1 Minutes of the 36th Meeting of the Expert Appraisal Committee ...

1 Minutes of the 36th Meeting of the Expert Appraisal Committee ...

1 Minutes of the 36th Meeting of the Expert Appraisal Committee ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

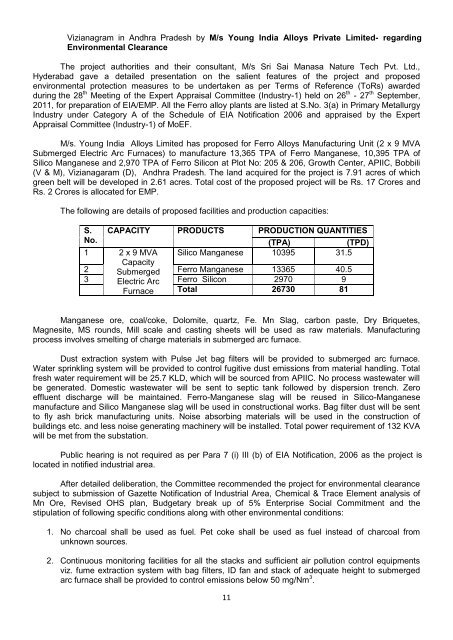

Vizianagram in Andhra Pradesh by M/s Young India Alloys Private Limited- regardingEnvironmental ClearanceThe project authorities and <strong>the</strong>ir consultant, M/s Sri Sai Manasa Nature Tech Pvt. Ltd.,Hyderabad gave a detailed presentation on <strong>the</strong> salient features <strong>of</strong> <strong>the</strong> project and proposedenvironmental protection measures to be undertaken as per Terms <strong>of</strong> Reference (ToRs) awardedduring <strong>the</strong> 28 th <strong>Meeting</strong> <strong>of</strong> <strong>the</strong> <strong>Expert</strong> <strong>Appraisal</strong> <strong>Committee</strong> (Industry-1) held on 26 th - 27 th September,2011, for preparation <strong>of</strong> EIA/EMP. All <strong>the</strong> Ferro alloy plants are listed at S.No. 3(a) in Primary MetallurgyIndustry under Category A <strong>of</strong> <strong>the</strong> Schedule <strong>of</strong> EIA Notification 2006 and appraised by <strong>the</strong> <strong>Expert</strong><strong>Appraisal</strong> <strong>Committee</strong> (Industry-1) <strong>of</strong> MoEF.M/s. Young India Alloys Limited has proposed for Ferro Alloys Manufacturing Unit (2 x 9 MVASubmerged Electric Arc Furnaces) to manufacture 13,365 TPA <strong>of</strong> Ferro Manganese, 10,395 TPA <strong>of</strong>Silico Manganese and 2,970 TPA <strong>of</strong> Ferro Silicon at Plot No: 205 & 206, Growth Center, APIIC, Bobbili(V & M), Vizianagaram (D), Andhra Pradesh. The land acquired for <strong>the</strong> project is 7.91 acres <strong>of</strong> whichgreen belt will be developed in 2.61 acres. Total cost <strong>of</strong> <strong>the</strong> proposed project will be Rs. 17 Crores andRs. 2 Crores is allocated for EMP.The following are details <strong>of</strong> proposed facilities and production capacities:S. CAPACITY PRODUCTS PRODUCTION QUANTITIESNo.(TPA)(TPD)1 2 x 9 MVA Silico Manganese 10395 31.5Capacity2 Submerged Ferro Manganese 13365 40.53 Electric Arc Ferro Silicon 2970 9Furnace Total 26730 81Manganese ore, coal/coke, Dolomite, quartz, Fe. Mn Slag, carbon paste, Dry Briquetes,Magnesite, MS rounds, Mill scale and casting sheets will be used as raw materials. Manufacturingprocess involves smelting <strong>of</strong> charge materials in submerged arc furnace.Dust extraction system with Pulse Jet bag filters will be provided to submerged arc furnace.Water sprinkling system will be provided to control fugitive dust emissions from material handling. Totalfresh water requirement will be 25.7 KLD, which will be sourced from APIIC. No process wastewater willbe generated. Domestic wastewater will be sent to septic tank followed by dispersion trench. Zeroeffluent discharge will be maintained. Ferro-Manganese slag will be reused in Silico-Manganesemanufacture and Silico Manganese slag will be used in constructional works. Bag filter dust will be sentto fly ash brick manufacturing units. Noise absorbing materials will be used in <strong>the</strong> construction <strong>of</strong>buildings etc. and less noise generating machinery will be installed. Total power requirement <strong>of</strong> 132 KVAwill be met from <strong>the</strong> substation.Public hearing is not required as per Para 7 (i) III (b) <strong>of</strong> EIA Notification, 2006 as <strong>the</strong> project islocated in notified industrial area.After detailed deliberation, <strong>the</strong> <strong>Committee</strong> recommended <strong>the</strong> project for environmental clearancesubject to submission <strong>of</strong> Gazette Notification <strong>of</strong> Industrial Area, Chemical & Trace Element analysis <strong>of</strong>Mn Ore, Revised OHS plan, Budgetary break up <strong>of</strong> 5% Enterprise Social Commitment and <strong>the</strong>stipulation <strong>of</strong> following specific conditions along with o<strong>the</strong>r environmental conditions:1. No charcoal shall be used as fuel. Pet coke shall be used as fuel instead <strong>of</strong> charcoal fromunknown sources.2. Continuous monitoring facilities for all <strong>the</strong> stacks and sufficient air pollution control equipmentsviz. fume extraction system with bag filters, ID fan and stack <strong>of</strong> adequate height to submergedarc furnace shall be provided to control emissions below 50 mg/Nm 3 .11