cw-6-2i

cw-6-2i

cw-6-2i

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

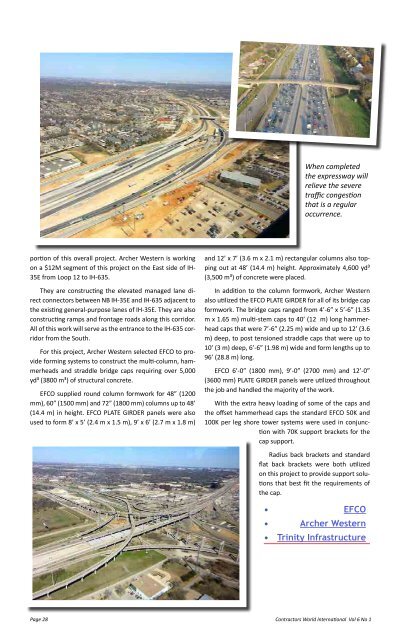

When completed<br />

the expressway will<br />

relieve the severe<br />

traffic congestion<br />

that is a regular<br />

occurrence.<br />

portion of this overall project. Archer Western is working<br />

on a $12M segment of this project on the East side of IH-<br />

35E from Loop 12 to IH-635.<br />

They are constructing the elevated managed lane direct<br />

connectors between NB IH-35E and IH-635 adjacent to<br />

the existing general-purpose lanes of IH-35E. They are also<br />

constructing ramps and frontage roads along this corridor.<br />

All of this work will serve as the entrance to the IH-635 corridor<br />

from the South.<br />

For this project, Archer Western selected EFCO to provide<br />

forming systems to construct the multi-column, hammerheads<br />

and straddle bridge caps requiring over 5,000<br />

yd³ (3800 m³) of structural concrete.<br />

EFCO supplied round column formwork for 48” (1200<br />

mm), 60” (1500 mm) and 72” (1800 mm) columns up to 48’<br />

(14.4 m) in height. EFCO PLATE GIRDER panels were also<br />

used to form 8’ x 5’ (2.4 m x 1.5 m), 9’ x 6’ (2.7 m x 1.8 m)<br />

and 12’ x 7’ (3.6 m x 2.1 m) rectangular columns also topping<br />

out at 48’ (14.4 m) height. Approximately 4,600 yd³<br />

(3,500 m³) of concrete were placed.<br />

In addition to the column formwork, Archer Western<br />

also utilized the EFCO PLATE GIRDER for all of its bridge cap<br />

formwork. The bridge caps ranged from 4’-6” x 5’-6” (1.35<br />

m x 1.65 m) multi-stem caps to 40’ (12 m) long hammerhead<br />

caps that were 7’-6” (2.25 m) wide and up to 12’ (3.6<br />

m) deep, to post tensioned straddle caps that were up to<br />

10’ (3 m) deep, 6’-6” (1.98 m) wide and form lengths up to<br />

96’ (28.8 m) long.<br />

EFCO 6’-0” (1800 mm), 9’-0” (2700 mm) and 12’-0”<br />

(3600 mm) PLATE GIRDER panels were utilized throughout<br />

the job and handled the majority of the work.<br />

With the extra heavy loading of some of the caps and<br />

the offset hammerhead caps the standard EFCO 50K and<br />

100K per leg shore tower systems were used in conjunction<br />

with 70K support brackets for the<br />

cap support.<br />

Radius back brackets and standard<br />

flat back brackets were both utilized<br />

on this project to provide support solutions<br />

that best fit the requirements of<br />

the cap.<br />

• EFCO<br />

• Archer Western<br />

• Trinity Infrastructure<br />

Page 28 Contractors World International Vol 6 No 1