You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

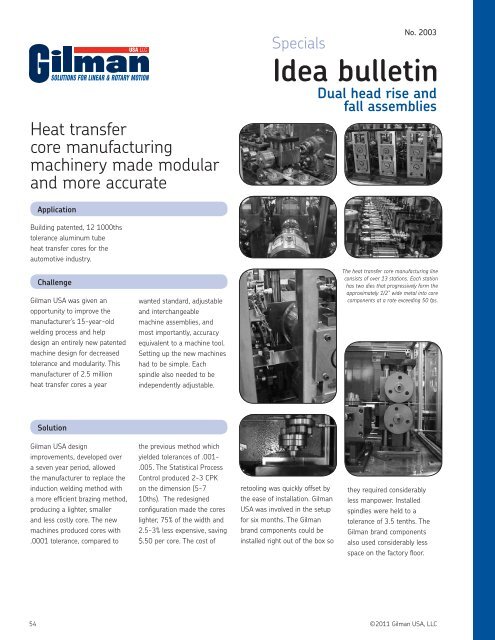

Heat transfercore manufacturingmachinery made modular<strong>and</strong> more accurateSpecialsNo. 2003Idea bulletinDual head rise <strong>and</strong>fall assembliesApplicationBuilding patented, 12 1000thstolerance aluminum tubeheat transfer cores for theautomotive industry.Challenge<strong>Gilman</strong> <strong>USA</strong> was given anopportunity to improve themanufacturer’s 15-year-oldwelding process <strong>and</strong> helpdesign an entirely new patentedmachine design for decreasedtolerance <strong>and</strong> modularity. Thismanufacturer of 2.5 millionheat transfer cores a yearwanted st<strong>and</strong>ard, adjustable<strong>and</strong> interchangeablemachine assemblies, <strong>and</strong>most importantly, accuracyequivalent to a machine tool.Setting up the new machineshad to be simple. Eachspindle also needed to beindependently adjustable.The heat transfer core manufacturing lineconsists of over 13 stations. Each stationhas two dies that progressively form theapproximately 1/2” wide metal into corecomponents at a rate exceeding 50 fps.Solution<strong>Gilman</strong> <strong>USA</strong> designimprovements, developed overa seven year period, allowedthe manufacturer to replace theinduction welding method witha more efficient brazing method,producing a lighter, smaller<strong>and</strong> less costly core. The newmachines produced cores with.0001 tolerance, compared tothe previous method whichyielded tolerances of .001-.005. The Statistical ProcessControl produced 2-3 CPKon the dimension (5-710ths). The redesignedconfiguration made the coreslighter, 75% of the width <strong>and</strong>2.5-3% less expensive, saving$.50 per core. The cost ofretooling was quickly offset bythe ease of installation. <strong>Gilman</strong><strong>USA</strong> was involved in the setupfor six months. The <strong>Gilman</strong>br<strong>and</strong> components could beinstalled right out of the box sothey required considerablyless manpower. Installed<strong>spindles</strong> were held to atolerance of 3.5 tenths. The<strong>Gilman</strong> br<strong>and</strong> componentsalso used considerably lessspace on the factory floor.54 ©2011 <strong>Gilman</strong> <strong>USA</strong>, LLC