MCset 3 part1 user_manual - Schneider Electric

MCset 3 part1 user_manual - Schneider Electric

MCset 3 part1 user_manual - Schneider Electric

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

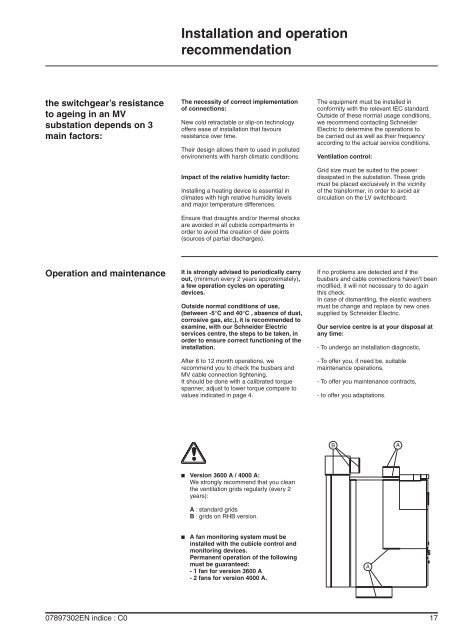

Installation and operationrecommendationthe switchgear’s resistanceto ageing in an MVsubstation depends on 3main factors:The necessity of correct implementationof connections:New cold retractable or slip-on technologyoffers ease of installation that favoursresistance over time.Their design allows them to used in pollutedenvironments with harsh climatic conditions.Impact of the relative humidity factor:Installing a heating device is essential inclimates with high relative humidity levelsand major temperature differences.Ensure that draughts and / or thermal shocksare avoided in all cubicle compartments inorder to avoid the creation of dew points(sources of partial discharges).The equipment must be installed inconformity with the relevant IEC standard.Outside of these normal usage conditions,we recommend contacting <strong>Schneider</strong><strong>Electric</strong> to determine the operations tobe carried out as well as their frequencyaccording to the actual service conditions.Ventilation control:Grid size must be suited to the powerdissipated in the substation. These gridsmust be placed exclusively in the vicinityof the transformer, in order to avoid aircirculation on the LV switchboard.Operation and maintenanceIt is strongly advised to periodically carryout, (minimun every 2 years approximately),a few operation cycles on operatingdevices.Outside normal conditions of use,(between -5°C and 40°C , absence of dust,corrosive gas, etc.), it is recommended toexamine, with our <strong>Schneider</strong> <strong>Electric</strong>services centre, the steps to be taken, inorder to ensure correct functioning of theinstallation.After 6 to 12 month operations, werecommend you to check the busbars andMV cable connection tightening.It should be done with a calibrated torquespanner, adjust to lower torque compare tovalues indicated in page 4.If no problems are detected and if thebusbars and cable connections haven’t beenmodified, it will not necessary to do againthis check.In case of dismantling, the elastic washersmust be change and replace by new onessupplied by <strong>Schneider</strong> <strong>Electric</strong>.Our service centre is at your disposal atany time:- To undergo an installation diagnostic,- To offer you, if need be, suitablemaintenance operations,- To offer you maintenance contracts,- to offer you adaptations.Ab Version 3600 A / 4000 A:We strongly recommend that you cleanthe ventilation grids regularly (every 2years):A : standard gridsB : grids on RHB version.b A fan monitoring system must beinstalled with the cubicle control andmonitoring devices.Permanent operation of the followingmust be guaranteed:- 1 fan for version 3600 A- 2 fans for version 4000 A.A07897302EN indice : C017