Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

WARINING<br />

Improper removal of the spring from the rear shock absorber body<br />

may cause the spring and associated parts to be ejected at high<br />

velocity. Always wear eye and face protection. Removal and installation<br />

of spring should be performed by an person or company.<br />

WHEELS<br />

Tires<br />

- Tire pressure affects traction, handling, and tire life.<br />

- Adjust the tire pressure to suit track conditions and rider preference,<br />

but do not stray too far from the recommended pressure.<br />

NOTE<br />

Tire pressure should be checked when the tires are cold before<br />

you ride.<br />

Track condition<br />

- When the track is wet, muddy, sandy or slippery, reduce the tire<br />

pressure.<br />

- When the track is pebbly or hard, increase the tire pressure.<br />

Spokes and Rim<br />

The spokes on both wheels must all be tightened securely and evenly<br />

and not be allowed to loosen. Unevenly tightened or loose spokes<br />

will cause the rim to warp, hasten nipple and overall spoke fatigue,<br />

and may result in spoke breakage.<br />

EC FSE 2003 -39-<br />

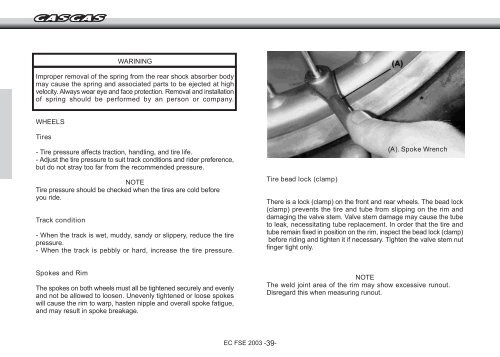

Tire bead lock (clamp)<br />

(A). Llave tensador radios<br />

(A). Spoke Wrench<br />

There is a lock (clamp) on the front and rear wheels. The bead lock<br />

(clamp) prevents the tire and tube from slipping on the rim and<br />

damaging the valve stem. Valve stem damage may cause the tube<br />

to leak, necessitating tube replacement. In order that the tire and<br />

tube remain fixed in position on the rim, inspect the bead lock (clamp)<br />

before riding and tighten it if necessary. Tighten the valve stem nut<br />

finger tight only.<br />

NOTE<br />

The weld joint area of the rim may show excessive runout.<br />

Disregard this when measuring runout.