Sanitary pumps

Sanitary pumps

Sanitary pumps

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

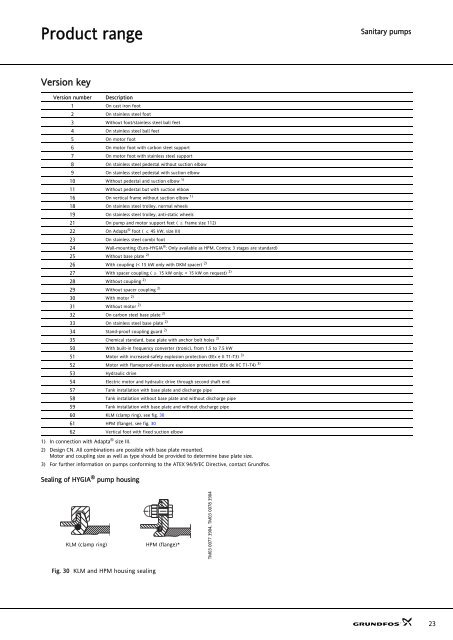

Product range<br />

<strong>Sanitary</strong> <strong>pumps</strong><br />

Version key<br />

Version number Description<br />

1 On cast iron foot<br />

2 On stainless steel foot<br />

3 Without foot/stainless steel ball feet<br />

4 On stainless steel ball feet<br />

5 On motor foot<br />

6 On motor foot with carbon steel support<br />

7 On motor foot with stainless steel support<br />

8 On stainless steel pedestal without suction elbow<br />

9 On stainless steel pedestal with suction elbow<br />

10 Without pedestal and suction elbow 1)<br />

11 Without pedestal but with suction elbow<br />

16 On vertical frame without suction elbow 1)<br />

18 On stainless steel trolley, normal wheels<br />

19 On stainless steel trolley, anti-static wheels<br />

21 On pump and motor support feet ( ≤ frame size 112)<br />

22 On Adapta ® foot ( ≤ 45 kW, size III)<br />

23 On stainless steel combi foot<br />

24 Wall-mounting (Euro-HYGIA ® : Only available as HPM, Contra; 3 stages are standard)<br />

25 Without base plate 2)<br />

26 With coupling (< 15 kW only with DKM spacer) 2)<br />

27 With spacer coupling ( ≥ 15 kW only; < 15 kW on request) 2)<br />

28 Without coupling 2)<br />

29 Without spacer coupling 2)<br />

30 With motor 2)<br />

31 Without motor 2)<br />

32 On carbon steel base plate 2)<br />

33 On stainless steel base plate 2)<br />

34 Stand-proof coupling guard 2)<br />

35 Chemical standard, base plate with anchor bolt holes 2)<br />

50 With built-in frequency converter (tronic), from 1.5 to 7.5 kW<br />

51 Motor with increased-safety explosion protection (EEx e II T1-T3) 3)<br />

52 Motor with flameproof-enclosure explosion protection (EEx de IIC T1-T4) 3)<br />

53 Hydraulic drive<br />

54 Electric motor and hydraulic drive through second shaft end<br />

57 Tank installation with base plate and discharge pipe<br />

58 Tank installation without base plate and without discharge pipe<br />

59 Tank installation with base plate and without discharge pipe<br />

60 KLM (clamp ring), see fig. 30<br />

61 HPM (flange), see fig. 30<br />

62 Vertical foot with fixed suction elbow<br />

1) In connection with Adapta ® size III.<br />

2) Design CN. All combinations are possible with base plate mounted.<br />

Motor and coupling size as well as type should be provided to determine base plate size.<br />

3) For further information on <strong>pumps</strong> conforming to the ATEX 94/9/EC Directive, contact Grundfos.<br />

Sealing of HYGIA ® pump housing<br />

KLM (clamp ring)<br />

HPM (flange)*<br />

TM03 0077 3904, TM03 0078 3904<br />

Fig. 30 KLM and HPM housing sealing<br />

23