cw-6-2i

cw-6-2i

cw-6-2i

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Panorama<br />

Germany<br />

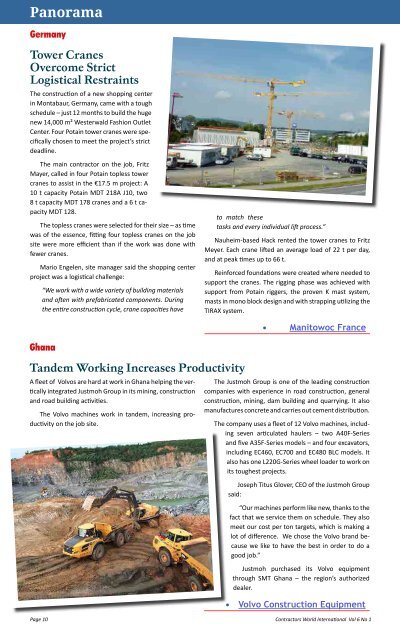

Tower Cranes<br />

Overcome Strict<br />

Logistical Restraints<br />

The construction of a new shopping center<br />

in Montabaur, Germany, came with a tough<br />

schedule – just 12 months to build the huge<br />

new 14,000 m² Westerwald Fashion Outlet<br />

Center. Four Potain tower cranes were specifically<br />

chosen to meet the project’s strict<br />

deadline.<br />

The main contractor on the job, Fritz<br />

Mayer, called in four Potain topless tower<br />

cranes to assist in the €17.5 m project: A<br />

10 t capacity Potain MDT 218A J10, two<br />

8 t capacity MDT 178 cranes and a 6 t capacity<br />

MDT 128.<br />

The topless cranes were selected for their size – as time<br />

was of the essence, fitting four topless cranes on the job<br />

site were more efficient than if the work was done with<br />

fewer cranes.<br />

Mario Engelen, site manager said the shopping center<br />

project was a logistical challenge:<br />

“We work with a wide variety of building materials<br />

and often with prefabricated components. During<br />

the entire construction cycle, crane capacities have<br />

to match these<br />

tasks and every individual lift process.”<br />

Nauheim-based Hack rented the tower cranes to Fritz<br />

Meyer. Each crane lifted an average load of 22 t per day,<br />

and at peak times up to 66 t.<br />

Reinforced foundations were created where needed to<br />

support the cranes. The rigging phase was achieved with<br />

support from Potain riggers, the proven K mast system,<br />

masts in mono block design and with strapping utilizing the<br />

TIRAX system.<br />

• Manitowoc France<br />

Ghana<br />

Tandem Working Increases Productivity<br />

A fleet of Volvos are hard at work in Ghana helping the vertically<br />

integrated Justmoh Group in its mining, construction<br />

and road building activities.<br />

The Volvo machines work in tandem, increasing productivity<br />

on the job site.<br />

The Justmoh Group is one of the leading construction<br />

companies with experience in road construction, general<br />

construction, mining, dam building and quarrying. It also<br />

manufactures concrete and carries out cement distribution.<br />

The company uses a fleet of 12 Volvo machines, including<br />

seven articulated haulers – two A40F-Series<br />

and five A35F-Series models – and four excavators,<br />

including EC460, EC700 and EC480 BLC models. It<br />

also has one L220G-Series wheel loader to work on<br />

its toughest projects.<br />

Joseph Titus Glover, CEO of the Justmoh Group<br />

said:<br />

“Our machines perform like new, thanks to the<br />

fact that we service them on schedule. They also<br />

meet our cost per ton targets, which is making a<br />

lot of difference. We chose the Volvo brand because<br />

we like to have the best in order to do a<br />

good job.”<br />

Justmoh purchased its Volvo equipment<br />

through SMT Ghana – the region’s authorized<br />

dealer.<br />

• Volvo Construction Equipment<br />

Page 10 Contractors World International Vol 6 No 1