Connection schemes Sepam 1000+ series 40 - Trinet

Connection schemes Sepam 1000+ series 40 - Trinet

Connection schemes Sepam 1000+ series 40 - Trinet

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

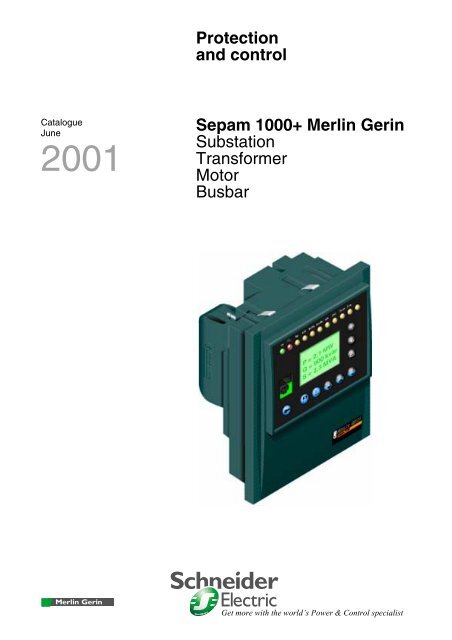

Protection<br />

and control<br />

Catalogue<br />

June<br />

2001<br />

<strong>Sepam</strong> <strong>1000+</strong> Merlin Gerin<br />

Substation<br />

Transformer<br />

Motor<br />

Busbar<br />

Get more with the world’s Power & Control specialist

Contents<br />

Presentation 2<br />

More solutions 2<br />

Flexible architecture 5<br />

User-machine interface 6<br />

Selection table 8<br />

<strong>Sepam</strong> <strong>1000+</strong> <strong>series</strong> 20 8<br />

<strong>Sepam</strong> <strong>1000+</strong> <strong>series</strong> <strong>40</strong> 9<br />

Metering 10<br />

Description 10<br />

Characteristics 11<br />

Protection function 12<br />

Description 12<br />

Setting ranges 14<br />

<strong>Connection</strong> <strong>schemes</strong> 16<br />

<strong>Sepam</strong> <strong>1000+</strong> <strong>series</strong> 20 16<br />

<strong>Sepam</strong> <strong>1000+</strong> <strong>series</strong> <strong>40</strong> 17<br />

Other connection <strong>schemes</strong> 18<br />

Control and monitoring 20<br />

Description 20<br />

Logic inputs and outputs 21<br />

Description 21<br />

Assignment by application <strong>Sepam</strong> <strong>1000+</strong> <strong>series</strong> 20 22<br />

Assignment by application <strong>Sepam</strong> <strong>1000+</strong> <strong>series</strong> <strong>40</strong> 23<br />

Optional remote modules 24<br />

Description 24<br />

<strong>Connection</strong>s 25<br />

Sensors 26<br />

Core balance CTs 26<br />

Interfaces 27<br />

Communication 28<br />

Description and characteristics 28<br />

Parameters and protection settings 30<br />

Description 30<br />

Program logic 31<br />

Characteristics 32<br />

Size and weight 32<br />

Electrical characteristics 34<br />

Environmental characteristics 35<br />

Schneider Electric<br />

1

Presentation<br />

More solutions<br />

The <strong>Sepam</strong> <strong>1000+</strong> family of protection and<br />

metering units is designed for the operation<br />

of machines and electrical distribution<br />

networks of industrial installations and utility<br />

substations for all levels of voltage.<br />

It consists of complete, simple and<br />

reliable solutions, suited to the following<br />

applications:<br />

# protection of substations (incomers and<br />

feeders)<br />

# protection of transformers<br />

# protection of motors<br />

# protection of busbars.<br />

<strong>Sepam</strong> <strong>1000+</strong> <strong>series</strong> 20<br />

Suitable for common applications, <strong>Sepam</strong> <strong>1000+</strong> <strong>series</strong> 20 offers simple<br />

solutions based on current or voltage metering.<br />

The <strong>Sepam</strong> <strong>1000+</strong> <strong>series</strong> 20 S20, T20 and M20 current units cover applications<br />

such as the following:<br />

# protection of substation incomers and feeders against phase-to-phase and<br />

phase-to-earth short-circuits<br />

5 16 IDMT tripping curves<br />

5 adjustable timer hold to detect recurrent faults<br />

5 switching of groups of setting to adapt to changes in the network configuration<br />

# protection of overhead lines with reclosers<br />

# protection of transformers against overloads, with ambient temperaturecompensated<br />

RMS thermal overload protection with 2 groups of settings for different<br />

ventilation operating rates<br />

# protection of motors<br />

5 against overloads, with ambient temperature-compensated RMS thermal overload<br />

protection with a cold tripping curve that can be adjusted to fit motor characteristics<br />

5 against internal faults and load-related faults<br />

5 with motor starting condition monitoring and machine operation assistance.<br />

The <strong>Sepam</strong> <strong>1000+</strong> <strong>series</strong> 20 B21 and B22 voltage units are suitable for the<br />

following situations:<br />

# monitoring of network voltage and frequency<br />

# loss of mains detection by rate of change of frequency protection for installations<br />

with local power generation.<br />

<strong>Sepam</strong> <strong>1000+</strong> <strong>series</strong> <strong>40</strong><br />

<strong>Sepam</strong> <strong>1000+</strong> <strong>series</strong> <strong>40</strong>, with its current and voltage metering capabilities, offers<br />

high-performing solutions for more demanding applications.<br />

<strong>Sepam</strong> <strong>1000+</strong> <strong>series</strong> <strong>40</strong> units perform the following functions in addition to those<br />

performed by <strong>Sepam</strong> <strong>1000+</strong> <strong>series</strong> 20:<br />

# protection of networks with parallel incomers by directional protection<br />

# directional earth fault protection suitable for all earthing systems, impedant,<br />

isolated or compensated neutral<br />

# all the necessary electrical measurements: phase and residual current, phase-toneutral,<br />

phase-to-phase and residual voltage, frequency, power and energy, …<br />

# comprehensive network diagnosis assistance: 20 seconds of disturbance<br />

recording, detailed history of the last 200 alarms, storage of contexts of the last<br />

5trips<br />

# adaptation of control functions by a logical equation editor<br />

# customization of alarm messages to fit each application, and/or in the user's<br />

language.<br />

<strong>Sepam</strong> <strong>1000+</strong> selection guide<br />

Selection Series 20 Series <strong>40</strong><br />

criteria<br />

Measurements I U U I and U I and U I and U<br />

Specific<br />

protection<br />

functions<br />

Loss of<br />

mains<br />

(ROCOF)<br />

Directional<br />

earth fault<br />

Directional<br />

earth fault and<br />

phase<br />

overcurrent<br />

Applications<br />

Substation S20 S<strong>40</strong> S41 S42<br />

Transformer T20 T<strong>40</strong> T42<br />

Motor M20 M41<br />

Busbar B21 B22<br />

Example : For motor protection and current and voltage measurements, your solution<br />

is the M41 type <strong>Sepam</strong> <strong>1000+</strong>.<br />

2 Schneider Electric

Presentation<br />

More solutions<br />

More simplicity<br />

Simple to install<br />

# no constraints for integration in cubicles due to the compact size of the base units<br />

and remote installation of optional modules<br />

# universal auxiliary power supply.<br />

Simple to commission<br />

# all the functions are ready to use<br />

# user-friendly, powerful PC setting software to utilize all the possibilities offered by<br />

<strong>Sepam</strong> <strong>1000+</strong>.<br />

Simple to operate<br />

With the advanced UMI, all local operations are made easier by a clear, complete<br />

presentation of all the required information in your language.<br />

Simple to maintain<br />

# digital unit self-diagnosis and watchdog<br />

# switchgear diagnosis assistance functions to assess equipment condition and<br />

schedule preventive maintenance operations:<br />

5 cumulative breaking current<br />

5 breaking device operating and charging time.<br />

More communication<br />

Modbus communication<br />

All the data needed for centralized management of your electrical network are<br />

available with the communication option based on the open, international Modbus<br />

protocol:<br />

# measurement and diagnosis values<br />

# remote indication and time-tagging of events<br />

# remote control of the installation<br />

# remote setting of protection functions<br />

# reading of disturbance recording files.<br />

Ethernet connection and Webserver<br />

<strong>Sepam</strong> <strong>1000+</strong> can be connected to an Ethernet broadband network by Ethernet/<br />

Modbus communication gateways.<br />

With these gateways :<br />

# <strong>Sepam</strong> <strong>1000+</strong> can be integrated in any automation and supervisory system based<br />

on Modbus / TCP/IP multi-master protocol<br />

# Web pages presenting information provided by <strong>Sepam</strong> may be consulted via an<br />

Internet/Intranet browser.<br />

PowerLogic System<br />

<strong>Sepam</strong> <strong>1000+</strong> is a component of PowerLogic System and may naturally be<br />

associated with SMS centralized industrial and commercial electrical network<br />

management software.<br />

Schneider Electric<br />

3

Presentation<br />

More solutions<br />

More modularity<br />

<strong>Sepam</strong> <strong>1000+</strong> is available with 2 User Machine Interface (UMI) levels:<br />

# advanced UMI, with keypad and graphic LCD display<br />

5 to provide all the data required for local operation of the installation:<br />

measurements, diagnosis information, alarms, etc.<br />

5 to set <strong>Sepam</strong> <strong>1000+</strong> parameters and protection functions<br />

5 to be understood by all, the screens can be displayed in the user’s language.<br />

The advanced UMI may be part of the base unit or installed as a remote unit in the<br />

most convenient location for the user.<br />

# basic UMI, with signal lamps<br />

5 no need for local operation<br />

5 for remotely operated installations.<br />

In order to adapt to as many situations as possible and allow for subsequent<br />

upgrading of the installation, <strong>Sepam</strong> <strong>1000+</strong> may be functionally enhanced at<br />

any time by the addition of optional modules:<br />

# logic input/output module with parameterizable program logic<br />

# communication module<br />

# temperature sensor module<br />

# analog output module.<br />

4 Schneider Electric

Presentation<br />

Flexible architecture<br />

E54735<br />

MES108 module<br />

4 logic outputs,<br />

4 logic inputs<br />

(1)<br />

or MES114<br />

4 logic outputs,<br />

10 logic inputs<br />

(1)<br />

<strong>Sepam</strong> <strong>1000+</strong><br />

base unit<br />

with advanced UMI<br />

ACE949-2 (2-wire) module<br />

ACE959 (4-wire) module<br />

communication network<br />

interface<br />

(1)<br />

on I >> 51 Io > 51n Io >> 51n ext<br />

0 off<br />

P=2.1 MW<br />

Q=900 Kvar<br />

S = 2.3 MVA<br />

clear<br />

I on Trip<br />

reset<br />

CCA612<br />

CCA772<br />

(2)<br />

I>51<br />

MERLIN GERIN<br />

sepam<br />

(1)<br />

MSA141 module<br />

1 analog output<br />

CCA783<br />

CCA770<br />

(2)<br />

(1)<br />

MET148 module<br />

8 temperature<br />

sensors<br />

SFT 2841<br />

parameter setting<br />

and operating software<br />

SFT 2826<br />

disturbance recording<br />

restoring software<br />

(1) optional additional module.<br />

(2) example, the prefabricated cords come in 3 different lengths.<br />

Schneider Electric<br />

5

Presentation<br />

User-machine interface<br />

E54928<br />

<strong>Sepam</strong> <strong>1000+</strong> has two levels of UMI<br />

(user-machine interface) suited to every<br />

operating requirement.<br />

on<br />

I>51<br />

I >> 51<br />

Io > 51N<br />

Io >> 51N<br />

ext<br />

0 off I on Trip<br />

reset<br />

Basic UMI<br />

This UMI includes:<br />

# 2 signal lamps indicating <strong>Sepam</strong> <strong>1000+</strong> operating status:<br />

5 green "on" indicator: device on<br />

5 red "wrench" indicator: device unavailable (initialization phase or detection of an<br />

internal failure)<br />

# 9 parameterizable yellow signal lamps equipped with a standard label (1)<br />

# "reset" button for clearing faults and resetting<br />

# 1 connection port for the RS232 link with the PC, the port is protected by a sliding<br />

cover.<br />

This UMI offers a low-cost solution for installations that do no require local operation<br />

(run from a remote monitoring and control system) or to replace electromechanical<br />

or analog electronic protection devices without any additional operating<br />

requirements.<br />

E54929<br />

Example of basic UMI with standard signal lamp assignment.<br />

on<br />

9<br />

I>51<br />

I> > 51<br />

8<br />

Io > 51N<br />

7<br />

Io >> 51N<br />

Example of advanced UMI with standard signal lamp<br />

assignment.<br />

ext<br />

I1 = 162A<br />

I2 = 161A<br />

I3 = 163A<br />

6<br />

clear<br />

5<br />

0 off<br />

I on<br />

reset<br />

4<br />

trip<br />

1<br />

2<br />

3<br />

Advanced UMI<br />

In addition to the basic UMI functions, this version provides:<br />

# a "graphic" LCD display with automatic contrast adjustment and user-triggered<br />

backlighting. It is used to display measurements, parameter/protection settings and<br />

alarm and operating messages.<br />

Number of lines, size of characters and symbols according to screens and language<br />

versions.<br />

# a 9-key keypad with two operating modes:<br />

White keys for current operation:<br />

➀ display of measurements.<br />

➁ display of switchgear and network diagnosis data.<br />

➂ display of alarm messages.<br />

➃ resetting.<br />

➄ acknowledgment and clearing of alarms.<br />

Blue keys for parameter setting and protection setting:<br />

➆ access to protection settings.<br />

➇ access to <strong>Sepam</strong> <strong>1000+</strong> parameter settings (2) .<br />

➈ used to enter the 2 passwords required to change protection and parameter<br />

settings.<br />

The “ ↵, ▲, ▼ ” keys (➃, ➄, ➅) are used to navigate in the menus and to scroll and<br />

accept the values displayed.<br />

➅ "lamp test" keys:<br />

switching on sequence of all the signal lamps.<br />

This UMI is an optimum solution for local operation facilitated by clear legibility,<br />

content and access to the different data items.<br />

Remote advanced UMI<br />

The advanced UMI functions are also available in a remote module that is connected<br />

to a <strong>Sepam</strong> <strong>1000+</strong> with a basic UMI (connection by prefabricated cable of different<br />

lengths)..<br />

The module is installed on the front panel of the cubicle in the most appropriate<br />

operating location.<br />

(1) this removable label may be replaced by a customized label produced using the SFT 2841<br />

software tool.<br />

(2) for parameter setting of the program logic, the expert UMI must be used.<br />

6 Schneider Electric

Presentation<br />

User-machine interface<br />

<strong>Sepam</strong> <strong>1000+</strong> <strong>series</strong> 20: measurements.<br />

<strong>Sepam</strong> <strong>1000+</strong> <strong>series</strong> 20: setting of protection function 50/51.<br />

Expert UMI<br />

This UMI is available as a complement to the standard or advanced UMI on the<br />

screen of a PC equipped with the SFT 2841 software tool and connected to the<br />

RS 232 link on the front panel of the <strong>Sepam</strong> (operating in a Windows > V95 or<br />

NT environment).<br />

All the data used for the same task are grouped together in the same screen to<br />

facilitate operation. Menus and icons are used for fast, direct access to the required<br />

information.<br />

Current operation<br />

# display of all metering and operating data<br />

# display of alarm messages with the time of appearance<br />

# display of diagnosis data such as:<br />

5 tripping current<br />

5 number of switchgear operations and cumulative breaking current<br />

# display of all protection and parameter settings<br />

# display of the logic status of inputs, outputs and signal lamps.<br />

This UMI is the solution suited to occasional local operation for demanding personnel<br />

who require fast access to all the information.<br />

Parameter setting – protection setting (1)<br />

# display and setting of all the parameters of each protection function in the same<br />

page<br />

# program logic parameter setting, parameter setting of general installation and<br />

<strong>Sepam</strong> data<br />

# input data may be prepared ahead of time and transferred into the corresponding<br />

<strong>Sepam</strong> units in a single operation (downloading function).<br />

Main functions performed by SFT 2841 :<br />

# changing of passwords<br />

# entry of general settings (ratings, integration period, …)<br />

# entry of protection settings<br />

# changing of program logic assignments<br />

# enabling/disabling of functions<br />

# saving of files.<br />

Saving<br />

# protection and parameter setting data may be saved<br />

# printing of reports is possible as well.<br />

This UMI may also be used to recover disturbance recording files and provide<br />

graphic display using the SFT 2826 software tool.<br />

Operating assistance<br />

Access from all the screens to a help section which contains all the technical data<br />

required for <strong>Sepam</strong> installation and use.<br />

(1) modes available via 2 passwords (protection setting level, parameter setting level).<br />

Schneider Electric<br />

7

Selection table <strong>Sepam</strong> <strong>1000+</strong> <strong>series</strong> 20<br />

Functions<br />

Type of <strong>Sepam</strong><br />

Substation Transformer Motor Busbar<br />

Protection ANSI code S20 T20 M20 B21 (5) B22<br />

Phase overcurrent 50/51 4 4 4<br />

Earth fault, sensitive earth fault 50N/51N 4 4 4<br />

Breaker failure<br />

50BF<br />

Negative sequence / unbalance 46 1 1 1<br />

Directional phase overcurrent 67<br />

Directional earth fault<br />

67N/67NC<br />

Active overpower<br />

32P<br />

Thermal overload 49RMS 2 2<br />

Phase undercurrent 37 1<br />

Locked rotor, excessive starting time 48/51LR 1<br />

Starts per hour 66 1<br />

Positive sequence undervoltage 27D/47 2 2<br />

Remanent undervoltage 27R 1 1<br />

Phase-to-phase undervoltage 27 2 2<br />

Phase-to-neutral undervoltage 27S 1 1<br />

Phase-to-phase overvoltage 59 2 2<br />

Neutral voltage displacement 59N 2 2<br />

Negative sequence overvoltage 47<br />

Overfrequency 81H 1 1<br />

Underfrequency 81L 2 2<br />

Rate of change of frequency 81R 1<br />

Recloser (4 cycles) 79 5<br />

Thermostat / Buchholz 5<br />

Temperature monitoring (with MET148, 2 set points per sensor) 38/49T 8 8<br />

Metering<br />

Phase current I1, I2, I3 RMS, Residual current Io # # #<br />

Average current I1, I2, I3, Peak demand phase currents # # #<br />

Voltage U21, U32, U13, V1, V2, V3, Residual voltage Vo # #<br />

Positive sequence voltage Vd / rotation direction # #<br />

Negative sequence voltage Vi<br />

Frequency # #<br />

Active and reactive power P and Q, Peak demand P and Q, Power factor<br />

Active and reactive energy (“Wh, “VARh)<br />

Temperature measurement 5 5<br />

Network and machine diagnosis<br />

Tripping current I1, I2, I3, Io # # #<br />

Tripping context<br />

Unbalance ratio / negative sequence current Ii # # #<br />

Phase angle ϕo, ϕ1, ϕ2, ϕ3<br />

Disturbance recording # # # # #<br />

Thermal capacity used # #<br />

Remaining operating time before overload tripping # #<br />

Waiting time after overload tripping # #<br />

Running hours counter / operating time # #<br />

Starting current and time #<br />

Start inhibit time delay, number of starts before inhibition #<br />

Switchgear diagnosis<br />

Cumulative breaking current # # #<br />

Trip circuit supervision 5 5 5<br />

Number of operations, Operating time, Charging time 5 5 5<br />

CT / VT supervision<br />

Control and monitoring<br />

Circuit breaker / contactor control (2) 5 5 5 5 5<br />

Logic discrimination 5 5 5<br />

Switching of setting groups # (3) # (3) # (3)<br />

Program logic parameter setting (Boolean equation editor: AND, OR, …)<br />

Additional modules<br />

8 temperature sensor outputs - MET148 module 5 5<br />

1 low level analog output - MSA141 module 5 5 5 5 5<br />

Logic inputs and ouputs - MES108 module (4I/4O) or MES114 (10I/4O) 5 5 5 5 5<br />

RS485 interface - ACE 949-2 (2-wire) or ACE959 (4-wire) module 5 5 5 5 5<br />

#Ãstandard, 5 according to parameter setting and MES108, MES114 or MET148 input/output module options<br />

(1) available in 2002.<br />

(2) for shunt trip unit or undervoltage release coil.<br />

(3) exclusive choice between logic discrimination and switching from one 2-relay group of settings to another 2-relay group.<br />

(4) 2 modules possible.<br />

(5) performs B20 type functions.<br />

8 Schneider Electric

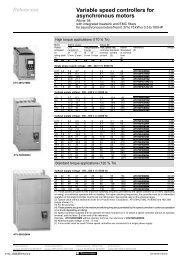

Selection table <strong>Sepam</strong> <strong>1000+</strong> <strong>series</strong> <strong>40</strong><br />

Functions<br />

Type of <strong>Sepam</strong><br />

Substation Transformer Motor<br />

Protection Code ANSI S<strong>40</strong> S41 S42 (1) T<strong>40</strong> (1) T42 (1) M41 (1)<br />

Phase overcurrent 50/51 4 4 4 4 4 4<br />

Earth fault, sensitive earth fault 50N/51N 4 4 4 4 4 4<br />

Breaker failure 50BF 1 (1) 1 (1) 1 1 1 1<br />

Negative sequence / unbalance 46 2 2 2 2 2 2<br />

Directional phase overcurrent 67 2 2<br />

Directional earth fault 67N/67NC 2 2 2 2<br />

Active overpower 32P 1 (1) 1 1<br />

Thermal overload 49RMS 2 2 2<br />

Phase undercurrent 37 1<br />

Locked rotor, excessive starting time 48/51LR 1<br />

Starts per hour 66 1<br />

Positive sequence undervoltage 27D/47 2<br />

Remanent undervoltage 27R 1<br />

Phase-to-phase undervoltage 27 (6) 2 2 2 2 2 2<br />

Phase-to-neutral undervoltage 27S (6) 2 2 2 2 2 2<br />

Phase-to-phase overvoltage 59 (6) 2 2 2 2 2 2<br />

Neutral voltage displacement 59N 2 2 2 2 2 2<br />

Negative sequence overvoltage 47 1 1 1 1 1 1<br />

Overfrequency 81H 2 2 2 2 2 2<br />

Underfrequency 81L 4 4 4 4 4 4<br />

Rate of change of frequency<br />

81R<br />

Recloser (4 cycles) 79 5 5 5<br />

Thermostat / Buchholz 5 5<br />

Temperature monitoring (with MET148, 2 set points per sensor) 38/49T 8/16 8/16 8/16<br />

Metering<br />

Phase current I1, I2, I3 RMS, Residual current Io # # # # # #<br />

Average current I1, I2, I3, Peak demand phase currents # # # # # #<br />

Voltage U21, U32, U13, V1, V2, V3, Residual voltage Vo # # # # # #<br />

Positive sequence voltage Vd / rotation direction # # # # # #<br />

Negative sequence voltage Vi # # # # # #<br />

Frequency # # # # # #<br />

Active and reactive power P and Q, Peak demand P and Q, Power factor # # # # # #<br />

Active and reactive energy (“Wh, “VARh) # # # # # #<br />

Temperature measurement 5 5 5<br />

Network and machine diagnosis<br />

Tripping current I1, I2, I3, Io # # # # # #<br />

Tripping context # # # # # #<br />

Unbalance ratio / negative sequence current Ii # # # # # #<br />

Phase angle ϕo, ϕ1, ϕ2, ϕ3 # # # # # #<br />

Disturbance recording # # # # # #<br />

Thermal capacity used # # #<br />

Remaining operating time before overload tripping # # #<br />

Waiting time after overload tripping # # #<br />

Running hours counter / operating time # # #<br />

Starting current and time #<br />

Start inhibit time delay, number of starts before inhibition #<br />

Switchgear diagnosis<br />

Cumulative breaking current # # # # # #<br />

Trip circuit supervision 5 5 5 5 5 5<br />

Number of operations, Operating time, Charging time 5 5 5 5 5 5<br />

CT / VT supervision # (1) # (1) # # # #<br />

Control and monitoring<br />

Circuit breaker / contactor control (2) # # # # # #<br />

Logic discrimination 5 5 5 5 5 5<br />

Switching of setting groups # # # # # #<br />

Program logic parameter setting (Boolean equation editor: AND, OR, …) # (1) # (1) # # # #<br />

Additional modules<br />

8 temperature sensor outputs - MET148 module 5 (4) 5 (4) 5 (4)<br />

1 low level analog output - MSA141 module 5 (1) 5 (1) 5 5 5 5<br />

Logic inputs and ouputs - MES108 module (4I/4O) or MES114 (10I/4O) 5 5 5 5 5 5<br />

RS485 interface - ACE 949-2 (2-wire) or ACE959 (4-wire) module 5 5 5 5 5 5<br />

# standard, 5Ãaccording to parameter setting and MES108, MES114 or MET148 input/output module options<br />

(1) available in 2002.<br />

(2) for shunt trip unit or undervoltage release coil.<br />

(3) exclusive choice between logic discrimination and switching from one 2-relay group of settings to another 2-relay group.<br />

(4) 2 modules possibles.<br />

(5) performs B20 type functions.<br />

(6) exclusive choice, phase-to-neutral or phase-to-phase voltage for each of the 2 relays.<br />

Schneider Electric<br />

9

Metering<br />

Description<br />

Metering fonctions<br />

The values are displayed as primary values with the<br />

related units: A,V,Hz,°C,°F, W, …<br />

Current<br />

# RMS current for each of the 3 phases in the circuit,<br />

taking into account harmonics up to number 17<br />

# residual current.<br />

Average current and peak demand current<br />

# average current on each of the 3 phases<br />

# greatest average current on each of the 3 phases<br />

(peak demand current).<br />

The peak demand currents give the current consumed<br />

at the time of peak loads.<br />

The average current is calculated over a period that<br />

may be parameterized from 5 to 60 mn, and may be<br />

reset to zero.<br />

Voltage<br />

# phase-to-neutral voltages V1, V2, V3<br />

# phase-to-phase voltages U21, U32, U13<br />

# positive sequence voltage Vd<br />

# residual voltage Vo<br />

# negative sequence voltage Vi.<br />

Frequency<br />

Power<br />

Active, reactive and apparent power, power factor (p.f.).<br />

Peak demand power<br />

Greatest value of active and reactive power absorbed,<br />

over the same period as peak demand currents, with<br />

the possibility of resetting to zero.<br />

Energy<br />

Active and reactive energy. A counter for each current<br />

flow direction.<br />

Temperature<br />

Measurement of the temperature of each sensor.<br />

Network diagnosis<br />

assistance functions<br />

Tripping current<br />

Storage of the 3 phase currents and earth current at the<br />

time <strong>Sepam</strong> gave the last tripping order, so as to find<br />

the fault current (fault analysis).<br />

The values are stored until the next trip order is given.<br />

Tripping context<br />

Storage of the tripping currents and the Io, U21, U32,<br />

U13, Vo, Vi, Vd, F, P, Q, values at the time of the<br />

detection of the fault. The values for the last five trips<br />

are stored.<br />

Negative sequence / unbalance<br />

Ratio of negative sequence phase current,<br />

characteristic of unbalanced power supply of the<br />

equipment to be protected.<br />

Phase angles<br />

# phase angle ϕ1, ϕ2, ϕ3 between phase currents l1,<br />

l2, l3 and voltages U32, U13, U21 respectively<br />

# phaseangle ϕo between residual current and<br />

residual voltage.<br />

Distrubance recording<br />

Recording of sampled values of analog measurement signals and logic states.<br />

Through parameter setting, it is possible to choose:<br />

# the events that will trigger a record<br />

# the recording time prior to the occurrence of the event<br />

# the number and duration of records (<strong>series</strong> <strong>40</strong> only).<br />

Characteristics Series 20 Series <strong>40</strong><br />

Number of records in<br />

2 Adjustable from 1 to 10<br />

COMTRADE format<br />

Total duration of a record 86 periods (1.72 s at 50 Hz ,<br />

1.43 s at 60 Hz)<br />

Number of points per cycle 12 12<br />

Duration of recording before the<br />

occurrence of the event<br />

Recorded data<br />

Adjustable from 0 to 85<br />

periods<br />

Currents or voltages, logic<br />

inputs, pick-up<br />

Adjustable from 1 s to 10 s<br />

The total of all the records plus<br />

one must not be more than<br />

20 s at 50 Hz and 16 s at<br />

60 Hz<br />

Adjustable from 0 to 99<br />

periods<br />

Currents and voltages, logic<br />

inputs, pick-up, logic outputs<br />

(O1 to O4)<br />

Machine operation assistance functions<br />

Thermal capacity used<br />

Temperature build-up related to the load.<br />

It is displayed as a percentage of the nominal machine temperature.<br />

Remaining operating time before overload tripping<br />

Indicates the time remaining before tripping by the thermal overload protection<br />

function.<br />

Waiting time after overload tripping<br />

Indicates the time remaining before starting is allowed according to inhibition by the<br />

thermal protection function.<br />

Starting current and time / motor overload<br />

Measurement of the maximum current consumed by the motor during a starting<br />

sequence or an overload, as well as the duration.<br />

Start inhibit time delay / number of starts before inhibition<br />

Indicates the remaining number of starts allowed by the starts per hour protection<br />

function and, if the number is zero, the waiting time before starting is allowed.<br />

Running hours counter / operating time<br />

Cumulative time during which the protected equipment (motor or transformer) is on<br />

load (I > 0.1 Ib).<br />

The cumulative value is displayed in hours (0 to 65535 h).<br />

Switchgear diagnosis assistance functions<br />

These measurements are to be compared with the data supplied by the switchgear<br />

manufacturer.<br />

Cumulative breaking current<br />

The value displayed may be used to evaluate the state of the circuit breaker poles.<br />

Number of operations<br />

Total number of opening operations performed by the device.<br />

Device operating time<br />

Operating time, charging time.<br />

These data may be used to evaluate the state of the pole operating mechanism.<br />

10 Schneider Electric

Metering<br />

Characteristics<br />

number (l1, l2, l3) or (l1, l3)<br />

number (l1, l2, l3)<br />

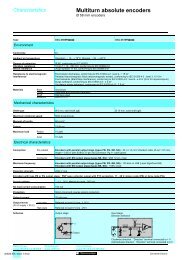

General settings (set in the general settings menu) Series 20 and Series <strong>40</strong> Series <strong>40</strong> only<br />

Frequency<br />

50 Hz or 60 Hz<br />

Current sensor<br />

CT 1 A or 5 A<br />

rated current In (1) 1 A to 6250 A<br />

LPCT<br />

rated current In (1) 25 A to 3150 A<br />

Residual current Io sensor<br />

CSH120/CSH200<br />

rated current Ino 2 A, 20 A 5 A<br />

Core balance CT + ACE990<br />

rated current Ino (1)<br />

1 A to 6250 A<br />

1 A or 5 A CT + CSH30<br />

rated current Ino (1)<br />

1 A to 6250 A (Ino = In)<br />

1 A ou 5 A CT + CSH30 sensitivity x10<br />

courant nominal Ino (1)<br />

1 A to 6250 A (Ino = In/10)<br />

Voltage sensor Primary rated voltage Unp (2) 220 V à 250 kV<br />

VT 100, 110, 115, 120 V (Uns) V1, V2, V3<br />

U21, U32<br />

U21<br />

VT 200, 230 V<br />

V1, V2, V3<br />

Metering functions Ranges Accuracy <strong>series</strong> 20 (7) Accuracy <strong>series</strong> <strong>40</strong> (7) MSA141 (3)<br />

Phase current 0.1 to 1.5 In (1) ± 1 % typically ± 0.5 % typically #<br />

Residual current 0.1 to 1.5 Ino (1) ± 1 % typically ± 1 % typically #<br />

Peak demand current (9) 0.1 to 1.5 In (1) ± 1 % typically ± 0.5 % typically<br />

Phase-to-phase voltages 0.05 to 1.2 Unp (2) ± 1 % typically ± 1 % typically #<br />

Phase-to-neutral voltages 0.05 to 1.2 Vnp (2) ± 1 % typically ± 1 % typically #<br />

Positive sequence voltage 0.05 to 1.5 Vnp (2) ± 2 % ± 2 %<br />

Negative sequence voltage 0.05 to 1.5 Vnp (2) ± 2 %<br />

Residual voltage 0.015 to 3 Vnp (2) ± 1 % typically ± 5 %<br />

Frequency 50/60 Hz ± 5 Hz ± 0.05 Hz typically ± 0.02 Hz typically #<br />

Active power 1.5 % Sn (8) at 999 MW ± 1 % typically #<br />

Reactive power 1.5 % Sn (8) at 999 Mvar ± 1 % typically #<br />

Apparent power 1.5 % Sn (8) at 999 MVA ± 1 % typically #<br />

Power factor -1 to 1 (CAP / IND) ± 1 % typically<br />

Peak demand active power (9) 1.5 % Sn (8) at 999 MW ± 1 % typically<br />

Peak demand reactive power (9) 1.5 % Sn (8) at 999 Mvar ± 1 % typically<br />

Active energy (9) 0 to 2.1 10 8 MW.h ± 1 %, ± 1 digit<br />

Reactive energy (9) 0 to 2.1 10 8 Mvar.h ± 1 %, ± 1 digit<br />

Temperature -30 to +200 °C (6) ± 1 °C ± 1 °C #<br />

Tripping current (9) phase 0.1 to <strong>40</strong> In (1) ± 5 % ± 5 %<br />

earth 0.1 to 20 Ino (1) ± 5 % ± 5 %<br />

Neg. sequence / unbalance 10 % to 500 % Ib (5) ± 2 % ± 2 %<br />

Phase angle ϕ1, ϕ2, ϕ3 0 to 359° ± 2° typically<br />

Phase angle ϕo 0 to 359° ± 2° typically<br />

Thermal capacity used (9) 0 to 800 % (4) #<br />

Operating time (9) 20 to 100 ms ± 1 ms typically ± 1 ms typically<br />

Charging time (9) 1 to 20 s ± 0.5 s ± 0.5 s<br />

Running hours counter 0 to 65535 h ± 1 % + 0.5 h ± 1 % + 0.5 h<br />

MSA141 measurement converter 4-20 mA or 0-20 mA or 0-10 mA ± 0.5 % ± 0.5 %<br />

(1) In, Ino: CT primary rated current.<br />

(2) Unp: primary rated phase-to-phase voltage, Vnp: primary phase-to-neutral voltage Vnp=(Unp/√3).<br />

(3) measurements available in analog format according to parameter setting and MSA141 module.<br />

(4) 100 % is the thermal capacity used of the equipment being protected under its rated load: I = Ib.<br />

(5) Ib basis current of the equipment being protected.<br />

(6) displayed in °C or °F according to parameter setting, typical accuracy from + 20 °C à + 1<strong>40</strong> °C.<br />

(7) in reference conditions (IEC 60255-4), typically at In or Un or Sn.<br />

(8) Sn: apparent power, Sn =√3.In.Un.<br />

(9) Saved in the event of power outage.<br />

Schneider Electric<br />

11

Protection functions<br />

Description<br />

Current protection functions<br />

Phase overcurrent (ANSI 50/51)<br />

Three-phase protection against overloads and phaseto-phase<br />

short-circuits. The protection comprises four<br />

units:<br />

# definite time (DT)<br />

# IDMT (16 types of IDMT curves)<br />

# instantaneous or time-delayed.<br />

Each unit has a reset time setting that allows:<br />

# detection of restriking faults<br />

# coordination with electromechanical relays.<br />

Earth fault (ANSI 50N/51N or 50G/51G)<br />

Earth fault protection.<br />

Earth faults may be detected according to parameter<br />

setting by:<br />

# current transformers on the three phases (3I sum)<br />

# a special core balance CT, CSH120 or CSH200,<br />

according to the required diameter; this method<br />

provides the highest sensitivity. The choice of<br />

parameterizable ratings provides a very wide setting<br />

range.<br />

# a current transformer (1 A or 5 A), combined with a<br />

CSH30 interposing ring CT.<br />

The protection comprises four units:<br />

# definite time (DT)<br />

# IDMT (16 types of IDMT curves)<br />

# instantaneous or time-delayed.<br />

Each unit has a reset time setting that allows:<br />

# detection of restriking faults<br />

# coordination with electromechanical relays.<br />

It also has a harmonic 2 restraint in order to ensure<br />

stability upon transformer energizing.<br />

Breaker failure (ANSI 50 BF)<br />

Backup protection that delivers a tripping order to the<br />

upstream or adjacent breakers should the breaker that<br />

is being commanded fail to trip, detected by<br />

measurement of the phase current after a tripping<br />

order.<br />

Negative sequence / unbalance (ANSI 46)<br />

Protection against phase unbalance.<br />

Sensitive protection to detect 2-phase faults at the end<br />

of long feeders.<br />

Protection of equipment against temperature build-up<br />

caused by an unbalanced supply or the inversion or<br />

loss of a phase and against phase current unbalance.<br />

IDMT or definite time characteristics.<br />

Directional current<br />

protection functions<br />

Directional phase overcurrent (ANSI 67)<br />

This protection function is 3-phase. It comprises a<br />

phase overcurrent function associated with direction<br />

detection. It picks up if the phase overcurrent function<br />

in the chosen direction (line or busbar) is activated for<br />

at least one of the three phases. It operates as definite<br />

time or IDMT. It is insensitive to the loss of<br />

measurement voltage at the time of the fault.<br />

Directional earth fault (ANSI 67N/67NC)<br />

It has 2 types of characteristics:<br />

# type 1, according to Io protection<br />

# type 2, according to Io magnitude.<br />

It can operate on impedant, isolated or compensated neutral grounding systems.<br />

The type 1 units allow the detection of restriking faults.<br />

The protection includes two units:<br />

# definite time (DT)<br />

# IDMT (16 types of IDMT curves) (type 2 only)<br />

# instantaneous or time-delayed.<br />

The type 2 units have a reset time setting that allows:<br />

# detection of restriking faults<br />

# coordination with electromechanical relays.<br />

Power protection functions<br />

Active overpower (ANSI 32P)<br />

This protection function is activated if the active power flowing in one direction or the<br />

other according to the application (supplied or absorbed) is greater than the set point.<br />

Machine protection functions<br />

Thermal overload (ANSI 49)<br />

Protection of equipment against thermal damage caused by overloads.<br />

The thermal capacity used is calculated according to a mathematical model which<br />

takes into account:<br />

# RMS current values<br />

# ambient temperature.<br />

The function comprises:<br />

# an adjustable alarm setting<br />

# an adjustable trip setting<br />

5 transformer application.<br />

The model takes into account the transformer heat rise and cooling time constants<br />

according to whether natural or forced ventilation is used (ONAN, ONAF) via a logic<br />

input.<br />

5 motor application.<br />

The model takes into account:<br />

- two time constants: the heat rise time constant, used when the motor is running,<br />

and the cooling time constant, used when the motor is stopped,<br />

- effect of negative sequence current on rotor heating.<br />

An additional setting may be used to adapt the protection to the motor thermal<br />

withstand indicated by the experimental hot and cold curves given by the machine<br />

manufacturer.<br />

The thermal protection function may be inhibited by a logic input when this is required<br />

by the process running conditions.<br />

Phase undercurrent (ANSI 37)<br />

Protection of pumps against the consequences of a loss of priming.<br />

The protection function detects time-delayed current drops that correspond to motor<br />

no-load operation, characteristic of the loss of pump priming.<br />

Locked rotor / excessive starting time (ANSI 48/51LR)<br />

Protection of motors that are liable to start with overloads or insufficient supply<br />

voltage and/or that drive loads that are liable to jam (e.g. crushers).<br />

The locked rotor function is an overcurrent protection function that is only confirmed<br />

after a time delay that corresponds to the normal starting time.<br />

Starts per hour (ANSI 66)<br />

Protection against overheating caused by too frequent starts.<br />

Checking of the number of:<br />

# starts per hour (or adjustable time period)<br />

# consecutive starts.<br />

The protection inhibits motor energizing for a preset time period when the<br />

permissible limits have been reached.<br />

Motor restarting may be taken into account by a logic input.<br />

12 Schneider Electric

Protection functions<br />

Description<br />

Thermostat, Buchholz, gas, pressure, temperature detection<br />

Protection of transformers against temperature rise and internal faults via logic inputs<br />

linked to devices integrated in the equipment.<br />

Temperature monitoring (RTDs) (ANSI 38/49T)<br />

Protection against abnormal overheating of motor windings and/or bearings<br />

equipped with RTDs.<br />

The protection includes 2 independent set points that are adjustable for each RTD.<br />

Positive sequence undervoltage (ANSI 27D) (ANSI 47)<br />

Motor protection against malfunctioning due to insufficient or unbalanced supply<br />

voltage.<br />

Detection of reverse rotation direction.<br />

In order for this protection to be used, voltage transformers must be connected to<br />

<strong>Sepam</strong> <strong>1000+</strong> to measure U21 and U32.<br />

Remanent undervoltage (ANSI 27R)<br />

Monitoring of the clearing of voltage sustained by rotating machines after circuit<br />

opening.<br />

The protection is used to prevent transient electrical and mechanical phenomena<br />

that are caused by fast re-energizing of motors.<br />

It monitors phase-to-phase voltage U21 or phase-to-neutral voltage V1.<br />

Voltage protection functions<br />

Phase-to-phase undervoltage (ANSI 27)<br />

Protection used either for automated functions (transfer, load shedding) or to protect<br />

motors against undervoltage. The protection function monitors the drop in each of the<br />

phase-to-phase voltages being metered.<br />

Phase-to-neutral undervoltage (ANSI 27S)<br />

Protection used to detect phase-to-earth faults (isolated neutral systems).<br />

Phase-to-phase overvoltage (ANSI 59)<br />

Protection against abnormally high voltage or checking that there is sufficient voltage<br />

for power supply changeover. It operates with phase-to-phase voltage (<strong>series</strong> 20 and<br />

<strong>series</strong> <strong>40</strong>) or with phase-to-neutral voltage (<strong>series</strong> <strong>40</strong> only).<br />

Neutral voltage displacement (ANSI 59N)<br />

Detection of insulation faults in isolated neutral systems by measurement of neutral<br />

voltage displacement. The protection function is generally associated with<br />

transformer incomer or busbar protection.<br />

The function includes 2 set points.<br />

Negative sequence overvoltage (ANSI 47)<br />

Protection against phase unbalance resulting from distant faults, a phase inversion<br />

or unbalanced power supply.<br />

Frequency protection functions<br />

Overfrequency (ANSI 81H)<br />

Protection against abnormally high frequency.<br />

Underfrequency (ANSI 81L)<br />

Detection of variances with respect to the rated frequency, in order to maintain a high<br />

quality power supply. The protection may be used for overall tripping or for load<br />

shedding.<br />

Rate of change of frequency / R. O. C. O. F (ANSI 81R)<br />

Protection used for fast disconnection of a source transmitting power into a power<br />

network when a fault occurs or to monitor load shedding.<br />

Recloser<br />

Automation device used to reclose the circuit breaker after tripping triggered by a<br />

transient fault on a line (the function includes 4 parameterizable reclosing cycles).<br />

Schneider Electric<br />

13

Protection functions<br />

Setting ranges<br />

General settings (set in the general settings menu)<br />

Frequency<br />

50 Hz or 60 Hz<br />

Current sensor<br />

CT 1 A or 5 A<br />

rated current In<br />

Number (I1, I2, I3) or (I1, I3)<br />

1 A to 6250 A<br />

Number (I1, I2, I3)<br />

LPCT<br />

rated current In (3) 25 A to 3150 A<br />

Residual current Io sensor<br />

CSH120/CSH200<br />

rated current Ino 2 A, 20 A or 5 A (4)<br />

Core balance CT (2) + ACE990<br />

rated current Ino<br />

1 A to 6250 A<br />

TC 1 A or 5 A + CSH30<br />

rated current Ino<br />

1 A to 6250 A<br />

TC 1 A or 5 A + CSH30 sensitivity x10 (4)<br />

rated current Ino<br />

1 A to 6250 A (Ino = In/10)<br />

Voltage sensor Primary rated voltage Unp 220 V to 250 kV<br />

VT : 100, 110, 115, 120 V<br />

V1, V2, V3<br />

(Uns)<br />

U21, U32<br />

U21<br />

VT : 200, 230 V<br />

V1, V2, V3<br />

Functions Settings Time delays<br />

Phase overcurrent<br />

Tripping curve<br />

Reset time<br />

Definite time<br />

DT<br />

SIT, LTI, VIT, EIT, UIT (1)<br />

DT<br />

RI<br />

DT<br />

CEI: SIT/A, LTI/B, VIT/B, EIT/C DT or IDMT<br />

IEEE: MI (D), VI (E), EI (F)<br />

DT or IDMT<br />

IAC: I, VI, EI<br />

DT or IDMT<br />

Is set point 0.1 to 24 In Definite time Inst.: 0.05 s to 300 s<br />

0.1 to 2,4 In IDMT 0.1 s à 12.5 s to 10 Is<br />

Reset time Definite time (DT: timer hold) Inst.: 0.05 s to 300 s<br />

IDMT (IDMT: reset time)<br />

0.5 s to 300 s<br />

Confirmation (4)<br />

None<br />

By negative sequence overvoltage<br />

By phase-to-phase undervoltage<br />

Earth fault<br />

Tripping curve<br />

Reset time<br />

Definite time<br />

DT<br />

SIT, LTI, VIT, EIT, UIT (1)<br />

DT<br />

RI<br />

DT<br />

CEI: SIT/A,LTI/B, VIT/B, EIT/C DT or IDMT<br />

IEEE: MI (D), VI (E), EI (F)<br />

DT or IDMT<br />

IAC: I, VI, EI<br />

DT or IDMT<br />

Iso set point 0.1 to 15 Ino Definite time Inst.: 0.05 s to 300 s<br />

0.1 to 1 Ino IDMT 0.1 s to 12.5 s at 10 Iso<br />

Reset time Definite time (DT: timer hold) Inst.: 0.05 s to 300 s<br />

IDMT (IDMT: reset time)<br />

0.5 s to 300 s<br />

Breaker failure<br />

Presence of current<br />

0.2 to 2 In<br />

Operating time<br />

0.05 s to 30 s<br />

Negative sequence / unbalance<br />

Definite time 0.1 to 5 Ib 0.1 s to 300 s<br />

IDMT 0.1 to 0.5 Ib (Schneider Electric) 0.1 to 1Ib (CEI, IEEE) 0.1 s to 1 s<br />

Tripping curve<br />

Schneider Electric<br />

CEI: SIT/A, LTI/B, VIT/B, EIT/C (4)<br />

IEEE: MI (D), VI (E), EI (F) (4)<br />

Directional phase overcurrent<br />

Tripping curve<br />

Reset time<br />

Definite time<br />

DT<br />

SIT, LTI, VIT, EIT, UIT (1)<br />

DT<br />

RI<br />

DT<br />

CEI: SIT/A, LTI/B, VIT/B, EIT/C DT or IDMT<br />

IEEE: MI (D), VI (E), EI (F)<br />

DT or IDMT<br />

IA: I, VI, EI<br />

DT or IDMT<br />

Is set point 0.1 to 24 In Definite time Inst.: 0.05 s to 300 s<br />

0.1 to 2,4 In IDMT 0.1 s to 12.5 s at 10 Is<br />

Reset time Definite time (DT: timer hold) Inst.: 0.05 s to 300 s<br />

IDMT (IDMT: reset time)<br />

0.5 s to 300 s<br />

Characteristic angle 30°, 45°, 60°<br />

14 Schneider Electric

Protection functions<br />

Setting ranges<br />

Functions Settings Time delay<br />

Directional earth fault, according to Io projection (type 1)<br />

Characteristic angle -45°, 0°, 15°, 30°, 45°, 60°, 90°<br />

Iso set point 0,1 to 15 Ino Definite time Inst.: 0.05 s to 300 s<br />

Vso set point<br />

2 to 80 % of Un<br />

Memory time Tomem duration 0; 0.05 s to 300 s<br />

Vomem validity set point<br />

0; 2 to 80 % of Un<br />

Directional earth fault, according to Io magnitude (type 2)<br />

Characteristic angle -45°, 0°, 15°, 30°, 45°, 60°, 90°<br />

Tripping curve<br />

Reset time<br />

Definite time<br />

DT<br />

SIT, LTI, VIT, EIT, UIT (1)<br />

DT<br />

RI<br />

DT<br />

CEI, SIT/A,LTI/B, VIT/B, EIT/C DT or IDMT<br />

IEEE: MI (D), VI (E), EI (F)<br />

DT or IDMT<br />

IAC: I, VI, EI<br />

DT or IDMT<br />

Iso set point 0.1 to 15 Ino Definite time Inst.: 0.05 s to 300 s<br />

0.1 to 1 Ino IDMT 0.1 s to 12.5 s at 10 Iso<br />

Vso set point<br />

2 to 80 % of Un<br />

Reset time Definite time (DT: timer hold) Inst.: 0.05 s to 300 s<br />

IDMT (IDMT: reset time)<br />

0.5 s to 300 s<br />

Active overpower<br />

1 to 120 % of Sn<br />

Thermal overload Rate 1 Rate 2<br />

Negative sequence factor 0 - 2.25 - 4.5 - 9<br />

Time constant Heat rise T1: 5 to 120 mn T1: 5 to 120 mn<br />

Cooling T2: 5 to 600 mn T2: 5 to 600 mn<br />

Alarm and trip set points<br />

50 to 300 % of rated thermal capacity used<br />

Cold curve change factor 0 to 100 %<br />

Rate change condition<br />

by logic input<br />

by Is setting from 0.25 to 8 Ib<br />

Maximum equipment temperature 60 to 200 °C<br />

Phase undercurrent<br />

0.15 to 1 Ib 0.05 s to 300 s<br />

Excessive starting time/locked rotor<br />

0.5 Ib to 5 Ib ST start time 0.5 s to 300 s<br />

LT and LTS time delays<br />

0.05 s to 300 s<br />

Starts per hour<br />

Starts per period 1 to 60 Period 1 to 6 h<br />

Consecutive starts 1 to 60 time between starts 0 to 90 mn<br />

Temperature (RTDs)<br />

Alarm and trip set points<br />

0 to 180 °C (or 32 to 356 °F)<br />

Positive sequence undervoltage<br />

15 to 60 % de Unp 0.05 s to 300 s<br />

Remanent undervoltage<br />

5 to 100 % of Unp 0.05 s to 300 s<br />

Phase-to-phase undervoltage<br />

5 to 100 % of Unp, 5 to 100 % of Vnp (4) 0.05 s to 300 s<br />

Phase-to-neutral undervoltage<br />

5 to 100 % of Vnp 0.05 s to 300 s<br />

Overvoltage phase-to-phase phase-to-neutral (4)<br />

50 to 150 % of Unp 50 to 150 % of Vnp 0.05 s to 300 s<br />

Neutral voltage displacement<br />

2 to 80 % of Unp 0.05 s to 300 s<br />

Negative sequence overvoltage<br />

1 to 50 % of Unp Inst.: 0.05 s to 300 s<br />

Overfrequency<br />

50 to 53 Hz or 60 to 63 Hz 0.1 s to 300 s<br />

Underfrequency<br />

45 to 50 Hz or 55 to 60 Hz 0.1 s to 300 s<br />

Rate of change of frequency<br />

0.1 to 10 Hz/s Inst.: 0.15 s to 300 s<br />

Reminder: In current, Unp rated voltage and Ino current are general settings that are made at the time of <strong>Sepam</strong> commissioning.<br />

They are given as the values on the measurement transformer primary windings.<br />

In is the current sensor rated current (CT rating) (adjustable from 1 A to 6250 A).<br />

Unp is the rated phase-to-phase voltage of the voltage sensor primary windings (adjustable from 220 V to 250 kV).<br />

Ino is the core balance CT current rating.<br />

Ib is the current which corresponds to the equipment power rating, adjustable from 0.4 to 1.3 In.<br />

The current, voltage and frequency values are set by direct entry of the values (resolution: 1 A, 1 V, 1 Hz, 1°C or F).<br />

(1) tripping as of 1.2 Is.<br />

(2) with ACE 990 interface for core balance CT with ratio n of 50 to 1500 turns.<br />

(3) table of In values in Amps: 25, 50, 100, 125, 133, 200, 250, 320, <strong>40</strong>0, 500, 630, 666, 1000, 1600, 2000, 3150.<br />

(4) on <strong>series</strong> <strong>40</strong> only.<br />

Schneider Electric<br />

15

<strong>Connection</strong> <strong>schemes</strong> <strong>Sepam</strong> <strong>1000+</strong> <strong>series</strong> 20<br />

S20 / T20 / M20 types<br />

<strong>Connection</strong> to 1 A / 5 A current sensors<br />

Connector Type Ref. Cable<br />

A Screw-on CCA620 1 wire 0.2 to 2.5 mm 2<br />

(4 AWG 24-12)<br />

2 wires 0.2 to 1 mm 2<br />

(4 AWG 24-16)<br />

A<br />

Ring lug<br />

6.35 mm<br />

CCA622<br />

B<br />

Ring lug<br />

4mm<br />

CCA630 1.5 to 6 mm 2<br />

(AWG 16 to AWG 10)<br />

C RJ45 CCA612<br />

D RJ45 CCA770: L = 0,6 m<br />

CCA772: L = 2 m<br />

CCA774: L = 4 m<br />

E79273<br />

L1<br />

L2<br />

L3<br />

4<br />

1<br />

5<br />

2<br />

6<br />

3<br />

B<br />

O1<br />

O2<br />

O3<br />

O4<br />

A<br />

5<br />

4<br />

8<br />

7<br />

11<br />

10<br />

15<br />

14<br />

13<br />

18<br />

A<br />

1<br />

2<br />

17<br />

+ / ~<br />

– / ~<br />

19<br />

communication<br />

C<br />

to<br />

communication<br />

network<br />

interface<br />

D<br />

to optional<br />

modules<br />

B21 / B22 types<br />

Connector Type Ref. Cable<br />

A Screw-on CCA620 1 wire 0.2 to 2.5 mm 2<br />

(4 AWG 24-12)<br />

2 wires 0.2 to 1 mm 2<br />

(4 AWG 24-16)<br />

A<br />

Ring lug CCA622<br />

6.35 mm<br />

B Screw-on CCT6<strong>40</strong> 1 wire 0.2 to 2.5 mm 2<br />

(4 AWG 24-12)<br />

2 wires 0.2 to 1 mm 2<br />

(4 AWG 24-16)<br />

C RJ45 CCA612<br />

D RJ45 CCA770: L = 0,6 m<br />

CCA772: L = 2 m<br />

CCA774: L = 4 m<br />

L1<br />

L2<br />

L3<br />

(1)<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

B<br />

O1<br />

O2<br />

O3<br />

A<br />

5<br />

4<br />

8<br />

7<br />

11<br />

10<br />

O4<br />

15<br />

14<br />

13<br />

1<br />

2<br />

17<br />

+ / ~<br />

– / ~<br />

communication<br />

C<br />

to<br />

communication<br />

network<br />

interface<br />

(1) this type of connection allows the calculation of residual voltage.<br />

D<br />

to optional<br />

modules<br />

16 Schneider Electric

<strong>Connection</strong> <strong>schemes</strong> <strong>Sepam</strong> <strong>1000+</strong> <strong>series</strong> <strong>40</strong><br />

S<strong>40</strong> / S41 / S42 types<br />

T<strong>40</strong> / T42 / M41 types<br />

<strong>Connection</strong> to 1 A / 5 A current sensors<br />

Connector Type Ref. Cable<br />

A Screw-on CCA620 1 wire 0.2 to 2.5 mm 2<br />

(4 AWG 24-12)<br />

2 wires 0.2 to 1 mm 2<br />

(4 AWG 24-16)<br />

A<br />

Ring lug<br />

6.35 mm<br />

CCA622<br />

B<br />

Ring lug<br />

4mm<br />

CCA630 1.5 to 6 mm 2<br />

(AWG 16 to AWG 10)<br />

C RJ45 CCA612<br />

D RJ45 CCA770: L = 0,6 m<br />

CCA772: L = 2 m<br />

CCA774: L = 4 m<br />

E Screw-on CCA626 1 wire 0.2 to 2.5 mm 2<br />

(4 AWG 24-12)<br />

2 wires 0.2 to 1 mm 2<br />

(4 AWG 24-16)<br />

E<br />

Ring lug<br />

6.35 mm<br />

CCA627<br />

E79225<br />

L1<br />

L2<br />

L3<br />

(2)<br />

(1)<br />

1<br />

2<br />

3<br />

5<br />

6<br />

4<br />

1<br />

5<br />

2<br />

6<br />

3<br />

18<br />

E<br />

B<br />

A<br />

O1<br />

O2<br />

O3<br />

O4<br />

A<br />

5<br />

4<br />

8<br />

7<br />

11<br />

10<br />

15<br />

14<br />

13<br />

1<br />

2<br />

17<br />

+ / ~<br />

– / ~<br />

19<br />

communication<br />

C<br />

to<br />

communication<br />

network<br />

interface<br />

D<br />

to optional<br />

modules<br />

(1) this type of connection allows the calculation of residual voltage.<br />

(2) accessory for bridging of terminals 3 and 5 supplied with CCA626 connector.<br />

Schneider Electric<br />

17

<strong>Connection</strong> <strong>schemes</strong><br />

Other connection <strong>schemes</strong><br />

Phase current<br />

L1 L2 L3<br />

<strong>Connection</strong> of two 1 A / 5 A current transformers with<br />

CCA630 connector.<br />

E79275<br />

4<br />

1<br />

B<br />

5<br />

2<br />

6<br />

3<br />

CCA630<br />

<strong>Connection</strong> of 3 LPCT type current transformers with<br />

CCA670 connector (the sensors are equipped with a<br />

standard connection cable: L = 5 m).<br />

E79276<br />

L1 L2 L3<br />

L1<br />

B<br />

L2<br />

L3<br />

CCA670<br />

Residual current<br />

# connection of CSH30 interposing ring CTs to 1 A:<br />

current transformers: make 2 turns through the CSH<br />

primary winding<br />

# connection of CSH30 interposing ring CTs to 5 A:<br />

current transformers: make 4 turns through the CSH<br />

primary winding<br />

# with <strong>series</strong> <strong>40</strong>, the sensitivity can be multiplied by 10<br />

by parameter setting with the CSH30 interposing ring<br />

CT: Ino = In/10.<br />

E79277<br />

1 A CT<br />

or<br />

5 A CT<br />

1 A CT: 2 turns<br />

5 A CT: 4 turns<br />

E79272<br />

1 A CT: 2 turns<br />

5 A CT: 4 turns<br />

<strong>Connection</strong> of the ACE990 interface to the core<br />

balance CT with ratio 1/n with 50 6 n 6 1500<br />

(n = number of turns on the core balance CT secondary<br />

winding).<br />

E79278<br />

L1 / L2 / L3<br />

A<br />

n turns E1<br />

En<br />

ACE<br />

990<br />

S1 18<br />

S2 19<br />

18 Schneider Electric

<strong>Connection</strong> <strong>schemes</strong><br />

Other connection <strong>schemes</strong><br />

Phase voltage (<strong>series</strong> 20)<br />

# connection of 1 voltage transformer (does not allow<br />

use of positive sequence undervoltage or neutral<br />

voltage displacement protection functions)<br />

# connection of 2 voltage transformers in V<br />

arrangement (does not allow use of neutral voltage<br />

displacement protection function)<br />

# connection of VTs to CCT6<strong>40</strong> connector.<br />

E79280<br />

L1<br />

L2<br />

L3<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

B<br />

L1<br />

L2<br />

L3<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

B<br />

Residual voltage (<strong>series</strong> 20)<br />

# measurement of phase voltages with 1, 2 or 3 VTs<br />

and measurement of residual voltage by VT in open<br />

delta connection<br />

# connection of VTs to CCT6<strong>40</strong> connector.<br />

E79281<br />

L1<br />

L2<br />

L3<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

B<br />

Phase voltage (<strong>series</strong> <strong>40</strong>)<br />

# connection of 1 voltage transformer (does not allow<br />

use of phase-to-phase or directional protection<br />

functions)<br />

# connection of 2 voltage transformers in V<br />

arrangement (does not allow use of neutral voltage<br />

displacement or directional earth fault protection<br />

functions)<br />

# connection of VTs directly to connector E on the<br />

base unit.<br />

E79228<br />

L1<br />

L2<br />

L3<br />

1<br />

2<br />

3<br />

5<br />

6<br />

E<br />

E79229<br />

L1<br />

L2<br />

L3<br />

1<br />

2<br />

3<br />

5<br />

6<br />

E<br />

Residual voltage (<strong>series</strong> <strong>40</strong>)<br />

# measurement of phase voltages with 1 or 2 VTs and<br />

measurement of residual voltage by VT in open delta<br />

connection<br />

# connection of VTs directly to connector E on the<br />

base unit.<br />

E79230<br />

L1<br />

L2<br />

L3<br />

1<br />

2<br />

3<br />

5<br />

6<br />

E<br />

Schneider Electric<br />

19

Control and monitoring<br />

Description<br />

<strong>Sepam</strong> <strong>1000+</strong> performs the basic control and<br />

monitoring functions necessary for the operation of the<br />

electrical network, thereby reducing the need for<br />

auxiliary relays.<br />

The control and monitoring functions may be<br />

parameterized using the SFT 2841 software tool,<br />

however each type of <strong>Sepam</strong> has parameter setting by<br />

default which allows easier commissioning in the most<br />

frequent cases of use.<br />

Two control modes are available<br />

# integrated circuit breaker control.<br />

This logical function processes all the circuit breaker<br />

closing and tripping conditions based on position<br />

information, external control orders and protection,<br />

recloser, etc.<br />

# individual parameter setting of output relays.<br />

Control of output relays according to an assignment<br />

matrix.<br />

Breaking device control<br />

# <strong>Sepam</strong> is used to control breaking devices equipped<br />

with different types of closing and tripping coils:<br />

5 circuit breakers with shunt trip or undervoltage trip<br />

units (parameter setting on front panel (1) or via<br />

SFT 2841)<br />

5 latching contactors with shunt-trip units.<br />

Output relay control (standard or fail-safe) may be<br />

parameterized.<br />

By default, the program logic is adapted to control a<br />

circuit breaker with a shunt trip unit.<br />

# open and close control via the communication link<br />

# inhibition of closing (ANSI 69)<br />

<strong>Sepam</strong> inhibits the closing of the circuit breaker or<br />

contactor according to the operating conditions.<br />

# remote tripping<br />

Remote control of the tripping of the circuit breaker or<br />

contactor is possible via a logic input or via the<br />

communication link.<br />

# inhibition of remote control<br />

A logic input inhibits the remote closing of the circuit<br />

breaker via the communication link.<br />

Switching of setting groups<br />

Used to switch from one group of (directionnal) phase<br />

overcurrent and earth fault protection settings to<br />

another group of settings. Switching may be performed<br />

by a logic input or via the communication link.<br />

Inhibition of thermal protection<br />

Thermal protection tripping may be inhibited via a logic<br />

input.<br />

Re-acceleration<br />

Allows a logic input to take into account the restarting<br />

of an unstopped motor.<br />

Logic discrimination (ANSI 68)<br />

This function allows quick, selective tripping of the<br />

definite time or IDMT phase overcurrent and earth fault<br />

protection relays, without requiring the use of time<br />

intervals between upstream and downstream<br />

protection devices. The downstream relay transmits a<br />

blocking input signal if the protection device set points<br />

are exceeded.<br />

The upstream relay receives the blocking input signal<br />

on the logic input used for the inhibition function. A<br />

saving mechanism ensures the operation of the<br />

protection in the event of an inhibition link failure.<br />

Latching / acknowledgment (ANSI 86)<br />

Output relay latching may be parameterized. Latched tripping orders are stored and<br />

must be acknowledged in order for the device to be put back into service. The user<br />

acknowledges via the keypad or remotely via a logic input or the communication link.<br />

Latching is stored in the event of a power outage.<br />

Annunciation (ANSI 30)<br />

<strong>Sepam</strong> indicates the appearance of alarms by:<br />

# signal lamps on the front panel<br />

# messages on the display.<br />

The addressing of the signal lamps may be parameterized.<br />

The sequence is as follows (advanced UMI):<br />

# when an event appears, the signal lamp goes on and the related message is<br />

displayed<br />

# the user presses the “clear” key to erase the message<br />

# after the fault disappears and the “reset”, key is pressed, the signal lamp goes off<br />

and/or the message is erased and the protection is reset<br />

# the list of alarm messages remains accessible ( key) and may be erased by<br />

pressing the “clear” key.<br />

Remote annunciation<br />

Used to transfer information via the communication link.<br />

Information such as circuit breaker position, SF6 fault alarm, etc.<br />

Trip circuit supervision<br />

Detects trip circuit faults (shunt trip units). Detects open/closed position discrepancy<br />

faults (undervoltage trip units).<br />

Watchdog<br />

Indicates <strong>Sepam</strong> unavailability via output O4.<br />

Output relay testing<br />

This function is used to activate each output relay (1) .<br />

Logical parameter setting (Boolean equation editor)<br />

Used for logical grouping of protection function outputs and logic inputs by the AND,<br />

OR, NO functions in order to supply new states that can activate a logic output, a<br />

signal lamp, an alarm message or a remote indication.<br />

List of main messages (1)<br />

Functions Messages (2)<br />

Phase overcurrent PHASE FAULT (4)<br />

Earth fault<br />

EARTH FAULT<br />

Directional phase overcurrent DIR. PHASE FAULT (4)<br />

Directional earth fault<br />

DIR. EARTH FAULT<br />

Active overpower<br />

REVERSE P<br />

Thermal overload<br />

THERMAL TRIP<br />

THERMAL ALARM.<br />

Negative sequence / unbalance<br />

UNBALANCE I<br />

Locked rotor<br />

ROTOR BLOCKING<br />

Excessive starting time<br />

LONG START<br />

Starts per hour<br />

START INHIBIT<br />

Undercurrent<br />

UNDER CURRENT<br />

Overvoltage OVERVOLTAGE (4)<br />

Undervoltage UNDERVOLTAGE (4)<br />

Positive sequence undervoltage<br />

UNDERVOLTAGE.PS<br />

Neutral voltage displacement<br />

Vo FAULT<br />

Negative sequence overvoltage<br />

UNBALANCE V<br />

Overfrequency<br />

OVER FREQ.<br />

Underfrequency<br />

UNDER FREQ.<br />

Temperature (RTDs)<br />

OVER TEMP.ALM<br />

Thermostat (3)<br />

THERMOS T . ALARM<br />

Buchholz (3)<br />

BUCHHOLZ ALARM<br />

Recloser<br />

FINAL TRIP<br />

Recloser<br />

CLEARED FAULT<br />

Breaker failure<br />

BREAKER FAILURE<br />

(1) according to type of <strong>Sepam</strong> and <strong>Sepam</strong> equipped with advanced UMI, or SFT 2841.<br />

(2) messages by default, the wording of the messages may be changed (please consult us).<br />

(3) or gas, pressure, temperature detector (DGPT).<br />

(4) indication of the faulty phase with <strong>series</strong> <strong>40</strong>.<br />

20 Schneider Electric

Logic inputs and ouputs<br />

Description<br />

E79422<br />

19<br />

18<br />

17<br />

15<br />

14<br />

13<br />

11<br />

10<br />

8<br />

7<br />

5<br />

4<br />

CSH<br />

2 - / a<br />

1 + / a<br />

O4<br />

O3<br />

O2<br />

O1<br />

E79423<br />

CSH<br />

19<br />

18<br />

17<br />

15<br />

14<br />

13<br />

11<br />

10<br />

8<br />

7<br />

5<br />

4<br />

2 - / a<br />

1 +/a<br />

O4<br />

O3<br />

O2<br />

O1<br />

4 output relays on the base unit<br />

The 4 relay outputs O1, O2, O3 and O4 on the base unit are connected to<br />

connector A .<br />

Connector A of the base unit may be either of the following:<br />

# CCA620 screw type connector<br />

# CCA622 ring lug connector.<br />

O1 and O2 are 2 control outputs used by the breaking device control function for:<br />

# O1: breaking device tripping<br />

# O2: inhibition of breaking device closing.<br />

O3 and O4 are indication outputs, only O4 can be activated by the watchdog function.<br />

CCA620 connector<br />

(screw-on terminal block for<br />

straight fittings).<br />

CCA622 connector<br />

(terminal block for ring<br />

terminals).<br />

E79424<br />

12<br />

12<br />

O14<br />

11<br />

11<br />

O14<br />

10<br />

I14<br />

I26<br />

10<br />

I14<br />

I25<br />

9 O13<br />

9<br />

8<br />

8<br />

O13<br />

6<br />

5<br />

O12<br />

6<br />

5<br />

O12<br />

3<br />

2<br />

O11<br />

3<br />

2<br />

O11<br />

L<br />

L<br />

8<br />

8 I24<br />

7<br />

I13<br />

7<br />

I13 I23<br />

I22<br />

5<br />

4<br />

2<br />

1<br />

I12<br />

I11<br />

E79425<br />

5<br />

4<br />

2<br />

1<br />

I12<br />

I11 I21<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

2<br />

1<br />

Optionnal input / output modules<br />

By the addition of an input/output extension module, the 4 outputs on the base unit<br />

may be completed by either of the following:<br />

# 4 inputs and 4 outputs with the MES108 module<br />

# 10 inputs and 4 outputs with the MES114 module.<br />

An MES module is mounted at the back of the base unit.<br />

Output characteristics<br />

# 4 relay outputs O11, O12, O13, O14<br />

5 O11: control output, used for breaking device closing<br />

5 O12, O13, O14: indication outputs.<br />

Input characteristics<br />

# 4 or 10 potential-free inputs<br />

5 DC input voltage of 24 V DC to 250 V DC, external DC supply source.<br />

<strong>Connection</strong> to screw-type connector<br />

# 1 wire with cross-section 0.2 à 2.5 mm² (4 AWG 24-12)<br />

# or 2 wires with cross-section 0.2 à 1 mm² (4 AWG 24-16).<br />

M<br />

M<br />

K<br />

MES108 module<br />

(4 inputs / 4 outputs).<br />

MES114 module<br />

(10 inputs / 4 outputs).<br />

E79426<br />

O1<br />

A<br />

5<br />

4<br />

D<br />

+<br />

_<br />

E79427<br />

O1<br />

A<br />

5<br />

4<br />

D<br />

+<br />

_<br />

Wiring of the breaking device trip circuit<br />

Wiring to be used when the "breaker control" function is activated.<br />

I11<br />

I12<br />

M<br />

1<br />

2<br />

4<br />

5<br />

I11<br />

I12<br />

M<br />

1<br />

2<br />

4<br />

5<br />

Wiring for shunt trip coil.<br />

With monitoring of trip circuit<br />

and open / closed matching.<br />

Wiring for undervoltage<br />

release coil.<br />

With monitoring of open /<br />

closed matching.<br />

Schneider Electric<br />

21

Logic inputs and ouputs<br />

Assignment by application<br />

<strong>Sepam</strong> <strong>1000+</strong> <strong>series</strong> 20<br />

Chart of input assignments by application (<strong>series</strong> 20)<br />

The use of the preset control and monitoring functions requires exclusive parameter setting and particular wiring of the inputs according to their<br />

application and the type of <strong>Sepam</strong>.<br />

The choice is made on the advanced UMI or expert UMI.<br />

Functions S20 T20 M20 B21 - B22 Assignment<br />

Logic inputs<br />

Open position # # # # I11<br />

Closed position # # # # I12<br />

Logic discrimination, receive BL<br />

# # I13<br />

Switching of groups of settings A/B<br />

# # #<br />

External reset<br />

External tripping 4 (1) #<br />

#<br />

#<br />

#<br />

I14<br />

External tripping 1 (1)<br />

External network synchronization<br />

External tripping 2 (1)<br />

Motor reacceleration<br />

External tripping 3 (1)<br />

Buchholz alarm (1) (Buchholz alarm message)<br />

Rotor rotation detection<br />

End of charging position<br />

Thermostat alarm (1) (thermostat alarm message)<br />

Inhibit remote control (1)<br />

SF6-1<br />

SF6-2<br />

Change of thermal settings<br />

Inhibit thermal overload<br />

Inhibit recloser<br />

#<br />

#<br />

#<br />

#<br />

# (2)<br />

#<br />

# # (3) #<br />

# # (4)<br />

#<br />

# #<br />

#<br />

#<br />

#<br />

#<br />

#<br />

#<br />

#<br />

#<br />

#<br />

#<br />

#<br />

#<br />

#<br />

#<br />

#<br />

#<br />

#<br />

#<br />

#<br />

I21<br />

# I22<br />

# I23<br />

# I24<br />

#<br />

#<br />

#<br />

#<br />

#<br />

#<br />

#<br />

I25<br />

# I26<br />

Logic outputs<br />

Tripping # # # # O1<br />

Inhibit closing # # # # O2<br />

Watchdog # # # # O4<br />

Closing order # # # # O11<br />