2011 Environmental Statement 1.8 MB - Sappi

2011 Environmental Statement 1.8 MB - Sappi

2011 Environmental Statement 1.8 MB - Sappi

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

tractor (STEK). No newly produced HCFK<br />

has been added in <strong>2011</strong>. Therefore, no additional<br />

measures are necessary.<br />

3.2.4 Odour<br />

Target (related to inconvenience)<br />

No odour emission<br />

Status of measures in this plan period<br />

Emissions at <strong>Sappi</strong> Nijmegen BV do not lead<br />

to detectable odour pollution outside of the<br />

premises. No additional measures are necessary.<br />

3.2.5 Dust<br />

Target (related to dissemination)<br />

No dust pollution<br />

Status of measures in this plan period<br />

Dust emission is the result of periodical filling<br />

of the starch containers. Total emission per<br />

year, based on a single measurement, is approx.<br />

40 kg. There have been no changes in<br />

installation or process circumstances since.<br />

3.3 Water<br />

Intaken groundwater is used in the production<br />

process.<br />

Sluice and regeneration water from the heatpowerplant<br />

is transferred, along with process<br />

waste water, to the <strong>Sappi</strong> Nijmegen owned<br />

purification installation in Weurt. The same is<br />

true for part of the waste water from the laboratories,<br />

the other part of which is drained to<br />

communal sewage - exact percentages are<br />

impossible to specify. Approx. 1% of the mill’s<br />

total water consumption concerns domestic<br />

water used in the offices. Waste water resulting<br />

from domestic use is drained to communal<br />

sewage.<br />

24 <strong>Environmental</strong> <strong>Statement</strong> <strong>2011</strong><br />

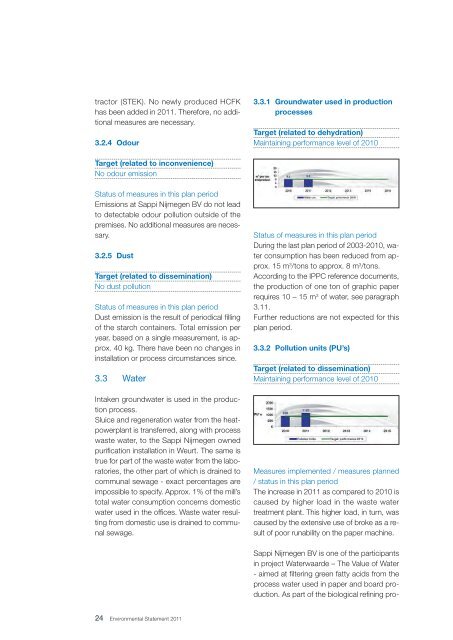

3.3.1 Groundwater used in production<br />

processes<br />

Target (related to dehydration)<br />

Maintaining performance level of 2010<br />

Status of measures in this plan period<br />

During the last plan period of 2003-2010, water<br />

consumption has been reduced from approx.<br />

15 m 3 /tons to approx. 8 m 3 /tons.<br />

According to the IPPC reference documents,<br />

the production of one ton of graphic paper<br />

requires 10 – 15 m 3 of water, see paragraph<br />

3.11.<br />

Further reductions are not expected for this<br />

plan period.<br />

3.3.2 Pollution units (PU’s)<br />

Target (related to dissemination)<br />

Maintaining performance level of 2010<br />

Measures implemented / measures planned<br />

/ status in this plan period<br />

The increase in <strong>2011</strong> as compared to 2010 is<br />

caused by higher load in the waste water<br />

treatment plant. This higher load, in turn, was<br />

caused by the extensive use of broke as a result<br />

of poor runability on the paper machine.<br />

<strong>Sappi</strong> Nijmegen BV is one of the participants<br />

in project Waterwaarde – The Value of Water<br />

- aimed at filtering green fatty acids from the<br />

process water used in paper and board production.<br />

As part of the biological refining pro-