POLYGON MILLLING Polygon Milling Cutter - Horn USA

POLYGON MILLLING Polygon Milling Cutter - Horn USA

POLYGON MILLLING Polygon Milling Cutter - Horn USA

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

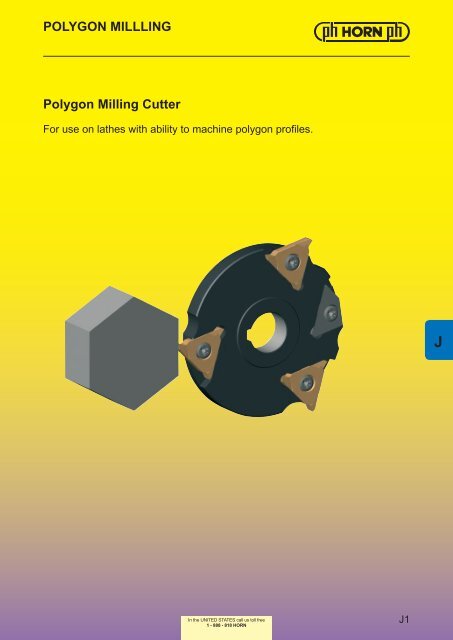

<strong>POLYGON</strong> <strong>MILLLING</strong><strong>Polygon</strong> <strong>Milling</strong> <strong>Cutter</strong>For use on lathes with ability to machine polygon profiles.JIn the UNITED STATES call us toll free1 - 888 - 818 HORNJ1

<strong>POLYGON</strong> MILLINGCUTTER Type381Cutting edge ØDs 2.362″ (60 mm)for machine: Star SR-20JPicture = left hand cutting versionfor insert N314.MK40.20JPart number Insert Ds d 2d 3h t maxType of machineL381.A060.13.04 N314... 60 50 13 8.2 4.5 Star SR-20JFurther sizes upon requestDimensions in mmFor torque specifications of the screw, please see Technical Instructions.Spare parts<strong>Cutter</strong> Screw TORX PLUS ® Wrench Balance elementL381.A060.13.04 5F.08T20P T20PQ N314.AT30.HMJ2In the UNITED STATES call us toll free1 - 888 - 818 HORN

<strong>POLYGON</strong> MILLINGCUTTER Type381Cutting edge ØDs 70/86/98 mmfor machine: GildemeisterPicture = left hand cutting versionfor insert L314.MK50.20Part number Insert Ds d 2d 3d 4h α t maxType of machineJL381.G070.15.04 L314... 70 58 11.5 15.0 15 8°16' 5 GLD25/GD32L381.G086.25.04 L314... 86 74 18.0 24.7 23 8°16' 5 GM20-6.-35-8/GMC35L381.G098.26.04 L314... 98 86 20.0 25.8 23 8°32' 5 GM35-6.-35-8.-42-6/GMC35Further sizes upon requestDimensions in mmFor torque specifications of the screw, please see Technical Instructions.Spare parts<strong>Cutter</strong> Screw TORX PLUS ® Wrench Balance elementL381.G070.15.04 5.10T20P T20PQ N314.AT40.HML381.G0...04 5.12T20P T20PQ N314.AT40.HMIn the UNITED STATES call us toll free1 - 888 - 818 HORNJ3

<strong>POLYGON</strong> MILLINGCUTTER Type381Cutting edge ØDs 3.150″ (80 mm)for machine: GildemeisterPicture = left hand cutting versionfor insert N314.MK40.20JPart number Insert Ds d 2d 3d 4h t maxType of machineL381.G080.16.04 N314... 80 68 16 16 9 5 SPRINT 20/32Further sizes upon requestDimensions in mmFor torque specifications of the screw, please see Technical Instructions.Spare parts<strong>Cutter</strong> Screw TORX PLUS ® Wrench Balance elementL381.G080.16.04 5F.08T20P T20PQ L314.AT30.HMJ4In the UNITED STATES call us toll free1 - 888 - 818 HORN

<strong>POLYGON</strong> MILLINGCUTTER Type381Cutting edge ØDs 2.894″ (73.5 mm)for machine: INDEXPicture = right hand cutting versionfor insert N314.MK40.20JPart number Insert Ds d 2d 3h t maxType of machineR381.X073.16.03 R314... 73.5 63.5 16 8 5 INDEX MS25Further sizes upon requestDimensions in mmFor torque specifications of the screw, please see Technical Instructions.Spare parts<strong>Cutter</strong> Screw TORX PLUS ® WrenchR381.X073.16.03 5F.08T20P T20PQJ8In the UNITED STATES call us toll free1 - 888 - 818 HORN

<strong>POLYGON</strong> MILLINGCUTTER Type381Cutting edge ØDs 3.543″ (90.0 mm)for machine: NakamuraPicture = left hand cutting versionfor insert N314.MK40.20Part number Insert Ds d 2d 3h t maxType of machineJL381.N090.16.04 N314... 90 80 16 7.8 5 WT250Further sizes upon requestDimensions in mmFor torque specifications of the screw, please see Technical Instructions.Spare parts<strong>Cutter</strong> Screw TORX PLUS ® Wrench Balance elementL381.N090.16.04 5F.08T20P T20PQ L314.AT30.HMIn the UNITED STATES call us toll free1 - 888 - 818 HORNJ9

<strong>POLYGON</strong> MILLINGCUTTER Type381Cutting edge ØDs 78/98/118 mmfor machine: A.H. SchüttePicture = left hand cutting versionfor insert L314.MK70.M0JPart number Insert Ds d 2d 3d 4h α t maxType of machineL381.S078.30.02 L314... 78 66.0 26.3 30.1 19 5°42'38'' * SG18.SG20.AG18L381.S098.30.02 L314... 98 94.6 26.3 30.1 19 5°42'38'' * SG20/SF26.-S.-L/SE18/AF26.32L381.S118.30.02 L314... 118 115.0 26.3 30.1 19 5°42'38'' * SF32.42.51.67/AF42Further sizes upon requestNote:reinforced pocket, feed in axial direction* t maxSide milling = .197" (5.0 mm) / Groove milling = .047" (1.2 mm)For torque specifications of the screw, please see Technical Instructions.Dimensions in mmSpare parts<strong>Cutter</strong> Screw TORX PLUS ® WrenchL381.S... 5.15T20P T20PQJ10In the UNITED STATES call us toll free1 - 888 - 818 HORN

<strong>POLYGON</strong> MILLINGCUTTER Type381Cutting edge ØDs 79/98/118 mmfor machine: A.H. SchüttePicture = left hand cutting versionfor insert L314.MK70.M0Part number Insert Ds d 2d 3d 4h α t maxType of machineJL381.S078.30.03 L314... 78 77.0 26.3 30.1 19 5°42'38'' * SG18.SG20.AG18L381.S098.30.03 L314... 98 94.6 26.3 30.1 19 5°42'38'' * SG20/SF26.-S.-L/SE18/AF26.32L381.S118.30.03 L314... 118 115.0 26.3 30.1 19 5°42'38'' * SF32.42.51.67/AF42Further sizes upon requestNote:reinforced pocket, feed in axial direction* t maxSide milling = .197" (5.0mm) / Groove milling = .047" (1.2mm)For torque specifications of the screw, please see Technical Instructions.Dimensions in mmSpare parts<strong>Cutter</strong> Screw TORX PLUS ® WrenchL381.S... 5.15T20P T20PQIn the UNITED STATES call us toll free1 - 888 - 818 HORNJ11

<strong>POLYGON</strong> MILLINGCUTTER Type381Cutting edge ØDs 3.150″ (80 mm)for machine: TornosPicture = left hand cutting versionfor insert N314.MK40.20JPart number Insert Ds d 2d 3h t maxType of machineL381.D080.16.04 N314... 80 57.5 16 13.6 5 DECO 2000/ DECO 13/20/26Further sizes upon requestDimensions in mmFor torque specifications of the screw, please see Technical Instructions.Spare parts<strong>Cutter</strong> Screw TORX PLUS ® Wrench Balance elementL381.D080.16.04 5F.08T20P T20PQ L314.AT30.HMJ12In the UNITED STATES call us toll free1 - 888 - 818 HORN

<strong>POLYGON</strong> MILLINGCUTTER Type381Cutting edge ØDs 3.386″ (86 mm)for machine: TornosPicture = left hand cutting versionfor inserts L314.MK50...Part number Insert Ds d 2d 3d 4h t maxType of machineJL381.D086.25.04 L314... 86 74 18 24.7 23 5 Tornos Multi-DecoFurther sizes upon requestDimensions in mmFor torque specifications of the screw, please see Technical Instructions.Spare parts<strong>Cutter</strong> Screw TORX PLUS ® Wrench Balance elementL381.D086.25.04 5.12T20P T20PQ N314.AT40.HMIn the UNITED STATES call us toll free1 - 888 - 818 HORNJ13

<strong>POLYGON</strong> MILLINGCUTTER Type381Cutting edge ØDs 3.150″ (80.0 mm)for machine: TraubPicture = right hand cutting versionfor insert N314.MK40.20JPart number Insert Ds d 2d 3h t maxType of machineR381.T080.16.04 N314... 80 69 16 12 5 TRAUB TNL18Further sizes upon requestDimensions in mmFor torque specifications of the screw, please see Technical Instructions.Spare parts<strong>Cutter</strong> Screw TORX PLUS ® Wrench Balance elementR381.T080.16.04 5F.08T20P T20PQ R314.AT40.HMJ14In the UNITED STATES call us toll free1 - 888 - 818 HORN

<strong>POLYGON</strong> MILLINGCUTTER Type381Cutting edge ØDs 2.717″ (69 mm)for machine: TraubPicture = left hand cutting versionfor insert N314.MK40.20Part number Insert Ds d 2d 3h t maxType of machineJL381.T069.12.04 N314... 69 57.5 12 8 5 TNL12-7/TNL26/TNK36Further sizes upon requestDimensions in mmFor torque specifications of the screw, please see Technical Instructions.Spare parts<strong>Cutter</strong> Screw TORX PLUS ® Wrench Balance elementL381.T069.12.04 5F.08T20P T20PQ L314.AT30.HMIn the UNITED STATES call us toll free1 - 888 - 818 HORNJ15

<strong>POLYGON</strong> MILLINGCUTTER TypeM275Cutting edge ØDs 1.575″ (40 mm)for machine: TornosPicture = left hand cutting versionL = left hand versionfor insertR/LS275.MK13.M0JPart number Insert Ds d 1d 2d 3h h 1t maxType of machineLM275.D040.10.04RM275.D040.10.04Further sizes upon requestLS275...RS275...40 33 15.5 10 7.9 8 3 DECO 7/10Dimensions in mmFor torque specifications of the screw, please see Technical Instructions.Spare parts<strong>Cutter</strong> Screw TORX PLUS ® Wrench Balance elementLM275.D040.10.04 030.357P.315 T10PL LS275.AT41.HMRM275.D040.10.04 030.357P.315 T10PL RS275.AT41.HMJ16In the UNITED STATES call us toll free1 - 888 - 818 HORN

<strong>POLYGON</strong> MILLINGCUTTER TypeM275Cutting edge ØDs 2.520″ (64 mm)for machine: TraubPicture = right hand cutting versionfor insertRS275.MK13.M0Part number Insert Ds d 1l 1d 3d 4t maxType of machineJRM275.T064.33.03 RS275... 64 56 39 36 33 3 TNL12-7 GegenspindelFurther sizes upon requestDimensions in mmFor torque specifications of the screw, please see Technical Instructions.Spare parts<strong>Cutter</strong> Screw TORX PLUS ® WrenchRM275.T064.33.03 3.5.10.T10P T10PLIn the UNITED STATES call us toll free1 - 888 - 818 HORNJ17

<strong>POLYGON</strong> MILLINGINDEXABLE INSERT TypeS275Width of milling .157″for use with <strong>Cutter</strong>TypeM275R = right hand version shownL = left hand versionJPart number w s rMG12TN35TI25TF45R/LS275.MK13.M0 .157 .154 .008 ▲/▲▲ on stock Δ 4 weeks P ●● main recommendation M ●ο alternative recommendation K ●███ uncoated grades N ●███ coated grades S ●███ brazed/CermetHDimensions in inchFurther sizes upon requestCarbide gradesJ18In the UNITED STATES call us toll free1 - 888 - 818 HORN

<strong>POLYGON</strong> MILLINGINDEXABLE INSERT Type314/N314Width of milling .157 - .276″for use with <strong>Cutter</strong>Type 381Part number w s r OperationMG12TN35TI25TA45AS45JN314.MK40.20 .157 .142 - 1 + 2 ▲ ▲R/L314.MK50.20 .197 .205 .006 1 + 2 ▲/▲L314.MK70.M0 .276 .291 .006 1 + 2 Δ ▲▲ on stock Δ 4 weeks P ο ● ●● main recommendation M ● ● ●ο alternative recommendation K ● ● ●███ uncoated grades N ● ● ●███ coated grades S ● ● ●███ brazed/CermetHDimensions in inchState R, L or N versionFurther sizes upon requestCarbide gradesIn the UNITED STATES call us toll free1 - 888 - 818 HORNJ19

<strong>POLYGON</strong> MILLINGINDEXABLE INSERT Type314Width of milling .197 - .213″for use with <strong>Cutter</strong>Type 381L = left hand version shownR = right hand versionJPart number w s r t maxMG12TN35TI25TF45R/L314.MK50.5.20 .197 .213 .006 .197 Δ/▲L314.MK50.20LR314.MK50.20LDimensions in inchState R or L versionFurther sizes upon request.213 .213 .024 .197▲ on stock Δ 4 weeks P ●● main recommendation M ●ο alternative recommendation K ●███ uncoated grades N ●███ coated grades S ●███ brazed/CermetH▲▲Carbide gradesJ20In the UNITED STATES call us toll free1 - 888 - 818 HORN

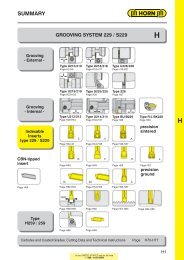

TECHNICAL INFORMATIONThe concept of <strong>Polygon</strong> <strong>Milling</strong><strong>Polygon</strong> milling describes the manufacturing of flats while rotating components with polygonmilling cutters on CNC lathes, Swiss Automatics lathes or Multi Spindle machines.The component (main spindle) and the milling cutter (live tool) have to run with synchronizedrotations.The operation only works in conventional milling!The number of flats depends on the rotation ratio between component and milling cutter aswell as on the number of inserts of the milling cutter.At a revolution ratio of 2:1, the shape of the produced flats are little convex. The form error issuitable for most applications such as across-flats.At a revolution ratio of 1:1, the shape of the produced flats are heavily convex. This shapeis not suitable for across-flats.At a revolution ratio of 3:1, the shape of the produced flats are heavily concave. This shapeis as well not suitable for across-flats.According to this, the number of flats at the component is twice the number of cutting insertson the milling cutter.To calculate the shape of the flats following parameter are necessary:1. Cutting diameter of the polygon miling cutter2. Across-flats dimension3. Premachined diameter of the component4. Number of flats5. Revolution ratio of component and milling cutterJThe flats can be produced by grooving or by turning. Chamfers can be produced by profiling(deburring).In the UNITED STATES call us toll free1 - 888 - 818 HORNJ21

TECHNICAL INFORMATIONTwo flats machined with 1 cutting edge. Revolution ratio 2:1 to the main spindle.Four flats machined with 2 cutting edges. Revolution ratio 2:1 to the main spindle.JSix flats machined with 3 cutting edges. Revolution ratio 2:1 to the main spindle.J22In the UNITED STATES call us toll free1 - 888 - 818 HORN

TECHNICAL INFORMATIONFormNo. of inserts on thecutterRatio =Tool:SpindelFlats1 1 : 1 not suitable, heavily convex2132121321321 : 12 : 11 : 11.5 : 13 : 12 : 14 : 11.66 : 12,5 : 15 : 12 : 13 : 1not suitable, convexvery suitable, little convexnot suitable, convexsuitable, convexvery suitable, little concavevery suitable, little convexnot suitable, concavesuitable, convexvery suitable, little concavenot suitable, concavevery suitable, little convexnot suitable, concave422 : 14 : 1very suitable, little convexnot suitable, concaveCutting dataMaterial Grades v csfm Feed rateIPTJAl MG12 1600 - 3200 .004 - .008Ms58 MG12 1600 - 3200 .004 - .0089SMnPb28 TI25 600 - 1600 .003 - .00616MnCr5/C45 TI25 500 - 800 .002 - .004Feed rate values only valid for turning process!At grooving process the feed rate has to be reduced by 30 - 50 %, dependingon the insert width!Example::<strong>Cutter</strong> Ø 90 mmSW 24 mmMaterial: Steelv c= 1474 SFMf Z= .003 IPT3 Inserts, l = 2:1Flat length: 12 mmCycle time: ~ 2 sec.In the UNITED STATES call us toll free1 - 888 - 818 HORNJ23

MILLING CUTTER - SUMMARYMachine manufacturer Machine <strong>Polygon</strong> milling cutter Indexable inserts Z RPM max.JGildemeister GD32 L381.G070.15.04 L314.MK50.20 TN35 2/3 13,000Gildemeister GDL25 L381.G070.15.04 L314.MK50.20 TN35 2/3 13,000Gildemeister GM20-6 L381.G086.25.04 L314.MK50.20 TN35 2/3 11,000Gildemeister GM26-6 L381.G080.16.04 L314.MK50.20 TN35 2/3 12,000Gildemeister GM35-6 L381.G098.26.04 L314.MK50.20 TN35 2/3 10,000Gildemeister GM35-8 L381.G086.25.04 L314.MK50.20 TN35 2/3 11,000Gildemeister GM35-8 L381.G098.26.04 L314.MK50.20 TN35 2/3 10,000Gildemeister GM42-6 L381.G098.26.04 L314.MK50.20 TN35 2/3 10,000Gildemeister GMC35 L381.G086.25.04 L314.MK50.20 TN35 2/3 11,000Gildemeister GMC35 L381.G098.26.04 L314.MK50.20 TN35 2/3 10,000Gildemeister SPRINT32L L381.G090.22.04 L314.MK50.20 TN35 2/3 13,000Gildemeister SPRINT44L L381.G090.22.04 L314.MK50.20 TN35 2/3 13,000INDEX ABC R381.X090.27.04 R314.MK50.20 TN35 2/3 11,000INDEX ABC L381.X090.27.04 L314.MK50.20 TN35 2/3 11,000INDEX MS25 R381.X073.16.04 N314.MK40.20 TN35 2/3 12,000INDEX MS25 R381.X073.16.03 N314.MK40.20 TN35 3 12,000NAKAMURA WT250 L381.N090.16.04 N314.MK40.20 TN35 2/3 11,000Alfred H. Schütte AF26 L381.S098.30.03 L314.MK70.M0 TN35 3 15,000 *Alfred H. Schütte AF26 L381.S098.30.02 L314.MK70.M0 TN35 2 15,000 *Alfred H. Schütte AF32 L381.S098.30.03 L314.MK70.M0 TN35 3 15,000 *Alfred H. Schütte AF32 L381.S098.30.02 L314.MK70.M0 TN35 2 15,000 *Alfred H. Schütte AF42 L381.S118.30.03 L314.MK70.M0 TN35 3 12,000 *Alfred H. Schütte AF42 L381.S118.30.02 L314.MK70.M0 TN35 2 12,000 *Alfred H. Schütte AG18 L381.S078.30.03 L314.MK70.M0 TN35 3 20,000 *Alfred H. Schütte AG18 L381.S078.30.02 L314.MK70.M0 TN35 2 20,000 *Alfred H. Schütte SE18 L381.S098.30.03 L314.MK70.M0 TN35 3 15,000 *Alfred H. Schütte SE18 L381.S098.30.02 L314.MK70.M0 TN35 2 15,000 *Alfred H. Schütte SF20 L381.S098.30.03 L314.MK70.M0 TN35 3 15,000 *Alfred H. Schütte SF20 L381.S098.30.02 L314.MK70.M0 TN35 2 15,000 *Alfred H. Schütte SF26L L381.S098.30.03 L314.MK70.M0 TN35 3 15,000 *Alfred H. Schütte SF26L L381.S098.30.02 L314.MK70.M0 TN35 2 15,000 *Alfred H. Schütte SF26S L381.S098.30.03 L314.MK70.M0 TN35 3 15,000 *Alfred H. Schütte SF26S L381.S098.30.03 L314.MK70.M0 TN35 3 15,000 *Alfred H. Schütte SF26S L381.S098.30.02 L314.MK70.M0 TN35 2 15,000 *Alfred H. Schütte SF26S L381.S098.30.02 L314.MK70.M0 TN35 2 15,000 *Alfred H. Schütte SF32 L381.S118.30.03 L314.MK70.M0 TN35 3 12,000 *Alfred H. Schütte SF32 L381.S118.30.02 L314.MK70.M0 TN35 2 12,000 *Alfred H. Schütte SF42 L381.S118.30.03 L314.MK70.M0 TN35 3 12,000 *Alfred H. Schütte SF42 L381.S118.30.02 L314.MK70.M0 TN35 2 12,000 *Alfred H. Schütte SF51 L381.S118.30.03 L314.MK70.M0 TN35 3 12,000 *Alfred H. Schütte SF51 L381.S118.30.02 L314.MK70.M0 TN35 2 12,000 *Alfred H. Schütte SF67 L381.S118.30.03 L314.MK70.M0 TN35 3 12,000 *Alfred H. Schütte SF67 L381.S118.30.02 L314.MK70.M0 TN35 2 12,000 *Alfred H. Schütte SG18 L381.S078.30.03 L314.MK70.M0 TN35 3 20,000 *Alfred H. Schütte SG18 L381.S078.30.02 L314.MK70.M0 TN35 2 20,000 *Alfred H. Schütte SG20 L381.S078.30.03 L314.MK70.M0 TN35 3 20,000 *Alfred H. Schütte SG20 L381.S078.30.02 L314.MK70.M0 TN35 2 20,000 *<strong>Polygon</strong> cutter for further machines upon request.J24In the UNITED STATES call us toll free1 - 888 - 818 HORN* reinforced pocket

MILLING CUTTER - SUMMARYMachine manufacturer Machine <strong>Polygon</strong> milling cutter Indexable inserts Z RPM max.Star SR-20J L381.A060.13.04 N314.MK40.20 TN35 3 13,000TORNOS Deco13 L381.D080.16.04 N314.MK40.20 TN35 2/3 12,000TORNOS Deco20 L381.D080.16.04 N314.MK40.20 TN35 2/3 12,000TORNOS Deco26 L381.D080.16.04 N314.MK40.20 TN35 2/3 12,000TORNOS Deco2000 L381.D080.16.04 N314.MK40.20 TN35 2/3 12,000TORNOS Multi-Deco L381.D086.25.04 L314.MK50... 3 11,000TORNOS Deco 7/10 LM275.D040.10.04 LS275.MK13.M0 TI25 3 15,000TORNOS Deco 7/10 RM275.D040.10.04 RS275.MK13.M0 TI25 3 15,000TRAUB TNL12-7 RM275.T064.33.03 RS275.MK13.M0TN35 3 13,000TRAUB TNL12-7 L381.T069.12.04 N314.MK40.20 TN35 2/3 13,000TRAUB TNL26 L381.T069.12.04 N314.MK40.20 TN35 2/3 13,000TRAUB TNK36 L381.T069.12.04 N314.MK40.20 TN35 2/3 13,000TRAUBTNL12-7/TNL26/TNK36L381.T069.12.04 N314.MK40.20 TN35 2/3 13,000<strong>Polygon</strong> cutter for further machines upon request.* reinforced pocketJIn the UNITED STATES call us toll free1 - 888 - 818 HORNJ25

HORN - THE LEADERS IN GROOVING TECHNOLOGYTHE TEAM APPROACHSWISS TURNINGJSpecialized toolholders from HORN bring innovative highperformance solutions to swiss style machining.HORN Supermini ® is a highly developed system for machiningof small internal features such as bores, grooves and threads.Supermini ® also includes fully engineered broaching capabilitiesfor slots, keyways and splines.HORN high performance external grooving, turning and partoff systems 264 and 274 include holders specifically tailored forswiss machine applications.HORN 300 series milling tools and polygon turning tools provideefficient and economical solutions to generating a variety of crosssections from round bar.The more difficult the material, the greater the advantage gainedwith HORN.HORN - INTELLIGENT TOOL DESIGN AT WORK.For further information, please contact HORN <strong>USA</strong>.J26In the UNITED STATES call us toll free1 - 888 - 818 HORN