Mini 18P (inch) - Horn USA

Mini 18P (inch) - Horn USA

Mini 18P (inch) - Horn USA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

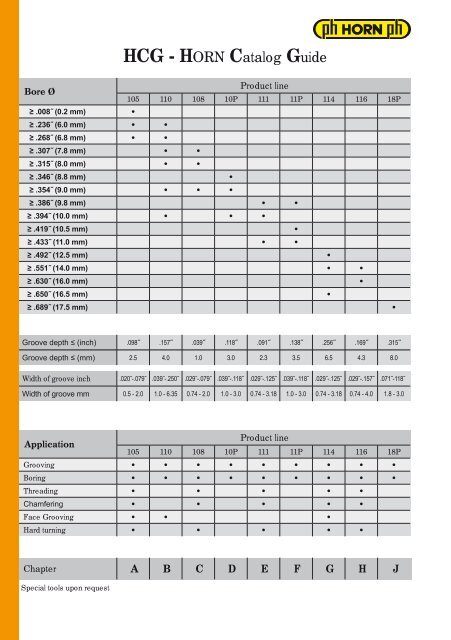

HCG - HORN Catalog GuideBore Ø≥ .008˝ (0.2 mm) •≥ .236˝ (6.0 mm) • •≥ .268˝ (6.8 mm) • •Product line105 110 108 10P 111 11P 114 116 <strong>18P</strong>≥ .307˝ (7.8 mm) • •≥ .315˝ (8.0 mm) • •≥ .346˝ (8.8 mm)•≥ .354˝ (9.0 mm) • • •≥ .386˝ (9.8 mm) • •≥ .394˝ (10.0 mm) • • •≥ .419˝ (10.5 mm)•≥ .433˝ (11.0 mm) • •≥ .492˝ (12.5 mm)•≥ .551˝ (14.0 mm) • •≥ .630˝ (16.0 mm)•≥ .650˝ (16.5 mm)•≥ .689˝ (17.5 mm)•Groove depth ≤ (<strong>inch</strong>) .098˝ .157˝ .039˝ .118˝ .091˝ .138˝ .256˝ .169˝ .315˝Groove depth ≤ (mm) 2.5 4.0 1.0 3.0 2.3 3.5 6.5 4.3 8.0Width of groove <strong>inch</strong> .020˝-.079˝ .039˝-.250˝ .029˝-.079˝ .039˝-.118˝ .029˝-.125˝ .039˝-.118˝ .029˝-.125˝ .029˝-.157˝ .071˝-118˝Width of groove mm 0.5 - 2.0 1.0 - 6.35 0.74 - 2.0 1.0 - 3.0 0.74 - 3.18 1.0 - 3.0 0.74 - 3.18 0.74 - 4.0 1.8 - 3.0ApplicationProduct line105 110 108 10P 111 11P 114 116 <strong>18P</strong>Grooving • • • • • • • • •Boring • • • • • • • • •Threading • • • • •Chamfering • • • • •Face Grooving • • •Hard turning • • • • •Chapter A B C D E F G H JSpecial tools upon request

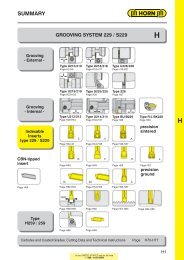

SUMMARYMINI CARBIDE GROOVING TOOLSToolholderBU<strong>18P</strong> / B<strong>18P</strong>Page J2-J3Inserts<strong>18P</strong> / S<strong>18P</strong>≥ Ø .709˝ (18 mm)Page J4, J6Page J5Page J7JTechnical InstructionsPageL1 - L9In the UNITED STATES call us toll free1 - 888 - 818 HORNJ1

GROOVING and BORINGTOOLHOLDER TypeBU<strong>18P</strong>with through coolant supplyBore Ø fromDepth of groove up toWidth of groove up to.709″.315″.118″Material of shank: Carbide - Giving a good vibration resistancefor use with InsertType<strong>18P</strong>S<strong>18P</strong>R = right hand version shownL = left hand versionPart number d l 1l 2h h 1l4JR/LBU<strong>18P</strong>.0500.003.937 .984R/LBU<strong>18P</strong>.0500.01.5004.724 1.575R/LBU<strong>18P</strong>.0625.003.937 .984R/LBU<strong>18P</strong>.0625.01 4.724 1.575.625R/LBU<strong>18P</strong>.0625.02 5.118 2.205R/LBU<strong>18P</strong>.0625.03 5.906 3.150.461 .500 1.969.585 .512 1.969State R or L version w, a, t maxand f see inserts Dimensions in <strong>inch</strong>Further sizes upon requestOrdering note:Toolholders with damaged seating can be repaired by HORN.Spare partsToolholder Screw TORX PLUS ® WrenchR/LBU<strong>18P</strong>.0... 5.13T20EP T20PQJ2In the UNITED STATES call us toll free1 - 888 - 818 HORN

GROOVING and BORINGTOOLHOLDER TypeB<strong>18P</strong>with through coolant supplyBore Ø fromDepth of groove up toWidth of groove up to.709″ (18.0 mm).315″ (8.0 mm).118″ (3.0 mm)Material of shank: Carbide - Giving a good vibration resistancefor use with InsertType<strong>18P</strong>S<strong>18P</strong>R = right hand version shownL = left hand versionPart number d l 1l 2h h 1l4R/LB<strong>18P</strong>.0012.00100 25R/LB<strong>18P</strong>.0012.0112120 40R/LB<strong>18P</strong>.0016.00100 25R/LB<strong>18P</strong>.0016.01 120 4016R/LB<strong>18P</strong>.0016.02 130 56R/LB<strong>18P</strong>.0016.03 150 8011 12.5 5015 13.0 50State R or L version w, a, t maxand f see inserts Dimensions in mmJFurther sizes upon requestOrdering note:Toolholders with damaged seating can be repaired by HORN.Spare partsToolholder Screw TORX PLUS ® WrenchR/LB<strong>18P</strong>.001... 5.13T20EP T20PQIn the UNITED STATES call us toll free1 - 888 - 818 HORNJ3

GROOVING (internal) ≥ Ø .709″INSERT TypeS<strong>18P</strong>Bore Ø fromDepth of groove up toWidth of groove.709″.236″.079 - .118″for use with ToolholderTypeB<strong>18P</strong>BU<strong>18P</strong>R = right hand version shownL = left hand versionPart number w r s f a d t maxD minMG12TN35TI25TH35JR/LS<strong>18P</strong>.0200.1.D2 .079▲/▲R/LS<strong>18P</strong>.0250.1.D2 .098 .008 .209 .472 .689 .433 .236 .709▲/▲R/LS<strong>18P</strong>.0300.1.D2 .118 ▲/▲▲ on stock Δ 4 weeks P ●● main recommendation M ●ο alternative recommendation K ●███ uncoated grades S ●███ coated grades N ●███ brazed/CermetHDimensions in <strong>inch</strong>Carbide gradesState R or L versionJ4In the UNITED STATES call us toll free1 - 888 - 818 HORN

GROOVING (internal) ≥ Ø .709″INSERT Type<strong>18P</strong>Bore Ø fromDepth of groove up toWidth of groove.709″.236″.071 - .118″for use with ToolholderTypeB<strong>18P</strong>BU<strong>18P</strong>R = right hand version shownL = left hand versionFull radiusPart number w r s f a d t maxD minMG12TN35TI25TH35R/L<strong>18P</strong>.0009.1.18 .071 .035▲/▲R/L<strong>18P</strong>.0011.1.22 .087 .043 .209 .472 .689 .433 .236 .709▲/▲R/L<strong>18P</strong>.0015.1.30 .118 .059 ▲/▲▲ on stock Δ 4 weeks P ●● main recommendation M ●ο alternative recommendation K ●███ uncoated grades S ●███ coated grades N ●███ brazed/CermetHDimensions in <strong>inch</strong>Carbide gradesJState R or L versionIn the UNITED STATES call us toll free1 - 888 - 818 HORNJ5

GROOVING (internal) ≥ Ø .787″INSERT TypeS<strong>18P</strong>Bore Ø fromDepth of groove up toWidth of groove.787″.315″.079 - .118″for use with ToolholderTypeB<strong>18P</strong>BU<strong>18P</strong>R = right hand version shownL = left hand versionPart number w r s f a d t maxD minMG12TN35TI25TH35JR/LS<strong>18P</strong>.0200.2.D2 .079▲/▲R/LS<strong>18P</strong>.0250.2.D2 .098 .008 .209 .551 .768 .433 .315 .787▲/▲R/LS<strong>18P</strong>.0300.2.D2 .118 ▲/▲▲ on stock Δ 4 weeks P ●● main recommendation M ●ο alternative recommendation K ●███ uncoated grades S ●███ coated grades N ●███ brazed/CermetHDimensions in <strong>inch</strong>Carbide gradesState R or L versionJ6In the UNITED STATES call us toll free1 - 888 - 818 HORN

BORING and PROFILING ≥ Ø .689″INSERT TypeS<strong>18P</strong>Bore Ø fromDepth of undercut up to.689″.217″for use with ToolholderTypeB<strong>18P</strong>BU<strong>18P</strong>R = right hand version shownL = left hand versionPart number r s f a d D minMG12TN35TI25TH35LS<strong>18P</strong>.1815.R2 .008▲RS<strong>18P</strong>.1815.R2 .008 ▲.209 .453 .669 .433 .689LS<strong>18P</strong>.1815.R4 .016 ▲RS<strong>18P</strong>.1815.R4 .016 ▲▲ on stock Δ 4 weeks P ●● main recommendation M ●ο alternative recommendation K ●███ uncoated grades S ●███ coated grades N ●███ brazed/CermetHDimensions in <strong>inch</strong>Carbide gradesJState R or L versionThe modified geometry allows boring of bores ≥ Ø .689'' and profiling of reliefs as per DIN 509 form E and F.In the UNITED STATES call us toll free1 - 888 - 818 HORNJ7

THREAD WHIRLINGJ• short tool changing times• high precision guaranteed for smooth cutting• very good surface finish on the threads• high tool life per edge due to even cutting actionFor further information, please contact HORN <strong>USA</strong>.J8In the UNITED STATES call us toll free1 - 888 - 818 HORN