Type 1 1 1 - Horn USA, Inc.

Type 1 1 1 - Horn USA, Inc.

Type 1 1 1 - Horn USA, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

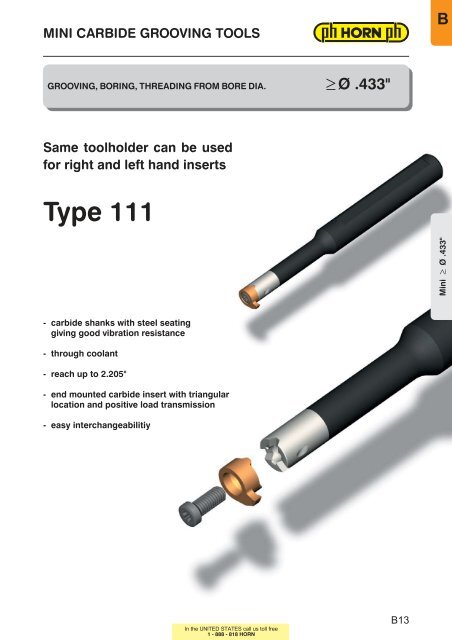

—MINI CARBIDE GROOVING TOOLSBGROOVING, BORING, THREADING FROM BORE DIA.—Ø.433"Same toolholder can be usedfor right and left hand inserts<strong>Type</strong>111−carbideshankswithsteelseatinggiving good vibration resistance− through coolant− reach up to 2.205"− end mounted carbide insert with triangularlocation and positive load transmission− easy interchangeabilitiyIn the UNITED STATES call us toll freeB1 3

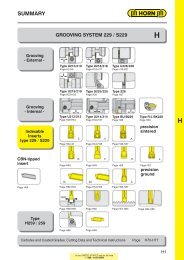

HCG - H orn C atalog G uideINTERNAL GROOVINGBore ØPRODUCT LINESUPER MINI MINI 21 7 264 S223 S224 231 S229/229 S31 2/31 2 31 5up to .31 5" (8 mm).315−.709"(8−18mm).709 − 1 .1 02" (1 8 − 28 mm)1.102−1.496"(28−38mm)from 1 .496" (38 mm)MachiningBoringGrooving and turningThreadingProfilingWidth of Groove in inchWidth of Groove in mm.039−.079" .028−.1 57" .020−.250" .059−.1 1 8" .079−.1 1 8" .079−.236" .098−.394" .098−.394" .020−.250" .043−.1 63"1 .0−2.0mm 0.7−4.0mm 0.5−6.35mm 1 .5−3.0mm 2.0−3.0mm 2.0−6.0mm 2.5−1 0mm 2.5−1 0mm 0.5−6.35mm 1 .1 −4.1 5mmChapter A B C D E F G H J KEXTERNAL GROOVINGDepth ofGroovePRODUCT LINESUPER MINI MINI 21 7 264 S223 S224 231 S229/229 S31 2/31 2 31 5up to .1 57" (4 mm)up to .236" (6 mm)up to .31 5" (8 mm)up to .394" (1 0 mm)up to .551 " (1 4 mm)up to .709" (1 8 mm)up to 1 .000" (25 mm)MachiningGroovingSide turningParting offThreadingProfilingWidth of Groove in inchWidth of Groove in mm.039−.079" .028−.1 57" .020−.250" .059−.1 1 8" .079−.1 1 8" .079−.236" .098−.394" .098−.394" .020−.250" .043−.1 63"1 .0−2.0mm 0.7−4.0mm 0.5−6.35mm 1 .5−3.0mm 2.0−3.0mm 2.0−6.0mm 2.5−1 0mm 2.5−1 0mm 0.5−6.35mm 1 .1 −4.1 5mmChapter A B C D E F G H J KIn the UNITED STATES call us toll free

SUMMARYBMINI CARBIDE GROOVING TOOLSBMINI U108/108— Ø.315"Toolholder Page B2Page B3−B6 Page B7−B1 0 Page B1 1Page B1 2MINI U111/111— Ø.433"Toolholder Page B1 4Page B1 5−B1 8 Page B19−B22 Page B23Page B24−B28MINI U114/114— Ø.551"Toolholder Page B30Page B33Page B32−B37Page B36Page B38−B40Page B41Page B42−B44Page B45−B48MINI U116/116— Ø.630"Toolholder Page B50Page B51 −B54 Page B55−B56 Page B57Page B58−B62Cartridge— Ø .787"<strong>Type</strong> 1 25/1 45Page B63Technical Instructions Page B64−B67In the UNITED STATES call us toll freeB1

For Customers/Vendors – updatedd 11Jan11Q: How will I be billed by the new company?A: After the merger invoicing will be done byPLX. Customers will begiven notification on thenew Billing process for the combined companies.Q: WhatA: Thereplaced.happens tomy existingbacklog?will be no changes to your existing backlog. All backlog willl be servicedand shipped asQ: What happens toany outstanding invoices?A: Payment on open or outstanding invoicesshould be processed ass per the existingrequirements. The new companywill not bere‐issuing invoices. Customers will be givennotification of the payment process for invoices issued on shipments post the close of theacquisition.Q: What is the status of existingcontracts, VPA’s, and NDA’s that are in place today witheither PLX or Teranetics?A: All terms and conditions of existing contracts signed with either PLX Technology orTeranetics will remain in place with the combined enterprise. In cases where there are twocontractsin place, PLX will work with the customer to resolve as required.PLXTechnology870 W.Maude Ave.Sunnyvale, CA 94085www.plxtech.com

GROOVING Internal —Ø .433"BINSERT <strong>Type</strong>U111/111Bore Ø from .433"Width ofgroove .030" − .039"ffor use with toolholderd <strong>Type</strong> BU11 1B111D minws 1st maxToolholder face*notface cutting—Right hand version shownPart number w −.001 6 s 1 s f d t max D minR/LU111.0031.00 .031R/LU111.0039.00 .039.156 .161 .264 .315 .047 .433*R/L111.0070.00 .030 .047*R/L 1 1 1 .0080.00 .034 .156 .161 .264 .315 .051 .433*R/L111.0090.00 .038 .059State R or L version.Dimensions in inchCarbide gradesMG12TN35TI25TF45· StandardSemistandardPlease check price anddelivery for all itemsIntermediate widths upon request.Depth ofgroove t max =1.5xwIn the UNITED STATES call us toll freeB1 5

NC−PROFILING Internal —Ø.433"INSERT <strong>Type</strong>U111/111Bore Ø from .433"Width of groove .031 −.1 25"ffor use with toolholderd <strong>Type</strong> BU11 1B111D minMini — Ø.433"wrrt maxsToolholder facewith corner radiusR = Right hand version shownL = Left hand versionPart number w +.001 2 r s f d tmax D minR/LU111.0031.08 .031R/LU111.0046.08 .046R/LU111.0062.08 .062R/LU111.0078.08 .078R/LU111.0094.08 .094R/LU111.0125.08 .125.008 .156 .264 .315 .091 .433R/LU111.0046.16 .046R/LU111.0062.16 .062R/LU111.0078.16 .078 .016 .156 .264 .315 .091 .433R/LU111.0094.16 .094R/LU111.0125.16 .125Carbide gradesMG12TN35TI25TF45· StandardSemistandardPlease check price anddelivery for all itemsR/L 111.0200.02 .079 .008 .156 .264 .315 .091 .433State R or L version.Dimensions in inchB1 6In the UNITED STATES call us toll free

GROOVING Internal —Ø .433"BINSERT <strong>Type</strong>U111/111Bore Ø from .433"Depth ofgroove up to .091 "Width of groove .046 − .1 25"ffor use with toolholderd <strong>Type</strong> BU11 1B111D minwst maxToolholder face—R = Right hand version shownL = Left hand versionPart number w +.001 2 s f d t max D minCarbide gradesMG12TN35TI25TF45R/LU111.0046.00 .046R/LU111.0056.00 .056R/LU111.0062.00 .062R/LU111.0078.00 .078R/LU111.0094.00 .094R/LU111.0125.00 .125State R or L version..156 .264 .315 .091 .433R/L 111.0110.00 .047R/L 111.0130.00 .055R/L 111.0150.00 .059R/L 111.0160.00 .067 .156 .264 .315 .091 .433R/L 111.0200.00 .079R/L 111.0250.00 .098R/L 111.0300.00 .118Dimensions in inch· StandardSemistandardPlease check price anddelivery for all itemsIn the UNITED STATES call us toll freeB1 7

GROOVING Internal —Ø.433"INSERT <strong>Type</strong>U111/111Bore Ø from .433"Full radius up to r .059"ffor use with toolholderd <strong>Type</strong> BU1 1 1B111D minMini — Ø.433"wrt maxsToolholder faceFull radiusR = Right hand version shownL = Left hand versionPart number w +.002 r s f d t max D minCarbide gradesMG1 2TN35TI25TF45R/LU111.0015.31 .031 .01 5R/LU111.0023.46 .046 .023R/LU111.0031.62 .062 .031 .1 56 .264 .31 5 .091 .433R/LU111.0039.78 .078 .039R/LU111.0047.94 .094 .047R/L 111.0004.08 .031 .01 6R/L 1 1 1 .0006.1 2 .047 .024R/L 111.0009.18 .071 .035 .1 56 .264 .31 5 .091 .433R/L 1 1 1 .001 0.20 .079 .039R/L 111.0015.30 .1 1 8 .059· StandardSemistandardPlease check price anddelivery for all itemsState R or L version.Dimensions in inchB1 8In the UNITED STATES call us toll free

BORING and PROFILING —Ø.386"BINSERT <strong>Type</strong>111Bore Ø from .386"max. depth ofundercut .091 "ffor use with toolholderd5˚ <strong>Type</strong> BU1 1 1B111D minw18˚r.01 6"sToolholder faceMini — Ø.386"R = Right hand version shownL = Left hand versionPart number w r s f d t max D minCarbide gradesMG1 2TN35TI25TF45R/L 111.1855.02 .1 06 .008 .1 57 .21 7 .31 5 .044 .386R/L 111.1867.02 .1 06 .008 .1 57 .264 .31 5 .091 .433State R or L version.Dimensions in inch· StandardSemistandardPlease check price anddelivery for all itemsThe modified geometry allows boring ofbores— Ø .386 and undercuts.In the UNITED STATES call us toll freeB1 9

BORING and PROFILING —Ø.433"INSERT <strong>Type</strong>111Bore Ø from .433"max. depth ofundercut .091 "ffor use with toolholderd5˚ <strong>Type</strong> BU1 1 1B111D minMini — Ø.433"8˚t maxr47˚.008"sToolholder faceR = Right hand version shownL = Left hand versionPart number r s f d t max D minCarbide gradesMG1 2TN35TI25TF45R/L 1 1 1 .4767.02 .008 .156 .264 .315 .091 .433State R or L version.The modified geometry allows boring ofbores— Ø .433" and undercuts.Dimensions in inch· StandardSemistandardPlease check price anddelivery for all itemsB20In the UNITED STATES call us toll free

BACKBORING —Ø.433"BINSERT <strong>Type</strong>111Bore Ø from .433"max. depth ofundercut .091 "ffor use with toolholderd <strong>Type</strong> BU1 1 1B111D min30˚s 1rs—t maxToolholder faceR = Right hand version shownL = Left hand versionPart number s 1 r s f d t max D minCarbide gradesMG1 2TN35TI25TF45R/L 111.3067.02 .055 .008 .1 61 .264 .31 5 .091 .433State R or L version.Dimensions in inch· StandardSemistandardPlease check price anddelivery for all itemsIn the UNITED STATES call us toll freeB21

BACKBORING and CHAMFERING (Internal)INSERT <strong>Type</strong>111Bore Ø from .433"max. depth ofcut .059"ffor use with toolholderd <strong>Type</strong> BU1 1 1B111Mini — Ø.433"D minXsrt max45˚45˚EDetail XsToolholder faceR = Right hand version shownL = Left hand versionPart number E r s f d t max D minCarbide gradesMG1 2TN35TI25TF45R/L 1 1 1 .4545.02 .094 .008 .1 61 .264 .31 5 .059 .433State R or L version.Dimensions in inch· StandardSemistandardPlease check price anddelivery for all itemsB22In the UNITED STATES call us toll free

PREGROOVING and CHAMFERING (Internal)BINSERT <strong>Type</strong>111Bore Ø from .433"ffor use with toolholderd <strong>Type</strong> BU1 1 1B111D min8˚.008wts—t1Toolholder faceR = Right hand version shownL = Left hand versionPart number w s f d t t 1 D minCarbide gradesMG1 2TN35TI25TF45R/L 1 1 1 .081 0.45 .039 .1 56 .264 .31 5 .008 .059 .433State R or L version.Dimensions in inch· StandardSemistandardPlease check price anddelivery for all itemsIn the UNITED STATES call us toll freeB23

THREADING (Internal) partial profileINSERT <strong>Type</strong>111TPI 9 − 64Pitch in mm(0.5 − 3.0 mm)ffor use with toolholderd <strong>Type</strong> BU1 1 1B111D minMini — Ø.433"Xs60˚EDetail XToolholder facePartial profile threadR = Right hand version shownL = Left hand versionPart number Pitch E s f d D minSTANDARD THREAD tpi mmCarbide gradesMG1 2TN35TI25TF45R/L 1 1 1 .1 020.01 11−16 (1.75−2.5) .118R/L 111.1325.01 9−1 2 (2.5−3.0) .1 1 0.1 61 .264 .31 5 .433· StandardSemistandardPart number Pitch E s f d D minFINE THREAD tpi mmPlease check price anddelivery for all itemsR/L 111.0205.01 28−64 (0.5−0.75) .1 38 .1 61 .264 .31 5 .433R/L 111.0510.01 18−32 (1.0−1.25)R/L 111.0815.01 12−20 (1.5−1.75)State R or L version..1 30 .1 61 .264 .31 5 .433Dimensions in inch(mm)B24In the UNITED STATES call us toll free

THREADING (Internal) full profileBINSERT <strong>Type</strong>111Bore Ø from .433"Pitch (metric)1 .0 − 3.0 mmffor use with toolholderd <strong>Type</strong> BU1 1 1B111D minXs60˚EDetail XToolholder faceMetric ISO threadMini — Ø.433"R = Right hand version shownL = Left hand versionPart number Pitch E s f d D minin mmSTANDARD THREADCarbide gradesMG1 2TN35TI25TF45R/L 1 1 1 .1 020.02 2.0 mm .1 1 8R/L 111.1325.02 2.5 mm .1 1 0 .1 61 .264 .31 5 .433R/L 1 1 1 .1 620.02 3.0 mm .1 06· StandardSemistandardPlease check price anddelivery for all itemsPart number Pitchin mmE s f d D minFINE THREADR/L 111.0510.02 1.0mm .1 30 .1 61 .264 .31 5 .433R/L 111.0815.02 1.5mmState R or L version.Dimensions in inch/mmIn the UNITED STATES call us toll freeB25

THREADING (Internal) partial profileINSERT <strong>Type</strong>U111Bore Ø from .433"Pitch5 - 1 0 tpiffor use with toolholderd <strong>Type</strong> BU1 1 1B111D minXMini — Ø.433"s29˚EDetail XToolholder faceACME / Stub ACMEthreadR = Right hand version shownL = Left hand versionPart number Pitch E s f d D mintpiCarbide gradesMG1 2TN35TI25TF45Standard ACME ThreadR/LU111.AC08.01 8 .119R/LU111.AC06.01 6 .106Stub ACME ThreadR/LU111.SA10.01 10 .126R/LU111.SA08.01 8 .112R/LU111.SA06.01 6 .110R/LU111.SA05.01 5 .102State R or L version..1 61 .264 .31 5 .433.1 61 .264 .31 5 .433Dimensions in inch· StandardSemistandardPlease check price anddelivery for all itemsB26In the UNITED STATES call us toll free

THREADING (Internal) partial profileBINSERT <strong>Type</strong>111Bore Ø from .433"Pitch1 .5 - 4.0 mmffor use with toolholderd <strong>Type</strong> BU1 1 1B111D minXs30˚EDetail XToolholder faceMetric ISO trapezoidalthread DIN 1 03Mini — Ø.433"R = Right hand version shownL = Left hand versionPart number Pitch E s f d D minin mmCarbide gradesMG1 2TN35TI25TF45R/L 111.1015.01 1.5mm .138R/L 111.1220.01 2.0 mm .1 30R/L 111.1730.01 3.0mm .118R/L 111.2240.01 4.0 mm .098State R or L version..1 61 .264 .31 5 .433Dimensions in inch· StandardSemistandardPlease check price anddelivery for all itemsIn the UNITED STATES call us toll freeB27

THREADING (Internal) full profileINSERT <strong>Type</strong>111Bore Ø from .433"Pitch P1 9−1 4 tpiffor use with toolholderd <strong>Type</strong> BU11 1B111Mini — Ø.433"XD minsR 2R1R155˚5˚EToolholder faceWhitworth pipe thread as perDIN ISO 228;(259) and 2999R = Right hand version shownL = Left hand versionPart number tpi Pitch R 1 R 2 E s f d D minin mmCarbide gradesMG12TN35TI25TF45R/L 111.1118.14 14 1.8 mm .009 .009 .098 .161 .264 .315 .433R/L 111.0813.19 1 9 1 .3 mm .007 .007 .1 1 4 .1 61 .264 .31 5 .433State R or L version.Dimensions in inch/mm· StandardSemistandardPlease check price anddelivery for all itemsB28In the UNITED STATES call us toll free

GROOVING Internal —Ø.630"BCARTRIDGE type125, 145for customized toolsBore Ø from .787"Depth of groove up to .1 69"Width of groove up to .1 57"hh 1AAl 2cGD minBt maxTHhfor use with insert<strong>Type</strong> U111/111U116/116d minfbe 1g20˚A−Al 1Right hand insert shownPart number h h 1 f l 1 l 2 e 1 c g D min t max Width ofgroove wInsertR/L 1 25.0608.00 .394 .236 .441 1 .1 81 .1 97 .504 .039 .1 77 .787 .091 .020 − .125 111R/L 145.1012.00 .669 .394 .657 1.417 .197 .543 .039 .260 1.260 .169 .020 - .157 116Heightof cutting edge h 1For cartridge 1 25.0608.00 special height h 1 = .1 97" available upon requestForcartridge145.1012.00specialheighth 1 = .236" or .276" available upon requestDimensions in inchSeating sizes H T B G d min hR/L 125.0608.00 .236 .177 .335 M4 .630 .394R/L 145.1012.00 .394 .354 .472 M6 1 .024 .669State R or L versionDimensions in inchSpare partsCartridge Screw Torx screw driver Adjusting screw axial Fastening screwR/L 1 25.0608.00 3.5.12T1 0E T1 0 4.06.020 4.1 2.1 25R/L 1 45.1 01 2.00 5.13T20E T20 4.06.020 6.20.232In the UNITED STATES call us toll freeB63

TECHNICAL INFORMATIONS − ThreadingRECOMMENDED NUMBER OF PASSESCarbide grade Steel (thousands oflb/in 2 ) Stainl.steel Cast iron AluminiumTN35 58−72 72−1 01 1 01 −1 23 1 23−1 67 > 1 67Vmaxfeet/min 525 460 390 300 230 300 330 980Pitchmm tpiNo. ofpasses0,8 32 8 8 9 9 1 0 1 0 9 81,0 24 10 10 12 12 12 12 12 101,25 20−19 12 12 14 14 15 15 14 121,5 16 15 15 17 17 18 18 17 151,75 14 17 17 19 19 21 21 18 172,0 1 2−1 1 1 9 20 22 22 25 25 20 1 82,5 10 22 24 26 26 31 31 22 203,0−3,5 8 28 30 32 32 38 38 24 22FEED DIRECTION AND SPINDLE ROTATION for internal threadingRight hand thread (internal)Left hand thread (internal)RIGHT HAND TOOLINGLEFT HAND TOOLINGLEFT HAND TOOLINGRIGHT HAND TOOLINGIN−FEEDRADIAL IN−FEEDMetal removed on both sides ofthe insertsimultaneously. Themost commonly used method for thread production.MODIFIED FLANK IN−FEEDLess wear of the trailing edge and better surface finish oncorresponding flank.radial in−feedmodified flank in−feedALTERNATING FLANK IN−FEEDBoth edges are being fully utilised which means longerinsert life.Technical InstructionsFLANK IN−FEEDMore easily formed chip and better heat dissipation.B64alternating flank−in feedIn the UNITED STATES call us toll freeflank in−feedAll threads up to 4.5˚ helix angle can be manufactured with HORN standard threading inserts.No special anvils will be necessary.

TECHNICAL INSTRUCTIONSABSEATINGSof MINI as well as SUPER − MINI guarantee the accurate center height of these tools.In spite ofthis always check center height because a difference may cause problemsespecially when machining small diameters.TORQUE OF SCREWS FOR MINIFollowing torques are allowed for screws of MINI inserts. We recommend not to use additionalmeans (such as copper paste) for screws.Screw T8(type108) T10(type111) T15(type114) T20(type116)Torque lbf-in. 9 − 1 3 22 − 26 35 − 40 50 − 55REMOVAL OF CHIPSPlease choose inserts with small cutting widths, which helps chips evacuation and chip flowout of the bore beside the tool. To avoid jam of chips use the technique to groove by steps.COOLANTUse a filtered coolant for transporting the chips out and for cooling the insert itself.A coolant pressure of75 psi min. is recommended.UNCOATED GRADESMG1 2 −a universal grade with good wear resistance. Used at low or medium cutting speeds formachining steel, cast iron and non ferrous materials.COATED GRADESTN35 −TI25 −TF45 −a very popular grade TIN coated used to low or medium cutting speeds. Also recommendedfor machining stainless steel or exotic alloyed materials.a TICN coated grade with high abrasion resistance. Recommended for machining steel andnon ferrous materials at medium cutting speeds.a TIALN coated grade. This coating has a very high temperature stability and high hardness.Machining small bores, therefore it is only used for special applications.In the UNITED STATES call us toll freeB65

GRADES and CUTTING SPEEDSwear resistancecutting speedtoughnessCarbide grades synthetic cutting-tool materialuncoated coatedPD1 0PD20TF45TI25MG1 2TN35 TF45MG1 2CB1 0feedrateCB20ISOANSINnon ferrous metalhigh temperaturematerialsSHhardened materialswear resistancecutting speedtoughnessfeedrateCarbide gradesuncoated coatedMG1 2TN35TI25MG1 2TN35 TI25TI25MG1 2TN35TF45TF45TF450110203040102030Technical Instructions4001102030C8C7C5----C4C3C2C1B66ANSIISOC8C7C5----C4C3C2C101102030401020304001102030Psteel stainless steel grey cast iron / aluminiumMIn the UNITED STATES call us toll freeK

GRADES and CUTTING SPEEDSABNominal cutting speeds with HORN gradesISO Material SUPERMINI® MINIFeed rates IPRHardnessBrinell.0004 − .0008 .0004 − .001 2.0008 − .0020 .0012 − .0040.0008 − .0020 .0004 − .0012Cutting speed *Vc ft/minPHB MG1 2 TN35 TI25 TF45 CB1 0/CB20Non−alloy carbon steelC 0,4% < 0,6% 1 50 45 − 360 45 − 590 45 − 590 45 − 590C > 0,6% < 0,8% 200Low−alloy steelAnnealed 1 80Hardened and tempered 275 50 − 300 50 − 500 50 − 500Hardened and tempered 300High−alloy steelAnnealed 200Hardened 32560−30060−300Steel castingsNon−alloy 1 80Low−alloy 200 60 − 360 60 − 590 60 − 590High−alloy 225Stainless steel, annealedMartensitic / ferritic 200 60 − 300 60 - 300MStainless steelAustenitic Ni > 8% 1 80 50 − 265Cr 1 8−25%Grey cast iron 1 80 − 260 50 − 300 50 − 500 50 − 500 50 − 500KModular SG iron 1 80 − 260 50 − 300 50 − 430 50 − 430 50 − 500Malleable iron 1 30 − 230 50 − 430 50 − 430 50 − 500Heat resistant alloys (NiFe) 60 - 250 60 - 250SHeat resistant alloys (NiCo) 60 - 1 30 60 - 1 30Aluminium alloys 50 − 725 50 − 2000 50 − 2000NBronze−brass alloys 50 − 725 50 − 2300 50 − 2300Hhardended materials>54HRC65 - 460*Vcis depending on the bore diameter and therefore ofthe maximum numbers ofrevolutions ofthe machine.In the UNITED STATES call us toll freeB67