Sanitary pumps

Sanitary pumps

Sanitary pumps

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

MAXA and MAXANA<br />

<strong>Sanitary</strong> <strong>pumps</strong><br />

MAXA and MAXANA<br />

TM03 0170 4304<br />

Construction<br />

The MAXA and MAXANA are single-stage, end-suction,<br />

centrifugal <strong>pumps</strong>.<br />

The <strong>pumps</strong> are available in a variety of flexible versions.<br />

The design fulfils the following requirements:<br />

• EHEDG recommendations for CIP cleanability. Only<br />

valid for certain models.<br />

• GOST sanitary standard (Russia).<br />

Fig. 16 MAXA and MAXANA<br />

Technical data<br />

MAXA <strong>pumps</strong><br />

Head:<br />

97 m<br />

Flow rate: up to 820 m 3 /h<br />

Operating pressure:<br />

up to 10 bar<br />

Operating temperature: 95 °C<br />

(up to 150 °C on request)<br />

Sterilisation temperature:<br />

140 °C (SIP)<br />

MAXANA <strong>pumps</strong><br />

Head:<br />

up to 97 m<br />

Flow rate: up to 165 m 3 /h<br />

Operating pressure:<br />

up to 10 bar<br />

Operating temperature: 95 °C<br />

(up to 150 °C on request)<br />

Sterilisation temperature:<br />

140 °C (SIP)<br />

Applications<br />

The MAXA and MAXANA <strong>pumps</strong> are suitable for these<br />

applications:<br />

Food and beverage industry<br />

• gentle pumping of mash and wort<br />

• beer filtration (hot side)<br />

• liquid transfer in dairies and food processing plants.<br />

Fig. 17 Certification<br />

For explanation, see Certification, page 55.<br />

Requirements complied with:<br />

Pump type<br />

Standard<br />

MAXA<br />

3A0 and 3A2*.<br />

MAXANA<br />

3A0<br />

*Applies to MAXA 100-200, 100-250, 125-250, 150-250, 200-400<br />

The major dimensions and characteristics of the <strong>pumps</strong><br />

are according to DIN EN 733 and DIN EN 22858.<br />

The pump housing is made of heavy-duty, rolled and<br />

deep-drawn stainless steel to DIN EN 1.4404. The back<br />

plate is made of rolled stainless steel to DIN EN 1.4571.<br />

The <strong>pumps</strong> feature closed steel impellers with optimised<br />

blade entry angles to DIN EN 1.4571. See page 51.<br />

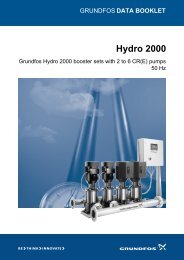

2 5 4 6 7<br />

Other industrial applications<br />

• water treatment plants<br />

• chemical handling systems<br />

• applications involving liquids with a high content of<br />

solid particles<br />

• environmental systems<br />

• bio fuel systems.<br />

1 3 8<br />

TM02 9609 3504<br />

Fig. 18 Sectional drawing of MAXANA-CN on base plate<br />

16