Challenges - Research and Innovative Technology Administration ...

Challenges - Research and Innovative Technology Administration ...

Challenges - Research and Innovative Technology Administration ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Storage technologies under development include high-pressure tanks with gaseous hydrogen compressed<br />

at up to 10,000 pounds per square inch, cryogenic liquid hydrogen cooled to -423°F (-253°C) in<br />

insulated tanks, <strong>and</strong> chemical bonding of hydrogen with another material (such as metal hydrides).<br />

DOE <strong>and</strong> DOT are funding research to explore fuel cell bus operations in 14 cities <strong>and</strong> some of these<br />

conveyances will be fueled with hydrogen. They also are studying how innovative composites can permit<br />

higher rates of hydrogen storage. The goal is to identify materials that increase the amount of hydrogen a<br />

tank holds <strong>and</strong> facilitate its flow during refueling.<br />

The infrastructure requirements for different vehicle onboard storage designs differ. If the preferred vehicle<br />

design is for liquefied hydrogen, this presents a significant challenge for the design of the infrastructure.<br />

Gaseous hydrogen has to be cooled, compressed, <strong>and</strong> stored before delivery to the vehicle at yet to<br />

be defined locations conditions <strong>and</strong> locations. An all-liquefied hydrogen supply chain would be difficult <strong>and</strong><br />

is probably infeasible. Safety <strong>and</strong> cost considerations will probably argue for liquefaction relatively close<br />

to the point of sale, but probably not at the service station (though this is possible). However, a liquefied<br />

hydrogen service station is a much more elaborate facility than a gaseous hydrogen station, <strong>and</strong> may<br />

present somewhat different safety <strong>and</strong> siting considerations.<br />

Raising storage pressures to 10,000 psi would likely increase the attractiveness of hydrogen vehicles.<br />

However, 10,000 psi storage raises design questions for service stations <strong>and</strong> local distribution. The<br />

fundamental question is whether service stations locally compress hydrogen to 10,000 psi for delivery to<br />

vehicles, or whether some portion of the supply chain (delivery trucks, for example) ought to operate at<br />

higher pressures as well.<br />

As in other cases, the challenge for infrastructure planners is to design an infrastructure when key parameters<br />

remain uncertain.<br />

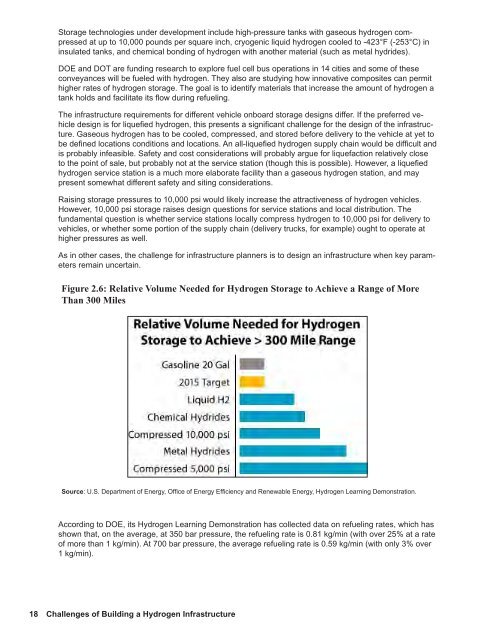

Figure 2.6: Relative Volume Needed for Hydrogen Storage to Achieve a Range of More<br />

Than 300 Miles<br />

Source: U.S. Department of Energy, Office of Energy Efficiency <strong>and</strong> Renewable Energy, Hydrogen Learning Demonstration.<br />

According to DOE, its Hydrogen Learning Demonstration has collected data on refueling rates, which has<br />

shown that, on the average, at 350 bar pressure, the refueling rate is 0.81 kg/min (with over 25% at a rate<br />

of more than 1 kg/min). At 700 bar pressure, the average refueling rate is 0.59 kg/min (with only 3% over<br />

1 kg/min).<br />

18 <strong>Challenges</strong> of Building a Hydrogen Infrastructure