One Hundred Years of Federal Mining Safety and Health Research

One Hundred Years of Federal Mining Safety and Health Research

One Hundred Years of Federal Mining Safety and Health Research

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Weighted Average exposure reduction <strong>of</strong> 3 dB(A). The urethane coating also extended the chain<br />

life by preventing any chain link failures during the 6-month test period.<br />

The dual-sprocket chain is another technology that was developed as a noise control for reducing<br />

noise overexposures <strong>of</strong> continuous mining machine operators. This control reduces noise by<br />

maintaining a constant level <strong>of</strong> tension <strong>and</strong> by decreasing chain slack that otherwise produces<br />

high-intensity noise-generating flight bar impacts at the conveyor transition points. Underground<br />

test results showed a 27 percent noise exposure reduction for the continuous mining machine<br />

operator.<br />

Both the dual-sprocket chain <strong>and</strong> the urethane-coated flight bar chain were categorized on the<br />

MSHA Program Information Bulletin (PIB) P08-12 as “technologically <strong>and</strong> administratively<br />

achievable” [MSHA 2008]. Both these noise controls are now available commercially.<br />

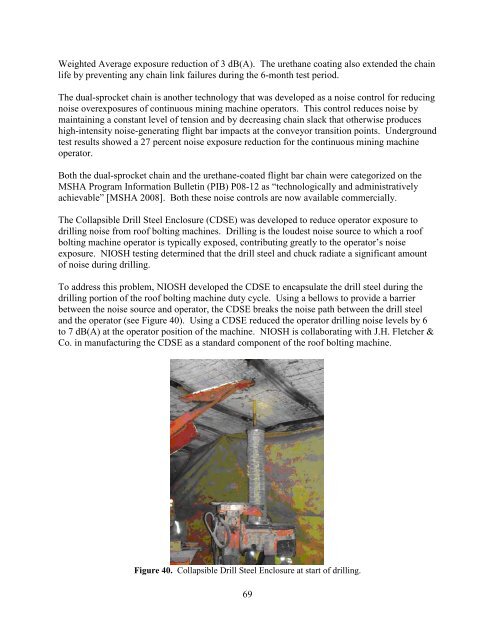

The Collapsible Drill Steel Enclosure (CDSE) was developed to reduce operator exposure to<br />

drilling noise from ro<strong>of</strong> bolting machines. Drilling is the loudest noise source to which a ro<strong>of</strong><br />

bolting machine operator is typically exposed, contributing greatly to the operator’s noise<br />

exposure. NIOSH testing determined that the drill steel <strong>and</strong> chuck radiate a significant amount<br />

<strong>of</strong> noise during drilling.<br />

To address this problem, NIOSH developed the CDSE to encapsulate the drill steel during the<br />

drilling portion <strong>of</strong> the ro<strong>of</strong> bolting machine duty cycle. Using a bellows to provide a barrier<br />

between the noise source <strong>and</strong> operator, the CDSE breaks the noise path between the drill steel<br />

<strong>and</strong> the operator (see Figure 40). Using a CDSE reduced the operator drilling noise levels by 6<br />

to 7 dB(A) at the operator position <strong>of</strong> the machine. NIOSH is collaborating with J.H. Fletcher &<br />

Co. in manufacturing the CDSE as a st<strong>and</strong>ard component <strong>of</strong> the ro<strong>of</strong> bolting machine.<br />

Figure 40. Collapsible Drill Steel Enclosure at start <strong>of</strong> drilling.<br />

69