> <strong>P0107</strong>, <strong>P0108</strong><br />

1<br />

Connect Breakout Box. With ignition ON,<br />

measure voltage between terminal 25<br />

and terminal 26 on Breakout Box.<br />

With key ON, engine OFF, voltage must be<br />

between 3.5 and 5.0 volts.<br />

With key ON, engine running, voltage must<br />

be between 1.5-3.0 volts at hot idle.<br />

Does voltage fit specifications<br />

YES<br />

NO<br />

Perform 5.8 WIGGLE TEST<br />

to check for intermittents.<br />

Intermittents pre<strong>se</strong>nt<br />

STOP<br />

Go to Test <strong>5.19</strong> (Part 2 of 2).<br />

YES<br />

NO<br />

To identify the source of intermittents,<br />

start with box marked by Bold Asterisk<br />

under Test <strong>5.19</strong> (Part 2 of 2). Wiggle<br />

harness while watching DVOM.<br />

Replace MAP <strong>se</strong>nsor. Clear codes and road<br />

test. Did check engine lamp illuminate and<br />

<strong>se</strong>t <strong>DTC</strong> <strong>P0107</strong> or <strong>P0108</strong><br />

YES<br />

NO<br />

Install original MAP <strong>se</strong>nsor.<br />

Replace ECM (reprogram,<br />

relearn) and road test again<br />

to verify.<br />

System<br />

now OK.<br />

At some point in the flow chart you<br />

may be instructed to jump directly<br />

to a the box with the bold asterisk.<br />

Disregard the asterisk (but not the<br />

instruction box) if your normal progression<br />

through the chart brings<br />

you to this location.<br />

Clear codes using speedometer <strong>se</strong>lf diagnostics.<br />

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.<br />

Confirm proper operation with no check engine<br />

lamp.<br />

2004 Touring: Engine Management (EFI) 5-71

HOME<br />

Test <strong>5.19</strong> (Part 2 of 2)<br />

MAP SENSOR: <strong>DTC</strong> <strong>P0107</strong>, <strong>P0108</strong><br />

Continued from<br />

Test <strong>5.19</strong> (Part 1 of 2).<br />

2<br />

Check the 5 volt reference supply at<br />

the MAP <strong>se</strong>nsor connector [80B]. With<br />

ignition ON, measure voltage between<br />

terminal C (R/W) and terminal A (BK/W).<br />

Voltage approximately 5.0 volts<br />

YES<br />

NO.<br />

Greater<br />

than 6V.<br />

NO.<br />

Less<br />

than 4.5V.<br />

2<br />

Connect Breakout Box to connector [78B]<br />

leaving ECM disconnected.<br />

OPEN CHECK: Measure resistance<br />

between MAP connector [80B]<br />

Terminal B and Breakout Box terminal 25.<br />

Resistance less than 1 ohm<br />

Locate short to 12 volts on R/W<br />

wire in wire harness. Repair as<br />

necessary.<br />

2<br />

Connect Breakout Box to connector [78B]<br />

leaving ECM disconnected.<br />

Check continuity between MAP connector<br />

[80B] Terminal C and Breakout Box<br />

terminal 14. Then measure continuity<br />

between MAP connector [80B] Terminal A<br />

and Breakout Box terminal 26.<br />

Resistance less than 1 ohm<br />

YES<br />

NO<br />

2<br />

SHORT CHECK: Measure<br />

resistance between MAP connector<br />

Terminal B and chassis<br />

ground. Resistance greater<br />

than 1 megohm<br />

Locate and repair<br />

open on V/W wire.<br />

YES<br />

NO<br />

YES<br />

NO<br />

Check resistance between<br />

MAP connector [80B]<br />

Terminal C and<br />

Breakout Box terminal 26.<br />

Resistance greater than<br />

1 megohm<br />

Repair<br />

open wire.<br />

Replace MAP <strong>se</strong>nsor. See<br />

Touring Service Manual.<br />

Locate and repair<br />

grounded V/W wire.<br />

YES<br />

NO<br />

Replace ECM.<br />

Reprogram and learn<br />

password.<br />

Locate and repair<br />

short between<br />

R/W and BK/W<br />

wires.<br />

Clear codes using speedometer <strong>se</strong>lf diagnostics.<br />

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.<br />

Confirm proper operation with no check engine<br />

lamp.<br />

At some point in the flow chart you<br />

may be instructed to jump directly<br />

to a the box with the bold asterisk.<br />

Disregard the asterisk (but not the<br />

instruction box) if your normal progression<br />

through the chart brings<br />

you to this location.<br />

5-72 2004 Touring: Engine Management (EFI)

HOME<br />

<strong>DTC</strong> P0112, P0113 5.20<br />

GENERAL<br />

DIAGNOSTICS<br />

IAT Sensor<br />

The ECM supplies and monitors a voltage signal (terminal 7)<br />

to one side of the intake air temperature <strong>se</strong>nsor (IAT <strong>se</strong>nsor).<br />

The other side of the IAT <strong>se</strong>nsor is connected to a common<br />

<strong>se</strong>nsor ground, which is also connected to the ECM (terminal<br />

26).<br />

The IAT <strong>se</strong>nsor is a thermistor device, meaning that at a specific<br />

temperature, it will have a specific resistance across its<br />

terminals. As this resistance varies, so does the voltage on<br />

(terminal 7).<br />

●<br />

At high temperatures, the resistance of the <strong>se</strong>nsor is very<br />

low, which effectively lowers the signal voltage on terminal<br />

7.<br />

● At low temperatures, the resistance is very high, allowing<br />

the voltage to ri<strong>se</strong> clo<strong>se</strong> to 5 volts.<br />

The ECM monitors this voltage to compensate for various<br />

operating conditions.<br />

<strong>DTC</strong><br />

P0112<br />

P0113<br />

Table 5-28. Code Description<br />

DESCRIPTION<br />

IAT <strong>se</strong>nsor voltage low<br />

IAT <strong>se</strong>nsor open/high<br />

Table 5-29. IAT Sensor Table<br />

TEMP °C RESISTANCE VOLTAGE TEMP °F<br />

-20 29121 4.9 -4<br />

-10 16599 4.8 14<br />

0 9750 4.6 32<br />

10 5970 4.3 50<br />

20 3747 4.0 68<br />

25 3000 3.8 77<br />

30 2417 3.6 86<br />

40 1598 3.1 104<br />

50 1080 2.6 122<br />

60 746 2.2 140<br />

70 526 1.7 158<br />

80 377 1.4 176<br />

90 275 1.1 194<br />

100 204 0.9 212<br />

Diagnostic Tips<br />

An intermittent may be cau<strong>se</strong>d by a poor connection, rubbed<br />

through wire insulation or a wire broken inside the insulation.<br />

Check the following conditions:<br />

●<br />

●<br />

●<br />

Poor connection: Inspect ECM and harness connector<br />

[78] for backed out terminals, improper mating, broken<br />

locks, improperly formed or damaged terminals, poor terminal-to-wire<br />

connection and damaged harness.<br />

Perform 5.8 WIGGLE TEST to locate intermittents: If<br />

connections and harness check out OK, u<strong>se</strong> a DVOM to<br />

check the intake air temperature <strong>se</strong>nsor voltage reading<br />

while moving related connectors and wiring harness. If<br />

the failure is induced, the intake air temperature <strong>se</strong>nsor<br />

voltage reading will change.<br />

Shifted <strong>se</strong>nsor: Refer to Table 5-29. This table may be<br />

u<strong>se</strong>d to test the intake air temperature <strong>se</strong>nsor at various<br />

temperature levels in order to evaluate the possibility of a<br />

shifted (out-of-calibration) <strong>se</strong>nsor which may result in<br />

driveability problems.<br />

NOTE<br />

All voltage and resistance values are approximate (±20%).<br />

Measure IAT <strong>se</strong>nsor resistance between ECM Terminal 7 and<br />

system ground (ECM Terminal 26).<br />

Diagnostic Notes<br />

The reference numbers below correlate with the circled numbers<br />

on the Test 5.20 flow charts.<br />

1. Connect BREAKOUT BOX (Part No. HD-43876) to EFI<br />

wire harness only (leave ECM disconnected). See 5.7<br />

BREAKOUT BOX: EFI.<br />

2. U<strong>se</strong> HARNESS CONNECTOR TEST KIT (Part No. HD-<br />

41404), gray pin probes and patch cords.<br />

3. U<strong>se</strong> HARNESS CONNECTOR TEST KIT (Part No. HD-<br />

41404), gray socket probes and patch cords.<br />

4. Replace IAT <strong>se</strong>nsor. See Touring Service Manual.<br />

2004 Touring: Engine Management (EFI) 5-73

HOME<br />

f1743r9s<br />

IAT<br />

Sensor<br />

[89A]<br />

A B<br />

[89B]<br />

A<br />

B<br />

Lt GN/Y<br />

BK/W<br />

To TP, ET &<br />

MAP Sensors<br />

Lt GN/Y<br />

BK/W<br />

[78B]<br />

[78A]<br />

ECM<br />

7 26<br />

Figure 5-47. IAT Sensor Circuit<br />

Table 5-30. Wire Harness Connectors in Figure 5-47.<br />

NO. DESCRIPTION TYPE LOCATION<br />

[78] ECM 36-Place Packard Under Right Side Cover<br />

[89] IAT Sensor 2-Place Packard Below Fuel Tank (Right Side)<br />

5-74 2004 Touring: Engine Management (EFI)

HOME<br />

Test 5.20 (Part 1 of 2)<br />

IAT SENSOR: <strong>DTC</strong> P0112, P0113<br />

1<br />

Connect Breakout Box to connector [78B] leaving<br />

ECM disconnected. With engine at room temperature<br />

(60-90° F or 16-32° C), u<strong>se</strong> a DVOM to measure<br />

resistance across terminals 7 and 26 on Breakout<br />

Box. If engine is warm, refer to Table 5-29.<br />

Resistance between 2.0k ohms and 5.0k ohms at<br />

room temperature<br />

YES<br />

NO<br />

Connect ECM to Breakout Box.<br />

Perform 5.8 WIGGLE TEST to check for<br />

intermittents. Intermittents pre<strong>se</strong>nt<br />

STOP<br />

Go to Test 5.20 (Part 2 of 2).<br />

YES<br />

NO<br />

While wiggling harness, perform<br />

steps marked by BOLD ASTER-<br />

ISKS under Test 5.20 (Part 2 of 2).<br />

Repair as necessary.<br />

Disconnect IAT <strong>se</strong>nsor connector [89].<br />

Turn ignition ON. Using a DVOM, measure<br />

the voltage<br />

between ECM terminal 7 (positive) and<br />

terminal 26 (negative) on Breakout Box.<br />

Voltage approximately 5 volts<br />

YES<br />

NO.<br />

Less than<br />

4.7 volts.<br />

NO.<br />

Greater than<br />

5.3 volts.<br />

Replace IAT <strong>se</strong>nsor, clear codes and<br />

road test. Did check engine lamp illuminate<br />

and <strong>se</strong>t <strong>DTC</strong> P0112 or<br />

P0113<br />

1<br />

With IAT <strong>se</strong>nsor disconnected,<br />

disconnect ECM from breakout box.<br />

Measure resistance between<br />

Breakout Box terminal 7 and terminals<br />

10 or 28.<br />

Resistance less than 1 megohm<br />

1<br />

Unplug ECM leaving Breakout Box connected<br />

at vehicle harness.<br />

Measure voltage between<br />

Breakout Box terminal 7 and terminals 10<br />

or 28.<br />

Voltage 0 volts<br />

YES<br />

NO<br />

YES<br />

NO<br />

YES<br />

NO<br />

Install original IAT<br />

<strong>se</strong>nsor, replace ECM,<br />

perform password<br />

learning and road test.<br />

System<br />

OK.<br />

Repair short to<br />

ground on<br />

Lt GN/Y wire.<br />

Replace ECM.<br />

Reprogram and<br />

learn password.<br />

Replace ECM.<br />

Reprogram and<br />

learn password.<br />

Examine IAT signal<br />

wire (Lt GN/Y)<br />

for short to voltage<br />

and repair.<br />

Clear codes using speedometer <strong>se</strong>lf diagnostics.<br />

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.<br />

Confirm proper operation with no check engine<br />

lamp.<br />

At some point in the flow chart you<br />

may be instructed to jump directly<br />

to a the box with the bold asterisk.<br />

Disregard the asterisk (but not the<br />

instruction box) if your normal progression<br />

through the chart brings<br />

you to this location.<br />

2004 Touring: Engine Management (EFI) 5-75

HOME<br />

Test 5.20 (Part 2 of 2)<br />

IAT SENSOR: <strong>DTC</strong> P0112, P0113<br />

Continued from<br />

Test 5.20 (Part 1 of 2).<br />

Disconnect IAT <strong>se</strong>nsor connector [89B] and<br />

examine for damage. Connector OK<br />

YES<br />

NO<br />

2<br />

Using a DVOM, measure the resistance<br />

between IAT <strong>se</strong>nsor connector [89B]<br />

Terminal A and ECM terminal 7 on Breakout<br />

Box. Resistance less than 1.0 ohm<br />

Repair<br />

connector.<br />

YES<br />

NO<br />

2<br />

Using a DVOM, measure the resistance<br />

between IAT <strong>se</strong>nsor connector [89B]<br />

Terminal B and ECM terminal 26 on Breakout<br />

Box. Resistance less than 1.0 ohm<br />

Examine Lt GN/Y wire in<br />

harness for open circuit<br />

and repair.<br />

YES<br />

NO<br />

Using a DVOM, measure the resistance<br />

between ECM terminal 7 and terminal 26 on<br />

Breakout Box. Resistance greater<br />

than 1.0 megohm<br />

Examine BK/W wire in<br />

harness for open circuit<br />

and repair.<br />

YES<br />

NO<br />

Using a DVOM, measure the resistance<br />

between ECM terminal 7 on Breakout Box<br />

and ground. Resistance greater<br />

than 1.0 megohm<br />

Examine Lt GN/Y and<br />

BK/W wires in harness<br />

for short between the<strong>se</strong><br />

two circuits and repair.<br />

YES<br />

NO<br />

3<br />

Remove IAT <strong>se</strong>nsor and measure resistance<br />

across the terminals of the IAT <strong>se</strong>nsor<br />

directly. Again, with <strong>se</strong>nsor at room temperature<br />

60-90° F or 16-32° C), is resistance<br />

between 2.0k ohms and 5.0k ohms<br />

Examine harness for<br />

short to ground and<br />

repair.<br />

YES<br />

Perform 5.8 WIGGLE TEST on steps<br />

marked with a BOLD ASTERISK above to<br />

locate intermittents. Repair as necessary.<br />

4<br />

NO<br />

Replace<br />

IAT <strong>se</strong>nsor.<br />

At some point in the flow chart you<br />

may be instructed to jump directly<br />

to a the box with the bold asterisk.<br />

Disregard the asterisk (but not the<br />

instruction box) if your normal progression<br />

through the chart brings<br />

you to this location.<br />

Clear codes using speedometer <strong>se</strong>lf diagnostics.<br />

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.<br />

Confirm proper operation with no check engine<br />

lamp.<br />

5-76 2004 Touring: Engine Management (EFI)

HOME<br />

<strong>DTC</strong> P0117, P0118 5.21<br />

GENERAL<br />

ET Sensor<br />

The ECM supplies and monitors a voltage signal (terminal 6)<br />

to one side of the engine temperature <strong>se</strong>nsor (ET <strong>se</strong>nsor).<br />

The other side of the ET <strong>se</strong>nsor is connected to a common<br />

<strong>se</strong>nsor ground (terminal 26) of the ECM.<br />

The ET <strong>se</strong>nsor is a thermistor device, which means that at a<br />

specific temperature it will have a specific resistance across<br />

its terminals. As this resistance varies, so does the voltage<br />

(terminal 6).<br />

●<br />

At high temperatures, the resistance of the <strong>se</strong>nsor is very<br />

low, which effectively lowers the signal voltage on terminal<br />

6.<br />

● At low temperatures, the resistance is very high, allowing<br />

the voltage to ri<strong>se</strong> clo<strong>se</strong> to 5 volts.<br />

The ECM monitors this voltage to compensate for various<br />

operating conditions. The ECM also u<strong>se</strong>s the <strong>se</strong>nsor input as<br />

a reference for determining IAC pintle position.<br />

<strong>DTC</strong><br />

P0117<br />

P0118<br />

Table 5-31. Code Description<br />

DESCRIPTION<br />

ET <strong>se</strong>nsor voltage low<br />

ET <strong>se</strong>nsor open/high<br />

Table 5-32. ET Sensor Table<br />

TEMP °C RESISTANCE VOLTAGE TEMP °F<br />

-20 28144 4.4 -4<br />

-10 15873 4.0 14<br />

0 9255 3.5 32<br />

10 5571 3.0 50<br />

20 3457 2.4 68<br />

25 2750 2.1 77<br />

30 2205 1.8 86<br />

40 1442 1.3 or 4.1* 104<br />

50 965 1.0 or 3.7* 122<br />

60 661 3.3 140<br />

70 462 2.9 158<br />

80 329 2.5 176<br />

90 238 2.1 194<br />

100 175 1.7 212<br />

DIAGNOSTICS<br />

Diagnostic Tips<br />

●<br />

●<br />

Once the engine is started, the ET voltage should ri<strong>se</strong><br />

steadily.<br />

An intermittent may be cau<strong>se</strong>d by a poor connection,<br />

rubbed through wire insulation or a wire broken inside<br />

the insulation.<br />

Check the following conditions:<br />

●<br />

●<br />

●<br />

Poor connection: Inspect ECM and harness connector<br />

[78] for backed out terminals, improper mating, broken<br />

locks, improperly formed or damaged terminals, poor terminal-to-wire<br />

connection and damaged harness.<br />

Perform 5.8 WIGGLE TEST to locate intermittents: If<br />

connections and harness check out OK, u<strong>se</strong> a DVOM to<br />

check the engine temperature <strong>se</strong>nsor voltage reading<br />

while moving related connectors and wiring harness. If<br />

the failure is induced, the engine temperature <strong>se</strong>nsor<br />

voltage reading will change.<br />

Shifted <strong>se</strong>nsor: Refer to Table 5-32. This table may be<br />

u<strong>se</strong>d to test the engine temperature <strong>se</strong>nsor at various<br />

temperature levels in order to evaluate the possibility of a<br />

shifted (out-of-calibration) <strong>se</strong>nsor which may result in<br />

driveability problems.<br />

NOTE<br />

All voltage and resistance values are approximate (±20%).<br />

Measure ET <strong>se</strong>nsor resistance between ECM Terminal 6 and<br />

system ground (ECM Terminal 26).<br />

Diagnostic Notes<br />

The reference numbers below correlate with the circled numbers<br />

on the Test 5.21 flow charts.<br />

1. Connect BREAKOUT BOX (Part No. HD-43876) to EFI<br />

wire harness only (leave ECM disconnected). See 5.7<br />

BREAKOUT BOX: EFI.<br />

2. U<strong>se</strong> HARNESS CONNECTOR TEST KIT (Part No. HD-<br />

41404), gray pin probes and patch cords.<br />

3. U<strong>se</strong> HARNESS CONNECTOR TEST KIT (Part No. HD-<br />

41404), gray socket probes and patch cords.<br />

4. Replace ET <strong>se</strong>nsor. See Touring Service Manual.<br />

* Between 40-50°C the ECM changes scaling. Voltages for ECT<br />

<strong>se</strong>nsor will shift scales in that range. This provides proper <strong>se</strong>nsor resolution<br />

for all temperatures.<br />

2004 Touring: Engine Management (EFI) 5-77

HOME<br />

f1743s9s<br />

ET<br />

Sensor<br />

[90A]<br />

[90B]<br />

A<br />

A<br />

B<br />

B<br />

PK/Y<br />

BK/W<br />

To TP, IAT &<br />

MAP Sensors<br />

PK/Y<br />

BK/W<br />

[78B]<br />

[78A]<br />

ECM<br />

6 26<br />

Figure 5-48. ET Sensor Circuit<br />

Table 5-33. Wire Harness Connectors in Figure 5-48.<br />

NO. DESCRIPTION TYPE LOCATION<br />

[78] ECM 36-Place Packard Under Right Side Cover<br />

[90] ET Sensor 2-Place Packard Back of Front Cylinder (Left Side)<br />

5-78 2004 Touring: Engine Management (EFI)

HOME<br />

Test 5.21 (Part 1 of 2)<br />

ET SENSOR: <strong>DTC</strong> P0117, P0118<br />

1<br />

Connect Breakout Box to connector [78B]<br />

leaving ECM disconnected. With engine at<br />

room temperature (60-90° F or 16-32° C),<br />

u<strong>se</strong> a DVOM to measure resistance across<br />

terminals 6 and 26 on Breakout Box. If<br />

engine is warm, refer to Table 5-32. Resistance<br />

between 2.0k ohms and 5.0k ohms<br />

YES<br />

NO<br />

Connect ECM to Breakout Box.<br />

Perform 5.8 WIGGLE TEST to check for<br />

intermittents. Intermittents pre<strong>se</strong>nt<br />

STOP<br />

Go to Test 5.21 (Part 2 of 2).<br />

YES<br />

NO<br />

While wiggling harness, perform<br />

steps marked by BOLD ASTER-<br />

ISKS under Test 5.21 (Part 2 of 2).<br />

Repair as necessary.<br />

Disconnect ET <strong>se</strong>nsor connector [90].<br />

Turn ignition ON. Using a DVOM, measure<br />

the voltage between<br />

terminal 6 (positive) and<br />

terminal 26 (negative) on Breakout Box.<br />

Voltage approximately 5 volts<br />

YES<br />

NO.<br />

Less than<br />

4.7 volts.<br />

NO.<br />

Greater than<br />

5.3 volts.<br />

Replace ET <strong>se</strong>nsor, clear codes and<br />

road test. Did check engine lamp illuminate<br />

and <strong>se</strong>t <strong>DTC</strong> P0117 or<br />

P0118<br />

With ET <strong>se</strong>nsor disconnected,<br />

disconnect ECM connector [78B].<br />

Measure resistance between<br />

terminal 6 and terminals 10 or 28.<br />

Resistance less than 1 megohm<br />

Unplug ECM leaving Breakout Box<br />

connected at vehicle harness.<br />

Measure voltage between<br />

terminal 6 and terminals 10 or 28.<br />

Voltage 0 volts<br />

YES<br />

NO<br />

YES<br />

NO<br />

YES<br />

NO<br />

Install original<br />

ET <strong>se</strong>nsor,<br />

replace ECM, perform<br />

password learning<br />

and road test.<br />

System<br />

OK.<br />

Repair short to<br />

ground on<br />

PK/Y wire.<br />

Replace ECM.<br />

Reprogram and<br />

learn password.<br />

Replace ECM.<br />

Reprogram and<br />

learn password.<br />

Examine ET signal<br />

wire (PK/Y) for<br />

short to voltage<br />

and repair.<br />

Clear codes using speedometer <strong>se</strong>lf diagnostics.<br />

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.<br />

Confirm proper operation with no check engine<br />

lamp.<br />

At some point in the flow chart you<br />

may be instructed to jump directly<br />

to a the box with the bold asterisk.<br />

Disregard the asterisk (but not the<br />

instruction box) if your normal progression<br />

through the chart brings<br />

you to this location.<br />

2004 Touring: Engine Management (EFI) 5-79

HOME<br />

Test 5.21 (Part 2 of 2)<br />

ET SENSOR: <strong>DTC</strong> P0117, P0118<br />

Continued from<br />

Test 5.21 (Part 1 of 2).<br />

Disconnect ET <strong>se</strong>nsor connector [90B] and<br />

examine for damage. Connector OK<br />

YES<br />

NO<br />

2<br />

Using a DVOM, measure the resistance<br />

between ET <strong>se</strong>nsor connector [90B]<br />

Terminal A and ECM terminal 6 on Breakout<br />

Box. Resistance less than 1.0 ohm<br />

Repair<br />

connector.<br />

YES<br />

NO<br />

2<br />

Using a DVOM, measure the resistance<br />

between ET <strong>se</strong>nsor connector [90B]<br />

Terminal B and ECM terminal 26 on Breakout<br />

Box. Resistance less than 1.0 ohm<br />

Examine PK/Y wire in<br />

harness for open circuit<br />

and repair.<br />

YES<br />

NO<br />

Using a DVOM, measure the resistance<br />

between ECM terminal 6 and terminal 26 on<br />

Breakout Box. Resistance greater<br />

than 1.0 megohm<br />

Examine BK/W wire in<br />

harness for open circuit<br />

and repair.<br />

YES<br />

NO<br />

Using a DVOM, measure the resistance<br />

between ECM terminal 6 on Breakout Box<br />

and ground. Resistance greater<br />

than 1.0 megohm<br />

YES<br />

Examine PK/Y and<br />

BK/W wires in harness<br />

for short between the<strong>se</strong><br />

two circuits and repair.<br />

NO<br />

At some point in the flow chart<br />

you may be instructed to jump<br />

directly to a the box with the bold<br />

asterisk. Disregard the asterisk<br />

(but not the instruction box) if your<br />

normal progression through the<br />

chart brings you to this location.<br />

3<br />

Remove ET <strong>se</strong>nsor and measure resistance<br />

across the terminals of the ET <strong>se</strong>nsor<br />

directly. Again, with <strong>se</strong>nsor at room temperature<br />

(60-90° F or 16-32° C), is resistance<br />

between 2.0k ohms and 5.0k ohms<br />

Examine harness for<br />

short to ground and<br />

repair.<br />

YES<br />

NO<br />

Perform 5.8 WIGGLE TEST on steps<br />

marked with a BOLD ASTERISK above to<br />

locate intermittents. Repair as necessary.<br />

Replace<br />

4<br />

ET <strong>se</strong>nsor.<br />

Clear codes using speedometer <strong>se</strong>lf diagnostics.<br />

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.<br />

Confirm proper operation with no check engine<br />

lamp.<br />

5-80 2004 Touring: Engine Management (EFI)

HOME<br />

<strong>DTC</strong> P0122, P0123 5.22<br />

GENERAL<br />

TP Sensor<br />

The ECM supplies a 5 volt signal (terminal 14) to the throttle<br />

position <strong>se</strong>nsor (TP <strong>se</strong>nsor). The TP <strong>se</strong>nsor <strong>se</strong>nds a signal<br />

back to the ECM (terminal 24). The returned signal varies in<br />

voltage according to throttle position.<br />

●<br />

At idle (clo<strong>se</strong>d throttle), the signal is typically in the range<br />

of 0.20-0.80 volts.<br />

● At wide open throttle, the signal is normally 4.0-4.9 volts.<br />

A code P0122 or P0123 will <strong>se</strong>t if the TP <strong>se</strong>nsor voltage signal<br />

does not fall within the acceptable range.<br />

●<br />

Check TP <strong>se</strong>nsor voltage reading with DVOM. If TP <strong>se</strong>nsor<br />

is equal to or greater than 3.8 volts then the system is<br />

in “clear flood” mode and engine will not start. While<br />

spark is pre<strong>se</strong>nt, fuel is shut off. Problem can be<br />

mechanical, such as stuck throttle cables.<br />

<strong>DTC</strong><br />

P0122<br />

P0123<br />

Table 5-34. Code Description<br />

DIAGNOSTICS<br />

Diagnostic Tips<br />

TP <strong>se</strong>nsor open/low<br />

TP <strong>se</strong>nsor high<br />

DESCRIPTION<br />

The DVOM reads throttle position in volts. Voltage should<br />

increa<strong>se</strong> at a steady rate as the throttle is moved from idle to<br />

wide open. A short to ground or open on the GY/V or R/W<br />

wires also will result in a <strong>DTC</strong> P0122. A short to ground or<br />

open on the R/W wire (+5v REF) <strong>se</strong>ts multiple codes as<br />

described below.<br />

Check for the following conditions:<br />

●<br />

●<br />

●<br />

Poor Connection: Inspect ECM and harness connector<br />

[78B] for backed out terminals, improper mating, broken<br />

locks, improperly formed or damaged terminals, poor terminal-to-wire<br />

connection and damaged harness.<br />

Perform 5.8 WIGGLE TEST to locate intermittents: If<br />

connections and harness check out OK, monitor TP <strong>se</strong>nsor<br />

voltage using a DVOM while moving related connectors<br />

and wiring harness. If the failure is induced, the TP<br />

<strong>se</strong>nsor voltage reading will change.<br />

TP <strong>se</strong>nsor scaling: Ob<strong>se</strong>rve the TP <strong>se</strong>nsor voltage display<br />

while opening the throttle with engine stopped and<br />

ignition key ON. Display should vary from clo<strong>se</strong>d throttle<br />

TP <strong>se</strong>nsor voltage (when throttle is clo<strong>se</strong>d) to greater<br />

than 4.0 volts (when throttle is held wide open). As the<br />

throttle is slowly moved, the voltage should change<br />

gradually without spikes or low voltages being ob<strong>se</strong>rved.<br />

Diagnostic Notes<br />

The reference numbers below correlate with the circled numbers<br />

on the Test 5.22 flow charts.<br />

1. Connect a BREAKOUT BOX (Part No. HD-43876)<br />

between EFI wire harness and ECM before measuring<br />

voltage. See 5.7 BREAKOUT BOX: EFI. If using a DVOM<br />

to measure voltage, take reading across terminal 24<br />

(positive lead) and terminal 26 (negative lead) on Breakout<br />

Box.<br />

2. Replace TP <strong>se</strong>nsor. See Touring Service Manual.<br />

3. U<strong>se</strong> HARNESS CONNECTOR TEST KIT (Part No. HD-<br />

41404), gray pin probes and patch cords.<br />

NOTE<br />

The MAP, TP and VSS <strong>se</strong>nsors are connected to the same<br />

reference line (+5V Vref). If the reference line goes to ground<br />

or open, multiple codes will be <strong>se</strong>t (<strong>DTC</strong> <strong>P0107</strong>, <strong>P0108</strong>,<br />

P0122, P0123, P0501, P0502). Start with the trouble code<br />

having the lowest ranking value.<br />

2004 Touring: Engine Management (EFI) 5-81

HOME<br />

s0452x9x<br />

TP<br />

<strong>se</strong>nsor<br />

[88A]<br />

A B C<br />

[88B]<br />

A<br />

BK/W<br />

B<br />

R/W<br />

C<br />

To MAP, ET &<br />

IAT <strong>se</strong>nsors<br />

To MAP<br />

<strong>se</strong>nsor<br />

R/W<br />

GY/V<br />

BK/W<br />

GY/V<br />

[78B]<br />

[78A]<br />

ECM<br />

14 24 26<br />

Figure 5-49. TP Sensor Circuit<br />

Table 5-35. Wire Harness Connectors in Figure 5-49.<br />

NO. DESCRIPTION TYPE LOCATION<br />

[78] ECM 36-Place Packard Under Right Side Cover<br />

[88] TP Sensor 3-Place Packard Below Fuel Tank (Right Side)<br />

5-82 2004 Touring: Engine Management (EFI)

HOME<br />

Test 5.22 (Part 1 of 2)<br />

TP SENSOR: <strong>DTC</strong> P0122, P0123<br />

1<br />

With ignition key ON, measure TP <strong>se</strong>nsor voltage while gradually<br />

opening throttle. Does voltage increa<strong>se</strong> steadily<br />

with no spikes or low voltages from 0.2-0.8 volts at idle<br />

(clo<strong>se</strong>d throttle) to 4.0-4.9 volts at wide open throttle<br />

YES<br />

NO<br />

Check engine lamp ON<br />

continuously and<br />

<strong>DTC</strong> P0122 or P0123<br />

the only one <strong>se</strong>t<br />

Voltage is<br />

greater than<br />

4.95 volts.<br />

STOP<br />

Go to Test 5.22 (Part 2 of 2).<br />

Low voltage<br />

or spikes<br />

ob<strong>se</strong>rved.<br />

Unplug TP <strong>se</strong>nsor connector [88B]<br />

and measure voltage between<br />

Terminal B (+) and Terminal A (-)<br />

with ignition ON.<br />

Is reading 4.8-5.0 volts<br />

YES<br />

NO<br />

YES<br />

NO<br />

Replace ECM.<br />

Reprogram and<br />

learn password.<br />

YES<br />

Perform 5.8 WIGGLE TEST<br />

to check for intermittents.<br />

Intermittents pre<strong>se</strong>nt<br />

NO<br />

Disconnect ECM from<br />

Breakout Box. Check<br />

resistance between ECM<br />

terminal 24 on Breakout<br />

Box to chassis ground.<br />

Greater than 1 megohm<br />

Measure<br />

resistance<br />

between<br />

TP <strong>se</strong>nsor<br />

connector [88B]<br />

Terminal B to<br />

ECM terminal 14<br />

on Breakout Box.<br />

Less than<br />

1.0 ohm<br />

While wiggling harness,<br />

start with the first step of<br />

Test 5.22 (Part 2 of 2)<br />

(marked by BOLD ASTER-<br />

ISK). Repair as necessary.<br />

2<br />

Replace TP <strong>se</strong>nsor, clear<br />

codes and road test.<br />

Did check engine lamp<br />

illuminate and <strong>se</strong>t <strong>DTC</strong><br />

P0122 or P0123<br />

2<br />

YES<br />

Replace<br />

TP <strong>se</strong>nsor.<br />

NO<br />

Find short to<br />

ground on GY/V<br />

signal wire.<br />

YES<br />

NO<br />

Install original<br />

TP <strong>se</strong>nsor, replace ECM<br />

(reprogram and learn<br />

password) and road test.<br />

System<br />

OK.<br />

YES<br />

Repair open<br />

in BK/W wire.<br />

NO<br />

Repair open<br />

in R/W wire.<br />

Clear codes using speedometer <strong>se</strong>lf diagnostics.<br />

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.<br />

Confirm proper operation with no check engine<br />

lamp.<br />

At some point in the flow chart you<br />

may be instructed to jump directly<br />

to a the box with the bold asterisk.<br />

Disregard the asterisk (but not the<br />

instruction box) if your normal progression<br />

through the chart brings<br />

you to this location.<br />

2004 Touring: Engine Management (EFI) 5-83

HOME<br />

Test 5.22 (Part 2 of 2)<br />

TP SENSOR: <strong>DTC</strong> P0122, P0123<br />

Continued from Test 5.22 (Part 1 of 2).<br />

With ignition key OFF, disconnect ECM connector [78B]. Turn<br />

ignition key ON. Voltage greater than 0 volts across terminal 24<br />

and terminal 26 on Breakout Box<br />

YES<br />

NO<br />

Repair short<br />

between GY/V signal<br />

wire and 12 volts.<br />

3<br />

Measure resistance between<br />

ECM terminal 24 on Breakout Box and<br />

TP <strong>se</strong>nsor connector [88B] Terminal C.<br />

Less than 0.5 ohm<br />

YES<br />

NO<br />

3<br />

Measure resistance from TP<br />

<strong>se</strong>nsor connector [88B]<br />

Terminal C to Terminal B.<br />

Less than 1.0 megohm<br />

Repair open<br />

GY/V<br />

signal wire.<br />

YES<br />

NO<br />

Repair short<br />

between R/W and<br />

GY/V signal wire.<br />

2<br />

Replace<br />

TP <strong>se</strong>nsor.<br />

Clear codes using speedometer <strong>se</strong>lf diagnostics.<br />

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.<br />

Confirm proper operation with no check engine<br />

lamp.<br />

At some point in the flow chart you<br />

may be instructed to jump directly<br />

to a the box with the bold asterisk.<br />

Disregard the asterisk (but not the<br />

instruction box) if your normal progression<br />

through the chart brings<br />

you to this location.<br />

5-84 2004 Touring: Engine Management (EFI)

HOME<br />

<strong>DTC</strong> P0261, P0262, P0263, P0264 5.23<br />

GENERAL<br />

s0472x9x<br />

Fuel Injectors<br />

The fuel injectors are solenoids that allow pressurized fuel<br />

into the intake tract. The injectors are timed to the engine<br />

cycle and triggered <strong>se</strong>quentially. The power for the injectors<br />

comes from the system relay. The system relay also provides<br />

power for the fuel pump and the ignition coil. The ECM provides<br />

the path to ground to trigger the injectors.<br />

NOTE<br />

ECM fu<strong>se</strong> and system relay failures or wiring harness problems<br />

will cau<strong>se</strong> 12 volt power to be lost to both injectors, ignition<br />

coils and fuel pump.<br />

Table 5-36. Code Description<br />

HD34730-2C<br />

Figure 5-50. Fuel Injector Connector<br />

<strong>DTC</strong><br />

DESCRIPTION<br />

P0261 Front injector open/low<br />

P0262 Front injector high<br />

P0263 Rear injector open/low<br />

P0264 Rear injector high<br />

DIAGNOSTICS<br />

Figure 5-51. Fuel Injector Test Lamp<br />

(Part No. HD-34730-2C)<br />

Diagnostic Notes<br />

The reference numbers below correlate with the circled numbers<br />

on the Test 5.23 flow charts.<br />

1. See Touring Service Manual for all <strong>se</strong>rvice information.<br />

2. U<strong>se</strong> HARNESS CONNECTOR TEST KIT (Part No. HD-<br />

41404), purple pin probe and patch cord.<br />

3. Connect a BREAKOUT BOX (Part No. HD-43876)<br />

between EFI wire harness and ECM. See 5.7 BREAK-<br />

OUT BOX: EFI.<br />

2004 Touring: Engine Management (EFI) 5-85

HOME<br />

f2208h8x<br />

[62B]<br />

System relay<br />

[78A]<br />

[78B]<br />

Y/GN<br />

BE/GY<br />

GN/O<br />

W/BK<br />

I Q C P R<br />

87<br />

87A<br />

30 85 86<br />

System relay<br />

Power gnd.<br />

Coil R<br />

Switch power<br />

ECM<br />

Inj. R<br />

Inj. F<br />

Ion <strong>se</strong>n<strong>se</strong><br />

Power gnd.<br />

Coil F<br />

Constant power<br />

1 2 3 4 5 6 7 8 9<br />

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36<br />

1 2 3 4 5 6 7 8 9<br />

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36<br />

GN/O<br />

Y/BE<br />

GN/GY<br />

W/Y<br />

BE/GY<br />

W/BK<br />

BE/O<br />

W/Y<br />

GY/BE<br />

AB<br />

AB<br />

AB<br />

[84B] [84A]<br />

AB<br />

[85B] [85A]<br />

W/BK<br />

BK<br />

15 amp<br />

ECM fu<strong>se</strong><br />

12<br />

11<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

R<br />

12<br />

11<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

[8B] [8A]<br />

Y/GN<br />

Y/GN<br />

GY/BE<br />

Y/BE<br />

BE/O<br />

W/BK<br />

BK<br />

BE/GY<br />

Y/GN<br />

15 amp<br />

IGN fu<strong>se</strong><br />

W/BK<br />

R<br />

GY<br />

R/BK<br />

15 amp<br />

fuel pump<br />

fu<strong>se</strong><br />

DCBA<br />

A B C D<br />

A B C D<br />

[83B] [83A]<br />

R<br />

12 11 10 9 8 7 6 5 4 3 2 1<br />

12 11 10 9 8 7 6 5 4 3 2 1<br />

[13A] [13B]<br />

BK<br />

[33B]<br />

[33A]<br />

1 2 3<br />

Ignition<br />

switch<br />

1 2 3<br />

Ignition<br />

coil<br />

O/GY<br />

40 Amp<br />

Maxi Fu<strong>se</strong><br />

[1B]<br />

[1A]<br />

1 2 3<br />

1 2 3<br />

[141B] [141A]<br />

Battery<br />

Fuel pump<br />

– +<br />

BK<br />

BK<br />

BK<br />

BK<br />

12 11 10 9 8 7 6 5 4 3 2 1<br />

12 11 10 9 8 7 6 5 4 3 2 1<br />

[22A]<br />

[22B]<br />

Engine stop<br />

switch<br />

Figure 5-52. Battery Voltage Circuit (FLTR, FLHT/C/U)<br />

Table 5-37. Wire Harness Connectors in Figure 5-52.<br />

NO. DESCRIPTION TYPE LOCATION<br />

[1] Main to Interconnect Harness 12-Place Deutsch (Black) Inner Fairing (Right Fairing Bracket)<br />

[8] Main to EFI Harness 12-Place Deutsch (Gray) Under Right Side Cover<br />

[22] Right Handlebar Switches 12-Place Deutsch (Black) Inner Fairing (Right Fairing Support Brace)<br />

[33] Ignition/Light Key Switch 4-Place Packard Inner Fairing (Top Fork Bracket)<br />

[78] ECM 36-Place Packard Under Right Side Cover<br />

[83] Ignition Coil 4-Place Packard Below Fuel Tank (Left Side)<br />

[84] Front Injector 2-Place Packard Below Fuel Tank (Left Side)<br />

[85] Rear Injector 2-Place Packard Below Fuel Tank (Left Side)<br />

5-86 2004 Touring: Engine Management (EFI)

HOME<br />

f2208m8x<br />

[62B]<br />

System relay<br />

[62B]<br />

[78A]<br />

[78B]<br />

Y/GN<br />

BE/GY<br />

GN/O<br />

W/BK<br />

I Q C P R<br />

87<br />

87A<br />

30 85 86<br />

System relay<br />

1 2 3 4 5 6 7 8 9<br />

1 2 3 4 5 6 7 8 9<br />

GN/O<br />

W/Y<br />

AB<br />

AB<br />

[84B] [84A]<br />

Y/GN<br />

Y/GN<br />

Y/GN<br />

15 amp<br />

fuel pump<br />

fu<strong>se</strong><br />

BK<br />

Y/GN<br />

1 2 3<br />

Fuel pump<br />

1 2 3<br />

[141B] [141A]<br />

Power gnd.<br />

Coil R<br />

Switch power<br />

ECM<br />

Inj. R<br />

Inj. F<br />

Ion <strong>se</strong>n<strong>se</strong><br />

Power gnd.<br />

Coil F<br />

Constant power<br />

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36<br />

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36<br />

Y/BE<br />

GN/GY<br />

W/Y<br />

BE/GY<br />

W/BK<br />

BE/O<br />

BK<br />

BK<br />

GY/BE<br />

AB<br />

AB<br />

[85B] [85A]<br />

W/BK<br />

BK<br />

15 amp<br />

ECM fu<strong>se</strong><br />

12<br />

11<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

R<br />

12<br />

11<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

[8B] [8A]<br />

GY/BE<br />

Y/BE<br />

BE/O<br />

W/BK<br />

BK<br />

BK<br />

BE/GY<br />

15 amp<br />

IGN fu<strong>se</strong><br />

W/BK<br />

R<br />

R/BK<br />

I B A<br />

GY<br />

A B C D<br />

A B C D<br />

[83B] [83A]<br />

R<br />

[33B]<br />

[33A]<br />

12 11 10 9 8 7 6 5 4 3 2 1<br />

12 11 10 9 8 7 6 5 4 3 2 1<br />

12-Place on<br />

FLHP Only<br />

Ignition<br />

coil<br />

40 Amp<br />

Maxi Fu<strong>se</strong><br />

Ignition<br />

switch<br />

[22A]<br />

[22B]<br />

Engine stop<br />

switch<br />

Battery<br />

– +<br />

BK<br />

Figure 5-53. Battery Voltage Circuit (FLHR/C/S)<br />

Table 5-38. Wire Harness Connectors in Figure 5-53.<br />

NO. DESCRIPTION TYPE LOCATION<br />

[8] Main to EFI Harness 12-Place Deutsch (Gray) Under Right Side Cover<br />

[22] Right Handlebar Switches 12-Place Deutsch (Black) Inside Headlamp Nacelle<br />

[33] Ignition/Light Key Switch 3-Place Packard Under Console<br />

[78] ECM 36-Place Packard Under Right Side Cover<br />

[83] Ignition Coil 4-Place Packard Below Fuel Tank (Left Side)<br />

[84] Front Injector 2-Place Packard Below Fuel Tank (Left Side)<br />

[85] Rear Injector 2-Place Packard Below Fuel Tank (Left Side)<br />

2004 Touring: Engine Management (EFI) 5-87

HOME<br />

Test 5.23 (Part 1 of 3)<br />

FUEL INJECTORS: <strong>DTC</strong> P0261, P0262, P0263, P0264<br />

1<br />

Is wire bail on connector <strong>se</strong>curely<br />

attached to the fuel injector<br />

YES<br />

NO<br />

See Figure 5-51. Using Fuel<br />

Injector Test Lamp, crank<br />

engine. Does lamp flash<br />

Reconnect.<br />

YES<br />

NO<br />

Recheck connections.<br />

Perform 5.8 WIGGLE TEST<br />

to check for intermittents.<br />

Intermittents pre<strong>se</strong>nt<br />

2<br />

Check Terminal A (Y/GN wire)<br />

on injector connector to ground.<br />

Voltage equivalent to<br />

battery voltage for 2 <strong>se</strong>conds<br />

after key ON<br />

YES<br />

NO<br />

YES<br />

NO<br />

Repair<br />

intermittent.<br />

2<br />

Measure resistance of<br />

suspect injector across<br />

injector terminals.<br />

Resistance<br />

10.0-25.0 ohms<br />

STOP<br />

Go to Test 5.23 (Part 2 of 3).<br />

Check for 12 volts at terminal 87 of system<br />

relay during first 2 <strong>se</strong>conds after<br />

key ON. Correct voltage pre<strong>se</strong>nt<br />

YES<br />

NO<br />

YES<br />

NO<br />

Check for loo<strong>se</strong><br />

or corroded terminals<br />

in harness.<br />

1<br />

Replace<br />

injector.<br />

System relay OK. Measure<br />

resistance between terminal 87 of STOP<br />

system relay and Terminal A<br />

(Y/GN wire) at injector connector.<br />

Resistance less than 0.5 ohm Go to Test 5.23<br />

(Part 3 of 3).<br />

YES<br />

NO<br />

Perform 5.8 WIGGLE TEST<br />

to check for intermittents.<br />

Repair as necessary.<br />

Find and repair<br />

bad connection<br />

or open wire.<br />

Clear codes using speedometer <strong>se</strong>lf diagnostics.<br />

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.<br />

Confirm proper operation with no check engine<br />

lamp.<br />

5-88 2004 Touring: Engine Management (EFI)

HOME<br />

Test 5.23 (Part 2 of 3)<br />

FUEL INJECTORS: <strong>DTC</strong> P0261, P0262, P0263, P0264<br />

2<br />

3<br />

FRONT INJECTOR: <strong>DTC</strong> P0261 or P0262.<br />

Measure resistance between Breakout Box terminal 21<br />

(W/Y wire) and Terminal B of front injector connector<br />

[84B].<br />

REAR INJECTOR: <strong>DTC</strong> P0263 or P0264.<br />

Measure resistance between Breakout Box terminal 19<br />

(GN/GY wire) and Terminal B of rear injector connector<br />

[85B].<br />

2<br />

3<br />

Resistance<br />

less than 0.5 ohm<br />

YES<br />

Check for continuity between terminal<br />

10 and ground.<br />

NO<br />

Repair open or<br />

poor connection.<br />

Front injector codes: Check continuity<br />

between terminal 21 and terminal 10.<br />

or<br />

Rear injector codes: Check continuity<br />

between terminal 19 and terminal<br />

10.<br />

NO<br />

Repair open<br />

Continuity pre<strong>se</strong>nt<br />

YES<br />

NO<br />

Repair short<br />

to ground.<br />

Check for voltage with key on.<br />

Front injector codes: Check<br />

Breakout Box terminal 21.<br />

Rear injector codes: Check<br />

Breakout Box terminal 19.<br />

Voltage pre<strong>se</strong>nt after 2 <strong>se</strong>conds<br />

YES<br />

NO<br />

Repair short<br />

to voltage.<br />

Replace ECM. Reprogram<br />

and learn password.<br />

Clear codes using speedometer <strong>se</strong>lf diagnostics.<br />

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.<br />

Confirm proper operation with no check engine<br />

lamp.<br />

2004 Touring: Engine Management (EFI) 5-89

HOME<br />

Test 5.23 (Part 3 of 3)<br />

FUEL INJECTORS: <strong>DTC</strong> P0261, P0262, P0263, P0264<br />

Continued from Test 5.23 (Part 1 of 3).<br />

Check for 12 volts at terminal 30 of the system relay.<br />

Correct voltage pre<strong>se</strong>nt<br />

YES<br />

NO<br />

3<br />

Check for 12 volts at terminal 86<br />

of the system relay.<br />

Correct voltage pre<strong>se</strong>nt<br />

Find and repair open on<br />

BE/GY wire between<br />

fu<strong>se</strong> and relay.<br />

YES<br />

NO<br />

Measure resistance between<br />

terminal 86 of the system<br />

relay and ECM terminal 13 on<br />

Breakout Box.<br />

Resistance less than 0.5 ohm<br />

See 5.11 NO ECM<br />

POWER.<br />

YES<br />

NO<br />

Measure resistance between<br />

terminal 85 of the system relay<br />

and ECM terminal 4 on Breakout<br />

Box.<br />

Resistance less than 0.5 ohm<br />

Find and repair<br />

open on W/BK<br />

wire.<br />

YES<br />

NO<br />

Install known good relay.<br />

Does fuel pump run for first<br />

2 <strong>se</strong>conds after key ON<br />

Find and repair<br />

open on GN/O<br />

wire.<br />

YES<br />

NO<br />

Clear codes using speedometer <strong>se</strong>lf diagnostics.<br />

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.<br />

Confirm proper operation with no check engine<br />

lamp.<br />

Replace<br />

relay<br />

Reinstall original relay.<br />

Replace ECM. Reprogram<br />

and learn password.<br />

5-90 2004 Touring: Engine Management (EFI)

HOME<br />

<strong>DTC</strong> P0373, P0374 5.24<br />

GENERAL<br />

CKP Sensor<br />

If the crank position <strong>se</strong>nsor (CKP <strong>se</strong>nsor) signal is weak or<br />

ab<strong>se</strong>nt, diagnostic trouble codes P0373 or P0374 will be <strong>se</strong>t.<br />

NOTE<br />

If signal is not detected or cannot synchronize (<strong>DTC</strong> P0374),<br />

engine will not start.<br />

f2217x8x<br />

Socket Screw<br />

Table 5-39. Code Description<br />

<strong>DTC</strong><br />

DESCRIPTION<br />

P0373 CKP <strong>se</strong>nsor intermittent<br />

P0374 CKP <strong>se</strong>nsor synch error<br />

DIAGNOSTICS<br />

f2256x8x<br />

Figure 5-54. Crankshaft Position Sensor<br />

Diagnostic Tips<br />

●<br />

Engine must be cranked for more than five <strong>se</strong>conds without<br />

CKP signal to <strong>se</strong>t code.<br />

Diagnostic Notes<br />

The reference numbers below correlate with the circled numbers<br />

on the Test 5.24 flow chart.<br />

1. Connect BREAKOUT BOX (Part No. HD-43876) to ECM<br />

wire harness only (leave ECM disconnected). See 5.7<br />

BREAKOUT BOX: EFI.<br />

2. One megohm is very high resistance. Some meters will<br />

read ∞, OL, etc.<br />

3. U<strong>se</strong> HARNESS CONNECTOR TEST KIT (Part No. HD-<br />

41404), brown socket probes and patch cords.<br />

4. For testing purpo<strong>se</strong>s, install <strong>se</strong>nsor without running wiring<br />

along normal path. Disconnect and route wiring properly<br />

if system is now OK.<br />

Crankshaft<br />

Position Sensor<br />

Connector [79]<br />

Under Voltage Regulator<br />

Figure 5-55. Voltage Regulator (Left Side View)<br />

2004 Touring: Engine Management (EFI) 5-91

HOME<br />

s0453x9x<br />

CKP<br />

<strong>se</strong>nsor<br />

[79A]<br />

[79B]<br />

1 2<br />

1<br />

2<br />

BK<br />

BK<br />

BK<br />

R<br />

R<br />

BK<br />

[78B]<br />

[78A]<br />

ECM<br />

10 12<br />

28 30<br />

Gnd.<br />

CKP.<br />

Gnd.<br />

CKP.<br />

Figure 5-56. CKP Circuit<br />

Table 5-40. Wire Harness Connectors in Figure 5-56.<br />

NO. DESCRIPTION TYPE LOCATION<br />

[78] ECM 36-Place Packard Under Right Side Cover<br />

[79] CKP Sensor 2-Place Mini-Deutsch Under Right Side Cover<br />

5-92 2004 Touring: Engine Management (EFI)

HOME<br />

Test 5.24<br />

CKP SENSOR: <strong>DTC</strong> P0373, P0374<br />

1<br />

2<br />

Connect Breakout Box to harness only,<br />

leaving ECM disconnected.<br />

Measure resistance between terminals 30 and 28<br />

and between terminals 12 and 28 on Breakout Box.<br />

Resistance more than 1 megohm<br />

YES<br />

Check for intermittent connection, pinched<br />

or damaged wires, and loo<strong>se</strong> CKP <strong>se</strong>nsor<br />

fasteners. Conditions found<br />

NO<br />

Disconnect connector [79]. Leaving<br />

ECM disconnected, measure resistance<br />

between terminals 12 and 28 and<br />

terminals 30 and 28 on Breakout Box.<br />

Continuity to ground<br />

(less than 1 megohm resistance)<br />

YES<br />

NO<br />

YES<br />

Repair as<br />

necessary.<br />

Connect DVOM to terminals 12 and 30<br />

on Breakout Box.<br />

Set DVOM to AC volts and crank engine.<br />

Does DVOM read 1 VAC minimum<br />

during cranking<br />

NO<br />

YES<br />

Repair short to<br />

ground on R or<br />

BK wire between<br />

connectors [78B]<br />

and [79B].<br />

NO<br />

Replace<br />

CKP <strong>se</strong>nsor.<br />

See Touring Service<br />

Manual.<br />

With DVOM still connected, check for intermittents<br />

using 5.8 WIGGLE TEST. Intermittents<br />

pre<strong>se</strong>nt<br />

3<br />

Connect DVOM at Terminals 1<br />

and 2 of connector [79A].<br />

Does DVOM read 1 VAC<br />

minimum while cranking<br />

YES<br />

NO<br />

Repair as<br />

necessary.<br />

Install known<br />

good CKP <strong>se</strong>nsor.<br />

Clear codes<br />

and retest. <strong>DTC</strong><br />

P0373 or P0374<br />

4<br />

YES<br />

Check for continuity between<br />

Terminal 1 of connector [79B]<br />

and terminal 30 on Breakout<br />

Box.<br />

Continuity pre<strong>se</strong>nt<br />

NO<br />

Replace CKP <strong>se</strong>nsor.<br />

See Touring<br />

Service Manual.<br />

YES<br />

NO<br />

YES<br />

NO<br />

Reinstall original<br />

CKP <strong>se</strong>nsor.<br />

Replace ECM.<br />

Reprogram and<br />

learn password.<br />

Replace CKP<br />

<strong>se</strong>nsor<br />

Repair open on BK wire<br />

between Terminal 2 of<br />

connector [79B] and<br />

terminal 12 of Breakout Box.<br />

Repair open on R wire<br />

between Terminal 1 of<br />

connector [79B] and<br />

terminal 30 of Breakout Box.<br />

Clear codes using speedometer <strong>se</strong>lf diagnostics.<br />

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.<br />

Confirm proper operation with no check engine<br />

lamp.<br />

2004 Touring: Engine Management (EFI) 5-93

HOME<br />

<strong>DTC</strong> P0501, P0502 5.25<br />

GENERAL<br />

7951<br />

Vehicle Speed Sensor<br />

See Figure 5-57. The vehicle speed <strong>se</strong>nsor is powered and<br />

monitored by the ECM. The ECM proces<strong>se</strong>s the vehicle<br />

speed signal and transmits this signal to the TSM/TSSM and<br />

speedometer through <strong>se</strong>rial data.<br />

NOTE<br />

When the vehicle speed is greater than 0, the clo<strong>se</strong>d loop idle<br />

speed control is inhibited.<br />

Table 5-41. Code Description<br />

<strong>DTC</strong><br />

P0501<br />

P0502<br />

DESCRIPTION<br />

VSS <strong>se</strong>nsor low<br />

VSS <strong>se</strong>nsor high/open<br />

Figure 5-57. Vehicle Speed Sensor<br />

f2183x8x<br />

DIAGNOSTICS<br />

Diagnostic Notes<br />

1<br />

The reference numbers below correlate with the circled numbers<br />

on the Test 5.25 flow charts.<br />

1. The speedometer has a built-in diagnostic mode. See<br />

2.3 SPEEDOMETER SELF DIAGNOSTICS.<br />

2. U<strong>se</strong> HARNESS CONNECTOR TEST KIT (Part No. HD-<br />

41404), black pin probe and patch cord.<br />

3. Connect BREAKOUT BOX (Part No. HD-43876)<br />

between wire harness and ECM. See 5.7 BREAKOUT<br />

BOX: EFI.<br />

1. Vehicle Speed Sensor [65]<br />

2. P&A Security Siren [142]<br />

2<br />

Figure 5-58. Electrical Bracket (Inboard Side)<br />

5-94 2004 Touring: Engine Management (EFI)

HOME<br />

f2208v8x<br />

Vehicle speed<br />

<strong>se</strong>nsor<br />

To Crui<strong>se</strong> and Sound System<br />

R<br />

W<br />

BK<br />

A<br />

B<br />

C<br />

A<br />

B<br />

C<br />

R/W<br />

W/GN<br />

BK<br />

[65A]<br />

[65B]<br />

Speedometer<br />

BK<br />

To TP, MAP Sensors<br />

[39A]<br />

[39B]<br />

2<br />

LGN/V<br />

[78B]<br />

[78A]<br />

5<br />

10<br />

14<br />

33<br />

<strong>se</strong>rial data<br />

ground<br />

5v power<br />

ECM<br />

VSS<br />

Figure 5-59. Vehicle Speed Sensor Circuit<br />

Table 5-42. Wire Harness Connectors in Figure 5-59.<br />

NO. DESCRIPTION MODEL TYPE LOCATION<br />

[39] Speedometer<br />

FLTR 12-Place Packard<br />

Under Instrument Bezel<br />

(Back of Speedometer)<br />

FLHT/C/U 12-Place Packard Inner Fairing (Back of Speedometer)<br />

FLHR/C/S 12-Place Packard Back of Speedometer (Under Console)<br />

[65] Speedometer Speed Sensor All 3-Place Deutsch<br />

Under Right Side Cover<br />

(Behind Electrical Bracket)<br />

[78] ECM All 36-Place Packard Under Right Side Cover<br />

2004 Touring: Engine Management (EFI) 5-95

HOME<br />

Test 5.25 (Part 1 of 2)<br />

VEHICLE SPEED SENSOR: <strong>DTC</strong> P0501, P0502<br />

Inspect connector [65]. Is connector mated properly<br />

YES<br />

NO<br />

1<br />

Remove and inspect speedometer <strong>se</strong>nsor. Inspect for<br />

debris and clean if necessary. Place speedometer<br />

into diagnostic mode and clear fault codes. Connect<br />

all circuits and ride motorcycle for approximately 1.0<br />

mile (1.6 km). Check for speedometer function.<br />

Speedometer functioning properly<br />

Mate connector [65].<br />

YES<br />

NO<br />

System OK.<br />

2<br />

Check for continuity between terminal<br />

A of connector [65B] (R/W wire) and<br />

ground. Continuity pre<strong>se</strong>nt<br />

YES<br />

NO<br />

Repair short to ground.<br />

2 Check for continuity between terminal A<br />

of connector [65B] (R/W wire) and terminal<br />

14 of breakout box. Continuity<br />

pre<strong>se</strong>nt<br />

3<br />

YES<br />

NO<br />

Clear codes using speedometer <strong>se</strong>lf diagnostics.<br />

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.<br />

Confirm proper operation with no check engine<br />

lamp.<br />

Check for continuity between terminal C<br />

of connector [65B] (BK wire) and<br />

ground. Continuity pre<strong>se</strong>nt<br />

Locate and repair open on<br />

R/W wire between [78B]<br />

and [65B].<br />

YES<br />

NO<br />

STOP<br />

Repair open on Black wire<br />

between [65B] and ground.<br />

Go to. Test 5.25<br />

(Part 2 of 2)<br />

5-96 2004 Touring: Engine Management (EFI)

HOME<br />

Test 5.25 (Part 2 of 2)<br />

VEHICLE SPEED SENSOR: <strong>DTC</strong> P0501, P0502<br />

2<br />

3<br />

Continued from Test 5.25 (Part 1 of 2).<br />

Check for continuity between terminal B of connector<br />

[65B] and terminal 33 of breakout box. Continuity<br />

pre<strong>se</strong>nt<br />

YES<br />

NO<br />

Check for voltage on W/GN wire of connector<br />

[65B] while connected. Meter should read 4-6<br />

volts when gear tooth ab<strong>se</strong>nt and 0-1 volts<br />

when gear tooth is pre<strong>se</strong>nt. Does it<br />

Locate and repair open on<br />

W/GN wire between [78B]<br />

and [65B].<br />

YES<br />

NO<br />

Replace ECM. Reprogram<br />

and learn password.<br />

4-6 volts not pre<strong>se</strong>nt. 4-6 volts pre<strong>se</strong>nt but no<br />

fluctuation from 0-1 volts.<br />

Replace ECM. Reprogram<br />

and learn password.<br />

Replace speed <strong>se</strong>nsor.<br />

Clear codes using speedometer <strong>se</strong>lf diagnostics.<br />

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.<br />

Confirm proper operation with no check engine<br />

lamp.<br />

2004 Touring: Engine Management (EFI) 5-97

HOME<br />

<strong>DTC</strong> P0562, P0563 5.26<br />

GENERAL<br />

System Fu<strong>se</strong> Block (Under Left Side Cover)<br />

Battery Voltage<br />

FLHR/C/S<br />

8<br />

Battery voltage is monitored by the ECM (terminal 13). If the<br />

battery voltage fails to meet normal operating parameters, a<br />

code is <strong>se</strong>t.<br />

●<br />

Code P0562 is displayed when battery positive voltage is<br />

less than 11.0 volts at 2000 RPM for longer than 5 <strong>se</strong>conds.<br />

11<br />

10<br />

9<br />

5<br />

●<br />

●<br />

Code P0563 is displayed when battery positive voltage is<br />

greater than 16.0 volts for more than 4 <strong>se</strong>conds.<br />

NOTES<br />

Warm idle speed will be automatically increa<strong>se</strong>d if battery<br />

voltage is low at idle.<br />

12<br />

f2210x8x<br />

1<br />

2<br />

3<br />

4<br />

● TSSM problems may also <strong>se</strong>t a code P0562 or P0563.<br />

FLTR, FLHT/C/U<br />

8 7<br />

<strong>DTC</strong><br />

Table 5-43. Code Description<br />

DESCRIPTION<br />

11<br />

10<br />

9<br />

6<br />

5<br />

P0562<br />

Battery voltage low<br />

P0563<br />

Battery voltage high<br />

4<br />

DIAGNOSTICS<br />

Diagnostic Tips<br />

●<br />

●<br />

Low voltage generally indicates a loo<strong>se</strong> wire, corroded<br />

connections, battery and/or a charging system problem.<br />

A high voltage condition may be cau<strong>se</strong>d by a faulty voltage<br />

regulator.<br />

f2204x8x<br />

1<br />

1. Headlamp<br />

2. Ignition<br />

3. Lighting<br />

4. Instruments<br />

5. Brakes/Crui<strong>se</strong><br />

6. Radio Memory<br />

2<br />

3<br />

7. Radio Power<br />

8. Accessory<br />

9. Battery<br />

10. Brake Light Relay<br />

11. P&A<br />

12. Starter Relay<br />

Diagnostic Notes<br />

The reference numbers below correlate with the circled numbers<br />

on the Test 5.26 flow charts.<br />

1. Was battery allowed to discharge Was battery drawn<br />

down by a starting problem<br />

a. Yes. Charge battery.<br />

b. No. See charging system troubleshooting.<br />

2. Connect BREAKOUT BOX (Part No. HD-43876)<br />

between wire harness and ECM. See 5.7 BREAKOUT<br />

BOX: EFI.<br />

3. U<strong>se</strong> DVOM with RPM Pick-up to check RPM on vehicles<br />

without tachometers.<br />

Figure 5-60. Fu<strong>se</strong> Locations<br />

4. This checks for voltage drops in the ECM circuit.<br />

a. Place (+) probe to battery positive terminal.<br />

b. Place (-) probe to W/BK terminal on Breakout Box.<br />

5. Problem is most likely the ground connection at the<br />

frame.<br />

6. Connect BREAKOUT BOX (Part No. HD-42682) to Connector<br />

[22]. FLHR/C/S models will also need HD-42962<br />

adapters.<br />

5-98 2004 Touring: Engine Management (EFI)

HOME<br />

f2208k8x<br />

[78A]<br />

[78B]<br />

[62B]<br />

System relay<br />

Power gnd.<br />

Switch power<br />

ECM<br />

Power gnd.<br />

Constant power<br />

1 2 3 4 5 6 7 8 9<br />

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36<br />

1 2 3 4 5 6 7 8 9<br />

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36<br />

GN/O<br />

15 amp<br />

ECM fu<strong>se</strong><br />

BE/GY<br />

BK<br />

W/BK<br />

BK<br />

BK<br />

W/BK<br />

12<br />

11<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

12<br />

11<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

[8B] [8A]<br />

15 amp<br />

IGN fu<strong>se</strong><br />

W/BK<br />

GY<br />

R/BK<br />

DCBA<br />

R<br />

12 11 10 9 8 7 6 5 4 3 2 1<br />

12 11 10 9 8 7 6 5 4 3 2 1<br />

Y/GN<br />

BE/GY<br />

GN/O<br />

W/BK<br />

[33B]<br />

[33A]<br />

Ignition<br />

switch<br />

[1B]<br />

[1A]<br />

I Q C P R<br />

87<br />

87A<br />

30 85 86<br />

40 Amp<br />

Maxi Fu<strong>se</strong><br />

System relay<br />

Battery<br />

– +<br />

BK<br />

BK<br />

12 11 10 9 8 7 6 5 4 3 2 1<br />

12 11 10 9 8 7 6 5 4 3 2 1<br />

Engine stop<br />

switch<br />

[22A]<br />

[22B]<br />

Figure 5-61. Battery Voltage Circuit (FLTR, FLHT/C/U)<br />

Table 5-44. Wire Harness Connectors in Figure 5-61.<br />

NO. DESCRIPTION TYPE LOCATION<br />

[1] Main to Interconnect Harness 12-Place Deutsch (Black) Inner Fairing (Right Fairing Bracket)<br />

[8] Main to EFI Harness 12-Place Deutsch (Gray) Under Right Side Cover<br />

[22] Right Handlebar Switches 12-Place Deutsch (Black) Inner Fairing (Right Fairing Support Brace)<br />

[33] Ignition/Light Key Switch 4-Place Packard Inner Fairing (Top Fork Bracket)<br />

[78] ECM 36-Place Packard Under Right Side Cover<br />

2004 Touring: Engine Management (EFI) 5-99

HOME<br />

f2208j8x<br />

[62B]<br />

[78A]<br />

[78B]<br />

Y/GN<br />

BE/GY<br />

GN/O<br />

W/BK<br />

I Q C P R<br />

87<br />

87A<br />

30 85 86<br />

System relay<br />

Power gnd.<br />

Switch power<br />

ECM<br />

Power gnd.<br />

Constant power<br />

1 2 3 4 5 6 7 8 9<br />

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36<br />

1 2 3 4 5 6 7 8 9<br />

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36<br />

GN/O<br />

15 amp<br />

ECM fu<strong>se</strong><br />

BE/GY<br />

BK<br />

W/BK<br />

BK<br />

BK<br />

BK<br />

W/BK<br />

12<br />

11<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

12<br />

11<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

[8B] [8A]<br />

R/BK<br />

15 amp<br />

IGN fu<strong>se</strong><br />

W/BK<br />

I B A<br />

GY<br />

R<br />

12 11 10 9 8 7 6 5 4 3 2 1<br />

12 11 10 9 8 7 6 5 4 3 2 1<br />

12-Place on<br />

FLHP Only<br />

40 Amp<br />

Maxi Fu<strong>se</strong><br />

[33B]<br />

[33A]<br />

Ignition<br />

switch<br />

[22A]<br />

[22B]<br />

Engine stop<br />

switch<br />

System relay<br />

Battery<br />

BK<br />

– +<br />

Figure 5-62. Battery Voltage Circuit (FLHR/C/S)<br />

Table 5-45. Wire Harness Connectors in Figure 5-62.<br />

NO. DESCRIPTION TYPE LOCATION<br />

[8] Main to EFI Harness 12-Place Deutsch (Gray) Under Right Side Cover<br />

[22] Right Handlebar Switches 12-Place Deutsch (Black) Inside Headlamp Nacelle<br />

[33] Ignition/Light Key Switch 3-Place Packard Under Console<br />

[78] ECM 36-Place Packard Under Right Side Cover<br />

5-100 2004 Touring: Engine Management (EFI)

HOME<br />

Test 5.26 (Part 1 of 2)<br />

BATTERY VOLTAGE: <strong>DTC</strong> P0562, P0563<br />

1<br />

Perform charging system tests.<br />

Charging system OK<br />

YES<br />

NO<br />

2<br />

3<br />

Connect Breakout Box. Measure voltage on<br />

Breakout Box between terminal 13 (+) and<br />

terminal 10 (-) and again between terminal<br />

13 and terminal 28 (-) with engine running at<br />

2000 RPM or higher for 10 <strong>se</strong>conds or<br />

longer. Is voltage above 11.0 volts<br />

Repair charging system.<br />

See Section 1.<br />

YES<br />

NO<br />

System<br />

With ignition ON, measure voltage drop<br />

1 4<br />

OK.<br />

between battery positive (+) terminal<br />

and Breakout Box terminal 13 (-).<br />

Is voltage drop greater<br />

than 0.5 volt<br />

YES<br />

NO<br />

With ignition ON, measure voltage drop<br />

between battery positive (+) terminal<br />

and connector [22A] terminal 4 (-) (black). Is<br />

voltage drop greater than 0.5 volt<br />

Check for voltage drop between battery<br />

negative (-) terminal and terminal 10 (+)<br />

on Breakout Box connector and between<br />

battery negative (-) terminal and terminal 28<br />

on<br />

Breakout Box. Is voltage drop greater than<br />

0.5 volt<br />

YES<br />

NO<br />

With ignition ON, measure voltage drop<br />

between battery positive (+) terminal<br />

and connector [22A] terminal 3 (-). Is voltage<br />

drop greater than 0.5 volt<br />

Replace W/BK<br />

wire between<br />

[22A] and [78B] or<br />

terminals.<br />

Locate and repair<br />

bad connection.<br />

5<br />

YES<br />

NO<br />

Problem is intermittent.<br />

Perform 5.8 WIGGLE<br />

TEST. Locate and<br />

repair bad connection.<br />

YES<br />

NO<br />

STOP<br />

Go to Test 5.26 (Part 2 of 2).<br />

Inspect [22] for corrosion or<br />

loo<strong>se</strong> wires. If above conditions<br />

are not pre<strong>se</strong>nt, replace engine<br />

stop switch.<br />

Clear codes using speedometer <strong>se</strong>lf diagnostics.<br />

See 5.6 SPEEDOMETER SELF DIAGNOSTICS.<br />

Confirm proper operation with no check engine<br />

lamp.<br />

2004 Touring: Engine Management (EFI) 5-101

HOME<br />

Test 5.26 (Part 2 of 2)<br />

BATTERY VOLTAGE: <strong>DTC</strong> P0562, P0563<br />

Continued from Test 5.26 (Part 1 of 2).<br />

With ignition ON, measure voltage drop between battery<br />

positive (+) terminal and GY terminal on 15 amp<br />