by riders for riders a history of innovation - Specialized

by riders for riders a history of innovation - Specialized

by riders for riders a history of innovation - Specialized

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

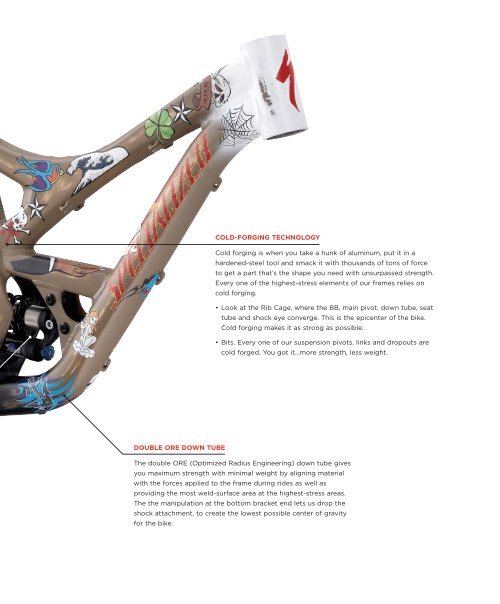

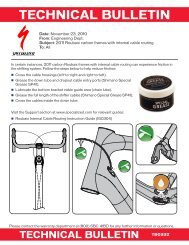

DOUBLE ORE DOWN TUBE<br />

COLD-FORGING TECHNOLOGY<br />

Cold <strong>for</strong>ging is when you take a hunk <strong>of</strong> aluminum, put it in a<br />

hardened-steel tool and smack it with thousands <strong>of</strong> tons <strong>of</strong> <strong>for</strong>ce<br />

to get a part that’s the shape you need with unsurpassed strength.<br />

Every one <strong>of</strong> the highest-stress elements <strong>of</strong> our frames relies on<br />

cold <strong>for</strong>ging.<br />

• Look at the Rib Cage, where the BB, main pivot, down tube, seat<br />

tube and shock eye converge. This is the epicenter <strong>of</strong> the bike.<br />

Cold <strong>for</strong>ging makes it as strong as possible.<br />

• Bits. Every one <strong>of</strong> our suspension pivots, links and dropouts are<br />

cold <strong>for</strong>ged. You got it…more strength, less weight.<br />

The double ORE (Optimized Radius Engineering) down tube gives<br />

you maximum strength with minimal weight <strong>by</strong> aligning material<br />

with the <strong>for</strong>ces applied to the frame during rides as well as<br />

providing the most weld-surface area at the highest-stress areas.<br />

The the manipulation at the bottom bracket end lets us drop the<br />

shock attachment, to create the lowest possible center <strong>of</strong> gravity<br />

<strong>for</strong> the bike.