FISKARS 1649 â 360 years of Finnish industrial history

FISKARS 1649 â 360 years of Finnish industrial history

FISKARS 1649 â 360 years of Finnish industrial history

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Fiskars <strong>1649</strong><br />

Fiskars <strong>1649</strong><br />

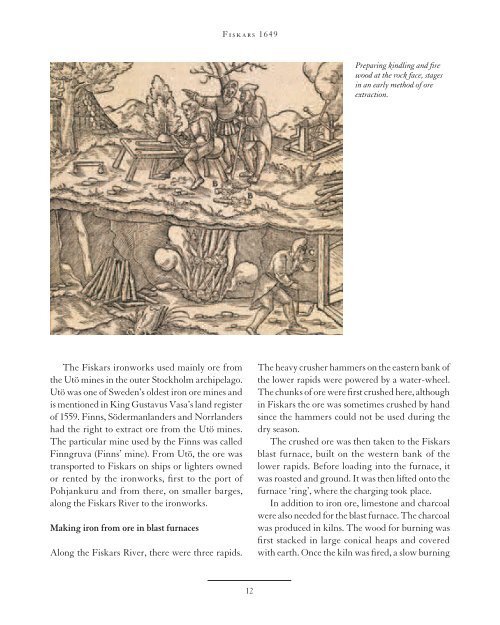

Preparing kindling and fire<br />

wood at the rock face, stages<br />

in an early method <strong>of</strong> ore<br />

extraction.<br />

The Fiskars ironworks used mainly ore from<br />

the Utö mines in the outer Stockholm archipelago.<br />

Utö was one <strong>of</strong> Sweden’s oldest iron ore mines and<br />

is mentioned in King Gustavus Vasa’s land register<br />

<strong>of</strong> 1559. Finns, Södermanlanders and Norrlanders<br />

had the right to extract ore from the Utö mines.<br />

The particular mine used by the Finns was called<br />

Finngruva (Finns’ mine). From Utö, the ore was<br />

transported to Fiskars on ships or lighters owned<br />

or rented by the ironworks, first to the port <strong>of</strong><br />

Pohjankuru and from there, on smaller barges,<br />

along the Fiskars River to the ironworks.<br />

Making iron from ore in blast furnaces<br />

Along the Fiskars River, there were three rapids.<br />

The heavy crusher hammers on the eastern bank <strong>of</strong><br />

the lower rapids were powered by a water-wheel.<br />

The chunks <strong>of</strong> ore were first crushed here, although<br />

in Fiskars the ore was sometimes crushed by hand<br />

since the hammers could not be used during the<br />

dry season.<br />

The crushed ore was then taken to the Fiskars<br />

blast furnace, built on the western bank <strong>of</strong> the<br />

lower rapids. Before loading into the furnace, it<br />

was roasted and ground. It was then lifted onto the<br />

furnace ‘ring’, where the charging took place.<br />

In addition to iron ore, limestone and charcoal<br />

were also needed for the blast furnace. The charcoal<br />

was produced in kilns. The wood for burning was<br />

first stacked in large conical heaps and covered<br />

with earth. Once the kiln was fired, a slow burning<br />

The charcoal used in the blast furnaces was made by burning wood in kilns. The picture shows different stages <strong>of</strong> this work in<br />

the 18th century.<br />

12<br />

13