SUPER MINI - Horn USA, Inc.

SUPER MINI - Horn USA, Inc.

SUPER MINI - Horn USA, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

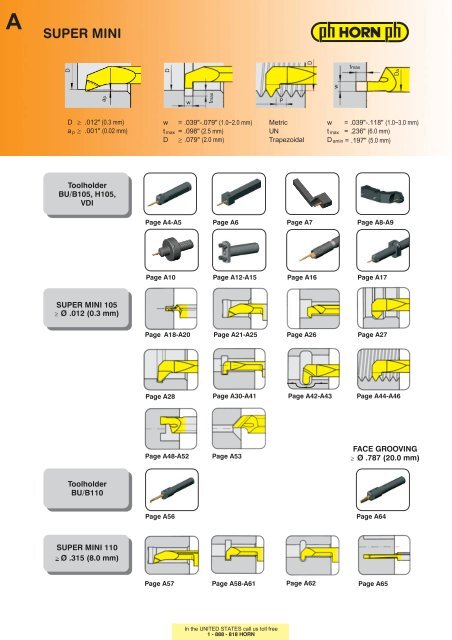

<strong>SUPER</strong> <strong>MINI</strong>DDDtmaxwDaapwtmaxPD .01 2" (0.3 mm)w = .039"−.079" (1 .0−2.0 mm) Metrica p .001"(0.02 mm) t max =.098" (2.5 mm)UND .079" (2.0 mm) Trapezoidalw = .039"−.118" (1 .0−3.0 mm)t max =.236" (6.0 mm)D amin =.197" (5.0 mm)ToolholderBU/B105, H105,VDIPage A4−A5Page A6Page A7Page A8-A9Page A1 0Page A1 2-A1 5 Page A1 6 Page A1 7<strong>SUPER</strong> <strong>MINI</strong> 1 05— Ø.012(0.3mm)Page A21 -A25Page A1 8−A20 Page A26 Page A27Page A28Page A30−A41Page A42−A43Page A44−A46Page A48−A52Page A53FACE GROOVING— Ø.787(20.0mm)ToolholderBU/B11 0Page A56Page A64<strong>SUPER</strong> <strong>MINI</strong> 110— Ø.315(8.0mm)Page A57Page A58−A61Page A62Page A65In the UNITED STATES call us toll free

GROOVING and BORINGBoringfrom Ø .01 2".012" (0.3 mm).028" (0.7 mm) .039" (1.0 mm)<strong>SUPER</strong><strong>MINI</strong>®best in small bores !A2In the UNITED STATES call us toll free

<strong>SUPER</strong><strong>MINI</strong>® CARBIDE GROOVING TOOLSAGROOVING, BORING, THREADING, FACE GROOVINGFROM BORE DIA.Ø.012"One toolholder can be used for allinsertsType 1 05− special shaped backend of inserts guaranteeaccurate center height and indexabilitywithout resetting the machine− through coolant− enlarged backend of inserts gives a rigid clampingand good vibration resistanceIn the UNITED STATES call us toll freeA3

GROOVING and BORINGTOOLHOLDER typeBU/B105with through coolantBore Ø from .01 2"Depth ofgroove up to .098"Width of groove up to .079"l 1l 4.200"hfor use with insert TypeU105105l 3d g6d g6Right hand insert shownPart number d g6 l 1 l 3 l 4 h<strong>Inc</strong>h ToolholderBU105.0500.01 .500 2.950 2.360 2.1 60 .433BU105.0625.01 .625 2.950 2.360 2.1 60 .551BU105.0750.01 .750 3.540 2.950 2.750 .671BU105.1000.01 1 .000 3.540 − 2.750 .921Metric Toolholder in mmB105.0010.01 1 0 75 57 50 9B105.0012.01 12 75 63 50 11B105.0016.01 16 75 63 50 14B105.0020.01 20 90 − 55 1 8B105.0025.01 25 1 00 − 55 23Further shank sizes upon request.Dimensions in inch/mmNoteToolholders can be used with right and lefthandinserts.Spare partsToolholder Screw Torx screw driverBU/B1 05...01 6.075 T1 5 T1 5A4In the UNITED STATES call us toll free

GROOVING and BORINGATOOLHOLDER typeBore Ø fromDepth ofgroove up toWidth of groove up toB/BU105with through coolant0.3 mm2.5 mm2.0 mml 1l 4l 5hfor use with insert TypeU105105d g6Right hand insert shownPart number d g6 l 1 l 4 l 5 h NoteB1 05.0020.2.01 20 1 50 − − − *B105.0022.01 22 90 55 5 20.0 −B105.0028.01 28 1 20 72 1 2 26.0 **BU105.0750.5.01 3/4" 3.450 2.750 .200 .671 **BU105.1000.5.01 1" 3.450 2.750 .200 .921 **Further shank sizes upon request.NoteToolholders can be used with right and left hand inserts.*Dimensions in mm/inchwithoutclamping flat, e.g. for TORNOS Deco**Adapter of cooling M1 2x1 .5 for TRAUBSpare partsToolholder Screw Torx screw driverB/BU1 05...01 6.075 T1 5 T1 5In the UNITED STATES call us toll freeA5

GROOVING and BORINGATOOLHOLDER typeHC105...with screwed clampingBore Ø from.01 2" (0.3 mm)Coolant through cranked fittingL 1for use with insertL 3f Type U1 05105h 1HhLDmax.21 InsertsType 1 05 = l 2 up to .591 "b1bL 2.41 InsertsType 1 05 = l 2 up to .984"L=lefthand version shownR = right hand versionPart number h h1 H b b 1 L 1 L 2 L 3 D max f*R/L HC1 05.0707.21 .276(7) .276(7) .51 2 .276(7) 1 .260 3.898 .709 1 .1 42 1 .024 .748*R/L HC1 05.0808.21 .31 5(8) .31 5(8) .51 2 .31 5(8) 1 .260 3.898 .709 1 .1 42 1 .024 .748R/L HC1 05.1 01 0.21 .394(1 0) .394(1 0) .630 .394(1 0) 1 .496 3.898 .709 1 .1 42 1 .024 .748R/L HC1 05.1 01 0.41 .394(1 0) .394(1 0) .630 .394(1 0) 1 .890 3.898 1 .1 02 1 .1 42 1 .024 .748R/L HC105.1212.21 .472(1 2) .472(1 2) .709 .472(1 2) 1 .496 3.898 .709 1 .1 42 1 .024 .748R/L HC105.1212.41 .472(1 2) .472(1 2) .709 .472(1 2) 1 .890 3.898 1 .1 02 1 .1 42 1 .024 .748R/L HC1 05.1 61 6.21 .630(1 6) .630(1 6) .866 .630(1 6) 1 .496 4.094 .709 1 .339 1 .41 7 .945R/L HC1 05.1 61 6.41 .630(1 6) .630(1 6) .866 .630(1 6) 1 .890 4.094 1 .1 02 1 .339 1 .41 7 .945State R or L version.Further shank sizes upon request.Dimensions in inch (mm)*withoutcoolantSpare partsfor Toolholder Screw Torx screw driver Cranked coolant fittingR/L HC1 05... 6.075 T1 5 T1 5 KQ2L06−M5In the UNITED STATES call us toll freeA7

RHC105...21GROOVING and BORINGTools for Tornos DECO2000Bore Ø from.01 2" (0.3 mm)for use with insert Type U1 05105RHC...41Toolholder Insert MachineRHC105.0710.21.21Inserts Type 105for l 2 up to .591 "(1 5 mm)RHC105.0710.41.41Inserts Type 105for l 2 up to .984"(25 mm)DECO7/1 0Dimensions in inch (mm)A8In the UNITED STATES call us toll free

GROOVING and BORINGATools for Tornos DECO2000Bore Ø from.01 2" (0.3 mm)DECO13for use with insert Type U1 05105DECO20/26Cassette Insert ToolholderRKC760.0105.21.21Inserts Type 1 05for l 2 up to .591 "(1 5 mm)L760.001 3.K1 *for machine DECO1 3RKC760.0105.41.41Inserts Type 1 05for l 2 up to .984"(25 mm)L760.2026.K1 *for machine DECO20/26* See chapter L for toolholdersDimensions in inch (mm)In the UNITED STATES call us toll freeA9

GROOVING and BORINGTOOLHOLDER typeVDI...Bore Ø from.01 2" (0.3 mm)L 2L 1D 1D 2for use with insertL Type U1 05105Cylindrical shank DIN69880-Part 1Dthrough coolantL=lefthand version shownR = right hand versionPart number D D1 D 2 L 1 L 2VDI1 6.R1 05.20.01 .630(1 6) 1 .575(40)VDI20.R1 05.20.01 .787(20) 1 .969(50)VDI25.R1 05.20.01 .984(25) 2.283(58)VDI30.R1 05.20.01 1.181(30) 2.677(68)VDI1 6.L1 05.20.01 .630(1 6) 1 .575(40)VDI20.L1 05.20.01 .787(20) 1 .969(50)VDI25.L1 05.20.01 .984(25) 2.283(58)VDI30.L1 05.20.01 1.181(30) 2.677(68)State R or L version.Further shank sizes upon request..787 1 .496 .787.787 1 .496 .787Dimensions in inch (mm)Spare partsfor Toolholder Screw Torx screw driverVDI... 6.075 T1 5 T1 5A1 0In the UNITED STATES call us toll free

GROOVING and BORINGAMODULAR TOOLING SYSTEMSRB105.00C...Adaptor for inserts type 1 05 <strong>Horn</strong>-CaptoLicence Sandvikl 1l 2for use with insert Type U1 05105d*f3l 3142D1INDEXMulti spindle systemMS32 / MS52*l 5Part number D 1 d l 1 l 2 l 3 MachineRB105.00C3.2.2.01 32 30 55 45 1 7 MS32RB105.00C4.2.2.01 40 30 55 45 26 MS52Further shank sizes upon requestDimensions in mm*Dimensionsf 3 and l 5 see insertSpare partsToolholder Screw Torx screw driverRB1 05.00C... 6.075 T1 5 T1 5In the UNITED STATES call us toll freeA1 1

GROOVING and BORINGTOOLHOLDER typeBGT...Adjustable round shanks for cartridge type BKTfor use with cartridge.31 5.31 5L 1 Type BKT1 05.2445...L 4Ø1 .772.51 2.51 2dh6hL 3.945.472Toolholder does not includecassettePart number d h6 L 1 L 3 L 4 h MachinetoolBGT001 .001 0.50 .394(1 0) 2.264 1 .969 1 .850 .354BGT001 .001 6.21 .630(16) 1.122 .827 .709 .551 StarBGT001 .0020.1 00 .787(20) 4.232 3.937 3.81 9 .709 TornosBGT001 .0022.30* .866(22) 1 .431 1 .1 81 1 .063 .787 StarBGT001 .0022.70 .866(22) 3.051 2.756 2.638 .787 StarBGT001 .0025.70 .984(25) 3.051 2.756 2.638 .906BGT001 .0028.80 1.102(28) 3.445 3.189 3.031 1.024 Traub* without coolant through Dimensions in inch (mm)Spare partsToolholder Fastening screw O-ringBGT... DIN912−M5x10 DIN3770−7x3A1 2In the UNITED STATES call us toll free

GROOVING and BORINGACARTRIDGE typeBKT...with through coolantBore Ø from .01 2" (0.3mm)Depth of groove up to .098" (2.5mm)Width of groove up to .079" (2.0mm)L 3 .315.039.315for use with insert TypeU105105d(.256).492Ø1 .772L 1.217.472.945Part number d L1 L3 for use with insertBKT1 05.2445.01 .787(20) .866(22) .630(1 6) R/L U1 05/1 05...BKT1 05.2445.02 .787(20) 1.260(32) 1.024(26) R/L U105/105...2..Dimensions in inchSpare partsToolholder Screw Torx screw driverBKT... 6.075T1 5 T1 5In the UNITED STATES call us toll freeA1 3

GROOVING and BORINGTOOLHOLDER typeBGT...Adjustable round shanks for cartridge type BKT.925.463L 1L 3for use with cartridge Type BKT1 05.2327.01L 41.063.354.354hdh6.276.276Toolholder does not includecassettePart number d h6 L 1 L 3 L 4 h MachinetoolBGT001 .1 627.1 0 .630(1 6) .689(1 7.5) .394(1 0) .295(7.5) .551 (1 4) StarDimensions in inch (mm)Spare partsToolholder Fastening screw O-ringBGT... DIN912−M5x10 DIN3770−7x3A1 4In the UNITED STATES call us toll free

GROOVING and BORINGACARTRIDGE typeBKT...with through coolantBore Ø from .01 2" (0.3mm)Depth of groove up to .098" (2.5mm)Width of groove up to .079" (2.0mm).925L 1 .463L 3.463.039for use with insert TypeU105105b.344.3441.063dBKT...01Part number d b L1 L 3 for use with insertBKT1 05.2327.01 .787(20) .472(12) .866(22) .630(16) R/L U105/105...Dimensions in inch(mm)Spare partsToolholder Screw Torx screw driverBKT... 6.075T1 5 T1 5In the UNITED STATES call us toll freeA1 5

GROOVING and BORINGTOOLHOLDER typeB105...01with through coolantBore Ø < .118" or > .197"l 1l 4 .197for use with insertd 2SWhType U105(Ø .1 97B105.0016.11.01 Ø 1 6 mm .630 3.937 1 2 mm 1 .969 .591 > .1 97Further shank sizes upon request.Dimensions in mm/inch* only valid for standard insertsNoteToolholders can be used with right and left hand inserts.Spare partsToolholderClamping nutB1 05.001 0.9.01 020.001 0.1 71 9B1 05.001 2.1 1 .01 020.001 6.1 999B1 05.001 6.1 1 .01 020.001 6.1 999A1 6

GROOVING and BORINGATOOLHOLDER typeBore Ø fromDepth of groove up toWidth ofgroove up toB105...with through coolant.01 2" (0.3 mm).098" (2.5 mm).079" (2.0 mm)l 1for use with insert TypeU105105Length adjustabled g6Right hand insert shownPart number "Toolholder" d g6 l 1B1 05.0020.2.01 * Ø 20 mm 5.906"Further shank sizes upon request.Dimensions in mm/inchNoteToolholders can be used with right and left hand inserts.* Adjusting ring not included with toolholder, seperate order required!ADJUSTING RING14d141550˚284Part number "Adjusting ring" d Type ofmachine020.0020.1 665 Ø20mm TornosDECOFurther shank sizes upon request.Dimensions in inchA1 7

BORING and PROFILING —Ø.012"INSERT type105Bore Ø from .01 2"l 5D minfor use with toolholder Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 058˚l 2Al 2B8˚affart maxrt maxR = right hand version shownL = lefthandversionPart number f a l 2 l 5 t max D min rFormCarbide gradesMG1 2TN35TI25TF45R/L 1 05.1 802.0.03 .039 .01 0 .039 .906 .0008 .012 .0008 BR/L 1 05.1 802.0.05 .039 .01 6 .078 .906 .002 .020 .002 BR/L 1 05.1 803.0.07 .01 2 .024 .078 .906 .002 .028 .002 AState R or L versionDimensions in inch· StandardSemistandardPlease check price anddelivery for all itemsA1 8

BORING and PROFILING —Ø.039"AINSERT type105Bore Ø from .039"l 5D minfor use with toolholder Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 05l 28˚20˚afdrt maxR = right hand version shownL = lefthandversionPart number f a d l 2 l 5 t max D min rCarbide gradesMG1 2TN35TI25TF45R/L 1 05.1 805.005.0.1 .1 57R/L 1 05.1 805.005.1 .1 .020 .035 .026 .236 .984 .004 .039 .002R/L 1 05.1 805.005.2.1 .31 5R/L 1 05.1 805.0.1 .157R/L 105.1805.1.1 .020 .035 .026 .236 .984 .004 .039 .004R/L 105.1805.2.1 .315· StandardSemistandardPlease check price anddelivery for all itemsR/L 1 05.1 81 3.005.0.1 5 .236 .984R/L 1 05.1 81 3.005.1 .1 5 .051 .055 .043 .354 .984 .006 .059 .002R/L 1 05.1 81 3.005.2.1 5 .472 1 .1 81R/L 1 05.1 81 3.01 .0.1 5 .236 .984R/L 1 05.1 81 3.01 .1 .1 5 .051 .055 .043 .354 .984 .006 .059 .004R/L 1 05.1 81 3.01 .2.1 5 .472 1.1 81State R or L versionDimensions in inchA1 9

BORING and PROFILING —Ø.079"INSERT type105Bore Ø from .079"l 5D minfor use with toolholderl 2(.1 1 8)8˚ Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 0520˚afdrt maxR = right hand version shownL = lefthandversionPart number f a d l 2 l 5 t max D min rCarbide gradesMG1 2TN35TI25TF45R/L 1 05.1 809.005.0.2 .236 .984R/L 1 05.1 809.005.1 .2 .039 .075 .063 .354 .984 .006 .079 .002R/L 1 05.1 809.005.2.2 .472 1 .1 81R/L 105.1809.01.0.2 .236 .984R/L 105.1809.01.1.2 .039 .075 .063 .354 .984 .006 .079 .004R/L 105.1809.01.2.2 .472 1 .1 81· StandardSemistandardPlease check price anddelivery for all itemsR/L 105.1809.0.2 .236 .984R/L 105.1809.1.2 .039 .075 .063 .354 .984 .006 .079 .006R/L 105.1809.2.2 .472 1 .1 81R/L 105.1813.005.1.25 .354 .984R/L 1 05.1 81 3.005.2.25 .051 .091 .077 .472 1 .1 81 .006 .098 .002R/L 105.1813.005.3.25 .630 1 .378State R or L versionDimensions in inchA20

BORING and PROFILING —Ø.118"AINSERT type105Bore Ø from .1 1 8"l 5(.1 1 8)D minfor use with toolholder Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 058˚l 2afdr20˚R = right hand version shownL = lefthandversionCarbide gradesMG1 2TN35TI25TF45t maxPart number f a d l 2 l 5 t max D min rR/L 1 05.1 81 3.005.1 .3 .394 .984R/L 1 05.1 81 3.005.2.3 .051 .1 02 .091 .591 1 .1 81 .006 .118 .002R/L 1 05.1 81 3.005.3.3 .787 1 .378R/L 1 05.1 81 3.01 .1 .3 .394 .984R/L 1 05.1 81 3.01 .2.3 .051 .1 02 .091 .591 1 .1 81 .006 .118 .004R/L 1 05.1 81 3.01 .3.3 .787 1 .378· StandardSemistandardPlease check price anddelivery for all itemsR/L 105.1813.1.3 .394 .984R/L 105.1813.2.3 .051 .1 02 .091 .591 1 .1 81 .006 .118 .008R/L 105.1813.3.3 .787 1 .378R/L 1 05.1 81 9.005.1 .4 .394 .984R/L 1 05.1 81 9.005.2.4 .075 .1 46 .1 1 4 .591 1 .1 81 .01 2 .157 .002R/L 1 05.1 81 9.005.3.4 .787 1 .378R/L 105.1819.1.4 .394 .984R/L 105.1819.2.4 .075 .1 46 .1 1 4 .591 1 .1 81 .01 2 .157 .008R/L 105.1819.3.4 .787 1 .378State R or L versionDimensions in inchA21

BORING and PROFILING —Ø.197"INSERT type105Bore Ø from .1 97"l 5D minfor use with toolholder8˚l 2(3) Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 05afdr20˚t maxR = right hand version shownL = lefthandversionPart number f a d l 2 l 5 t max D min rR/L 1 05.1 823.005.1 .5 .394 .984R/L 1 05.1 823.005.2.5 .591 1.181R/L 1 05.1 823.005.3.5 .091 .1 85 .1 57 .787 1 .378 .020 .197 .002R/L 1 05.1 823.005.4.5 .984 1 .575R/L 1 05.1 823.005.5.5 1.181 1.772R/L 105.1823.1.5 .394 .984R/L 105.1823.2.5 .591 1.181R/L 105.1823.3.5 .091 .1 85 .1 57 .787 1 .378 .020 .197 .008R/L 105.1823.4.5 .984 1 .575R/L 105.1823.5.5 1.181 1.772R/L 1 05.1 833.005.2.6 .591 1.181R/L 1 05.1 833.005.3.6 .787 1 .378R/L 1 05.1 833.005.4.6 .1 30 .224 .1 85 .984 1 .575 .020 .236 .002R/L 1 05.1 833.005.5.6 1.181 1.772R/L 105.1833.2.6 .591 1.181R/L 105.1833.3.6 .787 1 .378.1 30 .224 .1 85R/L 105.1833.4.6.984 1 .575 .020 .236 .008R/L 105.1833.5.6 1.181 1.772R/L 1 05.1 840.005.3.7 .787 1 .378R/L 1 05.1 840.005.4.7 .1 57 .252 .205 .984 1 .575 .020 .268 .002R/L 1 05.1 840.005.5.7 1.181 1.772R/L 105.1840.3.7 .787 1 .378R/L 105.1840.4.7 .1 57 .252 .205 .984 1 .575 .020 .268 .008R/L 105.1840.5.7 1.181 1.772State R or L versionDimensions in inchCarbide gradesMG1 2TN35TI25TF45· StandardSemistandardPlease check price anddelivery for all itemsA22

BORING and PROFILING —Ø.157"AINSERT type105Bore Ø from .1 57"l 5D minfor use with toolholder8˚l 2(.1 1 8) Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 05afdwith chip breaker(Geometry H)r20˚t maxR = right hand version shownL = lefthandversionPart number f a d l 2 l 5 t max D min rR/L 105.1819.1.H4 .394 .984R/L 105.1819.2.H4 .075 .1 46 .1 1 4 .591 1 .1 81 .01 2 .157 .008R/L 105.1819.3.H4 .787 1 .378R/L 105.1823.1.H5 .394 .984R/L 105.1823.2.H5 .591 1.181R/L 105.1823.3.H5 .091 .185 .157 .787 1.378 .020 .197 .008R/L 105.1823.4.H5 .984 1 .575R/L 105.1823.5.H5 1.181 1.772R/L 105.1833.2.H6 .591 1.181R/L 105.1833.3.H6 .787 1 .378.1 30 .224 .1 85R/L 105.1833.4.H6.984 1 .575R/L 105.1833.5.H6 1.181 1.772.020 .236 .008R/L 1 05.1 840.3.H7 .787 1 .378R/L 1 05.1 840.4.H7 .1 57 .252 .205 .984 1 .575 .020 .268 .008R/L 1 05.1 840.5.H7 1.181 1.772State R or L versionDimensions in inchCarbide gradesMG1 2TN35TI25TF45· StandardSemistandardPlease check price anddelivery for all itemsA23

BORING and PROFILING —Ø.118"INSERT Type105Bore Ø from .1 1 8"l 5D minfor use with toolholderl 2 Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 05afdr20˚t maxR = right hand version shownL = lefthandversionPart number f a d l 2 l 5 t max D min rR/L 105.9013.1.3 .394 .984.051 .1 02 .091R/L 105.9013.2.3.591 1.181.006 .118 .008R/L 105.9019.1.4 .394 .984.075 .1 46 .1 1 4R/L 105.9019.2.4.591 1.181.01 2 .157 .008R/L 105.9023.1.5 .394 .984R/L 105.9023.2.5 .091 .1 85 .1 57 .591 1 .1 81 .020 .197 .008R/L 105.9023.3.5 .787 1 .378Carbide gradesMG1 2TN35TI25TF45· StandardSemistandardPlease check price anddelivery for all itemsState R or L versionDimensions in inchA24In the UNITED STATES call us toll free

BORING and PROFILING —Ø.157"AINSERT Type105Bore Ø from .1 57"l 5D minfor use with toolholder8˚l 2(.1 20") Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 05afdr47˚+2˚t maxR = right hand version shownL = lefthandversionPart number f a d l 2 l 5 t max D min rCarbide gradesMG1 2TN35TI25TF45R/L 105.4719.3.4 .075 .1 46 .1 1 4 .787 1 .378 .01 2 .1 57R/L 105.4723.4.5 .091 .1 85 .1 46 .984 1 .575 .020 .1 97 .006R/L 105.4733.5.6 .1 30 .224 .1 46 1 .1 81 1 .772 .071 .236State R or L versionDimensions in inch· StandardSemistandardPlease check price anddelivery for all itemsIn the UNITED STATES call us toll freeA25

BACKBORINGINSERT Type105Bore Ø from .1 1 8"l 5D minfor use with toolholderl 2 Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 05af30˚rd2˚t max1,5R = right hand version shownL = lefthandversionPart number f a d l 2 l 5 t max D min rCarbide gradesMG1 2TN35TI25TF45R/L 105.3013.2.3 .051 .1 02 .075.591 1.181R/L 105.3013.3.3 .787 1 .378.020 .118 .004R/L 105.3019.2.4 .075 .1 46 .1 06.591 1.181R/L 105.3019.4.4 .984 1 .575.031 .157 .006R/L 105.3023.3.5 .091 .1 85 .1 38.787 1 .378R/L 105.3023.5.5 1.181 1.772.039 .197 .008· StandardSemistandardPlease check price anddelivery for all itemsR/L 105.3033.3.6 .1 30 .224 .1 46.787 1 .378R/L 105.3033.5.6 1.181 1.772.071 .236 .008R/L 1 05.3040.3.7 .1 57 .252 .1 46.787 1 .378R/L 1 05.3040.5.7 1.181 1.772.098 .268 .008State R or L versionDimensions in inchA26In the UNITED STATES call us toll free

BORING and CHAMFERING —Ø.197"AINSERT Type105Bore Ø from .1 97"l 5D minfor use with toolholderl 2Detail X Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 05E(.1 20")Eafd45˚45˚Xt maxrR = right hand version shownL = lefthandversionPart number E f d a l 2 l 5 t max D min rCarbide gradesMG1 2TN35TI25TF45R/L 1 05.4545.2.5 .039 .091 .1 38 .1 85 .591 1 .1 81 .028 .197 .008R/L 1 05.4545.3.7 .039 .1 57 .1 85 .252 .787 1 .378 .028 .276 .008State R or L versionDimensions in inch· StandardSemistandardPlease check price anddelivery for all itemsIn the UNITED STATES call us toll freeA27

PREGROOVING and CHAMFERING (Int.)INSERT Type105Bore Ø from .1 97"l 5D minfor use with toolholderl 23˚ Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 05af(.1 20")dDetail X8˚t145˚XwtR = right hand version shownL = lefthandversionPart number w f a d l 2 l 5 t max t D minCarbide gradesMG1 2TN35TI25TF45R/L 1 05.081 0.2.5 .039 .091 .1 85 .1 38 .591 1 .1 81 .028 .008 .197State R or L versionDimensions in inch· StandardSemistandardPlease check price anddelivery for all itemsA28In the UNITED STATES call us toll free

A<strong>SUPER</strong> <strong>MINI</strong>TYPE 105Grooving .079" (2.0 mm) bore diameterIn the UNITED STATES call us toll freeA29

GROOVING (Internal) —Ø.118"AINSERT type105...3Bore Ø from .1 1 8"Depth of groove up to .024"l 5D minfor use with toolholderl 2 Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 05(.118)afdwtmaxR = right hand version shownL = lefthandversionPart number w +.002 f a d l 2 l 5 t max D minCarbide gradesMG1 2TN35TI25TF45R/L 1 05.0070.1 .3 .31 5 .984R/L 1 05.0070.2.3 .028 .055 .1 06 .075 .472 1 .1 81 .024 .118R/L 1 05.0070.3.3 .630 1 .378State R or L versionDimensions in inch· StandardSemistandardPlease check price anddelivery for all itemsIn the UNITED STATES call us toll freeA31

GROOVING INTERNAL —Ø.157"INSERT TypeU105/1 05...4Bore Ø from .1 57"Depth of groove up to .031 "l 5D minfor use with toolholderl 2 Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 05(.1 20")afdwtmaxR = right hand version shownL = lefthandversionPart number w +.002 f d a l 2 l 5 t max D minCarbide gradesMG1 2TN35TI25TF45R/L U1 05.0031 .1 .4 .394 .984R/L U1 05.0031 .2.4 .031 .075 .1 06 .1 46 .591 1 .1 81 .031 .1 57R/L U1 05.0031 .3.4 .787 1 .378R/L 1 05.01 00.1 .4 .394 .984· StandardSemistandardPlease check price anddelivery for all itemsR/L 1 05.01 00.2.4 .039 .075 .1 06 .1 46 .591 1 .1 81 .031 .1 57R/L 1 05.01 00.3.4 .787 1 .378State R or L versionDimensions in inchA32In the UNITED STATES call us toll free

GROOVING INTERNAL —Ø.197"AINSERT Type105...5Bore Ø from .1 97"Depth of groove up to .039"l 5D minfor use with toolholderl 2 Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 05(.1 20")afdwt maxR = right hand version shownL = lefthandversionPart number w +.002 f d a l 2 l 5 t max D minR/L 105.0100.1.5 .039R/L 105.0150.1.5 .059 .091 .1 38 .1 85 .394 .984 .039 .197R/L 105.0200.1.5 .079R/L 105.0100.2.5 .039R/L 105.0150.2.5 .059 .091 .1 38 .1 85 .591 1 .1 81 .039 .197R/L 105.0200.2.5 .079Carbide gradesMG1 2TN35TI25TF45· StandardSemistandardPlease check price anddelivery for all itemsR/L 105.0100.3.5 .039R/L 105.0150.3.5 .059 .091 .1 38 .1 85 .787 1 .378 .039 .197R/L 105.0200.3.5 .079R/L 105.0100.4.5 .039R/L 105.0150.4.5 .059 .091 .1 38 .1 85 .984 1 .575 .039 .197R/L 105.0200.4.5 .079R/L 105.0100.5.5 .039R/L 105.0150.5.5 .059 .091 .1 38 .1 85 1 .1 81 1 .772 .039 .197R/L 105.0200.5.5 .079State R or L versionDimensions in inchIn the UNITED STATES call us toll freeA33

GROOVING INTERNAL —Ø.197"INSERT TypeU105...5Bore Ø from .1 97"Depth of groove up to .039"l 5D minfor use with toolholderl 2 Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 05(.1 20")afdwt maxR = right hand version shownL = lefthandversionPart number w +.002 f d a l 2 l 5 t max D minR/L U105.0031.1.5 .031R/L U105.0046.1.5 .046 .091 .1 38 .1 85 .394 .984 .039 .197R/L U105.0062.1.5 .062R/L U105.0078.1.5 .078R/L U105.0031.2.5 .031R/L U105.0046.2.5 .046 .091 .1 38 .1 85 .591 1 .1 81 .039 .197R/L U105.0062.2.5 .062R/L U105.0078.2.5 .078Carbide gradesMG1 2TN35TI25TF45· StandardSemistandardPlease check price anddelivery for all itemsR/L U105.0031.3.5 .031R/L U105.0046.3.5 .046 .091 .1 38 .1 85 .787 1 .378 .039 .197R/L U105.0062.3.5 .062R/L U105.0078.3.5 .078R/L U105.0031.4.5 .031R/L U105.0046.4.5 .046 .091 .1 38 .1 85 .984 1 .575 .039 .197R/L U105.0062.4.5 .062R/L U105.0078.4.5 .078R/L U105.0031.5.5 .031R/L U105.0046.5.5 .046 .091 .1 38 .1 85 1 .1 81 1 .772 .039 .197R/L U105.0062.5.5 .062R/L U105.0078.5.5 .078State R or L versionDimensions in inchA34In the UNITED STATES call us toll free

GROOVING INTERNAL —Ø.197"AINSERT TypeU105...5Bore Ø from .1 97"Depth of groove up to .039"l 5D minfor use with toolholderl 2 Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 05(.1 20")afdwith corner radiusrwrt maxR = right hand version shownL = lefthandversionPart number w +.002 f d a l 2 l 5 t max D min rR/L U105.4604.1.5 .046R/L U105.6204.1.5 .062 .091 .138 .1 85 .394 .984 .039 .197 .004R/L U105.7804.1.5 .078R/L U105.4604.3.5 .046R/L U105.6204.3.5 .062 .091 .1 38 .1 85 .787 1 .378 .039 .197 .004R/L U105.7804.3.5 .078Carbide gradesMG1 2TN35TI25TF45· StandardSemistandardPlease check price anddelivery for all itemsR/L U105.4604.5.5 .046R/L U105.6204.5.5 .062 .091 .1 38 .1 85 1 .1 81 1 .772 .039 .197 .004R/L U105.7804.5.5 .078State R or L versionDimensions in inchIn the UNITED STATES call us toll freeA35

GROOVING INTERNAL —Ø.236"INSERT Type105...6Bore Ø from .236"Depth of groove up to .071 "l 5D minfor use with toolholderl 2 Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 05(.1 20")afdwt maxR = right hand version shownL = lefthandversionPart number w +.002 f a d l 2 l 5 t max D minR/L 105.0100.1.6 .039R/L 105.0150.1.6 .059 .1 30 .224 .1 46 .394 .984 .071 .236R/L 105.0200.1.6 .079R/L 105.0100.2.6 .039R/L 105.0150.2.6 .059 .1 30 .224 .1 46 .591 1 .1 81 .071 .236R/L 105.0200.2.6 .079Carbide gradesMG1 2TN35TI25TF45· StandardSemistandardPlease check price anddelivery for all itemsR/L 105.0100.3.6 .039R/L 105.0150.3.6 .059 .1 30 .224 .1 46 .787 1 .378 .071 .236R/L 105.0200.3.6 .079R/L 105.0100.4.6 .039R/L 105.0150.4.6 .059 .1 30 .224 .1 46 .984 1 .575 .071 .236R/L 105.0200.4.6 .079R/L 105.0100.5.6 .039R/L 105.0150.5.6 .059 .1 30 .224 .1 46 1 .1 81 1 .772 .071 .236R/L 105.0200.5.6 .079State R or L versionDimensions in inchA36In the UNITED STATES call us toll free

GROOVING INTERNAL —Ø.236"AINSERT TypeU105...6Bore Ø from .236"Depth of groove up to .071 "l 5D minfor use with toolholderl 2 Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 05(.1 20")afdwt maxR = right hand version shownL = lefthandversionPart number w +.002 f a d l 2 l 5 t max D minR/L U105.0031.1.6 .031R/L U105.0046.1.6 .046 .1 30 .224 .1 46 .394 .984 .071 .236R/L U105.0062.1.6 .062R/L U105.0078.1.6 .078R/L U105.0031.2.6 .031R/L U105.0046.2.6 .046 .1 30 .224 .1 46 .591 1 .1 81 .071 .236R/L U105.0062.2.6 .062R/L U105.0078.2.6 .078Carbide gradesMG1 2TN35TI25TF45· StandardSemistandardPlease check price anddelivery for all itemsR/L U105.0031.3.6 .031R/L U105.0046.3.6 .046 .1 30 .224 .1 46 .787 1 .378 .071 .236R/L U105.0062.3.6 .062R/L U105.0078.3.6 .078R/L U105.0031.4.6 .031R/L U105.0046.4.6 .046 .1 30 .224 .1 46 .984 1 .575 .071 .236R/L U105.0062.4.6 .062R/L U105.0078.4.6 .078R/L U105.0031.5.6 .031R/L U105.0046.5.6 .046 .1 30 .224 .1 46 1 .1 81 1 .772 .071 .236R/L U105.0062.5.6 .062R/L U105.0078.5.6 .078State R or L versionDimensions in inchIn the UNITED STATES call us toll freeA37

GROOVING INTERNAL —Ø.236"INSERT TypeU105...6Bore Ø from .236"Depth of groove up to .071 "l 5D minfor use with toolholderl 2 Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 05(.1 20")with corner radiusadfR/L U105.7804.5.6 .078rrwR = right hand version shown L = lefthandversionPart number w +.002 f a d l 2 l 5 t max D min r Carbide gradesR/L U105.4604.1.6 .046R/L U105.6204.1.6 .062 .1 30 .224 .1 46 .394 .984 .071 .236 .004R/L U105.7804.1.6 .078· StandardSemistandardR/L U105.4604.3.6 .046R/L U105.6204.3.6 .062 .1 30 .224 .1 46 .787 1 .378 .071 .236 .004R/L U105.7804.3.6 .078delivery for allR/L U105.4604.5.6 .046R/L U105.6204.5.6 .062 .1 30 .224 .1 46 1 .1 81 1 .772 .071 .236 .004t maxMG1 2TN35TI25TF45Please check price anditemsState R or L versionDimensions in inchA38In the UNITED STATES call us toll free

GROOVING INTERNAL —Ø.268"AINSERT Type105...7Bore Ø from .268"Depth of groove up to .098"l 5D minfor use with toolholderl 2 Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 05(.1 20")afdwt maxR = right hand version shownL = lefthandversionPart number w +.002 f a d l 2 l 5 t max D minR/L 105.0100.1.7 .039R/L 105.0150.1.7 .059 .1 57 .252 .1 46 .394 .984 .098 .268R/L 105.0200.1.7 .079R/L 105.0100.2.7 .039R/L 105.0150.2.7 .059 .1 57 .252 .1 46 .591 1 .1 81 .098 .268R/L 105.0200.2.7 .079Carbide gradesMG1 2TN35TI25TF45· StandardSemistandardPlease check price anddelivery for all itemsR/L 105.0100.3.7 .039R/L 105.0150.3.7 .059 .1 57 .252 .1 46 .787 1 .378 .098 .268R/L 105.0200.3.7 .079R/L 105.0100.4.7 .039R/L 105.0150.4.7 .059 .1 57 .252 .1 46 .984 1 .575 .098 .268R/L 105.0200.4.7 .079R/L 105.0100.5.7 .039R/L 105.0150.5.7 .059 .1 57 .252 .1 46 1 .1 81 1 .772 .098 .268R/L 105.0200.5.7 .079State R or L versionDimensions in inchIn the UNITED STATES call us toll freeA39

GROOVING INTERNAL —Ø.268"INSERT TypeU105...7Bore Ø from .268"Depth of groove up to .098"l 5D minfor use with toolholderl 2 Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 05(.1 20")afdwt maxR = right hand version shownL = lefthandversionPart number w +.002 f a d l 2 l 5 t max D minCarbide gradesMG1 2TN35TI25TF45R/L U105.0031.1.7 .031R/L U105.0046.1.7 .046 .1 57 .252 .1 46 .394 .984 .098 .268R/L U105.0062.1.7 .062R/L U105.0078.1.7 .078R/L U105.0031.2.7 .031R/L U105.0046.2.7 .046 .1 57 .252 .1 46 .591 1 .1 81 .098 .268R/L U105.0062.2.7 .062R/L U105.0078.2.7 .078R/L U105.0031.3.7 .031R/L U105.0046.3.7 .046 .1 57 .252 .1 46 .787 1 .378 .098 .268R/L U105.0062.3.7 .062R/L U105.0078.3.7 .078R/L U105.0031.4.7 .031R/L U105.0046.4.7 .046 .1 57 .252 .1 46 .984 1 .575 .098 .268R/L U105.0062.4.7 .062R/L U105.0078.4.7 .078R/L U105.0031.5.7 .031R/L U105.0046.5.7 .046 .1 57 .252 .1 46 1 .1 81 1 .772 .098 .268R/L U105.0062.5.7 .062R/L U105.0078.5.7 .078State R or L versionDimensions in inch· StandardSemistandardPlease check price anddelivery for all itemsA40In the UNITED STATES call us toll free

GROOVING INTERNAL —Ø.268"AINSERT TypeU105...7Bore Ø from .268"Depth of groove up to .098"l 5D minfor use with toolholderl 2 Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 05(.1 20")afdwith corner radiuswt maxR = right hand version shownL = lefthandversionPart number w +.002 f a d l 2 l 5 t max D min rCarbide gradesMG1 2TN35TI25TF45R/L U105.4604.1.7 .046R/L U105.6204.1.7 .062 .1 57 .252 .1 46 .394 .984 .098 .268 .004R/L U105.7804.1.7 .078R/L U105.4604.3.7 .046R/L U105.6204.3.7 .062 .1 57 .252 .1 46 .787 1 .378 .098 .268 .004R/L U105.7804.3.7 .078· StandardSemistandardPlease check price anddelivery for all itemsR/L U105.4604.5.7 .046R/L U105.6204.5.7 .062 .1 57 .252 .1 46 1 .1 81 1 .772 .098 .268 .004R/L U105.7804.5.7 .078State R or L versionDimensions in inchIn the UNITED STATES call us toll freeA41

GROOVING INTERNAL —Ø.157"INSERT TypeU105Bore Ø from .1 57"Full radius r .023" - .039"l 5D minfor use with toolholderl 2(.1 20") Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 05afdFull radiuswr1t maxR = right hand version shownL = lefthandversionPart number w f d a l 2 l 5 t max D min rCarbide gradesMG1 2TN35TI25TF45R/L U105.2346.2.4 .046 .075 .1 06 .146 .591 1.181 .031 .157 .023R/L U105.2346.3.5 .046 .023R/L U105.3162.3.5 .062 .091 .1 38 .1 85 .787 1 .378 .039 .197 .031R/L U105.3978.3.5 .078 .039R/L U105.2346.4.6 .046 .023R/L U105.3162.4.6 .062 .130 .1 46 .224 .984 1.575 .071 .236 .031R/L U105.3978.4.6 .078 .039· StandardSemistandardPlease check price anddelivery for all itemsR/L U105.2346.5.7 .046 .023R/L U105.3162.5.7 .062 .157 .1 46 .252 1.181 1.772 .098 .268 .031R/L U105.3978.5.7 .078 .039State R or L versionDimensions in inchA42In the UNITED STATES call us toll free

THREADING (Internal)INSERT Type105Bore Ø from .157"Threads per inch1 8 − 40 tpil 5D minfor use with toolholderEl 2(.1 20") TypeBU105B1 05R/L H1 05R/L HC1 05VDI...R/L1 05afdThreadBSW/BSF - UN - NPTR = right hand version shownL = lefthandversionPart number tpi E f a d l 2 l 5 D minTHREAD BSW/BSF (full profile)R/L 105.5528.2.5 28R/L 105.5526.2.5 26 .031 .091 .185 .138 .591 1.181 .1 97R/L 105.5524.2.5 24R/L 105.5528.2.6 28R/L 105.5526.2.6 26 .031 .130 .224 .146 .591 1.181 .236R/L 105.5524.2.6 24R/L 105.5522.2.6 22R/L 105.5520.2.6 20 .039 .130 .224 .146 .591 1.181 .236R/L 105.5519.2.6 19THREAD UN (partial profile)55˚60˚Carbide gradesMG12TN35TI25TF45· StandardSemistandardPlease check price anddelivery for all itemsR/L 105.3240.2.4 32−40 .018 .075 .146 .106 .591 1.181 .157R/L 105.3240.2.5 32−40 .01 8 .091 .185 .138 .591 1.181 .197R/L 105.2428.2.5 24−28 .022R/L 105.2428.2.6 24−28 .022 .130 .224 .146 .591 1.181 .236R/L 1 05.1 620.2.6 16−20 .028THREAD NPT (partial profile)R/L 105.NP27.2.6 27 .031R/L 105.NP18.2.6 18 .039State R or L versionA4460˚.130 .224 .146 .591 1.181 .236Dimensions in inchIn the UNITED STATES call us toll free

THREADING (Internal) partial profileAINSERT Type105Bore Ø from .1 57"PitchP 0.5 − 1 .5 mmThreads per inch64 − 1 6 tpil 5D minfor use with toolholderEl 2(.1 20")EDetail X Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 05afd60˚Partial Profile ThreadXR = right hand version shownL = lefthandversionPart number Pitch E f a d l 2 l 5 D minSTANDARD THREAD tpi mmCarbide gradesMG1 2TN35TI25TF45R/L 105.0510.2.5 24-32 1 .0 .022 .083 .1 77 .1 38 .591 1 .1 81 .189R/L 105.0612.2.6 18−24 1.25 .026 .130 .224 .146 .591 1.181 .236R/L 105.0815.2.7 1 6−24 1 .5 .030 .1 57 .252 .1 46 .591 1 .1 81 .276· StandardSemistandardPlease check price anddelivery for all itemsPart number Pitch E f a d l 2 l 5 D minFINE THREAD tpi mmR/L 105.0205.2.4 32−64 0.5 .01 4 .075 .1 46 .1 06 .591 1 .1 81 .157R/L 105.0205.2.5 32−64 0.5 .01 4 .091 .1 85 .1 38 .591 1 .1 81 .197R/L 105.0407.2.5 28−64 0.75 .01 8 .091 .1 85 .1 38 .591 1 .1 81 .197R/L 105.0510.2.6 24−32 1 .0 .022 .1 30 .224 .1 46 .591 1 .1 81 .236State R or L versionDimensions in inch/mmIn the UNITED STATES call us toll freeA45

THREADING (Internal)INSERT Type105Bore Ø from .1 97"Threads per inch1 0 − 1 6 tpil 5D minfor use with toolholderEl 2(.1 20")E29˚Detail x Type BU1 05B1 05R/L H1 05R/L HC1 05VDI...R/L1 05afxdwACME / Stub ACMEthreadR = right hand version shownL = lefthandversionPart number tpi E f a d l 2 l 5 D min wCarbide gradesMG1 2TN35TI25TF45Standard ACME ThreadR/LU105.AC16.2.5 .591 1 .1 811 6 .028 .079 .1 73 .1 22R/LU105.AC16.4.5.984 1 .575R/LU105.AC14.2.6 .591 1 .1 81R/LU105.AC14.4.6 1 4 .035 .1 30 .224 .1 69 .984 1 .575.197 .020.236 .024· StandardSemistandardPlease check price anddelivery for all itemsR/LU105.AC12.3.7 1 2 .1 89 .787 1 .378 .028R/LU105.AC12.5.7 1 2 .039 .1 57 .252 .1 89 1 .1 81 1 .772 .276 .028R/LU105.AC10.3.7 1 0 .1 73 .787 1 .378 .032Stub ACME ThreadR/LU105.SA16.2.5 .591 1 .1 811 6 .028 .091 .1 85 .1 42R/LU105.SA16.4.5.984 1 .575R/LU105.SA14.2.5 .591 1 .1 811 4 .035 .1 31 .224 .1 77R/LU105.SA14.4.6.984 1 .575.197 .024.236 .028R/LU105.SA12.3.7 1 2 .201 .787 1 .378 .032R/LU105.SA12.5.7 1 2 .039 .1 57 .252 .201 1 .1 81 1 .772 .276 .032R/LU105.SA10.3.7 10 .193 .787 1.378 .037State R or L versionDimensions in inchA46In the UNITED STATES call us toll free

A<strong>SUPER</strong> <strong>MINI</strong>FACE GROOVING WITH INSERT TYPE 105-Fromouter-Ø.197"(5.0)mm- Depth of groove up to .197" (5.0) mmIn the UNITED STATES call us toll freeA47

w frFACE GROOVING (Internal)INSERT Type105from outer groove Ø .197"Depth ofgroove up to .1 97"Width ofgroove up to .079"l 5D minfor use with toolholdertmax TypeBU105B1 05R/L H1 05R/L HC1 05VDI...R/L1 05rl 2R = right hand version shownL = lefthandversionPart number w +.002 f r l 2 l 5 t max D minR/L 105.0510.1.8 .039 .079R/L 1 05.051 5.1 .8 .059 .079 .002 .394 .984 .118 .197R/L 105.0520.1.8 .079 .197R/L 105.0510.2.8 .039 .079R/L 1 05.051 5.2.8 .059 .079 .002 .591 1.378 .118 .197R/L 105.0520.2.8 .079 .197State R or L versionDimensions in inchCarbide gradesMG12TN35TI25TF45· StandardSemistandardPlease check price anddelivery for all itemsA48In the UNITED STATES call us toll free

w frFACE GROOVING (Internal)AINSERT Type105from outer groove Ø .236"Depth ofgroove up to .1 97"Width ofgroove up to .079"l 5D minfor use with toolholdertmax TypeBU105B1 05R/L H1 05R/L HC1 05VDI...R/L1 05rl 2R = right hand version shownL = lefthandversionPart number w +.002 f r l 2 l 5 t max D minR/L 1 05.061 0.1 .8 .039 .079R/L 105.0615.1.8 .059 .079 .002 .394 .984 .118 .236R/L 1 05.0620.1 .8 .079 .197R/L 1 05.061 0.2.8 .039 .079R/L 105.0615.2.8 .059 .079 .002 .591 1.378 .118 .236R/L 1 05.0620.2.8 .079 .197State R or L versionDimensions in inchCarbide gradesMG12TN35TI25TF45· StandardSemistandardPlease check price anddelivery for all itemsIn the UNITED STATES call us toll freeA49

w frFACE GROOVING (Internal)INSERT TypeU105/105from outer groove Ø .31 5"Depth ofgroove up to .236"Width ofgroove up to .1 25"l 5D minfor use with toolholdertmax TypeBU105B1 05R/L H1 05R/L HC1 05VDI...R/L1 05rl 2R = right hand version shownL = lefthandversionPart number w +.002 f r l 2 l 5 t max D minR/L U105.0846.1.8 .046 .098R/L U105.0862.1.8 .062 .118R/L U105.0878.1.8 .078 .079 .006 .394 .984 .157 .315R/L U105.0894.1.8 .094 .197R/L U105.0812.1.8 .125 .236R/L U105.0846.2.8 .046 .098R/L U105.0862.2.8 .062 .118R/L U105.0878.2.8 .078 .079 .006 .591 1.378 .157 .315R/L U105.0894.2.8 .094 .197R/L U105.0812.2.8 .125 .236R/L 1 05.081 0.1 .8 .039 .098R/L 105.0815.1.8 .059 .118R/L 1 05.0820.1 .8 .079 .079 .006 .394 .984 .157 .315R/L 105.0825.1.8 .098 .197R/L 1 05.0830.1 .8 .118 .236R/L 1 05.081 0.2.8 .039 .098R/L 105.0815.2.8 .059 .118R/L 1 05.0820.2.8 .079 .079 .006 .591 1.378 .157 .315R/L 105.0825.2.8 .098 .197R/L 1 05.0830.2.8 .118 .236State R or L versionDimensions in inchCarbide gradesMG12TN35TI25TF45· StandardSemistandardPlease check price anddelivery for all itemsA50In the UNITED STATES call us toll free

FACE GROOVING (Internal)AINSERT TypeU105/105from outer groove Ø .31 5"Depth ofgroove up to .236"Width ofgroove up to .1 25"l 5D minfor use with toolholdertmax TypeBU105B1 05R/L H1 05R/L HC1 05VDI...R/L1 05w frFull radiusl 2R = right hand version shownL = lefthandversionPart number w +.002 f r l 2 l 5 t max D minR/L U105.FF46.1.8 .046 .023 .098R/L U105.FF62.1.8 .062 .031 .118R/L U105.FF78.1.8 .078 .079 .039 .394 .984 .157 .315R/L U105.FF94.1.8 .094 .047 .197R/LU105.FF12.1.8 .125 .062 .236R/L U105.FF46.2.8 .046 .023 .098R/L U105.FF62.2.8 .062 .031 .118R/L U105.FF78.2.8 .078 .079 .039 .591 1.378 .157 .315R/L U105.FF94.2.8 .094 .047 .197R/LU105.FF12.2.8 .125 .062 .236Carbide gradesMG12TN35TI25TF45· StandardSemistandardPlease check price anddelivery for all itemsR/L 105.8V10.1.8 .039 .020 .079R/L 105.8V16.1.8 .063 .031 .118R/L 105.8V20.1.8 .079 .079 .039 .394 .984 .157 .315R/L 105.8V25.1.8 .098 .049 .197R/L 105.8V30.1.8 .118 .059 .236R/L 105.8V10.2.8 .039 .020 .079R/L 105.8V16.2.8 .063 .031 .118R/L 105.8V20.2.8 .079 .079 .039 .591 1.378 .157 .315R/L 105.8V25.2.8 .098 .049 .197R/L 105.8V30.2.8 .118 .059 .236State R or L versionDimensions in inchIn the UNITED STATES call us toll freeA51

FACE GROOVING (Internal)INSERT Type105from outer groove Ø .31 5"Depth ofgroove up to .236"Width ofgroove up to .1 1 8"l 5D minfor use with toolholderl 2 TypeBU105B1 05R/L H1 05R/L HC1 05VDI...R/L1 05wfrrtmaxR = right hand version shownL = lefthandversionPart number w +.002 f r l 2 l 5 t max D minR/L 1 05.081 0.1 .9 .039 .079R/L 105.0815.1.9 .059 .118R/L 1 05.0820.1 .9 .079 .016 .006 .394 .984 .157 .315R/L 105.0825.1.9 .098 .197R/L 1 05.0830.1 .9 .118 .236State R or L versionDimensions in inchCarbide gradesMG12TN35TI25TF45· StandardSemistandardPlease check price anddelivery for all itemsA52In the UNITED STATES call us toll free

CHAMFERINGAINSERT type105Angle of chamfer45˚/60˚Width of chamfer up to .1 57"l 5l 2for use with toolholder TypeBU105B1 05R/L H1 05tmaxfrD minaR = right hand version shownL = lefthandversionPart number a f r l 2 l 5 t max D minR/L 105.0045.1.1 45˚.138.020 .008 .472 .984.039R/L 1 05.0060.1 .1 60˚ .1 57State R or L versionDimensions in inchCarbide gradesMG12TN35TI25TF45· StandardSemistandardPlease check price anddelivery for all itemsIn the UNITED STATES call us toll freeA53

BORING and PROFILINGTOOLHOLDER typeBU/B105...02with through coolantl 1 l 4 .1 97hfor use with insert Type U1 05105.866 Clamping lengthd g6Right hand insert shownPart number d g6 l 1 l 4 h<strong>Inc</strong>h ToolholderBU105.0500.02 .500 3.346 1 .969 .433BU105.0625.02 .625 3.346 1 .969 .551BU105.0750.02 .750 3.937 2.1 65 .709Metric Toolholder in mmB105.0012.02 12 85 50 11B105.0016.02 16 85 50 14B105.0020.02 20 1 00 55 1 8Further shank sizes upon request.Dimensions in inch/mmNoteToolholders can be used with right and lefthandinserts.Spare partsToolholder Screw Torx screw driverB/BU1 05...02 6.075 T1 5 T1 5A54In the UNITED STATES call us toll free

BORING and PROFILINGAINSERT Typewith extended clamping shank105Bore Ø from .1 97"l 5for use with toolholder.866 Clamping lengthD min Type BU1 05....02B1 05...02.1 1 88˚l 2afrat maxdR = right hand version shownL = lefthandversionPart number f a d l 2 l 5 t max D min r aCarbide gradesMG1 2TN35TI25TF45R/L 105.1823.4.5.2 .984 1 .969.091 .185 .1 65R/L 1 05.1 823.5.5.2 1.181 2.165 .01 2 .197 .004 20ºR/L 105.1833.4.6.2 .984 1 .969.130 .224 .1 93R/L 105.1833.5.6.2 1.181 2.165 .01 2 .236 .004 20ºR/L 1 05.1 840.4.7.2 .984 1 .969.157 .252 .21 3.01 2 .268 .004 20ºR/L 1 05.1 840.5.7.2 1.181 2.165· StandardSemistandardPlease check price anddelivery for all itemsR/L 105.4733.5.6.2 .1 30 .224 .1 46 1 .1 81 2.1 65 .071 .236 .004 47ºState R or L versionDimensions in inchIn the UNITED STATES call us toll freeA55

TECHNICAL INFORMATIONS − ThreadingRECOMMENDED NUMBER OF PASSESCarbide grade Steel (thousands oflb/in 2 ) Stainl.steel Cast iron AluminiumTN35 58−72 72−1 01 1 01 −1 23 1 23−1 67 > 1 67Vmaxfeet/min 525 460 390 300 230 300 330 980Pitchmm tpiNo. ofpasses0,8 32 8 8 9 9 1 0 1 0 9 81,0 24 10 10 12 12 12 12 12 101,25 20−19 12 12 14 14 15 15 14 121,5 16 15 15 17 17 18 18 17 151,75 14 17 17 19 19 21 21 18 172,0 1 2−1 1 1 9 20 22 22 25 25 20 1 82,5 10 22 24 26 26 31 31 22 203,0−3,5 8 28 30 32 32 38 38 24 22FEED DIRECTION AND SPINDLE ROTATION for internal threadingRight hand thread (internal)Left hand thread (internal)RIGHT HAND TOOLINGLEFT HAND TOOLINGLEFT HAND TOOLINGRIGHT HAND TOOLINGIN−FEEDRADIAL IN−FEEDMetal removed on both sides ofthe insertsimultaneously. Themost commonly used method for thread production.MODIFIED FLANK IN−FEEDLess wear of the trailing edge and better surface finish oncorresponding flank.radial in−feedmodified flank in−feedALTERNATING FLANK IN−FEEDBoth edges are being fully utilised which means longerinsert life.Technical InstructionsFLANK IN−FEEDMore easily formed chip and better heat dissipation.B64alternating flank−in feedIn the UNITED STATES call us toll freeflank in−feedAll threads up to 4.5˚ helix angle can be manufactured with HORN standard threading inserts.No special anvils will be necessary.

TECHNICAL INSTRUCTIONSABSEATINGSof <strong>MINI</strong> as well as <strong>SUPER</strong> − <strong>MINI</strong> guarantee the accurate center height of these tools.In spite ofthis always check center height because a difference may cause problemsespecially when machining small diameters.TORQUE OF SCREWS FOR <strong>MINI</strong>Following torques are allowed for screws of <strong>MINI</strong> inserts. We recommend not to use additionalmeans (such as copper paste) for screws.Screw T8(type108) T10(type111) T15(type114) T20(type116)Torque lbf-in. 9 − 1 3 22 − 26 35 − 40 50 − 55REMOVAL OF CHIPSPlease choose inserts with small cutting widths, which helps chips evacuation and chip flowout of the bore beside the tool. To avoid jam of chips use the technique to groove by steps.COOLANTUse a filtered coolant for transporting the chips out and for cooling the insert itself.A coolant pressure of75 psi min. is recommended.UNCOATED GRADESMG1 2 −a universal grade with good wear resistance. Used at low or medium cutting speeds formachining steel, cast iron and non ferrous materials.COATED GRADESTN35 −TI25 −TF45 −a very popular grade TIN coated used to low or medium cutting speeds. Also recommendedfor machining stainless steel or exotic alloyed materials.a TICN coated grade with high abrasion resistance. Recommended for machining steel andnon ferrous materials at medium cutting speeds.a TIALN coated grade. This coating has a very high temperature stability and high hardness.Machining small bores, therefore it is only used for special applications.In the UNITED STATES call us toll freeB65

GRADES and CUTTING SPEEDSwear resistancecutting speedtoughnessCarbide grades synthetic cutting-tool materialuncoated coatedPD1 0PD20TF45TI25MG1 2TN35 TF45MG1 2CB1 0feedrateCB20ISOANSINnon ferrous metalhigh temperaturematerialsSHhardened materialswear resistancecutting speedtoughnessfeedrateCarbide gradesuncoated coatedMG1 2TN35TI25MG1 2TN35 TI25TI25MG1 2TN35TF45TF45TF450110203040102030Technical Instructions4001102030C8C7C5----C4C3C2C1B66ANSIISOC8C7C5----C4C3C2C101102030401020304001102030Psteel stainless steel grey cast iron / aluminiumMIn the UNITED STATES call us toll freeK

GRADES and CUTTING SPEEDSABNominal cutting speeds with HORN gradesISO Material <strong>SUPER</strong><strong>MINI</strong>® <strong>MINI</strong>Feed rates IPRHardnessBrinell.0004 − .0008 .0004 − .001 2.0008 − .0020 .0012 − .0040.0008 − .0020 .0004 − .0012Cutting speed *Vc ft/minPHB MG1 2 TN35 TI25 TF45 CB1 0/CB20Non−alloy carbon steelC 0,4% < 0,6% 1 50 45 − 360 45 − 590 45 − 590 45 − 590C > 0,6% < 0,8% 200Low−alloy steelAnnealed 1 80Hardened and tempered 275 50 − 300 50 − 500 50 − 500Hardened and tempered 300High−alloy steelAnnealed 200Hardened 32560−30060−300Steel castingsNon−alloy 1 80Low−alloy 200 60 − 360 60 − 590 60 − 590High−alloy 225Stainless steel, annealedMartensitic / ferritic 200 60 − 300 60 - 300MStainless steelAustenitic Ni > 8% 1 80 50 − 265Cr 1 8−25%Grey cast iron 1 80 − 260 50 − 300 50 − 500 50 − 500 50 − 500KModular SG iron 1 80 − 260 50 − 300 50 − 430 50 − 430 50 − 500Malleable iron 1 30 − 230 50 − 430 50 − 430 50 − 500Heat resistant alloys (NiFe) 60 - 250 60 - 250SHeat resistant alloys (NiCo) 60 - 1 30 60 - 1 30Aluminium alloys 50 − 725 50 − 2000 50 − 2000NBronze−brass alloys 50 − 725 50 − 2300 50 − 2300Hhardended materials>54HRC65 - 460*Vcis depending on the bore diameter and therefore ofthe maximum numbers ofrevolutions ofthe machine.In the UNITED STATES call us toll freeB67