Sanitary pumps

Sanitary pumps

Sanitary pumps

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Euro-HYGIA ®<br />

<strong>Sanitary</strong> <strong>pumps</strong><br />

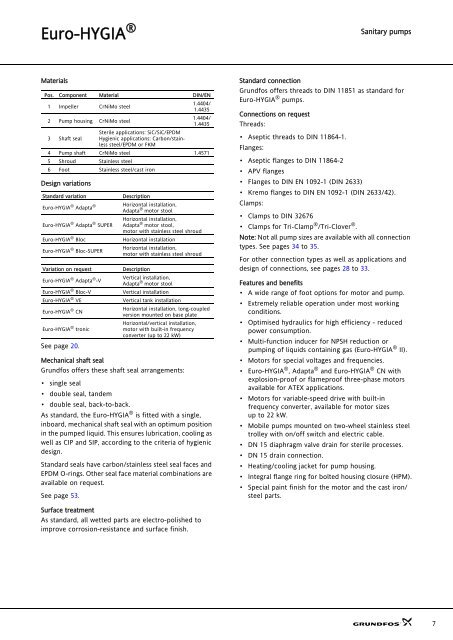

Materials<br />

Pos. Component Material DIN/EN<br />

1 Impeller CrNiMo steel<br />

2 Pump housing CrNiMo steel<br />

Design variations<br />

See page 20.<br />

Mechanical shaft seal<br />

Grundfos offers these shaft seal arrangements:<br />

• single seal<br />

• double seal, tandem<br />

• double seal, back-to-back.<br />

As standard, the Euro-HYGIA ® is fitted with a single,<br />

inboard, mechanical shaft seal with an optimum position<br />

in the pumped liquid. This ensures lubrication, cooling as<br />

well as CIP and SIP, according to the criteria of hygienic<br />

design.<br />

Standard seals have carbon/stainless steel seal faces and<br />

EPDM O-rings. Other seal face material combinations are<br />

available on request.<br />

See page 53.<br />

1.4404/<br />

1.4435<br />

1.4404/<br />

1.4435<br />

3 Shaft seal<br />

Sterile applications: SiC/SiC/EPDM<br />

Hygienic applications: Carbon/stainless<br />

steel/EPDM or FKM<br />

4 Pump shaft CrNiMo steel 1.4571<br />

5 Shroud Stainless steel<br />

6 Foot Stainless steel/cast iron<br />

Standard variation<br />

Euro-HYGIA ® Adapta ®<br />

Euro-HYGIA ® Adapta ® SUPER<br />

Euro-HYGIA ® Bloc<br />

Euro-HYGIA ® Bloc-SUPER<br />

Variation on request<br />

Euro-HYGIA ® Adapta ® -V<br />

Euro-HYGIA ® Bloc-V<br />

Euro-HYGIA ® VE<br />

Euro-HYGIA ® CN<br />

Euro-HYGIA ® tronic<br />

Description<br />

Horizontal installation,<br />

Adapta ® motor stool<br />

Horizontal installation,<br />

Adapta ® motor stool,<br />

motor with stainless steel shroud<br />

Horizontal installation<br />

Horizontal installation,<br />

motor with stainless steel shroud<br />

Description<br />

Vertical installation,<br />

Adapta ® motor stool<br />

Vertical installation<br />

Vertical tank installation<br />

Horizontal installation, long-coupled<br />

version mounted on base plate<br />

Horizontal/vertical installation,<br />

motor with built-in frequency<br />

converter (up to 22 kW)<br />

Standard connection<br />

Grundfos offers threads to DIN 11851 as standard for<br />

Euro-HYGIA ® <strong>pumps</strong>.<br />

Connections on request<br />

Threads:<br />

• Aseptic threads to DIN 11864-1.<br />

Flanges:<br />

• Aseptic flanges to DIN 11864-2<br />

• APV flanges<br />

• Flanges to DIN EN 1092-1 (DIN 2633)<br />

• Kremo flanges to DIN EN 1092-1 (DIN 2633/42).<br />

Clamps:<br />

• Clamps to DIN 32676<br />

• Clamps for Tri-Clamp ® /Tri-Clover ® .<br />

Note: Not all pump sizes are available with all connection<br />

types. See pages 34 to 35.<br />

For other connection types as well as applications and<br />

design of connections, see pages 28 to 33.<br />

Features and benefits<br />

• A wide range of foot options for motor and pump.<br />

• Extremely reliable operation under most working<br />

conditions.<br />

• Optimised hydraulics for high efficiency - reduced<br />

power consumption.<br />

• Multi-function inducer for NPSH reduction or<br />

pumping of liquids containing gas (Euro-HYGIA ® II).<br />

• Motors for special voltages and frequencies.<br />

• Euro-HYGIA ® , Adapta ® and Euro-HYGIA ® CN with<br />

explosion-proof or flameproof three-phase motors<br />

available for ATEX applications.<br />

• Motors for variable-speed drive with built-in<br />

frequency converter, available for motor sizes<br />

up to 22 kW.<br />

• Mobile <strong>pumps</strong> mounted on two-wheel stainless steel<br />

trolley with on/off switch and electric cable.<br />

• DN 15 diaphragm valve drain for sterile processes.<br />

• DN 15 drain connection.<br />

• Heating/cooling jacket for pump housing.<br />

• Integral flange ring for bolted housing closure (HPM).<br />

• Special paint finish for the motor and the cast iron/<br />

steel parts.<br />

Surface treatment<br />

As standard, all wetted parts are electro-polished to<br />

improve corrosion-resistance and surface finish.<br />

7