You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

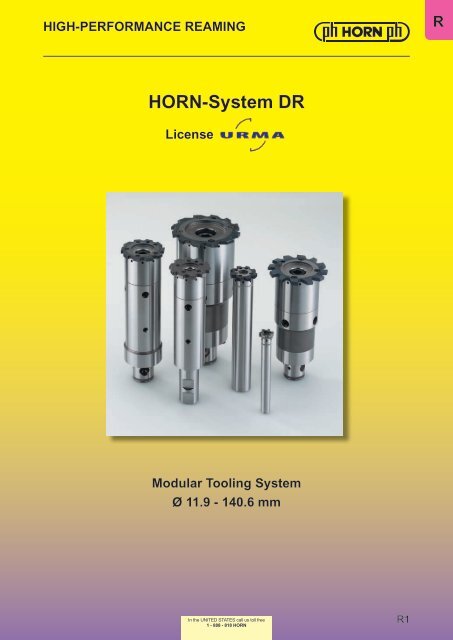

HIGH-PERFORMANCE REAMINGR<strong>HORN</strong>-<strong>System</strong> <strong>DR</strong>LicenseModular Tooling <strong>System</strong>Ø 11.9 - 140.6 mmIn the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>R1

RHIGH-PERFORMANCE REAMINGINSERT type<strong>DR</strong>straight flutedCutting edge Ø Ds11.900 - 140.600 mmfor through hole and blind holefor use with Reaming insert holdertypeM<strong>DR</strong>A<strong>DR</strong>Right hand version shownPart numberExample:Ds Size Z recommended carbide grades recommended cermetgradesMG10HL3HAC4HAC5HAN2HAN4HAD3HDT2HH20HL38AD48AC48AC58HL38DT28<strong>DR</strong>.016...Straight 11.900 - 15.600 016 6 • • • • • • • • • • • • • • •<strong>DR</strong>.019...Straight 15.601 - 18.600 019 6 • • • • • • • • • • • • • • •<strong>DR</strong>.024...Straight 18.601 - 23.600 024 6 • • • • • • • • • • • • • • •<strong>DR</strong>.029...Straight 23.601 - 28.600 029 8 • • • • • • • • • • • • • • •<strong>DR</strong>.036...Straight 28.601 - 35.600 036 8 • • • • • • • • • • • • • • •<strong>DR</strong>.044...Straight 35.601 - 43.600 044 8 • • • • • • • • • • • • • • •<strong>DR</strong>.052...Straight 43.601 - 51.600 052 10 • • • • • • • • • • • • • • •<strong>DR</strong>.061...Straight 51.601 - 60.600 061 10 • • • • • • • • • • • • • • •<strong>DR</strong>.081...Straight 60.601 - 80.600 081 12 • • • • • • • • • • • • • • •<strong>DR</strong>.101...Straight 80.601 - 100.600 101 12 • • • • • • • • • • • • • • •<strong>DR</strong>.121...Straight 100.601 - 120.600 121 12 • • • • • • • •<strong>DR</strong>.141...Straight 120.601 - 140.600 141 12 • • • • • • • •Dimensions in mm - according customers‘ requirements -Contact <strong>HORN</strong> <strong>USA</strong> for further information.R2In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>

HIGH-PERFORMANCE REAMINGRINSERT type<strong>DR</strong>left helical flutedCutting edge Ø Ds11.900 - 140.600 mmThrough holefor use with Reaming insert holdertypeM<strong>DR</strong>A<strong>DR</strong>Right hand version shownPart numberExample:Ds Size Z recommended carbide grades recommended cermetgradesMG10HL3HAC4HAC5HAN2HAN4HAD3HDT2HH20HL38AD48AC48AC58HL38DT28<strong>DR</strong>.016...Helical 11.900 - 15.600 016 6 • • • • • • • • • • • • • • •<strong>DR</strong>.019...Helical 15.601 - 18.600 019 6 • • • • • • • • • • • • • • •<strong>DR</strong>.024...Helical 18.601 - 23.600 024 6 • • • • • • • • • • • • • • •<strong>DR</strong>.029...Helical 23.601 - 28.600 029 8 • • • • • • • • • • • • • • •<strong>DR</strong>.036...Helical 28.601 - 35.600 036 8 • • • • • • • • • • • • • • •<strong>DR</strong>.044...Helical 35.601 - 43.600 044 8 • • • • • • • • • • • • • • •<strong>DR</strong>.052...Helical 43.601 - 51.600 052 10 • • • • • • • • • • • • • • •<strong>DR</strong>.061...Helical 51.601 - 60.600 061 10 • • • • • • • • • • • • • • •<strong>DR</strong>.081...Helical 60.601 - 80.600 081 12 • • • • • • • • • • • • • • •<strong>DR</strong>.101...Helical 80.601 - 100.600 101 12 • • • • • • • • • • • • • • •<strong>DR</strong>.121...Helical 100.601 - 120.600 121 12 • • • • • • • •<strong>DR</strong>.141...Helical 120.601 - 140.600 141 12 • • • • • • • •Dimensions in mm - according customers‘ requirements -Contact <strong>HORN</strong> <strong>USA</strong> for further information.In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>R3

RHIGH-PERFORMANCE REAMINGREAMING INSERT HOLDER TypeM<strong>DR</strong>with through coolant supplyCutting edge Ø11.900 - 35.600 mmMaterial of shank: HM = Carbide ST = Steelfor use with InsertType<strong>DR</strong>Form A =Cylindrical shank DIN 1835-APart number Ds Ds maxl 1d b Form SizeM<strong>DR</strong>.016.ST10.100.A.D/S10060M<strong>DR</strong>.016.HM10.160.A.D/S 11.900 15.600 160 10 120 A 016M<strong>DR</strong>.016.ST10.160.A.D/S 160 120M<strong>DR</strong>.019.ST12.115.A.D/S11570M<strong>DR</strong>.019.HM12.185.A.D/S 15.601 18.600 185 12 140 A 019M<strong>DR</strong>.019.ST12.185.A.D/S 185 140M<strong>DR</strong>.024.ST16.128.A.D/S12880M<strong>DR</strong>.024.HM16.208.A.D/S 18.601 23.600 208 16 160 A 024M<strong>DR</strong>.024.ST16.208.A.D/S 208 160M<strong>DR</strong>.029.ST20.145.A.D/S14595M<strong>DR</strong>.029.HM20.240.A.D/S 23.601 28.600 240 20 190 A 029M<strong>DR</strong>.029.ST20.240.A.D/S 240 190M<strong>DR</strong>.036.ST25.170.A.D/S170110M<strong>DR</strong>.036.HM25.274.A.D/S 28.601 35.600 274 25 214 A 036M<strong>DR</strong>.036.ST25.274.A.D/S 274 214State D or S version Further sizes upon request Dimensions in mm1 Set of screws, 1 Torx wrench - no separate order required!For torque specifications of the screw, please see Technical Instructions.Spare partsReaming insert holderScrewM<strong>DR</strong>.016-019...M<strong>DR</strong>.024-036...C009000C009001R4In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>

HIGH-PERFORMANCE REAMINGRREAMING INSERT HOLDER TypeM<strong>DR</strong>with through coolant supplyCutting edge Ø35.601 - 140.600 mmfor use with InsertType<strong>DR</strong>Form V =for use with shank type V<strong>DR</strong>, allowingfor “0” runout adjustment.Part number Ds Ds maxl 1d 2Form SizeM<strong>DR</strong>.044.32.30.V.D/S 35.601 43.600 30 32 V 044M<strong>DR</strong>.052.39.35.V.D/S 43.601 51.600 35 39 V 052M<strong>DR</strong>.061.46.40.V.D/S 51.601 60.600 40 46 V 061M<strong>DR</strong>.081.56.50.V.D/S 60.601 80.600 50 56 V 081M<strong>DR</strong>.101.76.60.V.D/S 80.601 100.600 60 76 V 101M<strong>DR</strong>.121.76.60.V.D/S 100.601 120.600 60 76 V 121M<strong>DR</strong>.141.76.60.V.D/S 120.601 140.600 60 76 V 141State D or S versionFurther sizes upon requestDimensions in mm1 Set of screws, 1 Torx wrench - no separate order required!For torque specifications of the screw, please see Technical Instructions.Spare partsReaming insert holderScrewM<strong>DR</strong>.044-061...M<strong>DR</strong>.081-141...C009002C009004In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>R5

RHIGH-PERFORMANCE REAMINGSHANK TypeV<strong>DR</strong>with integrated compensationmechanismCutting edge Ø35.601 - 60.600 mmfor use with InsertType<strong>DR</strong>FormA = Cylindrical shank DIN 1835-AB = Weldon shank DIN 1835-BE = Whistle-Notch DIN 1835-EBM = URMA Beta Modul (ABS)Part number Ds Ds maxl 1d 2d Form SizeV<strong>DR</strong>.044.32.55.20.A20 AV<strong>DR</strong>.044.32.55.20.B 20 B35.601 43.600 55 32V<strong>DR</strong>.044.32.55.20.E 20 EV<strong>DR</strong>.044.32.55.32.BM 32 BMV<strong>DR</strong>.044.32.80.20.A20 AV<strong>DR</strong>.044.32.80.20.B 20 B35.601 43.600 80 32V<strong>DR</strong>.044.32.80.20.E 20 EV<strong>DR</strong>.044.32.80.32.BM 32 BMV<strong>DR</strong>.052.39.60.25.A25 AV<strong>DR</strong>.052.39.60.25.B 25 B43.601 51.600 60 39V<strong>DR</strong>.052.39.60.25.E 25 EV<strong>DR</strong>.052.39.60.40.BM 40 BMV<strong>DR</strong>.052.39.100.25.A25 AV<strong>DR</strong>.052.39.100.25.B 25 B43.601 51.600 100 39V<strong>DR</strong>.052.39.100.25.E 25 EV<strong>DR</strong>.052.39.100.40.BM 40 BMV<strong>DR</strong>.061.46.70.32.A32 AV<strong>DR</strong>.061.46.70.32.B 32 B51.601 60.600 70 46V<strong>DR</strong>.061.46.70.32.E 32 EV<strong>DR</strong>.061.46.70.50.BM 50 BMV<strong>DR</strong>.061.46.120.32.A32 AV<strong>DR</strong>.061.46.120.32.B 32 B51.601 60.600 120 46V<strong>DR</strong>.061.46.120.32.E 32 EV<strong>DR</strong>.061.46.120.50.BM 50 BMFurther sizes upon requestSpare parts see page R7044044052052061061Dimensions in mmR6In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>

HIGH-PERFORMANCE REAMINGRSHANK TypeV<strong>DR</strong>with integrated compensationmechanismCutting edge Ø60.601 - 140.600 mmfor use with InsertType<strong>DR</strong>FormA = Cylindrical shank DIN 1835-AB = Weldon shank DIN 1835-BE = Whistle-Notch DIN 1835-EBM = URMA Beta Modul (ABS)Part number Ds Ds maxl 1d 2d Form SizeV<strong>DR</strong>.081.56.80.40.A40 AV<strong>DR</strong>.081.56.80.40.B 40 B60.601 80.600 80 56V<strong>DR</strong>.081.56.80.40.E 40 EV<strong>DR</strong>.081.56.80.50.BM 50 BMV<strong>DR</strong>.081.56.140.40.A40 AV<strong>DR</strong>.081.56.140.40.B 40 B60.601 80.600 140 56V<strong>DR</strong>.081.56.140.40.E 40 EV<strong>DR</strong>.081.56.140.50.BM 50 BMV<strong>DR</strong>.101.76.100.40.A40 AV<strong>DR</strong>.101.76.100.40.B 40 B80.601 140.600 100 76V<strong>DR</strong>.101.76.100.40.E 40 EV<strong>DR</strong>.101.76.100.63.BM 63 BMV<strong>DR</strong>.101.76.160.40.A40 AV<strong>DR</strong>.101.76.160.40.B 40 B80.601 140.600 160 76V<strong>DR</strong>.101.76.160.40.E 40 EV<strong>DR</strong>.101.76.160.63.BM 63 BMFurther sizes upon request081081101 / 141101 / 141Dimensions in mmSpare partsExtensionAdjustmentScrewBoltLocating pinV<strong>DR</strong>.044... C009008 Z003221 Z003223V<strong>DR</strong>.052 C009010 Z004021 Z004023V<strong>DR</strong>.061 C009010 Z005021 Z005023V<strong>DR</strong>.081 C009012 Z005021 Z005023V<strong>DR</strong>.101 C009016 Z006321 Z006323In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>R7

RADDITIONAL EQUIPMENTEXTENSION TypeVAM/VBMfor alpha- and beta-modulesCutting edge ØDs 35.601 - 140.600 mmPart number alpha-modul beta-modul Lgd d 1Weight SWVAM.1818.02525VAM.1818.03518.535Further sizes upon request18.5 18.5 0.1kg 17VBM.2525.045 25 45 25.0 25.0 0.2 kgVBM.3232.035 32 35 32.0 32.0 0.2 kgVBM.3232.070 32 70 32.0 32.0 0.4 kgVBM.4040.045 40 45 42.0 42.0 0.4 kgVBM.4040.070 40 70 42.0 42.0 0.7 kgVBM.5050.065 50 65 50.0 50.0 1.0 kgVBM.5050.100 50 100 50.0 50.0 1.5 kgVBM.6363.060 63 60 63.0 63.0 1.3 kgVBM.6363.125 63 125 63.0 63.0 2.9 kgDimensions in mm-Spare partsExtension Locating pin Screw Bolt Threaded pin KeyVBM.2525.045 Z002523 Z002521 Z002524VBM.3232.035/070 Z003223 Z003221 Z003224VBM.4040.045/070 Z004023 C002258 Z004021 Z004024 Z004025VBM.5050.065/100 Z005023 C002260 Z005021 Z005024 Z005025VBM.6363.060/125 Z006323 C002205 Z006321 Z006324 Z006325R8In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>

ADDITIONAL EQUIPMENTRREDUCER TypeRAM/RBMfor alpha- and beta-modulesCutting edge ØDs 35.601 - 140.600 mmPart number alpha-modul beta-modul Lgl d d 1Weight SWRAM.2518.040 18.5 25 40 25 18.5 25 0.1kg 17RBM.3225.040 32 / 25 40 25 25.0 32 0.2 kgRBM.4025.040 40 / 25 40 25 25.0 42 0.3 kgRBM.4032.040 40 / 32 45 30 32.0 42 0.3 kgRBM.5040.050 50 / 40 50 35 42.0 50 0.5 kgRBM.6325.045 63 / 25 45 25 25.0 63 0.7 kgRBM.6332.050 63 / 32 50 30 32.0 63 0.9 kgRBM.6340.055 63 / 40 55 35 42.0 63 1.1 kgFurther sizes upon requestDimensions in mm-Spare partsReducer Locating pin Screw Bolt Threaded pin KeyRAM.2518.040 Z002523 Z002521 Z002524RBM.3225.040 Z003223 Z003221 Z003224RBM.4025.040 Z002523 C002258 Z002521 Z004024 Z004025RBM.4032.040 Z003223 C002258 Z004021 Z004024 Z004025RBM.5040.050 Z004023 C002258 Z004021 Z004024 Z004025RBM.6325.045 Z006323 C002205 Z006321 Z006324 Z006325RBM.6332.050 Z006323 C002205 Z006321 Z003224 Z006325RBM.6340.055 Z004023 C002205 Z004021 Z004024 Z004025In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>R9

RHIGH-PERFORMANCE REAMINGSYSTEM HOLDER URMA TypeBDBeta Module 25/32/40/50/63/80/100Cutting edge ØDs 35.601 - 140.600 mmCAT compatible / Metric retention threadsPart number beta-modul Lgl d Weight <strong>System</strong>BD1040A25050 25 50 31 25 0.8 kgBD1040A32050 32 50 31 35 0.9 kgBD1040A40035 40 35 16 42 0.9 kgBD1040A40050 40 50 31 42 1.1 kgBD1040A50050 50 50 31 50 1.2 kgBD1040A63065 63 65 46 63 1.5 kgBD1040A63090 63 90 70 63 2.0 kgBD1050A25060 25 60 41 25 2.8 kgBD1050A32060 32 60 41 32 2.9 kgBD1050A40060 40 60 41 42 3.0 kgBD1050A50060 50 60 41 50 3.2 kgBD1050A63060 63 60 41 63 3.3 kgBD1050A80070 80 70 51 50 4.0 kgBD1050A100115 100 115 96 50 6.9 kgSpare partsSK40SK50Dimensions in mm<strong>System</strong> Holder URMAThreaded pinBD10...A25...BD10...A32...BD10...A40...BD10...A50...BD10...A63...BD1050A100115BD1050A80070Z002524Z003224Z004024Z005024Z006324Z0010024Z008024R10In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>

HIGH-PERFORMANCE REAMINGRSYSTEM HOLDER URMA TypeBDBeta Module 25/32/40/50/63/80/100Cutting edge ØDs 35.601 - 140.600 mmCAT compatible / Metric retention threadsPart number beta-modul Lgl d Weight <strong>System</strong>BD1040B25050 25 50 31 25 0.8 kgBD1040B32050 32 50 31 35 0.9 kgBD1040B40035 40 35 16 42 0.9 kgBD1040B40050 40 50 31 42 1.1 kgBD1040B50050 50 50 31 50 1.2 kgBD1040B63065 63 65 46 63 1.5 kgBD1040B63090 63 90 70 63 2.0 kgBD1050B25060 25 60 41 25 2.8 kgBD1050B32060 32 60 41 32 2.9 kgBD1050B40060 40 60 41 42 3.0 kgBD1050B50060 50 60 41 50 3.2 kgBD1050B63060 63 60 41 63 3.3 kgBD1050B80070 80 70 51 80 4.0 kgBD1050B100115 100 115 96 100 6.9 kgSpare partsSK40SK50Dimensions in mm<strong>System</strong> Holder URMAThreaded pinBD10...B25...BD10...B32...BD10...B40...BD10...B50...BD10...B63...BD1050B100115BD1050B80070Z002524Z003224Z004024Z005024Z006324Z0010024Z008024In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>R11

RHIGH-PERFORMANCE REAMINGSYSTEM HOLDER URMA TypeBIBeta Module 40/63/100Cutting edge ØDs 35.601 - 140.600 mmPart number beta-modul Lgl d Weight <strong>System</strong>BI104040035 40 35 23 42 0.7 kgBI104040050 40 50 38 42 1.1 kgBI104063070 63 70 58 63 1.8 kgBI105040060 40 60 45 42 3.0 kgBI105063060 63 60 45 63 3.5 kgBI1050100100 100 100 85 100 6.8 kgSK40SK50Dimensions in mmSpare parts<strong>System</strong> Holder URMAThreaded pinBI10...40...BI10...63...BI1050100100Z004024Z006324Z0010024R12In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>

HIGH-PERFORMANCE REAMINGRSYSTEM HOLDER URMA TypeBTBeta Module 25/32/40/50/63/80/100Cutting edge ØDs 35.601 - 140.600 mmPart number beta-modul Lgl d Weight <strong>System</strong>BT1040A25060 25 60 33 25 0.8 kgBT1040A32060 32 60 33 32 0.9 kgBT1040A40028 40 28 1 42 0.9 kgBT1040A40060 40 60 33 42 1.2 kgBT1040A50060 50 60 33 50 1.3 kgBT1040A63055 63 55 28 63 1.4 kgBT1040A63070 63 70 43 63 1.7 kgBT1050A32070 32 70 32 32 3.7 kgBT1050A40070 40 70 32 42 3.9 kgBT1050A50070 50 70 32 50 4.1 kgBT1050A63080 63 80 42 63 4.3 kgBT1050A80100 80 100 62 80 5.5 kgBT1050A100100 100 110 72 100 7.0 kgSK40SK50Dimensions in mmSpare parts<strong>System</strong> Holder URMAThreaded pinBT1040A25060BT10...A32...BT10...A40...BT10...A50...BT10...A63...BT1050A100100BT1050A80100Z002524Z003224Z004024Z005024Z006324Z0010024Z008024In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>R13

RHIGH-PERFORMANCE REAMINGSYSTEM HOLDER URMA TypeBHBeta Module 25/32/40/50/63/80/100Cutting edge ØDs 35.601 - 140.600 mmPart number beta-modul Lgl d Weight <strong>System</strong>BH1050A25055 25 55 29 25 0.5 kgBH1050A32060 32 60 34 32 0.6 kgBH1050A40065 40 65 39 42 0.7 kgBH1063A25055 25 55 29 25 0.9 kgBH1063A32060 32 60 34 32 1.0 kgBH1063A40065 40 65 23 42 1.1 kgBH1063A50070 50 70 44 50 1.5 kgBH1063A63080 63 80 38 63 1.5 kgBH10100A40080 40 80 35 42 2.3 kgBH10100A50080 50 80 35 50 2.5 kgBH10100A63080 63 80 35 63 2.8 kgBH10100A80090 80 90 45 80 3.8 kgBH10100A100100 100 100 55 100 4.0 kgSpare partsHSK50HSK63HSK100Dimensions in mm<strong>System</strong> Holder URMA Threaded pin Coolant tubeOrdering note:Coolant tube is not included - separate order required!BH10100A100100 Z0010024 H0010001BH10100A40080 Z004024 H0010001BH10100A50080 Z005024 H0010001BH10100A63080 Z006324 H0010001BH10100A80090 Z008024 H0010001BH1050A25055 Z002524 H005001BH1050A32060 Z003224 H005001BH1050A40065 Z004024 H005001BH1063A25055 Z002524 H006301BH1063A32060 Z003224 H006301BH1063A40065 Z004024 H006301BH1063A50070 Z005024 H006301BH1063A63080 Z006324 H006301R14In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>

HIGH-PERFORMANCE REAMINGRDIRECT MOUNTING URMA TypeV<strong>DR</strong>with integrated compensationmechanismCutting edge Ø35.601-100.600 mmCAT compatible / Metric retention threadsPart number l Lgd Weight <strong>System</strong> SizeV<strong>DR</strong>.044.065.40AD 46 65 32 1.1 kg044V<strong>DR</strong>.052.065.40AD 46 65 39 1.2 kg 052V<strong>DR</strong>.061.075.40AD 56 75 46 1.4 kg SK40061V<strong>DR</strong>.081.080.40AD 61 80 56 1.6 kg 081V<strong>DR</strong>.101.095.40AD 76 95 76 2.2 kg 101V<strong>DR</strong>.044.065.50AD 46 65 32 2.9 kg044V<strong>DR</strong>.052.065.50AD 46 65 39 3.0 kg 052V<strong>DR</strong>.061.075.50AD 56 75 46 3.2 kg SK50061V<strong>DR</strong>.081.080.50AD 66 80 56 3.6 kg 081V<strong>DR</strong>.101.095.50AD 76 95 76 4.6 kg 101Further sizes upon requestDimensions in mmSpare partsExtensionV<strong>DR</strong>.044...V<strong>DR</strong>.052V<strong>DR</strong>.061V<strong>DR</strong>.081V<strong>DR</strong>.101AdjustmentScrewC009008C009010C009010C009012C009016In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>R15

RHIGH-PERFORMANCE REAMINGDIRECT MOUNTING URMA TypeV<strong>DR</strong>with integrated compensationmechanismCutting edge Ø35.601-100.600 mmCAT compatible / Metric retention threadsPart number l Lgd Weight <strong>System</strong> SizeV<strong>DR</strong>.044.065.40BD 46 65 32 1.1 kg044V<strong>DR</strong>.052.065.40BD 46 65 39 1.2 kg 052V<strong>DR</strong>.061.075.40BD 56 75 46 1.4 kg SK40061V<strong>DR</strong>.081.080.40BD 61 80 56 1.6 kg 081V<strong>DR</strong>.101.095.40BD 76 95 76 2.2 kg 101V<strong>DR</strong>.044.065.50BD 46 65 32 2.9 kg044V<strong>DR</strong>.052.065.50BD 46 65 39 3.0 kg 052V<strong>DR</strong>.061.075.50BD 56 75 46 3.2 kg SK50061V<strong>DR</strong>.081.085.50BD 66 85 56 3.6 kg 081V<strong>DR</strong>.101.095.50BD 76 95 76 4.6 kg 101Further sizes upon requestDimensions in mmExtensionV<strong>DR</strong>.044...V<strong>DR</strong>.052V<strong>DR</strong>.061V<strong>DR</strong>.081V<strong>DR</strong>.101AdjustmentScrewC009008C009010C009010C009012C009016R16In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>

HIGH-PERFORMANCE REAMINGRDIRECT MOUNTING URMA TypeV<strong>DR</strong>with integrated compensationmechanismCutting edge Ø35.601-100.600 mmPart number l Lgd Weight <strong>System</strong> SizeV<strong>DR</strong>.044.060.40BT 33 60 32 1.1 kg044V<strong>DR</strong>.052.065.40BT 38 65 39 1.3 kg 052V<strong>DR</strong>.061.070.40BT 43 70 46 1.4 kg SK40061V<strong>DR</strong>.081.080.40BT 53 80 56 1.7 kg 081V<strong>DR</strong>.101.095.40BT - 95 76 2.5 kg 101V<strong>DR</strong>.044.065.50BT 27 65 32 3.7 kg044V<strong>DR</strong>.052.065.50BT 27 65 39 3.8 kg 052V<strong>DR</strong>.061.075.50BT 37 75 46 4.0 kg SK50061V<strong>DR</strong>.081.085.50BT 47 85 56 4.3 kg 081V<strong>DR</strong>.101.095.50BT 57 95 76 5.1 kg 101Further sizes upon requestDimensions in mmExtensionV<strong>DR</strong>.044...V<strong>DR</strong>.052V<strong>DR</strong>.061V<strong>DR</strong>.081V<strong>DR</strong>.101AdjustmentScrewC009008C009010C009010C009012C009016In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>R17

RHIGH-PERFORMANCE REAMINGDIRECT MOUNTING URMA TypeV<strong>DR</strong>with integrated compensationmechanismCutting edge Ø35.601-100.600 mmPart number l Lgd Weight <strong>System</strong> SizeV<strong>DR</strong>.044.085.A063 59 85 32 1.0 kg044V<strong>DR</strong>.052.090.A063 64 90 39 1.2 kg 052V<strong>DR</strong>.061.100.A063 74 100 46 1.5 kg HSK63061V<strong>DR</strong>.081.105.A063 79 105 56 1.8 kg 081V<strong>DR</strong>.101.120.A063 94 120 76 2.4 kg 101V<strong>DR</strong>.044.090.A100 61 90 32 2.3 kg044V<strong>DR</strong>.052.095.A100 66 95 39 2.6 kg 052V<strong>DR</strong>.061.100.A100 71 100 46 2.8 kg HSK100 061V<strong>DR</strong>.081.120.A100 91 120 56 3.5 kg 081V<strong>DR</strong>.101.130.A100 101 130 76 5.0 kg 101Further sizes upon requestDimensions in mmExtensionAdjustmentScrewCoolant tubeCoolant tubeV<strong>DR</strong>.044... C009008 H006301 H0010001V<strong>DR</strong>.052 C009010 H006301 H0010001V<strong>DR</strong>.061 C009010 H006301 H0010001V<strong>DR</strong>.081 C009012 H006301 H0010001V<strong>DR</strong>.101 C009016 H006301 H0010001R18In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>

ADJUSTABLE HY<strong>DR</strong>AULIC EXPANSIONTOOLHOLDERRSYSTEM HOLDER Type<strong>DR</strong>HDAdjustable run-out, with axial length adjustment,for automatic tool changeHSK ADIN69882-7Part number l 1l 2l4l 5X d 1d 2d 3d 4Weight <strong>System</strong><strong>DR</strong>HD.12.A063 85 46 40 59 39 12 32 50 28 1.1 kg<strong>DR</strong>HD.20.A063 90 51 48 64 39 20 42 50 38 1.3 kg<strong>DR</strong>HD.32.A063 125 61 63 99 64 32 64 75 60 2.7 kg<strong>DR</strong>HD.12.A100 95 46 47 66 49 12 32 50 28 2.6 kg<strong>DR</strong>HD.20.A100 105 51 59 76 54 20 42 50 38 2.8 kg<strong>DR</strong>HD.32.A100 110 61 62 81 49 32 64 75 60 3.8 kgHSK-A 63HSK-A 100Dimensions in mmOrdering note:Coolant tube is not included - separate order required!Spare parts<strong>System</strong> Holder Screw TORX PLUS ® Wrench Coolant tube<strong>DR</strong>HD....A063 6.075T15P T15PQ H006301<strong>DR</strong>HD....A100 6.075T15P T15PQ H0010001In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>R19

RADJUSTABLE HY<strong>DR</strong>AULIC EXPANSIONTOOLHOLDERSYSTEM HOLDER Type<strong>DR</strong>HDAdjustable run-out, with axial length adjustment, forautomatic tool changeSKDIN69871 AD/BPart number l 1l 2l4l 5X d 1d 2d 3d 4Weight <strong>System</strong><strong>DR</strong>HD.12.040B<strong>DR</strong>HD.20.040B 80.5465131.534.0 61.534.529.51220324249.549.528381.4 kg1.4 kg<strong>DR</strong>HD.32.040B 61 25.5 19.5 32 63 80.0 60 2.0 kg<strong>DR</strong>HD.12.050B Upon request 12 Upon request<strong>DR</strong>HD.20.050B 80.5 51 34.0 61.5 29.5 20 42 49.5 38 3.3 kg<strong>DR</strong>HD.32.050B Upon request 32 Upon requestSK 40SK 50Dimensions in mmSpare parts<strong>System</strong> Holder Screw TORX PLUS ® Wrench<strong>DR</strong>HD.... 6.075T15P T15PQR20In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>

ADJUSTABLE HY<strong>DR</strong>AULIC EXPANSIONTOOLHOLDERRSYSTEM HOLDER Type<strong>DR</strong>HDAdjustable run-out, with axial length adjustment, forautomatic tool changeJIS-BT JIS B 6339Part number l 1l 2l4l 5X d 1d 2d 3d 4Weight <strong>System</strong><strong>DR</strong>HD.12.BT4046 44.544 12 3228 1.4 kg<strong>DR</strong>HD.20.BT409051 47.56339 20 4244.538 1.5 kg<strong>DR</strong>HD.12.BT50 90 46 34.0 52 44 12 32 44.5 28 4.0 kg<strong>DR</strong>HD.20.BT50 90 51 34.0 52 39 20 42 44.5 38 4.0 kg<strong>DR</strong>HD.32.BT50 Upon request 32 Upon requestJIS-BT 40JIS-BT 50Dimensions in mmSpare parts<strong>System</strong> Holder Screw TORX PLUS ® Wrench<strong>DR</strong>HD.... 6.075T15P T15PQIn the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>R21

RADJUSTABLE HY<strong>DR</strong>AULIC EXPANSIONTOOLHOLDERSYSTEM HOLDER Type<strong>DR</strong>HDAdjustable run-out, with axial length adjustment, forautomatic tool change<strong>HORN</strong> Polygon shankaccording to ISO 26623Part number l 1l 2l4X d 1d 2d 3d 4Weight <strong>System</strong><strong>DR</strong>HD.12.C040 81 46 47 35 12 32.0 32.0 28 0.70 kg<strong>DR</strong>HD.20.C040 Upon request 20 Upon request<strong>DR</strong>HD.12.C050 85 46 44 39 12 32.0 32.0 28 0.90 kg<strong>DR</strong>HD.20.C050 90 51 52 39 20 42.0 42.0 38 1.05 kg<strong>DR</strong>HD.32.C050 Upon request 32 Upon request<strong>DR</strong>HD.12.C060 87 46 39 41 12 32.0 50.0 28 1.30 kg<strong>DR</strong>HD.20.C060 97 51 55 46 20 42.0 42.0 38 1.60 kg<strong>DR</strong>HD.32.C060 110 61 62 49 32 62.5 62.5 59 2.80 kgC4C5C6Dimensions in mmSpare parts<strong>System</strong> Holder Screw TORX PLUS ® Wrench<strong>DR</strong>HD.... 6.075T15P T15PQR22In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>

ADJUSTABLE HY<strong>DR</strong>AULIC EXPANSIONTOOLHOLDERRSYSTEM HOLDER Type<strong>DR</strong>HDAdjustable run-out, with axial length adjustment, forautomatic tool changeABS HBeta ModulPart number l 1l 2l4X d 1d 2d 4Weight <strong>System</strong><strong>DR</strong>HD.12.BM50 65 46 45.5 19 12 32 28 0.7 kg<strong>DR</strong>HD.20.BM50 75 51 58.0 24 20 42 38 0.9 kg<strong>DR</strong>HD.32.BM50 Upon request 32 Upon requestABS-H 50Dimensions in mmSpare parts<strong>System</strong> Holder Screw TORX PLUS ® Wrench<strong>DR</strong>HD.... 6.075T15P T15PQIn the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>R23

RADJUSTABLE HY<strong>DR</strong>AULIC EXPANSIONTOOLHOLDERINTERMEDIATE SLEEVE Type<strong>DR</strong>ZBFor internal coolant supplyPart number l 1l 2d 1d 2d 3<strong>DR</strong>ZB12066<strong>DR</strong>ZB120845.0 2 128<strong>DR</strong>ZB2006<strong>DR</strong>ZB200868<strong>DR</strong>ZB2010 50.5 2 2010<strong>DR</strong>ZB2012 12<strong>DR</strong>ZB2016 16<strong>DR</strong>ZB322020<strong>DR</strong>ZB322560.5 3 322516.524.035.5Dimensions in mmR24In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>

HIGH-PERFORMANCE REAMINGRADAPTOR TypeA<strong>DR</strong>Cutting edge Ø.496 - 2.386″ (12.600 - 60.600 mm)for use with InsertType<strong>DR</strong>Part number Ds Ds maxX l 1SizeA<strong>DR</strong>.016.135.01 12.600 15.600 1.5 13.5 016A<strong>DR</strong>.019.140.02 15.601 18.600 1.5 14.0 019A<strong>DR</strong>.024.162.03 18.601 23.600 1.5 16.2 024A<strong>DR</strong>.029.187.04 23.601 28.600 1.5 18.7 029A<strong>DR</strong>.036.190.05 28.601 35.600 1.5 19.0 036A<strong>DR</strong>.044.190.06 35.601 43.600 2.0 19.0 044A<strong>DR</strong>.052.185.06 43.601 51.600 2.0 18.5 052A<strong>DR</strong>.061.185.07 51.601 60.600 2.0 18.5 061Dimensions in mm1 Set of screws, 1 Torx wrench - no separate order required!For torque specifications of the screw, please see Technical Instructions.Spare partsAdaptorScrewA<strong>DR</strong>.01...01/02A<strong>DR</strong>.0...03/04/05A<strong>DR</strong>.0...06/07C009000C009001C009002In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>R25

RUser guideThe information below explains the proper handling and set up for reaming tools.Tool adjustments should be performed directly in themachine/spindle to achieve highest precision.Insert the reamer shaft into the Hydraulic ExpansionToolholder or reducer sleeve until it bottoms out.Tighten the clamping screw of the Hydraulic ExpansionToolholder with a hex wrench.R26In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>

User guideRTurn the four adjusting screws with the TORX-PLUS ®wrench T15PQ until contact, and check the concentricitywith a µm indicator inside the arbor by hand rotating thetool.Adjust the concentricity by turning the adjustment screwson their axis.Lay insert on shaft with positioning hole over the pin andtighten the screws lightly.Tighten the screws with a torque setter screw driver in acrisscross pattern.In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>R27

RUser guideAdjustingTo achieve the best reaming results a tool with zero run-out is desirable. In order to compensate for anyerrors due to run-out from the tool holders or the machine spindle, the following holders are recommendend:compensation holders, hydraulic chucks, or shrink fit holders. <strong>DR</strong> reamers can be measured with differentmethods:Through insert holder short taperWith the reamer disassembled measure directly on the insert holdersshort taper. High accuracy, simple handling. This is the most accurate andpreferred method.Through circular landMeasuring directly behind chamfer angle on external insert diameter.All interface errors are eliminated. This is the preferred method for smalldiameter inserts.On the external diameter of the insert holder<strong>DR</strong> tool holders are manufactured very accurately on all diameters. A methodeasy to handle that offers reasonable measuring results.Shanks with integrated compensation deviceThese shanks with integrated comp. must be used for reamingdiameters bigger than 35 mmR28In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>

User guideRHandlingSecure central locking screw (see value no 1). Measure run-out andset the cutting edge of the insert to the highest point. Compensatehalf of the total run-out by using the adjustment screws. Check runoutand repeat the adjustment if necessary. Secure central lockingsrew according to value 2 in chart below.Parameter Md1Nm2Nm<strong>DR</strong> 044 35 -<strong>DR</strong> 052 35 -<strong>DR</strong> 061 55 -<strong>DR</strong> 081 60 85<strong>DR</strong> 101 60 120<strong>DR</strong> 121 60 120<strong>DR</strong> 141 60 120Changing inserts1. Don't take the shank out of the taper holder. Remove clampingscrews and used insert.2. Clean short taper of the shank carefully and check for possibledamages.3. Set new insert on position (pay attention to the positioning pin)and slightly tighten the clamping screws.4. If available, use the torxtorque screw driver to tighten the screwscrosswise (see torque chart)22Parameter Md Nm<strong>DR</strong> 016 0.75<strong>DR</strong> 019 0.75<strong>DR</strong> 024 1.5<strong>DR</strong> 029 1.5<strong>DR</strong> 036 1.5<strong>DR</strong> 044 1.5<strong>DR</strong> 052 1.5<strong>DR</strong> 061 1.5<strong>DR</strong> 081 3.5<strong>DR</strong> 101 3.5Measuring of insert diameter<strong>DR</strong> inserts have an unequally spaced pitch. To measure the diameter lineup the two marked cutting edges. Measure directly on the chamfered anglebecause the inserts are ground with taper.In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>R29

RMATERIAL COMPARISON TABLEISO Code MaterialP123Unalloyed carbon steelGeneral structural steelLow-alloy carbon steel,Structural-, Cast-hardened-,Tool-, Low-alloy steelAlloyed tool steelNitride steelRmN/mm 2HBHRC< 500 < 160500 - 900 140 - 325800 - 1200 250 - 3503.1 High alloyed steel < 10003.2 High alloyed steel < 16003.3 High speed steelM5 Stainless steel, martenistic 500 - 10005.1 Stainless steel, austenitic5.2 Stainless heat resisting steelK66.16.2N7Grey cast ironAlloyed grey cast ironSpheroidal graphitecast iron (GGG40)Spheroidal graphitecast iron, ferritic/perliticMalleable cast ironAluminium < 10 % Si,Al-wrough alloys> 550< 2507.1 Al-alloys7.2Non ferrous metals, Copper alloys, Brass,Bronze7.3 Titanium7.4 Nickelbased allyosS8 Thermo-plastics, Duroplast8.1 Fibre reinforced plasticsR30In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>

CUTTING MATERIALR<strong>HORN</strong>-GradesISO513 Properties Recommended applicationsCarbideHL3HHCALCrN-CoatingFirst choice for Steel and cast iron. Extremely high hothardness and high resistance against oxidation. Highlubricity with resistance to build up edge. For high cuttingspeed and with coolant or mist coolant. Copper colour.AC4HAC5HHCALCrN-CoatingSimilar coating structure and application range to HL3H.Grey colour.AD3HAD4HHCTiALN-CoatingGood hot hardness and resistance against oxidation withexcellent lubricity properties. For medium to high cuttingspeed and mist coolant. Resistant to build up edge.MG10 HW uncoated(micro grain)Universal grade for most materials at low cutting speed. ForVariopoint only.DT2HHCPVD-DLC-Coating"Diamond-Like-Carbon". Very good lubricity propertiesresistant to build up edge. Excellent chemical stability as wellas very high hardness. Particularly suitable for Aluminumwith less than 12 % Si at medium cutting speed.CermetH20 HT uncoatedReaming of carbon and low alloyed steel of up to 1200 N/mm 2 tensile strength and nodular cast iron at high cuttingspeed. Suitable for interrupted cuts due to high toughness.AD38AD48AC48AC58HL38DT28- coatedCoatings similar to those for carbide with resistance to buildup edge. Application specific combination of substrate,geometry and coatings for improved tool life.In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>R31

RCUTTING DATAISOCodeBore D* Bore *S Recommended radial cutting deptha pLeft HelicalFlutes25°P 1●233.13.23.3●●●●●M 5●5.15.2●●K 6●6.16.2●●N 7●7.17.27.37.4●●●●S 8●StraightFlutes45°●●●●●●●●●●●●●●●●●●Ø

RTROUBLESHOOTING SOLUTIONSFaultHole too largeRemedy1. Reduce run-out error and use compensation holder2. Reduce cutting speed3. <strong>Inc</strong>rease feed rate, increase coolant mix4. Reduce depth of cut5. Check tool wear (especiall build-up edges)6. Control reamer-øTapered hole1. Reduce run-out error and use compensation holder2. Reduce cutting speed and feed, check coolant mix3. Improve pre-machining4. Improve workpiece clamping5. Measure bore in clamped and unclamped condition6. Check chip flowHole shows chatter marks1. Reduce run-out error and use compensation holder2. Change chamfer angle3. Improve workpiece clamping4. Reduce cutting speed5. <strong>Inc</strong>rease feed rateR34In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>

TROUBLESHOOTING SOLUTIONSRFaultSurface quality unsatisfactoryRemedy1. Check insert wear2. Reduce run-out error and use compensation holder,check cutting data (pages R32-R33)3. Use tool with internal coolant supply4. <strong>Inc</strong>rease coolant mixRetention marks in hole1. Reduce run-out error and use compensation holder2. Check insert wear (build-up edges)3. Reduce depth of cut4. Use a sharper geometry5. Reduce pull back feedReamer jams1. Reduce coolant mix2. <strong>Inc</strong>rease depth of cut3. Check insert wear4. Change chamfer angleHole too small1. Change insert2. Reduce coolant mix3. <strong>Inc</strong>rease depth of cut4. <strong>Inc</strong>rease cutting speed5. Reduce feed rateIn the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>R35

RFORMULASZ = Number of teethd = Cutting edge Ø [mm]L = Length of bore [mm]SL =Clearance distance [mm]n = Revolutionsn = v c • 1000 [1/min] [RPM]d • v c= Cutting speedv c= d• • n [m/min] / .3048 = sfm1000f z= Feed/toothf z=v fZ • n[mm] / 25.4 = inchf =Feed per revolutionsf = f • Z [mm/U] [mm/rev]zv f= Feed ratev f= f z• Z • n [mm/min] / 25.4 = inch/minT c= Process timeT c= L + SL [min]v fR36In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>

RNotes:In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>R37

RNotes:R38In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>

RNotes:In the UNITED STATES call us toll free1 - 888 - 818 <strong>HORN</strong>R39