geostationary telecommunications satellites electronic telephone set ...

geostationary telecommunications satellites electronic telephone set ...

geostationary telecommunications satellites electronic telephone set ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

121<br />

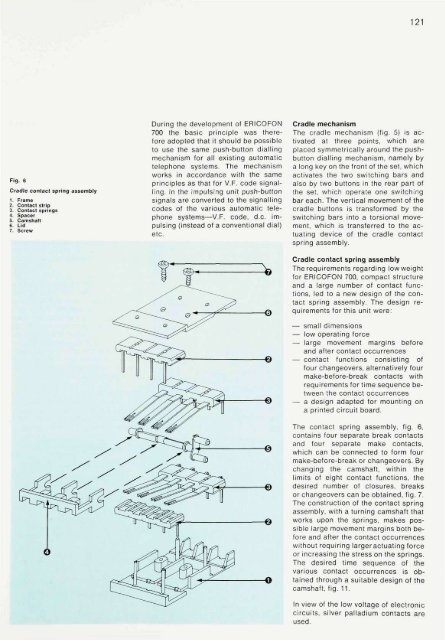

Fig. 6<br />

Cradle contact spring assembly<br />

1. Frame<br />

2. Contact strip<br />

3. Contact springs<br />

4. Spacer<br />

5. Camshaft<br />

6. Lid<br />

7. Screw<br />

During the development of ERICOFON<br />

700 the basic principle was therefore<br />

adopted that it should be possible<br />

to use the same push-button dialling<br />

mechanism for all existing automatic<br />

<strong>telephone</strong> systems. The mechanism<br />

works in accordance with the same<br />

principles as that for V.F. code signalling.<br />

In the impulsing unit push-button<br />

signals are converted to the signalling<br />

codes of the various automatic <strong>telephone</strong><br />

systems—V.F. code, d.c. impulsing<br />

(instead of a conventional dial)<br />

etc.<br />

Cradle mechanism<br />

The cradle mechanism (fig. 5) is activated<br />

at three points, which are<br />

placed symmetrically around the pushbutton<br />

dialling mechanism, namely by<br />

a long key on the front of the <strong>set</strong>, which<br />

activates the two switching bars and<br />

also by two buttons in the rear part of<br />

the <strong>set</strong>, which operate one switching<br />

bar each. The vertical movement of the<br />

cradle buttons is transformed by the<br />

switching bars into a torsional movement,<br />

which is transferred to the actuating<br />

device of the cradle contact<br />

spring assembly.<br />

Cradle contact spring assembly<br />

The requirements regarding low weight<br />

for ERICOFON 700, compact structure<br />

and a large number of contact functions,<br />

led to a new design of the contact<br />

spring assembly. The design requirements<br />

for this unit were:<br />

— small dimensions<br />

— low operating force<br />

—• large movement margins before<br />

and after contact occurrences<br />

— contact functions consisting of<br />

four changeovers, alternatively four<br />

make-before-break contacts with<br />

requirements for time sequence between<br />

the contact occurrences<br />

— a design adapted for mounting on<br />

a printed circuit board.<br />

The contact spring assembly, fig. 6,<br />

contains four separate break contacts<br />

and four separate make contacts,<br />

which can be connected to form four<br />

make-before-break or changeovers. By<br />

changing the camshaft, within the<br />

limits of eight contact functions, the<br />

desired number of closures, breaks<br />

or changeovers can be obtained, fig. 7.<br />

The construction of the contact spring<br />

assembly, with a turning camshaft that<br />

works upon the springs, makes possible<br />

large movement margins both before<br />

and after the contact occurrences<br />

without requiring largeractuating force<br />

or increasing the stress on the springs.<br />

The desired time sequence of the<br />

various contact occurrences is obtained<br />

through a suitable design of the<br />

camshaft, fig. 11.<br />

In view of the low voltage of <strong>electronic</strong><br />

circuits, silver palladium contacts are<br />

used.