You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

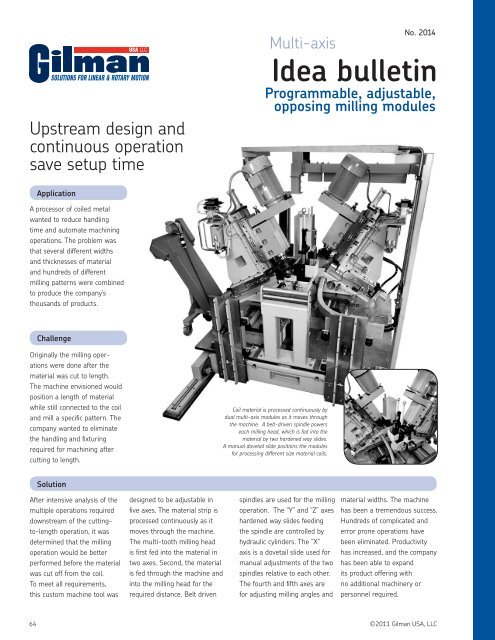

Upstream design <strong>and</strong>continuous operationsave setup timeMulti-axisNo. 2014Idea bulletinProgrammable, adjustable,opposing milling modulesApplicationA processor of coiled metalwanted to reduce h<strong>and</strong>lingtime <strong>and</strong> automate machiningoperations. The problem wasthat several different widths<strong>and</strong> thicknesses of material<strong>and</strong> hundreds of differentmilling patterns were combinedto produce the company’sthous<strong>and</strong>s of products.ChallengeOriginally the milling operationswere done after thematerial was cut to length.The machine envisioned wouldposition a length of materialwhile still connected to the coil<strong>and</strong> mill a specific pattern. Thecompany wanted to eliminatethe h<strong>and</strong>ling <strong>and</strong> fixturingrequired for machining aftercutting to length.Coil material is processed continuously bydual multi-axis modules as it moves throughthe machine. A belt-driven spindle powerseach milling head, which is fed into thematerial by two hardened way slides.A manual dovetail slide positions the modulesfor processing different size material coils.SolutionAfter intensive analysis of themultiple operations requireddownstream of the cuttingto-lengthoperation, it wasdetermined that the millingoperation would be betterperformed before the materialwas cut off from the coil.To meet all requirements,this custom machine tool wasdesigned to be adjustable infive axes. The material strip isprocessed continuously as itmoves through the machine.The multi-tooth milling headis first fed into the material intwo axes. Second, the materialis fed through the machine <strong>and</strong>into the milling head for therequired distance. Belt driven<strong>spindles</strong> are used for the millingoperation. The “Y” <strong>and</strong> “Z” axeshardened way slides feedingthe spindle are controlled byhydraulic cylinders. The “X”axis is a dovetail slide used formanual adjustments of the two<strong>spindles</strong> relative to each other.The fourth <strong>and</strong> fifth axes arefor adjusting milling angles <strong>and</strong>material widths. The machinehas been a tremendous success.Hundreds of complicated <strong>and</strong>error prone operations havebeen eliminated. Productivityhas increased, <strong>and</strong> the companyhas been able to exp<strong>and</strong>its product offering withno additional machinery orpersonnel required.64 ©2011 <strong>Gilman</strong> <strong>USA</strong>, LLC