Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

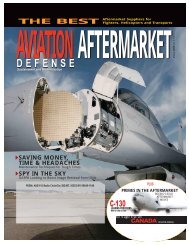

A Global Hawk sits on the runway before<br />

beginning a nighttime mission. The aircraft is<br />

unmanned, and is used to capture imagery from<br />

high altitudes.<br />

the same company makes the<br />

Integrated Sensor Suite, which includes<br />

the electro-optical, infrared, and<br />

synthetic aperature radar imaging used<br />

on all RQ-4As. To keep them in top<br />

operational order, the seven primary<br />

sensor LRUs on the RQ-4 are hand<br />

massaged on a daily basis.<br />

Maintenance providers need<br />

replacement parts to keep aircraft<br />

flying, and this can be a problem for the<br />

current operational RQ-4, because<br />

there are only nine Block 10 models in<br />

the entire world. U.S. Navy Captain<br />

Robert Dishman, Program Manager for<br />

Persistent Maritime Unmanned Aircraft<br />

Systems, at Patuxent River Naval Air<br />

Station in Maryland, tells us that a daily<br />

report is circulated to all units involved<br />

with RQ-4 operations, providing the<br />

status and availability of critical parts<br />

used on the aircraft.<br />

Cannibalization is a fact of life for<br />

Block 10 RQ-4s, as these UAVs have<br />

been projected to be replaced by more<br />

capable follow-on variants since the<br />

program's inception. This results in a<br />

higher cannibalization rate than<br />

normally is considered acceptable for a<br />

weapons system intended for long-term<br />

use.<br />

The fuselage of the RQ-4 is<br />

aluminum, and the wings and<br />

empennage are composite and, as<br />

such, are pretty standard in terms of<br />

maintenance upkeep. The issue faced<br />

by maintainers is that the RQ-4, like any<br />

new aircraft, still is undergoing damage<br />

tolerance assessment; this results in the<br />

need for engineering dispositions from<br />

Northrop Grumman before making<br />

most related repairs.<br />

Technicians update maintenance<br />

manuals as they encounter and repair<br />

damage to the skin of the RQ-4 in order<br />

to continually improve its capabilities.<br />

For example, U.S. Navy BAMS RQ-4N<br />

aircraft will include leading-edge<br />

modifications, which have undergone<br />

hail and bird strike tests.<br />

Another difference between the<br />

U.S. Navy's planned BAMS version of<br />

the RQ-4B and the U.S. Air Force's<br />

Blocks 20-40 is the addition of leadingedge<br />

anti-icing and de-icing<br />

capabilities. Icing is a definite problem<br />

encountered in RQ-4 operations, so<br />

much so that the Air Force has lost<br />

quite a few sorties due to icing<br />

conditions.<br />

During initial design, the<br />

assumption was made that the aircraft<br />

would transit the icing regime quickly<br />

enough, so that ice buildup would not<br />

be an issue. It took further engineering<br />

analysis and in-flight experience to<br />

determine that was not the case;<br />

however, this still was unknown during<br />

initial reviews of the U.S. Air Force<br />

variants.<br />

As more data was available when<br />

the U.S. Navy went on contract, a<br />

requirement for anti-icing and de-icing<br />

features was added. Since retrofitting<br />

this desirable capability is expensive,<br />

the U.S. Air Force is looking at adding it<br />

to future production models.<br />

U.S. Navy RQ-4Ns also will have<br />

KEEPING THE RQ-4 IN THE AIR<br />

increased wing strength to allow for<br />

greater gust load environments and<br />

increase safety factors. This has been<br />

accomplished by adding several more<br />

layers of composite to the wings, while<br />

taking some of the thickness away from<br />

the wing spars. This tradeoff allows the<br />

wing shape to remain the same.<br />

Despite these subtle model<br />

differences, the U.S. Air Force and the<br />

U.S. Navy are working together in their<br />

RQ-4 operations around the world,<br />

sharing maintenance technicians, parts,<br />

and ground support equipment, such as<br />

the LRE (Launch and Recovery Element).<br />

Most important, the two services are<br />

sharing their experiences and ongoing<br />

information, with the goal of improving<br />

and maximizing the use of the versatile<br />

RQ-4.<br />

This cooperation is exemplified by<br />

the recent 380 Air Expeditionary Wing's<br />

addition of the first operational U.S.<br />

Navy RQ-4A. This joint mission is an<br />

outgrowth of the GHMD program,<br />

known as the Broad Area Maritime<br />

Surveillance Demonstrator.<br />

WWW.ABDONLINE.COM AVIATION AFTERMARKET <strong>DEFENSE</strong> | SPRING 2010<br />

AAD<br />

37<br />

Photo by John Schwab, Beale Air Force Base, California