Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

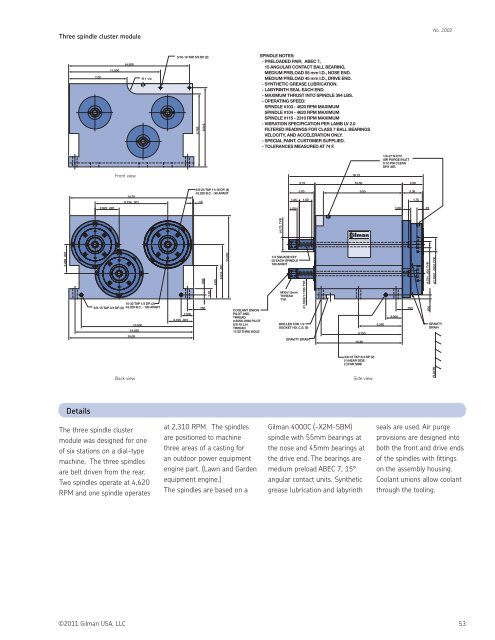

Precision Machine Tool ComponentsThree spindle cluster moduleNo. 20027.0011.00014.500R 1 1/45/16-18 TAP 5/8 DP (2)8.7689.518SPINDLE NOTES:- PRELOADED PAIR, ABEC 7,15 ANGULAR CONTACT BALL BEARING,MEDIUM PRELOAD 55 mm I.D., NOSE END.MEDIUM PRELOAD 45 mm I.D., DRIVE END.- SYNTHETIC GREASE LUBRICATION.- LABYRINTH SEAL EACH END.- MAXIMUM THRUST INTO SPINDLE 394 LBS.- OPERATING SPEED:SPINDLE #103 - 4620 RPM MAXIMUMSPINDLE #104 - 4620 RPM MAXIMUMSPINDLE #115 - 2310 RPM MAXIMUM- VIBRATION SPECIFICATION PER LAMB LV 2.0FILTERED READINGS FOR CLASS 7 BALL BEARINGSVELOCITY, AND ACCELERATION ONLY.- SPECIAL PAINT. CUSTOMER SUPPLIED.- TOLERANCES MEASURED AT 74 F.1/8-27 N.P.T.F.AIR PURGE INLET5-10 PSI CLEANDRY AIR.Front view16.133.1310.502.5014.758.734 .0013/8-24 TAP 11/16 DP. (4)ø3.250 B.C. - 90 APART.133.001.25 1.509.502.381.752.922 .0011.001.00.75ø1.75 TYP.3.469 .00110-32 TAP 1/2 DP. (2)3/8-16 TAP 3/4 DP. (2) ø3.250 B.C. - 180 APART .7501.5003.125 .00113.50014.25015.00.5001.254.006.516 .00110.000COOLANT UNIONPILOT ANDTHREADø.6556/.6560 PILOT5/8-18 L.H.THREAD17/32 THRU HOLE1/4 SQUARE KEY(2) EACH SPINDLE180 APARTM30x1.5mmTHREADTYP.ø1.1800/1.1795 TYP.DRILLED FOR 1/2SOCKET HD. C.S. (6)GRAVITY DRAIN9.75010.385.2502.000.750ø.751 .001 TYP.ø1.7501 .0001 TYP..500GRAVITYDRAIN3/8-16 TAP 3/4 DP. (2)(1) NEAR SIDE(1) FAR SIDEBack viewSide viewFLOORDetailsThe three spindle clustermodule was designed for oneof six stations on a dial-typemachine. The three <strong>spindles</strong>are belt driven from the rear.Two <strong>spindles</strong> operate at 4,620RPM <strong>and</strong> one spindle operatesat 2,310 RPM. The <strong>spindles</strong>are positioned to machinethree areas of a casting foran outdoor power equipmentengine part. (Lawn <strong>and</strong> Gardenequipment engine.)The <strong>spindles</strong> are based on a<strong>Gilman</strong> 4000C (-X2M-SBM)spindle with 55mm bearings atthe nose <strong>and</strong> 45mm bearings atthe drive end. The bearings aremedium preload ABEC 7, 15°angular contact units. Syntheticgrease lubrication <strong>and</strong> labyrinthseals are used. Air purgeprovisions are designed intoboth the front <strong>and</strong> drive endsof the <strong>spindles</strong> with fittingson the assembly housing.Coolant unions allow coolantthrough the tooling.©2011 <strong>Gilman</strong> <strong>USA</strong>, LLC53