1 Minutes of the 36th Meeting of the Expert Appraisal Committee ...

1 Minutes of the 36th Meeting of the Expert Appraisal Committee ...

1 Minutes of the 36th Meeting of the Expert Appraisal Committee ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

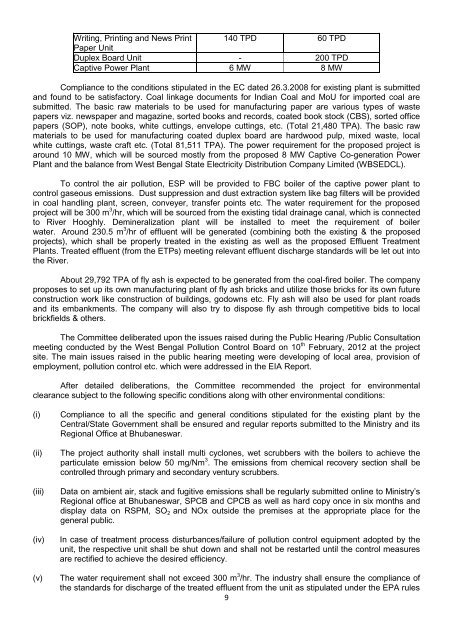

Writing, Printing and News Print 140 TPD 60 TPDPaper UnitDuplex Board Unit - 200 TPDCaptive Power Plant 6 MW 8 MWCompliance to <strong>the</strong> conditions stipulated in <strong>the</strong> EC dated 26.3.2008 for existing plant is submittedand found to be satisfactory. Coal linkage documents for Indian Coal and MoU for imported coal aresubmitted. The basic raw materials to be used for manufacturing paper are various types <strong>of</strong> wastepapers viz. newspaper and magazine, sorted books and records, coated book stock (CBS), sorted <strong>of</strong>ficepapers (SOP), note books, white cuttings, envelope cuttings, etc. (Total 21,480 TPA). The basic rawmaterials to be used for manufacturing coated duplex board are hardwood pulp, mixed waste, localwhite cuttings, waste craft etc. (Total 81,511 TPA). The power requirement for <strong>the</strong> proposed project isaround 10 MW, which will be sourced mostly from <strong>the</strong> proposed 8 MW Captive Co-generation PowerPlant and <strong>the</strong> balance from West Bengal State Electricity Distribution Company Limited (WBSEDCL).To control <strong>the</strong> air pollution, ESP will be provided to FBC boiler <strong>of</strong> <strong>the</strong> captive power plant tocontrol gaseous emissions. Dust suppression and dust extraction system like bag filters will be providedin coal handling plant, screen, conveyer, transfer points etc. The water requirement for <strong>the</strong> proposedproject will be 300 m 3 /hr, which will be sourced from <strong>the</strong> existing tidal drainage canal, which is connectedto River Hooghly. Demineralization plant will be installed to meet <strong>the</strong> requirement <strong>of</strong> boilerwater. Around 230.5 m 3 /hr <strong>of</strong> effluent will be generated (combining both <strong>the</strong> existing & <strong>the</strong> proposedprojects), which shall be properly treated in <strong>the</strong> existing as well as <strong>the</strong> proposed Effluent TreatmentPlants. Treated effluent (from <strong>the</strong> ETPs) meeting relevant effluent discharge standards will be let out into<strong>the</strong> River.About 29,792 TPA <strong>of</strong> fly ash is expected to be generated from <strong>the</strong> coal-fired boiler. The companyproposes to set up its own manufacturing plant <strong>of</strong> fly ash bricks and utilize those bricks for its own futureconstruction work like construction <strong>of</strong> buildings, godowns etc. Fly ash will also be used for plant roadsand its embankments. The company will also try to dispose fly ash through competitive bids to localbrickfields & o<strong>the</strong>rs.The <strong>Committee</strong> deliberated upon <strong>the</strong> issues raised during <strong>the</strong> Public Hearing /Public Consultationmeeting conducted by <strong>the</strong> West Bengal Pollution Control Board on 10 th February, 2012 at <strong>the</strong> projectsite. The main issues raised in <strong>the</strong> public hearing meeting were developing <strong>of</strong> local area, provision <strong>of</strong>employment, pollution control etc. which were addressed in <strong>the</strong> EIA Report.After detailed deliberations, <strong>the</strong> <strong>Committee</strong> recommended <strong>the</strong> project for environmentalclearance subject to <strong>the</strong> following specific conditions along with o<strong>the</strong>r environmental conditions:(i)(ii)(iii)(iv)(v)Compliance to all <strong>the</strong> specific and general conditions stipulated for <strong>the</strong> existing plant by <strong>the</strong>Central/State Government shall be ensured and regular reports submitted to <strong>the</strong> Ministry and itsRegional Office at Bhubaneswar.The project authority shall install multi cyclones, wet scrubbers with <strong>the</strong> boilers to achieve <strong>the</strong>particulate emission below 50 mg/Nm 3 . The emissions from chemical recovery section shall becontrolled through primary and secondary ventury scrubbers.Data on ambient air, stack and fugitive emissions shall be regularly submitted online to Ministry’sRegional <strong>of</strong>fice at Bhubaneswar, SPCB and CPCB as well as hard copy once in six months anddisplay data on RSPM, SO 2 and NOx outside <strong>the</strong> premises at <strong>the</strong> appropriate place for <strong>the</strong>general public.In case <strong>of</strong> treatment process disturbances/failure <strong>of</strong> pollution control equipment adopted by <strong>the</strong>unit, <strong>the</strong> respective unit shall be shut down and shall not be restarted until <strong>the</strong> control measuresare rectified to achieve <strong>the</strong> desired efficiency.The water requirement shall not exceed 300 m 3 /hr. The industry shall ensure <strong>the</strong> compliance <strong>of</strong><strong>the</strong> standards for discharge <strong>of</strong> <strong>the</strong> treated effluent from <strong>the</strong> unit as stipulated under <strong>the</strong> EPA rules9