You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

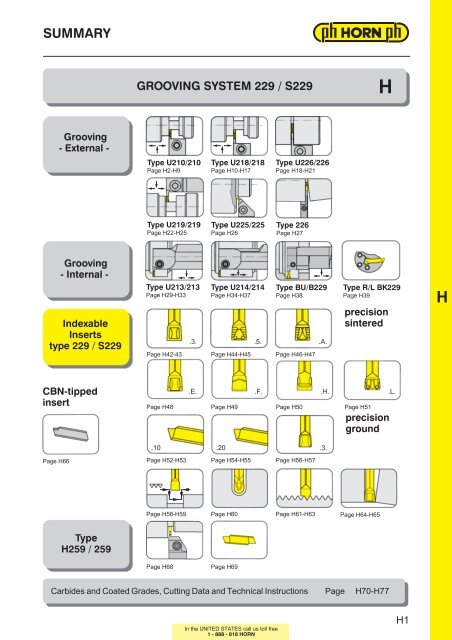

<strong>SUMMARY</strong>GROOVING SYSTEM 229 / S229HGrooving−External−Type U21 0/21 0Page H2−H9Type U21 8/21 8Page H1 0−H1 7Type U226/226Page H1 8−H21Type U21 9/21 9Page H22−H25Type U225/225Page H26Type 226Page H27Grooving−Internal−IndexableInsertsType U21 3/21 3Page H29−H33Type U21 4/21 4Page H34−H37Type BU/B229Page H38.3. .5. .A.type 229 / S229Page H42−43 Page H44−H45 Page H46−H47Type R/L BK229Page H39precisionsinteredHCBN−tippedinsertPage H48.E.Page H49.F.Page H50.H.Page H51.L.precisionground.1 0 .20 .3.Page H66Page H52−H53Page H54−H55Page H56−H57Page H58−H59Page H60Page H61 −H63Page H64−H65TypeH259 / 259Page H68Page H69Carbides and Coated Grades, Cutting Data and Technical Instructions Page H70−H77In the UNITED STATES call us toll freeH1

GROOVING and TURNING (External)TOOLHOLDER typeU210...02-05Depth of groove up to .433"Width of groove .098 − .236"Depth ofcut a p up to .1 57"1.378l 1.197for use with indexableinserth 1h h type 229S229l 2tf f1 R bwR = right hand version shownL = lefthandversionPart number h b l 1 h 1 f f 1 l 2 t Widthofgroove "w"SeatingSizeR/L U210.0750.02* .750 .750 6.000 1.000 .693 1.375 .433 .098 − .1 1 8 02R/L U210.1000.02* 1 .000 1 .000 6.000 1 .000 .943 -R/L U210.0625.03 .625 .625 6.000 1.000 .568 1.750R/L U210.0750.03 .750 .750 6.000 1.000 .693 1.375 .433 .118−.157 03R/L U210.1000.03 1 .000 1 .000 6.000 1 .000 .943 -R/L U210.1250.03 1 .250 1 .000 6.625 1 .250 .943 -R/L U210.0750.04 .750 .750 6.000 1.000 .659 1.375R/L U210.1000.04 1 .000 1 .000 6.000 1 .000 .909 - .433 .1 57 − .1 96 04R/L U210.1250.04 1 .250 1 .000 6.625 1 .250 .909 -R/L U210.0750.05 .750 .750 6.000 1.000 .640 1.375R/L U210.1000.05 1 .000 1 .000 6.000 1 .000 .890 − .433 .201 − .236 05R/L U210.1250.05 1 .250 1 .000 6.625 1 .250 .890 −State R or L version.Spare partsfor Toolholder Screw Wrenchf= f1 + w /2Dimensions in inch*max. depth of groove up to Ø 5.906"R/L U210...02−05 218.3 SW 6.911H2In the UNITED STATES call us toll freeFurther shank sizes upon request.

GROOVING and TURNING (External)TOOLHOLDER typeDepth of groove up toWidth of grooveDepth ofcut a p up to210...02-051 1 .0 mm2.5 − 6.0 mm4.0 mm35l 15for use with indexableinserth 1h h type 229S229l 2tf f1 R bwHR = right hand version shownL = lefthandversionPart number h b l 1 h 1 f f 1 l 2 t Widthofgroove "w"SeatingSizeR/L 21 0.2020.02* 20 20 1 50 25 1 8.55 35R/L 210.2525.02* 25 25 1 50 25 23.55 −R/L 21 0.1 61 6.03 16 16 150 25 14.55 45R/L 21 0.2020.03 20 20 1 50 25 1 8.55 35R/L 210.2525.03 25 25 1 50 25 23.55 −R/L 210.3225.03 32 25 1 70 32 23.55 −f= f1 + w /211 2.5−3.0 0211 3.0−4.0 03R/L 21 0.2020.04 20 20 1 50 25 1 7.7 35R/L 210.2525.04 25 25 1 50 25 22.7 − 1 1 4.0 − 5.0 04R/L 210.3225.04 32 25 1 70 32 22.7 −R/L 21 0.2020.05 20 20 1 50 25 1 7.2 35R/L 210.2525.05 25 25 1 50 25 22.2 − 1 1 5.1 − 6.0 05R/L 210.3225.05 32 25 1 70 32 22.2 −State R or L version.Dimensions in mm*max. depth of groove up to Ø 1 50 mmSpare partsfor Toolholder Screw WrenchR/L 21 0...02−05 218.3 SW 6.911In the UNITED STATES call us toll freeFurther shank sizes upon request.H3

GROOVING and TURNING (External)TOOLHOLDER typeU210..K3-K5with cassetteDepth of groove up to .433"Width of groove .1 1 8 − .236"Depth ofcut a p up to .1 57"1.378l 1.197for use with indexableinserth 1hh type 229S229l 2tf f1RbwR = right hand version shownL = lefthandversionPart number h b l 1 h 1 f f 1 l 2 t Widthofgroove "w"SeatingSizeR/L U210.1000.K3 1 .000 1 .000 6.000 1 .250 .943 2.000 .433 .118 − .157 03R/L U210.1250.K3 1 .250 1 .000 6.625 1 .250 .943 -R/L U210.1000.K4 1 .000 1 .000 6.000 1 .250 .909 2.000 .433 .157 − .197 04R/L U210.1250.K4 1 .250 1 .000 6.625 1 .250 .909 -R/L U210.1000.K5 1 .000 1 .000 6.000 1 .250 .890 2.000 .433 .201 − .236 05R/L U210.1250.K5 1 .250 1 .000 6.625 1 .250 .890 -State R or L version.Further shank sizes upon request.f= f1 + w /2Dimensions in inchSpare partsfor Toolholder Cassette Screw Torx screw Screw WrenchdriverR/L U21 0..K3 NK 21 0.32.03 030.051 8 T20 T20 21 8.3 SW 6.91 1R/L U21 0..K4 NK 21 0.32.04 030.051 8 T20 T20 21 8.3 SW 6.91 1R/L U21 0..K5 NK 21 0.32.05 030.051 8 T20 T20 21 8.3 SW 6.91 1H6In the UNITED STATES call us toll free

GROOVING and TURNING (External)TOOLHOLDER typeDepth of groove up toWidth of grooveDepth ofcut a p up to21 0..K3-K5with cassette1 1 .0 mm3.0 − 6.0 mm4.0 mm35l 17for use with indexableinserth 1hh type 229S229l 2tf f1wRbHR = right hand version shownL = lefthandversionPart number h b l 1 h 1 f f 1 l 2 t Widthofgroove "w"SeatingSizeR/L 210.2525.K3 25 25 1 50 32 23.55 35R/L 210.3225.K3 32 25 1 70 32 23.55 −f= f1 + w /2R/L 210.2525.K4 25 25 1 50 32 22.70 35R/L 210.3225.K4 32 25 1 70 32 22.70 −R/L 210.2525.K5 25 25 1 50 32 22.2 35R/L 210.3225.K5 32 25 1 70 32 22.2 −State R or L version.Further shank sizes upon request.11 3.0−4.0 0311 4.0−5.0 0411 5.1 −6.0 05Dimensions in mmSpare partsfor Toolholder Cassette Screw Torx screw Screw WrenchdriverR/L 21 0..K3 NK 21 0.32.03 030.051 8 T20 T20 21 8.3 SW 6.91 1R/L 21 0..K4 NK 21 0.32.04 030.051 8 T20 T20 21 8.3 SW 6.91 1R/L 21 0..K5 NK 21 0.32.05 030.051 8 T20 T20 21 8.3 SW 6.91 1In the UNITED STATES call us toll freeH7

GROOVING and TURNING (External)TOOLHOLDER typeU210..K7/K9 with cassetteDepth of groove up to .433"Width of groove .240 − .409"Depth ofcut a p up to .1 57"1.378l 1.276for use with indexableinserth 1hh type 229S229l 2tf f1RbwR = right hand version shownL = lefthandversionPart number h b l 1 h 1 f f 1 l 2 t Widthofgroove "w"SeatingSizeR/L U210.1000.K7 1 .000 1 .000 6.000 1 .250 .850 2.000 .433 .240 − .315 07R/L U210.1250.K7 1 .250 1 .000 6.625 1 .250 .850 -R/L U210.1000.K9 1 .000 1 .000 6.000 1 .250 .81 1 2.000 .433 .319 − .409 09R/L U210.1250.K9 1 .250 1 .000 6.625 1 .250 .81 1 -f= f1 + w /2State R or L version.Further shank sizes upon request.Dimensions in inchSpare partsfor Toolholder Cassette Screw Torx screw Clamp Torx screwdriverdriverR/L U/21 0..K7 NK 21 0.32.07 030.051 8 T20 T20 R/L 21 8.5.7 T1 5R/L U/21 0..K9 NK 21 0.32.09 030.051 8 T20 T20 R/L 21 8.9 T1 5H8In the UNITED STATES call us toll free

GROOVING and TURNING (External)TOOLHOLDER type21 0..K7/K9 with cassetteDepth of groove up toWidth of grooveDepth ofcut a p up to1 1 ,0 mm6.1 − 1 0.4 mm.4.0 mm35l 17for use with indexableinserth 1hh type 229S229l 2tf f1 RwbHR = right hand version shownL = lefthandversionPart number h b l 1 h 1 f f 1 l 2 t Widthofgroove "w"SeatingSizeR/L 21 0.2525.K7 25 25 1 50 32 21 .2 35R/L 210.3225.K7 32 25 170 32 21.2 −R/L 21 0.2525.K9 25 25 1 50 32 20.2 35R/L 210.3225.K9 32 25 1 70 32 20.2 −f= f 1 + w / 21 1 6.1 − 8.0 0711 8.1 −10.4 09State R or L version.Further shank sizes upon request.Dimensions in mmSpare partsfor Toolholder Cassette Screw Torx screw Clamp Torx screwdriverdriverR/L U/21 0..K7 NK 21 0.32.07 030.051 8 T20 T20 R/L 21 8.5.7 T1 5R/L U/21 0..K9 NK 21 0.32.09 030.051 8 T20 T20 R/L 21 8.9 T1 5In the UNITED STATES call us toll freeH9

GROOVING and TURNING (External)TOOLHOLDER typeU218..02−05Depth of groove up to .709"Width of groove .098 − .236"Depth ofcut a p up to .1 57"1.378l 1.197for use with indexableinserth 1hh type 229S229l 2t maxf f1wR = right hand version shownRL = lefthandversionbPart number h b l 1 h 1 f f 1 l 2 t max Width ofgroove "w"SeatingSizeR/L U218.0750.02* .750 .750 6.000 1.000 .693 1.375 .709 .098 − .118 02R/L U218.1000.02* 1 .000 1 .000 6.000 1 .000 .943 −R/L U218.0625.03 .625 .625 6.000 1.000 .568 1.750R/L U218.0750.03 .750 .750 6.000 1.000 .693 1.375R/L U218.1000.03 1 .000 1 .000 6.000 1 .000 .943 −R/L U218.1250.03 1 .250 1 .000 6.625 1 .250 .943 −.709 .118−.157 03R/L U218.0750.04 .750 .750 6.000 1.000 .659 1.375R/L U218.1000.04 1 .000 1 .000 6.000 1 .000 .909 − .709 .1 57 −.1 97 04R/L U218.1250.04 1 250 1 000 6.625 1 .250 .909 −R/L U218.0750.05 .750 .750 6.000 1.000 .640 1.375R/L U218.1000.05 1 .000 1 .000 6.000 1 .000 .890 − .709 .200 − .236 05R/L U218.1250.05 1 .250 1 .000 6.625 1 .250 .890 −State R or L version.*max. depth ofgroove up to Ø 2.362"f= f1 + w /2Dimensions in inchSpare partsfor Toolholder Screw WrenchR/L U21 8..02-05 218.3 SW 6.911H10In the UNITED STATES call us toll freeFurther shank sizes upon request.

GROOVING and TURNING (External)TOOLHOLDER type21 8..02−05Depth of groove up toWidth of grooveDepth ofcut a p up to1 8.0 mm2.5 − 6.0 mm4.0 mm35l 15for use with indexableinserth 1hh type 229S229l 2t maxf f1wRbHR = right hand version shownL = lefthandversionPart number h b l 1 h 1 f f 1 l 2 t max Width ofgroove "w"SeatingSizeR/L 21 8.2020.02* 20 20 1 50 25 1 8.55 35R/L 218.2525.02* 25 25 1 50 25 23.55 −R/L 21 8.1 61 6.03 16 16 150 25 14.55 45R/L 21 8.2020.03 20 20 1 50 25 1 8.55 35R/L 218.2525.03 25 25 1 50 25 23.55 −R/L 218.3225.03 32 25 1 70 32 23.55 −State R or L version.*max. depth of groove up to Ø 60 mm18 2.5−3.0 0218 3.0−4.0 03R/L 21 8.2020.04 20 20 1 50 25 1 7.70 35R/L 218.2525.04 25 25 1 50 25 22.70 − 1 8 4.0 − 5.0 04R/L 218.3225.04 32 25 1 70 32 22.70 −R/L 21 8.2020.05 20 20 1 50 25 1 7.20 35R/L 218.2525.05 25 25 1 50 25 22.20 − 1 8 5.1 − 6.0 05R/L 218.3225.05 32 25 1 70 32 22.20 −f= f1 + w /2Dimensions in mmSpare partsfor Toolholder Screw WrenchR/L 21 8..02-05 218.3 SW 6.911In the UNITED STATES call us toll freeFurther shank sizes upon request.H11

GROOVING and TURNING (External)TOOLHOLDER typeU218..07/09Depth of groove up to .709"Width of groove .240 − .409"Depth ofcut a p up to .1 57"1.378l 1.276for use with indexableinserth 1hh type 229S229l 2t maxff1RbwR = right hand version shownL = lefthandversionPart number h b l 1 h 1 f f 1 l 2 t max Width ofgroove "w"SeatingSizeR/L U218.0750.07 .750 .750 6.000 1.000 .600 1.375R/L U218.1000.07 1 .000 1 .000 6.000 1 .000 .850 − .709 .240 − .31 5 07R/L U218.1250.07 1 .250 1 .000 6.625 1 .250 .850 −R/L U218.0750.09 .750 .750 6.000 1.000 .561 1.375R/L U218.1000.09 1 .000 1 .000 6.000 1 .000 .81 1 − .709 .31 9 − .409 09R/L U218.1250.09 1 .250 1 .000 6.625 1 .250 .81 1 −State R or L version.Further shank sizes upon request.f= f1 + w /2Dimensions in inchSpare partsfor Toolholder Clamp Torx screw driverR/L U21 8/21 8..07 R/L 218.5.7 T15R/L U21 8/21 8..09 R/L 218.9 T15H12In the UNITED STATES call us toll free

GROOVING and TURNING (External)TOOLHOLDER typeDepth of groove up toWidth of grooveDepth ofcut a p up to21 8..07/091 8.0 mm5.1 − 1 0.4 mm4.0 mm35l 17for use with indexableinserth 1hh type 229S229l 2t maxff1RbwHR = right hand version shownL = lefthandversionPart number h b l 1 h 1 f f 1 l 2 t max Width ofgroove "w"SeatingSizeR/L 21 8.2020.07 20 20 1 50 25 1 6.20 35R/L 21 8.2525.07 25 25 1 50 25 21 .20 − 1 8 6.1 − 8.0 07R/L 218.3225.07 32 25 170 32 21.20 −R/L 21 8.2020.09 20 20 1 50 25 1 5.20 35R/L 21 8.2525.09 25 25 1 50 25 20.20 − 1 8 8.1 − 1 0.4 09R/L 218.3225.09 32 25 1 70 32 20.20 −State R or L version.Further shank sizes upon request.f= f1 + w /2Dimensions in mmSpare partsfor Toolholder Clamp Torx screw driverR/L U21 8/21 8..07 R/L 218.5.7 T15R/L U21 8/21 8..09 R/L 218.9 T15In the UNITED STATES call us toll freeH13

GROOVING and TURNING (External)TOOLHOLDER typeU218..K3−K5 with cassetteDepth of groove up to .709"Width of groove .1 1 8 − .236"Depth ofcut a p up to .1 57"1.378l 1.197for use with indexableinsert type 229S229h 1hhl 2t maxf f1RbwR = right hand version shownL = lefthandversionPart number h b l 1 h 1 f f 1 l 2 t max Width ofgroove "w"SeatingSizeR/L U218.1000.K3 1 .000 1 .000 6.000 1 .250 .943 2.000 .709 .118 − .157 03R/L U218.1250.K3 1 .250 1 .000 6.625 1 .250 .943 −R/L U218.1000.K4 1 .000 1 .000 6.000 1 .250 .909 2.000 .709 .157 − .196 04R/L U218.1250.K4 1 .250 1 .000 6.625 1 .250 .909 −R/L U218.1000.K5 1 .000 1 .000 6.000 1 .250 .890 2.000 .709 .201 − .236 05R/L U218.1250.K5 1 .250 1 .000 6.625 1 .250 .890 -State R or L version.Further shank sizes upon request.f= f1 + w /2Dimensions in inchSpare partsfor Toolholder Cassette Screw Torx screw Screw WrenchdriverR/L U21 8..K3 NK 21 8.32.03 030.051 8 T20 T20 21 8.3 SW 6.91 1R/L U21 8..K4 NK 21 8.32.04 030.051 8 T20 T20 21 8.3 SW 6.91 1R/L U21 8..K5 NK 21 8.32.05 030.051 8 T20 T20 21 8.3 SW 6.91 1H14In the UNITED STATES call us toll free

GROOVING and TURNING (External)TOOLHOLDER typeDepth of groove up toWidth of grooveDepth ofcut a p up to218..K3−K5with cassette1 8.0 mm3.0 − 6.0 mm4.0 mm35l 15for use with indexableinsert type 229S229h 1hhl 2t maxf f1RbHwR = right hand version shownL = lefthandversionPart number h b l 1 h 1 f f 1 l 2 t max Width ofgroove "w"SeatingSizeR/L 218.2525.K3 25 25 1 50 32 23,55 48R/L 218.3225.K3 32 25 1 70 32 23,55 −f= f1 + w /2R/L 218.2525.K4 25 25 1 50 32 22,70 48R/L 218.3225.K4 32 25 1 70 32 22,70 −R/L 218.2525.K5 25 25 1 50 32 22.2 48R/L 218.3225.K5 32 25 1 70 32 22.2 −State R or L version.Further shank sizes upon request.18 3,0−4,0 0318 4,0−5,0 0418 5.1 −6.0 05Dimensions in mmSpare partsfor Toolholder Cassette Screw Torx screw Screw WrenchdriverR/L 21 8..K3 NK 21 8.32.03 030.051 8 T20 T20 21 8.3 SW 6.91 1R/L 21 8..K4 NK 21 8.32.04 030.051 8 T20 T20 21 8.3 SW 6.91 1R/L 21 8..K5 NK 21 8.32.05 030.051 8 T20 T20 21 8.3 SW 6.91 1In the UNITED STATES call us toll freeH15

GROOVING and TURNING (External)TOOLHOLDER typeU218...K7/K9Depth of groove up to .709"Width of groove .240 − .409"Depth ofcut a p up to .1 57"1.378l 1.276for use with indexableinserth 1hh type 229S229l 2t maxf f1wRbR = right hand version shownL = lefthandversionPart number h b l 1 h 1 f f 1 l 2 t max Width ofgroove "w"SeatingSizeR/L U218.1000.K7 1 .000 1 .000 6.000 1 .250 .850 2.000 .709 .240 − .315 07R/L U218.1250.K7 1 .250 1 .000 6.625 1 .250 .850 -R/L U218.1000.K9 1 .000 1 .000 6.000 1 .250 .81 1 2.000 .709 .319 − .409 09R/L U218.1250.K9 1 .250 1 .000 6.625 1 .250 .81 1 -State R or L version.Further shank sizes upon request.f= f1 + w /2Dimensions in inchSpare partsfor Toolholder Cassette Screw Torx screw Clamp Torx screwdriverdriverR/L U21 8..K7 NK 21 8.32.07 030.051 8 T20 T20 R/L 21 8.5.7 T1 5R/L U21 8..K9 NK 21 8.32.09 030.051 8 T20 T20 R/L 21 8.9 T1 5H16In the UNITED STATES call us toll free

GROOVING and TURNING (External)TOOLHOLDER typeDepth of groove up toWidth of grooveDepth ofcut a p up to218..K5-K9with cassette1 8.0 mm6.1 − 1 0.4 mm4.0 mml 135 7for use with indexableinserth 1hh type 229S229l 2t maxf f1RbHwR = right hand version shownL = lefthandversionPart number h b l 1 h 1 f f 1 l 2 t max Width ofgroove "w"SeatingSizeR/L 21 8.2525.K7 25 25 150 32 21.2 48 18 6.1 −8.0 07R/L 218.3225.K7 32 25 170 32 21.2 −R/L 21 8.2525.K9 25 25 1 50 32 20.2 48R/L 218.3225.K9 32 25 1 70 32 20.2 −State R or L version.Further shank sizes upon request.f= f1 + w /218 8.1 −10.4 09Dimensions in mmSpare partsfor Toolholder Cassette Screw Torx screw Clamp Torx screwdriverdriverR/L 21 8..K7 NK 21 8.32.07 030.051 8 T20 T20 R/L 21 8.5.7 T1 5R/L 21 8..K9 NK 21 8.32.09 030.051 8 T20 T20 R/L 21 8.9 T1 5In the UNITED STATES call us toll freeH17

GROOVING (External)TOOLHOLDER typeU226..03/..04Depth of groove up to 1 .000"Widthofgroove.118"−.197"1.689l 1.276for use with indexableinsertø5.906h 1hh type 229S229.39430˚t maxl 2ff1RbwR = right hand version shownL = lefthandversionPart number h b l 1 h 1 f f 1 l 2 t max Width ofgroove "w"SeatingSizeR/L U226.0625.03 .625 .625 6.000 1.250 .568 2.000R/L U226.0750.03 .750 .750 6.000 1.250 .693 1.675 1.000 .118−.157 03R/L U226.1000.03 1 .000 1 .000 6.000 1 .250 .943 1 .675R/L U226.1250.03 1 .250 1 .000 6.625 1 .250 .943 −R/L U226.0625.04 .625 .625 6.000 1.250 .534 2.000R/L U226.0750.04 .750 .750 6.000 1.250 .659 1.675R/L U226.1000.04 1 .000 1 .000 6.000 1 .250 .909 1 .675R/L U226.1250.04 1 .250 1 .000 6.625 1 .250 .909 −State R or L version.Further shank sizes upon request.f= f1 + w /21.000 .157−.197 04Dimensions in inchSpare partsfor Toolholder Screw WrenchR/L U226... 218.3 SW 6.911H18In the UNITED STATES call us toll free

GROOVING (External)TOOLHOLDER type226..03/..04Depth of groove up to25.0 mmWidth of groove 3.0 − 5.0 mm42.9l 17for use with indexableinsertØ150h 1hh type 229S2291030˚t maxl 2ff1RbHwR = right hand version shownL = lefthandversionPart number h b l 1 h 1 f f 1 l 2 t max Width ofgroove "w"SeatingSizeR/L 226.1 61 6.03 16 16 150 32 18.55 52.5R/L 226.2020.03 20 20 1 50 32 1 8.55 42.5 25 3.0 − 4.0 03R/L 226.2525.03 25 25 1 50 32 23.55 42.5R/L 226.3225.03 32 25 1 70 32 23.55 −R/L 226.1 61 6.04 16 16 150 32 13.70 52.5R/L 226.2020.04 20 20 1 50 32 1 7.70 42.5R/L 226.2525.04 25 25 1 50 32 22.70 42.5 25 4.0 − 5.0 04R/L 226.3225.04 32 25 1 70 32 22.70 −State R or L version.Further shank sizes upon request.f= f1 + w /2Dimensions in mmSpare partsfor Toolholder Screw WrenchR/L 226... 218.3 SW 6.911In the UNITED STATES call us toll freeH19

GROOVING (External)TOOLHOLDER typeU226..05/..07/..09Depth of groove up to .984"Width of groove .201 " − .409"ø3.150h 11.969l 1.591hhfor use with indexableinsert type 229S229l 2tmaxf f1RbSize ..05/..07wR = right hand version shownL = lefthandversionPart number h b l 1 h 1 f f 1 l 2 t max Width ofgroove "w"R/L U226.0750.05 .750 .750 6.000 .640 1.675R/L U226.1000.05 1 .000 1 .000 6.000 1 .250 .890 1 .675 1 .000 .201 − .236 05R/L U226.1250.05 1 .250 1 .000 6.625 .890 −R/L U226.1000.07 1 .000 1 .000 6.000 1.250.850 1.675 1 .000 .240 − .31 5 07R/L U226.1250.07 1 .250 1 .000 6.625 .850 −R/L U226.1000.09 1 .000 1 .000 6.000 1.250.811 1.675 1 .000 .31 9 − .409 09R/L U226.1250.09 1 .250 1 .000 6.625 .850 −State R or L version.Further shank sizes upon request.f= f1 + w /2SeatingSizeDimensions in inchSpare partsfor Toolholder Screw Clamp Torx screw driver WrenchR/L U226..05/..07 21 8.3 − − SW 6.91 1R/L U226..09 − 020.1 008.0041 T1 5 −H20In the UNITED STATES call us toll free

GROOVING (External)TOOLHOLDER type226..05/..07/..09Depth of groove up toWidth of groove25.0 mm5.1 − 1 0.4 mmh 1ø 8050l 115hhfor use with indexableinsert type 229S229l 2t maxf f1RbSize ..05/..07HwR = right hand version shownL = lefthandversionPart number h b l 1 h 1 f f 1 l 2 t max Width ofgroove "w"R/L 226.2020.05 20 20 1 50 1 7.20 42.5R/L 226.2525.05 25 25 1 50 32 22.20 42.5 25 5.1 − 6.0 05R/L 226.3225.05 32 25 1 70 22.20 −f= f1 + w /2R/L 226.2525.07 25 25 1 503221 .20 42.5R/L 226.3225.07 32 25 170 21.20 −R/L 226.2525.09 25 25 1 503220.20 42.5R/L 226.3225.09 32 25 1 70 20.20 −State R or L version.Further shank sizes upon request.25 6.1 − 8.0 0725 8.1 − 1 0.4 09SeatingSizeDimensions in mmSpare partsfor Toolholder Screw Clamp Torx screw driver WrenchR/L 226..05/..07 21 8.3 − − SW 6.91 1R/L 226..09 − 020.1 008.0041 T1 5 −In the UNITED STATES call us toll freeH21

GROOVING and TURNING (External)TOOLHOLDER typeU219..03−05Depth of groove up to .591 "Widthofgroove .118" − .236"Depth ofcut a p up to .1 57".787l.197for use with indexableinserthhh 1 type 229S229l 2ff 1Rb bwtmaxl 1R = right hand version shownL = lefthandversionPart number h h 1 b l l 2 l 1 f f 1 t max Width ofgroove "w"SeatingSizeR/L U219.0750.03 .750 1 .000 .750 6.000 .750 1 .41 9 .057 .433 .118 − .157 03R/L U219.1000.03 1 .000 1 .000 1 .000 6.000 − 1 .472 .057 .433R/L U219.0750.04 .750 1 .000 .750 6.000 .750 1 .41 9 .090 .433R/L U219.1000.04 1 .000 1 .000 1 .000 6.000 − 1 .472 .090 .433 .157 − .197 04R/L U219.0750.05 .750 1 .000 .750 .590 1 .000 1 .734 .1 49 .591R/L U219.1000.05 1 .000 1 .000 1 .000 .590 − 1 .787 .1 49 .591.201 − .236 05State R or L version.Further shank sizes upon request.l 1=l−f1 + w /2Dimensions in inchSpare partsfor Toolholder Screw WrenchR/L U219...03−05 218.3 SW 6.911H22In the UNITED STATES call us toll free

GROOVING and TURNING (External)TOOLHOLDER typeDepth of groove up toWidth of grooveDepth ofcut a p up to21 9..03−051 5.0 mm3.0 − 6.0 mm4.0 mm20l5for use with indexableinserthhh 1 type 229S229l 2ff 1Rb bwt maxHl 1R = right hand version shownL = lefthandversionPart number h h 1 b l l 2 l 1 f f 1 t max Width ofgroove "w"SeatingSizeR/L 21 9.2020.03 20 25 20 1 50 20 37 1 .45 1 1 3.0 − 4.0 03R/L 219.2525.03 25 25 25 150 − 37 1.45 11R/L 21 9.2020.04 20 25 20 1 50 20 37 2.30 1 1 4.0 − 5.0 04R/L 219.2525.04 25 25 25 1 50 − 37 2.30 1 1R/L 21 9.2020.05 20 25 20 1 50 23 45 2.80 1 5R/L 219.2525.05 25 25 25 1 50 − 45 2.80 1 5State R or L version.Further shank sizes upon request.l 1=l−f1 + w /25.1 − 6.0 05Dimensions in mmSpare partsfor Toolholder Screw WrenchR/L 21 9...03−05 218.3 SW 6.911In the UNITED STATES call us toll freeH23

GROOVING and TURNING (External)TOOLHOLDER typeU219..07/..09Depth of groove up to .591 "Width of groove .240" − .409"Depth ofcut a p up to .1 57".906l.276for use with indexableinserth hh 1 type 229S229l 2ff 1Rbbwt maxl 1R = right hand version shownL = lefthandversionPart number h h 1 b l l 2 l 1 f f 1 t max Width ofgroove "w"SeatingSizeR/L U219.0750.07 .750 1 .000 .750 6.000 1 .000 1 .734 .1 1 0 .591R/L U219.1000.07 1 .000 1 .000 1 .000 6.000 − 1 .787 .1 1 0 .591R/L U219.0750.09 .750 1 .000 .750 6.000 1 .000 1 .734 .1 89 .591l 1 =l−f1+ w /2.240 − .315 07.319 − .409 09R/L U219.1000.09 1 .000 1 .000 1 .000 6.000 − 1 .787 .1 89 .591 Dimensions in inchState R or L version.Further shank sizes upon request.Spare partsfor Toolholder Clamp Torx screw driverPlease note type of clamp.RU219..07 L 218.5.7.32 T15L U219..07 R 218.5.7.32 T15RU219..09 L 218.9.32 T15L U219..09 R 218.9.32 T15H24In the UNITED STATES call us toll free

GROOVING and TURNING (External)TOOLHOLDER typeDepth of groove up toWidth of grooveDepth ofcut a p up to219..07/..091 5.0 mm6.1 − 1 0.4 mm4.0 mm23l7for use with indexableinserth hh 1 type 229S229l 2ff 1Rbbwt maxHl 1R = right hand version shownL = lefthandversionPart number h h 1 b l l 2 l 1 f f 1 t max Width ofgroove "w"SeatingSizeR/L 21 9.2020.07 20 25 20 1 50 23 45 3.8 1 5R/L 21 9.2525.07 25 25 25 1 50 − 45 3.8 1 5R/L 21 9.2020.09 20 25 20 1 50 23 45 4.8 1 5R/L 21 9.2525.09 25 25 25 1 50 − 45 4.8 1 5State R or L version.Further shank sizes upon request.l 1 =l−f1+ w /26.1 − 8.0 078.1 − 1 0.4 09Dimensions in mmSpare partsfor Toolholder Clamp Torx screw driverPlease note type of clamp.R219..07 L 218.5.7.32 T15L 219..07 R 218.5.7.32 T15R219..09 L 218.9.32 T15L 219..09 R 218.9.32 T15In the UNITED STATES call us toll freeH25

GROOVING CORNER RELIEF (External)TOOLHOLDER typeU225/225Widthofgroove.118"−.236"35l 15for use with indexableinserth 1h type 229S22945˚fRbwR = right hand version showncL = lefthandversionPart number h b l 1 h 1 f c D min Width ofgroove "w"SeatingSizeInch ToolholderR/L U225.1000.04 1.000 1.000 6.000 1.000 1.197 .197 1.968 .118−.197 03or04R/L U225.1000.05 1 .000 1 .000 6.000 1 .000 1 .21 6 .21 7 1 .968 .201 − .236 05Metric Toolholder in mmR/L 225.2525.04 25 25 1 50 25 30.0 5.0 50 3.0 − 5.0 03 or 04R/L 225.2525.05 25 25 1 50 25 30.5 5.5 50 5.1 − 6.0 05State R or L version.Dimensions in inch/mmDimensionD l 1 , D c andD fchange in relation to radius rr D l 1 D c D f.098 −.1 1 8 .000 .000 .000.078 − .0058 −.0058 −.0058.059 −.0115 −.0115 −.0115DfDcDimensions in inchrDl 1Spare partsfor Toolholder Screw WrenchR/L U225/225.. 218.3 SW 6.911H26In the UNITED STATES call us toll freeFurther shank sizes upon request

GROOVING and PARTING OFF (External)TOOLHOLDER typereinforced 226 versionDepth of groove up to 1 .000"Widthofgroove.118"−.157"1.575lD maxfb15˚for use with indexableinsert type 229S229h 21.535hh 115˚wtmaxHR = right hand version shownL = lefthandversionPart number h h 1 h 2 b l f t max D max Width ofgroove "w"SeatingSizeR/L 226.2608.03 1.023 .842 .976 .31 5 4.331 .047 1 .000 6.000 .1 1 8 03R/L 226.3208.03 1.260 .976R/L 226.2608.04 1.023 .842 .976 .31 5 4.331 .067 1 .000 6.000 .1 1 8 04R/L 226.3208.04 1.260 .976State R or L version.Further shank sizes upon requestDimensions in inchParting off solid barsParting offtubesor1.9671.0006.000Spare partsfor Toolholder Screw Torx screw driverR/L 226... 4.15T1 5 T1 5In the UNITED STATES call us toll freeH27

NEWCASSETTES TYPEBK223...BK224...BK229...FOR INTERNAL MACHININGH28In the UNITED STATES call us toll free

GROOVING and TURNING (External)TOOLHOLDER type213...0..Short reachBore Ø from 1 .81 1 " (46.0mm)Depth of groove up to .453" (1 5.0mm)Width ofgroove.1 1 8 − .1 97" (3.0−6.0mm)l 3D min tmaxfor use with indexableinserthh 1 type 229S2291.181"(30mm)l 1fwRØdHR = right hand version shownL = lefthandversionPart number d l 1 l 3 h h 1 f D min t maxg7SeatingSizeR/L 21 3.0032.0.03 1 .260(32) 5.906(1 50) 1 .378(35) 1 .1 81 (30) .591 (1 5) 1 .1 02(28) 1 .81 1 (46) .453(1 1 .5) 03R/L 21 3.0040.0.03 1 .575(40) 7.087(1 80) 1 .378(35) 1 .496(38) .748(1 9) 1 .260(32) 2.1 26(54)R/L 213.0032.0.0 4 1 .260(32) 5.906(1 50) 1 .378(35) 1 .1 81 (30) .591 (1 5) 1 .1 02(28) 1 .81 1 (46)R/L 21 3.0040.0.04 1 .575(40) 7.087(1 80) 1 .378(35) 1 .496(38) .748(1 9) 1 .260(32) 2.1 26(54).453(1 1 .5) 04R/L 21 3.0032.0.05 1 .260(32) 5.906(1 50) 1 .378(35) 1 .1 81 (30) .591 (1 5) 1 .1 02(28) 1 .81 1 (46) .453(1 1 .5) 05R/L 21 3.0040.0.05 1 .575(40) 7.087(1 80) 1 .378(35) 1 .496(38) .748(1 9) 1 .260(32) 2.1 26(54) Dimensions in inch(mm)State R or L version.Further shank sizes or with through coolant upon request.Spare partsfor Toolholder Screw WrenchR/L 21 3..03/..04 218.3 SW 6.911In the UNITED STATES call us toll freeH29

GROOVING and TURNING (Internal)TOOLHOLDER typeU213..03−05 Short reachBore Ø from 1 .496"Depth of groove up to .591 "Width ofgroove .1 1 8" − .236"l 3hD min tmaxh 1for use with indexableinsert type 229S2291.181l 2l 1RØdfwR = right hand version shownL = left hand versionPart number d l 1 l 2 l 3 h h 1 f D min t max Width ofg7groove "w"SeatingSizeR/L U213.1000.03 1.000 6.000 − 1.375 .921 .461 .964 1.496* .295R/L U213.1250.03 1 .250 6.000 1 .250 1 .375 1 .1 71 .586 1 .1 02 1 .496* .295 .118−.157 03R/L U213.1500.03 1.500 7.000 1.250 1.375 1.421 .711 1.260 1.968 .453R/L U213.2000.03 2.000 8.000 1 .250 1 .500 1 .921 .961 1 .594 2.362 .591R/L U213.1000.04 1.000 6.000 − 1.375 .921 .461 .964 1.496* .295R/L U213.1250.04 1 .250 6.000 1 .250 1 .375 1 .1 71 .586 1 .1 02 1 .496* .295 .157 − .197 04R/L U213.1500.04 1.500 7.000 1.250 1.375 1.421 .711 1.260 1.968 .453R/L U213.2000.04 2.000 8.000 1 .250 1 .500 1 .921 .961 1 .594 2.362 .591R/L U213.1250.05 1 .250 6.000 − 1 .375 1 .1 71 .586 1 .1 02 1 .81 1 .453R/L U213.1500.05 1.500 7.000 1.250 1.375 1.421 .711 1.260 1.968 .453 .201 − .236 05R/L U213.2000.05 2.000 8.000 1 .250 1 .500 1 .921 .961 1 .594 2.362 .591State R or L version.Spare partsDimensions in inch*tmax.453" from ø 1 .81 1 "for Toolholder Screw WrenchR/L U21 3..03−05 218.3 SW 6.911H30In the UNITED STATES call us toll freeFurther shank sizes or with through coolantupon request.

GROOVING and TURNING (Internal)TOOLHOLDER typeBore Ø fromDepth of groove up toWidth ofgroove21 3..03−05 Short reach38.0 mm1 5.0 mm3.0 − 6.0 mml 3hD min tmaxh 1for use with indexableinsert type 229S22930l 2l 1fwRØdHR = right hand version shownL = left hand versionPart number d l 1 l 2 l 3 h h 1 f D min t max Width ofg7groove "w"SeatingSizeR/L 213.0025.03 25 1 50 − 35 23 1 1 .5 24.5 38* 7.5R/L 213.0032.03 32 1 50 30 35 30 1 5.0 28.0 38* 7.5 3.0 − 4.0 03R/L 21 3.0040.03 40 180 30 35 38 19.0 32.0 50 11.5R/L 21 3.0050.03 50 200 30 40 47 23.5 40.5 60 1 5.0R/L 213.0025.04 25 1 50 − 35 23 1 1 .5 24.5 38* 7.5R/L 213.0032.04 32 1 50 30 35 30 1 5.0 28.0 38* 7.5 4.0 − 5.0 04R/L 21 3.0040.04 40 180 30 35 38 19.0 32.0 50 11.5R/L 21 3.0050.04 50 200 30 40 47 23.5 40.5 60 1 5.0R/L 213.0032.05 32 150 − 35 30 15.0 28.0 46 11.5R/L 21 3.0040.05 40 180 30 35 38 19.0 32.0 50 11.5 5.1 −6.0 05R/L 21 3.0050.05 50 200 30 40 47 23.5 40.5 60 1 5.0State R or L version.Dimensions in mm*tmax11.5mmab ø 46 mmSpare partsfor Toolholder Screw WrenchR/L 21 3..03−05 218.3 SW 6.911In the UNITED STATES call us toll freeFurther shank sizes or with through coolantupon request.H31

GROOVING and TURNING (Internal)TOOLHOLDER typeU213..07/09Short reachBore Ø from 1 .968"Depth of groove up to .591 "Width of groove .240" − .409"l 3D min tmaxfor use with indexableinserthh 1 type 229S2291.181l 2l 1fwRØdR = right hand version shownL = left hand versionPart number d l 1 l 2 l 3 h h 1 f D min. t max. Width ofg7groove "w"R/L U213.1500.07 1.500 7.000 1.250 1.375 1.421 .711 1.260 1.968 .453 .240 − .315 07R/L U213.2000.07 2.000 8.000 1 .250 1 .500 1 .921 .961 1 .594 2.362 .591R/L U213.1500.09 1.500 7.000 1.250 1.375 1.421 .711 1.260 1.968 .453 .319 − .409 09R/L U213.2000.09 2.000 8.000 1 .250 1 .500 1 .921 .961 1 .594 2.362 .591State R or L version.Further shank sizes or with through coolant upon request.SeatingSizeDimensions in inchSpare partsfor Toolholder Clamp Torx screw driverPlease note type of clamp.RU213.1250.05 L218.5.7.32LU213.1250.05 R218.5.7.32R U213..05/..07 L218.5.7L U213..05/..07 R218.5.7R U213..09 L218.9L U213..09 R218.9H32T1 5In the UNITED STATES call us toll free

GROOVING and TURNING (Internal)TOOLHOLDER typeBore Ø fromDepth of groove up toWidth of groove21 3..07/09Short reach50.0 mm1 5.0 mm6.1 − 1 0.4 mml 3D min tmaxfor use with indexableinserthh 1 type 229S22930l 2l 1fwRØdHR = right hand version shownL = left hand versionPart number d l 1 l 2 l 3 h h 1 f D t Widthofg7 min. max.groove "w"SeatingSizeR/L 21 3.0040.07 40 180 30 35 38 19.0 32.0 50 11.5 6.1 − 8.0 07R/L 21 3.0050.07 50 200 30 40 47 23.5 40.5 60 1 5.0R/L 21 3.0040.09 40 180 30 35 38 19.0 32.0 50 11.5 8.1 − 1 0.4 09R/L 21 3.0050.09 50 200 30 40 47 23.5 40.5 60 1 5.0 Dimensions in mmState R or L version.Further shank sizes or with through coolant upon request.Spare partsfor Toolholder Clamp Torx screw driverPlease note type of clamp.R 21 3.0032.05 L218.5.7.32L 21 3.0032.05 R218.5.7.32R 213..05/..07 L218.5.7L 213..05/..07 R218.5.7R213..09 L218.9L213..09 R218.9T1 5In the UNITED STATES call us toll freeH33

GROOVING and TURNING (Internal)TOOLHOLDER typeU214..03−05Bore Ø from 1 .496"Depth of groove up to .591 "Width of groove .1 1 8" − .236"l 3hD min tmaxh 1for use with indexableinsert type 229S2291.181l 2l 1RØdfwR = right hand version shownL = lefthandversionPart number d l 1 l 2 l 3 h h 1 f D min t max Width ofg7groove "w"SeatingSizeR/L U214.1250.03R/L U214.1500.03R/L U214.2000.03R/L U214.1250.04R/L U214.1500.04R/L U214.2000.04R/L U214.1250.05R/L U214.1500.05R/L U214.2000.05State R or L version.1 .250 8.000 2.750 1 .375 1 .1 71 .586 1 .1 021.496 .2951.811 .4531 .500 1 0.000 3.250 1 .375 1 .421 .71 1 1 .265 1 .968 .4532.000 1 0.000 4.000 1 .500 1 .921 .961 1 .594 2.362 .5911 .250 8.000 2.750 1 .375 1 .1 71 .586 1 .1 021.496 .2951.811 .4531 .500 1 0.000 3.250 1 .375 1 .421 .71 1 1 .265 1 .968 .4532.000 1 0.000 4.000 1 .500 1 .921 .961 1 .594 2.362 .591.118−.157 03.157 − .197 041 .250 8.000 − 1 .375 1 .1 71 .586 1 .1 02 1 .81 1 .4531.500 10.000 3.250 1.375 1.421 .711 1.260 1.968 .453 .201 − .236 052.000 1 0.000 4.000 1 .500 1 .921 .961 1 .594 2.362 .591Dimensions in inchSpare partsfor Toolholder Screw WrenchR/L U21 4..03−05 218.3 SW 6.911H34In the UNITED STATES call us toll freeFurther shank sizes or with through coolantupon request.

GROOVING and TURNING (Internal)TOOLHOLDER typeBore Ø fromDepth of groove up toWidth ofgroove214..03−0538.0 mm1 5.0 mm3.0 − 6.0 mml 3hD min tmaxh 1for use with indexableinsert type 229S2291.181l 2l 1fHR/L 214.0032.05 32 200 − 35 30 1 5.0 28.0 46 1 1 .5R/L 21 4.0040.05 40 250 80 35 38 1 9.0 32.0 50 1 1 .5R/L 21 4.0050.05 50 250 1 00 40 47 23.5 40.5 60 1 5.0 5.1 − 6.0 05wL = lefthandversionPart number dg7l 1 l 2 l 3 h h 1 f D min t max Width ofgroove "w"R/L 214.0032.03 32 200 70 35 30 1 5.0 28.0 38 7.546 1 1 .53.0 − 4.0 03R/L 21 4.0040.03 40 250 80 35 38 1 9.0 32.0 50 1 1 .5R/L 21 4.0050.03 50 250 1 00 40 47 23.5 40.5 60 1 5.0R/L 214.0032.04 32 200 70 35 30 1 5.0 28.0 38467.51 1 .54.0 − 5.0 04R/L 21 4.0040.04 40 250 80 35 38 1 9.0 32.0 50 1 1 .5R/L 21 4.0050.04 50 250 1 00 40 47 23.5 40.5 60 1 5.0R = right hand version shownState R or L version.Spare partsRØdfor Toolholder Screw WrenchSeatingSizeDimensions in mmR/L 21 4..03−05 218.3 SW 6.911In the UNITED STATES call us toll freeFurther shank sizes or with through coolantupon request.H35

GROOVING and TURNING (Internal)TOOLHOLDER typeU214..07/09Bore Ø from 1.811"Depth of groove up to .591 "Width of groove .240" − .409"l 3D min tmaxfor use with indexableinserthh 1 type 229S22930l 2l 1RØdfwR = right hand version shownL = lefthandversionPart number d l 1 l 2 l 3 h h 1 f D min. t max. Width ofg7groove "w"SeatingSizeR/L U214.1500.07 1.500 10.000 3.250 1.375 1.421 .711 1.260 1.968 .453 .240 − .315 07R/L U214.2000.07 2.000 10.000 4.000 1.500 1.921 .961 1.594 2.362 .591R/L U214.1500.09 1.500 10.000 3.250 1.375 1.421 .711 1.260 1.968 .453 .319 − .409 09R/L U214.2000.09 2.000 10.000 4.000 1.500 1.921 .961 1.594 2.362 .591State R or L version.Further shank sizes or with through coolant upon request.Dimensions in inchSpare partsfor Toolholder Clamp Torx screw driverR U214..07 L218.5.7L U214..07 R218.5.7R U214..09 L218.9L U214..09 R218.9H36T1 5In the UNITED STATES call us toll free

GROOVING and TURNING (Internal)TOOLHOLDER typeBore Ø fromDepth ofgroove up toWidth of groove21 4..07/0950.0 mm1 5.0 mm6.1 − 1 0.4 mml 3D min tmaxfor use with indexableinserthh 1 type 229S22930R = right hand version shownL = lefthandversionfwl 2l 1RØdHR = right hand version shownL = lefthandversionPart number d l 1 l 2 l 3 h h 1 f D t Widthofg7 min. max.groove "w"SeatingSizeR/L 21 4.0040.07 40 250 80 35 38 1 9.0 32.0 50 1 1 .5 6.1 − 8.0 07R/L 21 4.0050.07 50 250 1 00 40 47 23.5 40.5 60 1 5.0R/L 21 4.0040.09 40 250 80 35 38 1 9.0 32.0 50 1 1 .5 8.1 − 1 0.4 09R/L 21 4.0050.09 50 250 1 00 40 47 23.5 40.5 60 1 5.0 Dimensions in mmState R or L version.Further shank sizes or with through coolant upon request.Spare partsfor Toolholder Clamp Torx screw driverR214..07L218.5.7L214..07R218.5.7R214..09 L218.9L214..09 R218.9T1 5In the UNITED STATES call us toll freeH37

GROOVING and TURNING (Internal)TOOLHOLDER typeBU/B229...K2with through coolantBore Ø 1 .969/2.236" (50.0/60.0) mmDepth of groove up to .472/.591 " (1 2.0/1 5.0) mmWidth ofgroove .1 1 8−.236" (3.0−6.0) mmD minfor use with indexableinsertRh type S229l 2tmaxfwll 1ødToolholder does notinclude cassetteR = right hand version shownL = lefthandversionPart number d g7 l l 1 l 2 h f Dmin tmax wInch ToolholderR/L BU229.1500.1.K2 1 .500 6.923 7.500 1 .250 1 .421 1 .398R/L BU229.1 500.2.K2 1 .500 7.429 8.000 2.250 1 .421 1 .398Metric Toolholder in mmR/L B229.0040.1.K2 40 1 66.3 1 87 30 38 35.5R/L B229.0040.2.K2 40 1 86.3 200 60 38 35.5State R or L version.Further shank sizes upon request.see cassettesDimensions in inch/mmSpare partsfor Toolholder Screw Torx screw driverR/L BU/B229..K2 030.051 8 T20 T20H38In the UNITED STATES call us toll free

GROOVING and TURNING (Internal)CASSETTE TypeR/LBK229Bore Ø 1 .969/2.236" (50.0/60.0) mmDepth of groove up to .472/.591 " (1 2.0/1 5.0) mmWidth ofgroove .1 1 8−.236" (3.0−6.0) mmbb 1RD minfor use with indexableinsert type 229S229wt maxR = right hand version shownL = lefthandversionHPart number D min t max b 1 b f Widthof for toolholdergroove "w" shankRBK229.0050.03RBK229.0050.04RBK229.0050.05LBK229.0050.03LBK229.0050.04LBK229.0050.05State R or L version.Further shank sizes upon request.1 .969/2.236 .472/.591 .51 2 .561 .1 1 8 − .1 57 031 .969/2.236 .472/.591 .492 .559 .1 57 − .1 97 04 R BU/B229...K21 .969/2.236 .472/.591 .453 .545 .201 − .236 051 .969/2.236 .472/.591 .51 2 .561 .1 1 8 − .1 57 031 .969/2.236 .472/.591 .492 .559 .1 57 − .1 97 04 L BU/B229...K21 .969/2.236 .472/.591 .453 .545 .201 − .236 05see toolholderSeatingSizeDimensions in inchSpare partsCassette Screw Fastening screw Torx screw driverR/L BK229... 5.1 3 T20E see toolholderR/L BU/B229...K2 T20In the UNITED STATES call us toll freeH39

GROOVING (Internal)CARTRIDGE Type257Bore Ø from 3.150"Width of groove .1 98" − 409"D min2.1 65.787tmaxSeating for cartridgeAAhh 1A2.1 651.614.945A:A.098 min1.6141.49645˚.059.079 .079A:A.453.394R4.039M10.8661.142f.354.94545˚A.5513.1 50 minl 1l 2Ø11R = right hand version shownL = lefthandversionDepth ofgroove inrelation to bore−ØPart number h 1 h f l 2 l 1 Width ofD min t maxgroove "w"R/L 257.2222.05 .846 1 .1 41 1 .653 2.055 .200 − .236 053.1 49 .393R/L 257.2222.07 .846 1 .1 41 1 .653 2.01 5 .240 − .31 5 07R/L 257.2222.09 .846 1.141 1.653 1.976 .319− .409 09 4.724 .591State R or L version.Further shank sizes upon request.l 1=l2− w /2SeatingSizeDimensions in inchSpare partsPlease note type of clampfor Toolholder Clamp Torx screw Adjusting screw Adjusting screw Fasteningdriver axial radial screwR 257..05/..07 L218.5.7.32L 257..05/..07 R218.5.7.32R 257..09T1 5 6.1 2.020 4.08.91 3 0.30.208L218.9.32L 257..09 R218.9.32H40In the UNITED STATES call us toll free

GROOVING (Internal)CASSETTE Type050Bore Ø from 2.441 "Depth of groove up to .551 "Width of groove .1 1 8" − .1 97".591l 1Seating for cassette1.874.728h1.0631.6341.163.740R.118.236.996b10˚.055.833.925.319R.1 1 8.72830˚.024.126.748 .8541.065.220R.1 1 8M5 x 20 (x4).020.193HR = right hand version shownL = lefthandversionDepth ofgroove inrelation to bore−ØPart number l 1 b h D min t max Width ofgroove "w"050.1 827.0071 1.850 .193 1.004 2.441 .118− .157 03050.1 827.0009 1.850 .193 1.004 2.441 .157− .197 04State R or L version.Further shank sizes upon request.see tableSeatingSize—D mint max2.440 .3942.556 .4332.755 .51 23.1 45 .551Dimensions in inchSpare partsfor Toolholder Fastening screw Torx screw driver050.1 827.0071 030.051 8 T20 T20In the UNITED STATES call us toll freeH41

GROOVING and TURNINGINDEXABLE INSERT typeS229...3.precision sinteredGeometry .3.Geometry with chip forming for all materialsCharacteristics excellent chip control suitablefor high alloy−high strength steels reduced swarf width giveshigh flank surface finishApplication Groovingdepth of groove up to 1 .000" Side turningdepth of cut a p up to .1 57"* increased edge strength throughgood chip controlFeed rates Grooving − f .006" up to .01 0"/rev. Side turning − fup to .01 6"/rev.** dependent upon width of inserta p (inch)Turning.1 57.1 1 8.078Geometry .34.039Indexable inserts with profiles, intermediatesizes or other edge radii are available uponrequest..004 .006 .008 .01 0 .01 2 .01 4 .01 6 f(inch)Indexable inserts can be used in right andlefthand toolholders.Chip control graph S229.0500.34 material 51 1 5H42In the UNITED STATES call us toll free

GROOVING and TURNINGINDEXABLE INSERT TypeS229...3.with chip formingDepth ofgroove up to 1 .000"Width ofgroove .1 1 8" − .394"precision sintered1.1971.205.315.31510˚10˚rrwwrrWidth ofinsert .1 1 8" − .1 97" Width ofinsert .236" − .394"IndexabilityLength ±.002HPart numberw± .002 rS229.0300.32 .118 .008S229.0300.34 .118 .016S229.0400.32 .157 .008S229.0400.34 .157 .016S229.0500.34 .197 .016S229.0500.36 .197 .024S229.0600.34 .236 .016S229.0600.38 .236 .031S229.0700.36 .276 .024S229.0800.36 .315 .024S229.0800.38 .315 .031S229.0800.3K .315 .047S229.1 000.36 .394 .024S229.1 000.3K .394 .047Dimensions in inchSeating size.03.03.04.04.05.07.09orCarbide gradesMaterial ClassPMKTC92TF45TI25TI25TF45TN35AL96TC92TF45· StandardSemistandardIndexable inserts can be used in right and lefthand toolholdersIn the UNITED STATES call us toll freeH43

GROOVING and TURNINGINDEXABLE INSERT typeS229...5.precision sinteredGeometry .5Easy cutting geometry for materials with medium strengthCharacteristics excellent chip control on a widefeed range easycutting−low power requirementApplication Groovingdepth of groove up to 1 .000" Side turningdepth of cut a p up to .1 57"* reduced swarf width givesimproved surface finish increased edge strength throughgood chip controlFeed rates Grooving − f .006" up to .01 0"/rev. Side turning − fup to .01 6"/rev.** dependent upon width of inserta p (inch)Turning.1 57.1 1 8.078Geometry .54Indexables inserts with profiles, intermediatesizes or other edge radii are available uponrequest.Indexable inserts can be used in right andlefthandtoolholders..039.004 .006 .008 .01 0 .01 2 .01 4 .01 6 f(inch)Chip control graph S229.0500.54 material 51 1 5H44In the UNITED STATES call us toll free

GROOVING and TURNINGINDEXABLE INSERT TypeS229...5.with chip formingDepth ofgroove up to 1 .000"Width ofgroove .1 1 8" − .394"precision sintered1.1971.205.31 5.31510˚10˚rrwwrrWidth ofinsert .1 1 8" − .1 97" Width ofinsert .236" − .394"IndexabilityLength ±.002HPart numberw± .002 rS229.0300.52 .118 .008S229.0300.54 .118 .016S229.0400.52 .157 .008S229.0400.54 .157 .016S229.0500.54 .197 .016S229.0500.56 .197 .024S229.0600.54 .236 .016S229.0600.56 .236 .024S229.0700.56 .276 .024S229.0800.56 .315 .024S229.0800.58 .315 .031S229.0800.5K .315 .047S229.1 000.56 .394 .024Dimensions in inchSeating size03030404050709orCarbide gradesMaterial ClassPMKTC92TF45ALX2TI25TF45ALX5TF45TC92ALX5· StandardSemistandardIndexable inserts can be used in right and lefthand toolholdersIn the UNITED STATES call us toll freeH45

GROOVING and TURNINGINDEXABLE INSERT typeS229...A.precision sinteredGeometry .AGeometry with excellent chip breaking for materials with medium strengthCharacteristics excellent swarf control on anexpanded feed range controlled chips, also in partialcuttingApplication Groovingdepth of groove up to .984" Side turningdepth of cut a p up to .098"* reduced swarf width giveshigh flank surface finish high edge security throughgood swarf controlFeed rates Grooving−fup to.012"/rev. Side turning − fup to .01 2"/rev.** dependent upon width of inserta p (inch)Turning.1 57.1 1 8.078Geometry .A.Indexables inserts with profiles, intermediatesizes or other edge radii are available uponrequest.Indexable inserts can be used in right andlefthandtoolholders..039.004 .006 .008 .01 0 .01 2 .01 4 .01 6 f(inch)Chip control graph S229.0500.A4 material 51 1 5H46In the UNITED STATES call us toll free

GROOVING and TURNINGINDEXABLE INSERT TypeS229...A.with chip formingDepth ofgroove up to 1 .000"Width ofgroove .1 1 8" − .394"precision sintered1.1971.205.31 5.31510˚10˚rrwwrrWidth ofinsert .1 1 8" − .1 97" Width ofinsert .236" − .394"IndexabilityLength ±.002HPart numberw± .002 rS229.0300.A2 .118 .008S229.0300.A4 .118 .016S229.0400.A2 .157 .008S229.0400.A4 .157 .016S229.0500.A4 .197 .016S229.0500.A6 .197 .024S229.0600.A4 .236 .016S229.0700.A6 .276 .024S229.0800.A6 .315 .024S229.0800.A8 .315 .031S229.0800.AK .315 .047S229.1 000.A6 .394 .024S229.1 000.A8 .394 .031Dimensions in inchSeating size03030404050709orCarbide gradesMaterial ClassPMKTC92TF45ALX2TI25TF45ALX5TF45TC92ALX5· StandardSemistandardIndexable inserts can be used in right and lefthand toolholdersIn the UNITED STATES call us toll freeH47

GROOVING and PARTING OFFINDEXABLE INSERT TypeS229...E.with chip formingDepth of groove up to 1 .000"Width of groove .1 1 8" − .1 57"precision sintered1.197.31510˚wrrWidth ofinsert .1 1 8" − .1 57"IndexabilityLength ±.002Part numberw± .002 rS229.0300.E2 .118 .008S229.0300.E4 .118 .016S229.0400.E2 .157 .008S229.0400.E4 .157 .016Dimensions in inchSeating size030304orCarbide gradesMaterial ClassPMKTF45TI25TI25TF45TF45TI25TF46· StandardSemistandardIndexable inserts can be used in right and lefthand toolholdersH48In the UNITED STATES call us toll free

GROOVING and PARTING OFFINDEXABLE INSERT TypeS229...F.with chip formingDepth ofgroove up to 1 .000"Width of groove .1 1 8" − .1 57"precision sintered1.197.31510˚rwrWidthofinsert.118"−.157"IndexabilityLength ±.002HPart numberw± .002 rS229.0300.F2 .118 .008S229.0300.F4 .118 .016S229.0400.F2 .157 .008S229.0400.F4 .157 .016Dimensions in inchSeating size030304orCarbide gradesMaterial ClassPMKTF43TF45TI22TF43TF45TF43TF45TF46· StandardSemistandardIndexable inserts can be used in right and lefthand toolholdersIn the UNITED STATES call us toll freeH49

GROOVING and TURNINGINDEXABLE INSERT TypeS229...H.with chip breakerDepth ofgroove up to 1 .000"Width of groove .1 1 8" − .236"precision sintered1.197.31 510˚wrrWidth ofinsert .1 1 8" − .236"IndexabilityLength ±.002Part numberw± .002 rS229.0300.H4 .118 .016S229.0300.H6 .118 .024S229.0400.H4 .157 .016S229.0400.H6 .157 .024S229.0400.H8 .157 .031S229.0500.H4 .197 .016S229.0500.H6 .197 .024S229.0500.H8 .197 .031S229.0600.H4 .236 .016S229.0600.H6 .236 .024S229.0600.H8 .236 .031S229.0600.HK .236 .047Dimensions in inchSeating size.03.03.04.04.05orCarbide gradesMaterial ClassPMKTF43TF45TI22TF43TF45TF43TF45TF46· StandardSemistandardIndexable inserts can be used in right and lefthand toolholdersH50In the UNITED STATES call us toll free

GROOVING and TURNINGINDEXABLE INSERT TypeS229...L.with chip breakerDepth ofgroove up to 1 .000"Width of groove .1 57" − .31 5"precision sintered1.1971.197.315.31510˚10˚rrwwrWidth ofinsert .1 57" − .236"rWidth ofinsert .31 5"IndexabilityLength ±.002HPart numberw± .002 r Seating sizeS229.0400.L4 .157 .016S229.0500.L4 .197 .016S229.0500.L6 .197 .024S229.0600.L4 .236 .016S229.0600.L6 .236 .024S229.0800.L6 .315 .024Dimensions in inch.03/.04.04.05.07Carbide gradesMaterial ClassPMKTF43TF45TI22TF43TF45TF43TF45TF46· StandardSemistandardIndexable inserts can be used in right and lefthand toolholdersIn the UNITED STATES call us toll freeH51

GROOVING and TURNINGINDEXABLE INSERT type229...10precision groundGeometry .10Easy cutting geometry without chip formingCharacteristics easycutting−low power requirementApplication Groovingdepth of groove up to 1 .000" suitablefor unstable parts for internal grooving inrestricted bores suitablefor low feedsFeed rates Grooving − f .002" up to .006"/rev.Groove profiling with a cutting depthof the edge radius is possible.Indexables inserts with profiles, intermediatesizes or other edge radii are available uponrequest.Indexable inserts can be used in right andlefthandt oolholders.H52In the UNITED STATES call us toll free

GROOVING (External and Internal)INDEXABLE INSERT Type229...10Depth ofgroove up to 1 .000"Width ofgroove .098" − .394"precision ground1.1971.205.315.31510˚10˚rrwwrrWidth ofinsert .098" − .1 97" Width ofinsert .201 " − .394"IndexabilityLength ±.001HPart numberw± .002 r229.0250.1 0 .098 .008229.0300.1 0 .118 .008229.0400.1 0 .157 .008229.0500.1 0 .197 .008229.0600.1 0 .236 .016229.0700.1 0 .276 .016229.0800.1 0 .315 .016229.0900.1 0 .354 .016229.1 000.1 0 .394 .016Dimensions in inchSeating size0203030404050709orCarbide gradesMaterial ClassPMKTC92TN32TN32TC92TC92TN32· StandardSemistandardIndexable inserts can be used in right and lefthand toolholdersIn the UNITED STATES call us toll freeH53

GROOVING and TURNINGINDEXABLE INSERT type229...20precision groundGeometry .20Geometry without chip forming for grey cast iron andmaterials with higher tensile strengthCharacteristics strong wedge angle for inserts with largerprofile depthApplication Groovingdepth of groove up to 1 .000" recommended forinterrupted cutting suitablefor low feedsFeed rates Grooving − f .003" up to .01 0"/rev.Groove profiling with a cutting depthoftheedgeradiusispossible.Indexables inserts with profiles, intermediatesizes or other edge radii are available uponrequest.Indexable inserts can be used in right andlefthandt oolholders.H54In the UNITED STATES call us toll free

GROOVING (External and Internal)INDEXABLE INSERT Type229...20Depth ofgroove up to 1 .000"Width ofgroove .1 1 8" − .394"precision ground1.1971.205.315.31510˚10˚rrwwrrWidth ofinsert .1 1 8" − .1 97" Width ofinsert .201 " − .394"IndexabilityLength ±.001HPart numberw± .002 r229.0300.20 .1 1 8 .008229.0400.20 .1 57 .008229.0500.20 .1 97 .008229.0600.20 .236 .016229.0700.20 .276 .016229.0800.20 .315 .016229.0900.20 .354 .016229.1 000.20 .394 .016Dimensions in inchSeating size0303 or 0404050709Carbide gradesMaterial ClassPMKK1 0ALX6TF46· StandardSemistandardIndexable inserts can be used in right and lefthand toolholdersIn the UNITED STATES call us toll freeH55

GROOVING and TURNINGINDEXABLE INSERT type229...3.precision groundGeometry .3Geometry with chip forming for all materialsCharacteristics excellent chip control suitablefor high alloy−high strength steels reduced chip width givesimproved surface finishApplication Groovingdepth of groove up to 1 .000" Side turningdepth of cut a p up to .1 57"* increased edge strength throughgood chip controlFeed rates Grooving − f .006" up to .01 0"/rev. Side turning − fup to .01 6"/rev.** dependent upon width of inserta p (inch)Turning.1 57.1 1 8.078Geometrie Geometry .34 .34geometry .34Indexables inserts with profiles, intermediatesizes or other edge radii are available uponrequest.Indexable inserts can be used in right andlefthandtoolholders..039.004 .006 .008 .01 0 .01 2 .01 4 .01 6 f(inch)Chip control graph 229.0500.34 material 51 1 5H56In the UNITED STATES call us toll free

GROOVING and TURNINGINDEXABLE INSERT Type229...3.with chip formingDepth ofgroove up to 1 .000"Width ofgroove .1 1 8" − .394"precision ground1.1971.205.315.31510˚10˚rrwwrrWidth ofinsert .1 1 8" − .1 97" Width ofinsert .201 " − .394"IndexabilityLength ±.001HPart numberw± .002 r229.0300.31 .118 .008229.0300.34 .118 .016229.0400.31 .157 .008229.0400.34 .157 .016229.0500.31 .197 .008229.0500.34 .197 .016229.0500.36 .197 .024229.0600.31 .236 .016229.0600.38 .236 .031229.0700.31 .276 .016229.0800.31 .315 .016229.0800.38 .315 .031229.0900.31 .354 .016229.1 000.31 .393 .01 6Dimensions in inchSeating size03030404050709orCarbide gradesMaterial ClassPMKTC92TN32TN32TC92TC92TN32· StandardSemistandardIndexable inserts can be used in right and lefthand toolholdersIn the UNITED STATES call us toll freeH57

FINISHING ON NC-LATHESINDEXABLE INSERT Type229with chipbreakerDepth ofgroove up to 1 .000"Width of groove .1 1 8" − .1 57"1.197Available in Cermet H20with chipbreaker, for bestsurface qualities..31510˚RRwxrwrIndexabilityLength ±.001Part number w +.001 r *wx229.NC30.02 .118 .008 .177229.NC40.02 .157 .008 .252Dimensions in inch*wx= Width of groove - R (right) -R (left)Seating size03 or 04Carbide gradesMaterial ClassPMKH20H20H20· StandardSemistandardIndexable inserts can be used in right and lefthand toolholdersH58In the UNITED STATES call us toll free

FINISHING ON NC-LATHESINDEXABLE INSERT Type229Depth ofgroove up to 1 .000"Width of groove .1 1 8" − .1 57"1.197Available in Cermet H20with chipbreaker, for bestsurface qualities..31510˚wrrHIndexabilityLength ±.001Part numberw+.001 r229.0300.02 .118 .008229.0400.02 .157 .008Seating size03 or 04Carbide gradesMaterial ClassPMKH20H20H20· StandardSemistandardIndexable inserts can be used in right and lefthand toolholdersIn the UNITED STATES call us toll freeH59

GROOVING (External and Internal)INDEXABLE INSERT Type229Depth ofgroove up to 1 .000"Width of groove .1 1 8" − .236"precision groundProfiling1.197.31510˚orrwFull radius with surroundingchip breakerIndexabilityLength ±.001Corner reliefto use with R/L U225....Part numberw+.001 r229.001 5.30 .118 .059229.0020.40 .157 .079229.0025.50 .197 .098229.0030.60 .236 .118Dimensions in inchSeating size0303 or 040405Carbide gradesMaterial ClassPMKTN32ALX2TN32ALX2TN32ALX2· StandardSemistandardIndexable inserts can be used in right and lefthand toolholdersH60In the UNITED STATES call us toll free

THREADING (External) − FULL PROFILEINDEXABLE INSERT Type229...02Metric ISO−thread Pitch P1.0−2.5mmprecision ground1 .1 97.31 510˚H 1R.004 maxmax. .984Er60˚.118Suitable for threading behindashoulder.HR = right hand version shownL = left hand versionStandard threadFull profileIndexabilityLength ±.001Part number P H 1 r ER/L 229.061 0.02 1 .00 mm .024 .005 .031R/L 229.071 2.02 1 .25 mm .030 .006 .031R/L 229.0915.02 1 .50 mm .036 .008 .026R/L 229.1 01 7.02 1 .75 mm .042 .01 0 .020R/L 229.1220.02 2.00 mm .048 .01 0 .020R/L 229.1525.02 2.50 mm .060 .01 4 .01 2Seating size03 or 04Carbide gradesMaterial ClassPMKTN35TN35TN35· StandardSemistandardState R or L version.Dimensions in inch/mmNo shims necessary. All HORN thread profiles are manufacturedwith full ground radial clearance.In the UNITED STATES call us toll freeH61

THREADING (Ext.) − PARTIAL PROFILEINDEXABLE INSERT Type229...01Partial Profile PitchTpi 9−28precision ground1.1 97.31 510˚H 1max. .984Er60˚.1 1 8Suitable for threading behindashoulder.R = right hand version shownL = left hand versionStandard threadPartial profileIndexabilityLength ±.001Part number Tpi H 1 r ER/L 229.061 0.01 24−28 .024 .005 .031R/L 229.071 2.01 1 8−24 .030 .006 .031R/L 229.0915.01 1 6−1 8 .036 .008 .026R/L 229.1 01 7.01 1 3−1 6 .042 .01 0 .020R/L 229.1220.01 1 2−1 3 .048 .01 0 .020R/L 229.1525.01 9−1 2 .060 .01 4 .01 2Seating size03 or 04Carbide gradesMaterial ClassPMKTN35TN35TN35· StandardSemistandardState R or L version.Dimensions in inchNo shims necessary. All HORN thread profiles are manufacturedwith full ground radial clearance.H62In the UNITED STATES call us toll free

THREADING (External) − FULL PROFILEINDEXABLE INSERT Type229Whitworth pipe thread (BSW/BSF) Pitch28 − 1 1 Gg/"1.197precision ground.31510˚H 15˚R 1R 2max. .98455˚wSuitable for threading behindashoulder.HFull profileIndexabilityLength ±.001Part number Gg/" H 1 R 1 R 2 wtpiN 229.0509.28 28 .023 .005 .005 .102N229.0813.19 1 9 .034 .007 .007 .1 1 8N 229.1118.14 14 .046 .009 .009 .118N 229.1 423.1 1 11 .058 .012 .012 .122Dimensions in inchSeating size03 or 04Carbide gradesMaterial ClassPMKTN35TN35TN35· StandardSemistandardNo shims necessary. All HORN thread profiles are manufacturedwith full ground radial clearance.In the UNITED STATES call us toll freeH63

PARTING OFFINDEXABLE INSERT Type229...3.Depth ofparting offup to 1 .000"Width of parting off .118"− .157"*1.197.31 510˚R Neutral LaawaPart numberw±.002aR/L 229.5300.31 * .118 5˚S229.0300.32 .118 0˚R/L S229.0530.32 .118 5˚S229.0400.32 .157 0˚R/L S229.0540.32 .157 5˚State R or L version.* precision ground length: 1 .1 81 "Dimensions in inchSeating size0303 or 04Carbide gradesMaterial ClassPMKTF45TI25TC92TI25TF45TF45TI25TC92· StandardSemistandardParting offsolid barsParting offtubesDDupto1.969WDWupto1.000Indexable inserts can be used in right and lefthand toolholdersH64In the UNITED STATES call us toll free

PARTING OFFINDEXABLE INSERT TypeS229...C.Depth ofparting offupto 1.000"Width of parting off .118"− .157"1.181precision sintered.31 5R Neutral L10˚aawraPart numberw±.002a rS229.0030.C0R/L S229.0530.C0R/L S229.0830.C0S229.0040.C0R/L S229.0540.C0R/L S229.0840.C0.118 0˚ −.118 5˚ −.118 8˚ −.157 0˚ −.157 5˚ −.157 8˚ −S229.0030.C1 .118 0˚ .006R/L S229.0530.C1 .118 5˚ .006R/L S229.0830.C1 .118 8˚ .006S229.0040.C1 .1 57 0˚ .006R/L S229.0540.C1 .1 57 5˚ .006R/L S229.0840.C1 .1 57 8˚ .006State R or L version.Dimensions in inchSeating size030304030304ororCarbide gradesMaterial ClassPMKTF45TI25TC92TI25TF45TN35TF45TI25TC92· StandardSemistandardHParting offsolid barsParting offtubesDDupto1.969WDWupto1.000Indexable inserts can be used in right and lefthand toolholdersIn the UNITED STATES call us toll freeH65

HARD TURNINGINSERT Type229Depth ofgroove up to 1 .000"Width of groove .1 1 8" − .236"CBN−tipped insertSingle tipped insert1.1971.205.315.31 510˚10˚rrwwrrPart numberw± .002 r229.0300.22.B .118 .008229.0300.24.B .118 .016229.0400.22.B .1 57 .008229.0400.24.B .157 .016229.0500.22.B .1 97 .008229.0500.24.B .197 .016229.0600.24.B .236 .016229.0600.26.B .236 .024Dimensions in inchSeating size03040405Carbide gradesMaterial ClassPMKCB1 0CB20CB1 0CB20· StandardSemistandardIndexable inserts can be used in right and lefthand toolholdersH66In the UNITED STATES call us toll free

Machining of brass (Ms58)with insert type 259w = 3.0 mm (.118") and 4.0 mm (.157")Grooving and Parting offup totmax=18mm(.709")HIn the UNITED STATES call us toll freeH67

GROOVING and PARTING OFFTOOLHOLDER typeR/L H259with screwed clampingDepth of groove up to max. 1 8.0 mm (.709")Width ofgroove 3.0 − 4.0 mm (.118"-.157")L 3L 16for use with indexable insert Type 259h 1RhhL 2tmaxff1bwR = right hand version shownL = lefthandversionPart number t max w h h1 b f1 f L1 L 2 L 3R/L H259.1616.03 1 6 20 1 6 1 4.55 1 35 30 30R/L H259.2020.03 1 1 .0 3.0 20 20 20 1 8.55 1 35 − 30R/L H259.2525.03 25 25 25 23.55 1 35 − 30R/L H259.1616.13 1 6 20 1 6 1 4.55 1 35 33 33R/L H259.2020.1 3 18.0 4.0 20 20 20 18.55 135 − 33R/L H259.2525.1 3 25 25 25 23.55 1 35 − 33State R or L version.Further shank sizes upon request.f= f1 + w /2Dimensions in mmSpare partsToolholder Screw Torx screw driverR/L H259... 6.23T25 T25H68In the UNITED STATES call us toll free

GROOVING and PARTING OFFINDEXABLE INSERT type259...M1/M2Depth ofgroove up to .709"Width of groove .1 1 8" − .1 57"precision groundfor use with toolholder1.177 Type R/L H259.3155˚ap=2 x wwrrIndexabilityLength ± .0006HUsable length ofminor cutting edge 2 x w for machining brass (Ms58).Part number w ±.0008 r259.0300.M1 .118 .006259.0400.M1 .157 .006259.0300.M2 .118 .008259.0400.M2 .157 .008Dimensions in inchfor toolholderR/L H259...Carbide gradesMaterial ClassPMKMG12MG12MG12· StandardSemistandardIndexable inserts can be used in right and lefthand toolholdersIn the UNITED STATES call us toll freeH69

Choice of geometriesGeometryIndexable InsertType 229 / S229ApplicationFeed ratesin/rev..1 0groovingfinishing ofgroovesfor long chipping materials, low feed rates.002 − .006.20grooving, finishing ofgroovesgeometry for inserts with profilefor short chipping materials andhigh tensile strength.003 −.01 0.3.grooving, side turning, profiling andfinishing ofgrooves, for long chippingmaterialssuitable for materials with high tensilestrength.006 − .01 0.006 − .01 6*.5.grooving, side turning, profiling ofgroovesexcellent reduction of chip width inmaterialswith medium tensile strength.004 − .01 8.006 − .024*.A.grooving, side turning, finishing or profilingof groovesexcellent chip breaking in materialswith medium tensile strength.002 − .01 2.004 − .01 2*.C.parting offfor long chipping materials.0008 − .004.E.groovingprofiling and finishing of groovesfor long chipping materialssuitable for materials with high tensilestrength.003 − .01 2.F.groovingfinishing ofgroovesfor long chipping materials, low feed rates.001 − .006.H.grooving in "pecking process",profiling in partial cut for long chippingmaterials.006 - 01 0.004 - 01 0.L.grooving in full and partial cut withexcellent chip control.004 - 0085.002 - 008* dependant upon insert width, edge radii and material grooving side turningH70In the UNITED STATES call us toll free

Carbide grades insert type 229 / S229HORN− ISO properties workpiece recommendedgrades material applicationsH20*(HT)P01 −P1 5Cermetcarbon steelslow alloyd steelscast steel, stainless steelsexotic alloysfor grooving and finishing, for best surfacequalities, no tendency to built up edge,resistant to wearH54(HT)P05−P20Cermetcarbon steelslow alloyd steelscast steel, stainless steelsexotic alloysfor grooving and finishing, for best surfacequalities, no tendency to built up edge,resistant to wearP20(HW)P20uncoatedcarbidesteel, cast steelmalleable cast ironfor grooving and finishing at moderatecutting speedTC92(HC)P1 0−P30multilayercoatingsteel, cast steelmalleable cast ironfor grooving and finishing at highcutting speedAL96(HC)P1 0−P30K05−K20multilayercoating(AL 2 O 3 )steel, cast steel, malleablecast iron, martensiticstainless steelfor grooving and finishing at very highcutting speed, heat resistant,suitable for dry cuttingTN32(HC)P1 0−P25TIN−coatedsteel, cast steelmalleable cast ironfor grooving and finishing at highcutting speedTN35(HC)P20−P35K1 0−K20TIN−coatedsteel, cast steel, malleablecast iron, martensiticstainless steelfor grooving and finishing at lowcutting speed, thread cutting,unfavourable conditionsHTI22(HC)P1 0−P25TICN−coatedsteel, cast steelmalleable cast ironfor grooving and finishing at highcutting speedTI25(HC)P1 5−P35K1 0−K20TICN−coatedsteel, cast steel, malleablecast iron, martensiticstainless steelfor grooving and finishing at lowcutting speed, thread cutting,unfavourable conditionsTF45(HC)P1 0−P35K1 0−K20TIALN−coatedsteel, cast steel, malleablecast iron, martensiticstainless steelfor grooving and finishing at lowcutting speed, cooling with oilTF46K1 0(HC)P05−P20K05−K20(HW)K1 0TIALN−coateduncoatedcarbidesteel, cast steel, malleablecast iron, martensiticstainless steelgrey cast iron, malleablecast iron, Si−aluminium andcopper alloysheat resistant alloysfor grooving and finishing at very highcutting speed, heat resistant,suitable for dry cuttingfor grooving and finishingMG12(HW)K1 0−K30uncoatedcarbide(micro grain)grey cast iron, malleablecast iron, Si−aluminium andcopper alloysheat resistant alloysfor grooving and finishing at lowcutting speed, unfavourableconditionsC02**(CM)mixed ceramicsgrey cast iron, hardened steelheat resistant alloysfor grooving and finishing ofhardenedparts (>48HRC), grey cast iron at extremlyhigh cutting speedSN1 **(CN)Silicon nitride(Si 3 N 4 )grey cast ironfor grooving and finishing ofgrey cast iron atextremly high cutting speedCBN− or PCD tipped inserts upon request.Carbide grades on stock are shown in the catalogue or in the price− and stock listNot mentioned grades can be supplied only against firm order.* geometry .10/.20 only** geometry .20 onlyIn the UNITED STATES call us toll freeH71

HORN −Carbide gradeswear resistancecutting speedtoughnessCarbide grades synthetic cutting-tool materialuncoated coatedPD1 0PD20K1 0TF45TI25MG1 2K1 0TN35 TF45MG1 2CB1 0feedrateCB20ANSIC8C7C5----C4C3C2C1ISO01102030401020304001102030Nnon ferrous metalShigh temperaturematerialsHhardened materialswear resistancecutting speedtoughnessfeedrateCarbide grades Cermetsuncoated coatedH20AL96TF46H54TC92TF45P20TN32TI22TN35TI25AL96TF45H54MG1 2TN35TI25AL96TF46H20K1 0TC92TF45 H54MG1 2ANSIC8C7C5----C4C3C2C1ISO01102030401020304001102030Psteel stainless steel grey cast iron / aluminiumMKH72In the UNITED STATES call us toll free

CUTTING DATAfor groovingMaterial to be machinedHardnessBrinell (HB)Cutting speed (sfm)K1 0 MG1 2 P20 TI22 TI25 TF45 TF46 TC92 AL96 H20 H54TN32 TN35PNon-AlloyCarbon Steel0,2 % C0,4 % C140180325-460295-425425-525 360-460395-460 325-4251 95-2601 65-260460-720390-655460-720425-625460-785395-720460-625425-590395-525425-4600,6 % C200260-395395-460 260-395325-625425-590360-655395-555260-460annealed180260-395395-460 325-4601 65-260395-525260-655395-555325-460Alloy Steelquenched280230-295295-460 260-360295-460260-590325-460260-460quenchedand tempered350130-195230-395 1 95-260260-360230-525195-395195-325High Alloyannealed200195-325230-325325-490395-590260-3601 95-260Steel (>%5)hardened−unalloyed180260-360395-525395-525325-460Cast Steelalloyed2201 95-295260-460260-395195-395MStainless Steelannealedmartensitic,ferriticaustenitic2001801 95-2601 95-260260-360 1 65-3601 95-260325-525325-395360-425395-490260-360325-490325-460HKGrey cast ironlow tensilestrengthhigh tensilestrength1802501 65-230 1 65-2301 65-230 1 65-230230-3601 95-260325-460195-395325-460260-395325-525325-460Spheroidalferritic1601 95-295 1 95-260195-325260-460230-490360-490graphitecast ironperlitic2501 95-260 1 65-1 951 95-295230-425195-395325-460Malleableferritic1251 95-260325-395 1 95-260260-325360-525325-590cast ironperlitic225130-1951 95-260 1 65-1 951 95-260260-395260-490SHeat resistantAlloys (Fe)annealedhardened200275100-13065-1 1 5100-13065-1 1 5Heat resistantannealed25065-8065-80Alloys (Ni, Co)hardened35030-6530-65NAluminiumAlloysnot heattreatableheat treatable30−8080−1 201 950-3300 1 300-2650720-1 300 655-9851950-3300720-1 300Aluminiumnot heattreatable801 950-3300 1 300-26501950-3300Cast Alloysheat treatable100985-1 950 820-1 300985-1 950Copper Alloysnot heattreatableheat treatable90100325-525260-425425-525 360-6251 95-425 260-460In the UNITED STATES call us toll freeH73

Technical instructionsSIDE TURNINGHORN−grooving tools will give you absolute accuracy of profile andangles, even when profiling with one−sided cutting forces.Aflexiblecuttingedgewouldbedesirablefor turning, but is not useful forprecision grooving.Please note when setting the toolAlways ensure that the tool is perpendicularto the axis of the workpiece.90˚Improper settingFeed direction 1will create vibrations.The tendency to vibrate will increaseon rigid workpieces.f1 2fFeed direction 2is suitable for turning andwill have no negative effects to the operation.aH74In the UNITED STATES call us toll free

Technical instructionsSIDE TURNINGThe grooving tool should not be seen as a replacement for a turning tool with ISO−inserts.On certain operations, for instance grooving and turning can reduce the number oftoolchanges and so offer reduced cycle time.Width .157" .197" .236"Width ofinsertThe width .157", .197" and .236" arerecommended forthesideturning.The profile and rigidity ofthe workpiecedetermines the width ofinsert.Always choose the largest possibleedge radius.a pmax .110 .138 .157f .006 − .01 2 .006 − .01 6 .006 − .01 6a pmax .110 .138 .157f .006 − .01 2 .006 − .020 .006 − .024.3..5.a pmax .110 .138 .157f .004 − .01 0 .004 − .01 2 .004 − .01 2.A.HCutting depth a pWhen side turning the cutting depth is dependent upon the width of insert as well as onthe material and the rigidity ofthe workpiece. The max. depth will be limited by thelength ofthe cutting edge.The smallest cutting depth a p min is governed by the edge radius ofthe insert. Cuttingdepth below the corner radius will create poor cutting conditions.Rule ofthumb for calculation:a pmax= wx0.7ormax.157"a pmin=edgeradius(r)Max. feed rate f maxRule ofthumb for calculation:f max = wx0.1In the UNITED STATES call us toll freeH75

Technical instructionsSIDE TURNINGSide turning between shoulders561324Cut 1 − 4Cut 5 − 65xfAlways start at the shoulder when side turning, towards shoulder. An operation towards theshoulder will influence the run off of the chip and creates the risk of insert breaking.Grooving and turning is recommended as shown.The second cut and subsequent cuts leave a distance of5 x fto the shoulder. This cut widthwill help prevent swarf being trapped under the advancing cutting edge.GROOVE CHAMFERINGwith standard insertsWidth ofgroove and insertare equalGroove wider than insertH76In the UNITED STATES call us toll free

Technical instructionsSEALGROOVE FINISHINGThis process requires both turningand grooving where very high qualitysurface finishes are required.Diagramm 2 shows the modified inserttype 229...NC...D2 (page H58).1.2.HCHIP RING CREATIONChip ring creation can be avoided by turning across the smaller diameter in onecontinuous pass.Well defined cutting edges and small corner radii will reduce the tendency to createrings.2 112Risk ofring creationNo ring createdIn the UNITED STATES call us toll freeH77